STAR INDUSTRIES 1310 User manual

4101 Garland Drive, Fort Worth, TX 76117

Phone 817.485.6073 Fax 817.428.6008

www. starindustries.com

If you need clarication or any additional information call

your Star dealer or call Star Industries @ 1-800-541-1797

during normal business hours.

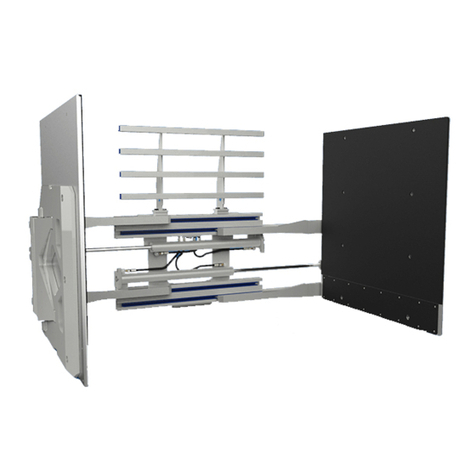

Star models 1300 series Quick-Tach truss Booms

(excluding model 1302) are designed for use on

extendable-reach forklifts. They are available with

a quick-tach that is compatible with a specied

make and model of telehandler. They have

been engineered to a 3 to 1 factor of safety Star

Industries has been manufacturing telehandler

attachments for approximately 25 years and has

earned an excellent safety record. In addition, Star

attachments have proven themselves repeatedly

on all types of jobs all over the United States as well

as in Canada, Mexico and South America.

Please be aware that the information contained in

this manual is intended as a guide and does not

replace the need for the user to know, understand,

and observe all applicable company, local, state,

and federal safety codes and/or requirements.

In addition, any relevant safety requirements or

recommendations contained in the telehandler

operator’s manual must be observed.

BEFORE USE, READ AND UNDERSTAND THE COMPLETE OPERATOR’S MANUAL.

If you need clarication or any additional information call your Star dealer or call

Star Industries @ 1-800-541-1797 during normal business hours.

Customers Who Bought this product also bought

Lift Hooks -

Lift up to 22,000 lbs

Safely and securely

Safety Work Platforms -

Turn your forklift into an

Aerial work platform

Concrete Hoppers -

Turns your forklift into

A concrete placer.

Visit www.starindustries.com or call us at 800-541-1797 for more information on these and other great products.

Before Use:

Make sure the operator is well qualied to operate the

specic telehandler model to be used, has read and

understands this manual and has reviewed the telehandler

operator’s manual for any additional requirements,

limitations, restrictions, or additional safety procedures

prescribed by the telehandler manufacturer when using

this type of attachment. The telehandler operator must

also be properly certied under OSHA requirements to

operate the telehandler to be used.

Inspect the Truss Boom to make sure it is in good condition.

There must not be any broken welds, deformation of the

steel tube or other component, nor any cracks in the steel.

Inspect the pintle-hitch to make sure it is complete, and in

good condition. Make sure the Truss Boom quick-tach is

fully compatible with the specic telehandler being used.

Make sure the quick-tach retaining pin(s) or attachment is

properly engaged. Check that all decals are in place and

legible. The following decals are required: “Product Label”,

“Empty Weight”, and “Rated Lift Capacity”. Replacement

decals are available from a Star dealer. If any defects or

damage are found discontinue use until corrections or a

safety assessment can be made by qualied personnel.

Make sure personnel involved understand any hand

signals that will be required and all involved personnel

understand what will be required of them.

Make sure the travel path is clear of obstructions and that

adequate clearance will be maintained from all power

lines.

Rated Capacities:

The rated capacity as shown in specications also appears

on the Truss Boom decal. Be aware that this capacity is

for the Truss Boom itself and does not in any way reect

the capacity of the telehandler. Refer to the telehandler’s

load chart for a respective length Truss Boom and the

telehandler’s operator’s manual for any limitations and/or

restrictions when using this type of attachment.

Never exceed the rated capacities of the truss boom except

for the purpose of a test and then do not exceed 125% of

its rated capacity. Also make sure that the load rating for

slings, chains, or straps used with the Truss Boom are

equal to or exceed the rating of both the telehandler and

Truss Boom, if not; always limit the load to the lowest rated

part of the lifting system.

Upon notication, Star Industries will advise if the product

will need to be returned to Star Industries for inspection

and/or repair, or If the Star Dealer, or other entity, can be

authorized to make the inspection/repair at their location,

or if circumstances dictate other solutions. Dealer or other

entity repairs must have prior written authorization. A “cost

of repair” estimate will be required prior to authorization.

Reimbursement will be at the current “Star Warranty Labor

Rate” and will not include reimbursement for o-site travel.

A Warranty Claim Form must be submitted within 45 days

of warranty repair authorization to receive credit for repair.

A return authorization number must be obtained from Star

Industries before a product can be returned for inspection

and/or warranty and that number must appear on the

return shipping label. Upon inspection, Star Industries will

determine if the product is defective and if so, whether it

will be repaired or replaced. Repair or replacement is at

the discretion of Star Industries. Transportation charges

to Star Industries are not covered under the warranty and

must be prepaid by dealer or customer unless it is within

the rst two years of warranty. In which case, if evidence

acceptable to Star Industries, is provided that the product

is defective and the return is from within the continental

United States or Canada, Star will arrange for return

shipment at Star Industries expense. Products found to

be defective within the initial two year period and returned

to Star Industries for repair or replacement will be returned

to the dealer or customer freight prepaid providing it is

within the continental United States or Canada. Warranted

products to be shipped outside the United States or

Canada and those warranted after the initial 2 years will

be shipped freight collect. Unwarrantable products will

be returned freight collect at the request of the dealer or

customer, otherwise they will be destroyed.

Star’s obligation under this warranty shall not include

costs of installation, duty, taxes or any other charges

whatsoever or any liability for direct, indirect, incidental

or consequential damages or delay. Star’s liability for any

and all losses and damage to purchaser resulting from any

cause whatsoever, including negligence or breach of form

of warranty, express or implied by Star, alleged damage

for defective goods, irrespective of whether such defects

are discoverable or latent, shall in no event exceed the

purchase price of the particular goods. Products repaired

or replaced under this warranty are warranted only for

the remainder of the original warranty. Any improper use

including operation after discovery of defective or worn

parts not approved by Star or any alteration or repair by

others in such manner as in Star’s judgment aects the

product materially and adversely shall void this warranty.

Star Products are warranted to the original purchaser

against defective workmanship and/or materials (when

properly installed, used, and maintained) for a period as

specied below from date of delivery to the customer by

an authorized Star Dealer or direct from Star Industries.

This warranty does not cover misuse, abuse, normal wear

and tear, or accidental damage.

All Star products except as

noted below. (Includes HD

Auger Drives & most non-

hydraulic products)

Medium Duty Auger Drives

Auger Bits and Auger

Accessories (excludes

auger drives), Crane Forks.

Grapples, Angle Broom,

Self Dumping Hoppers,

Replacement Forks, and Over

the Bucket Forks

Concrete Mixers

Product defects should be reported to the Star

dealer from whom the product was purchased or to

Star Industries in writing promptly after discovery.

Preferably photographs showing the defect should

also be provided along with a written report of

circumstances involved. Warranty claims not made

within 30 days after discovery of the defect shall be

null and void.

If a warranty claim is found worthy and made within the

warranty period we reserve the right at our discretion

to repair existing defects or to replace it with the same

or current model free of charge or to issue a credit

for the reasonable cost of repair or take possession

of the equipment and issue reimbursement for the

calculated value.

Use:

When using the Truss Boom it must remain level or tilted

slightly upward. The Truss Boom is designed for vertical

lift only and must not be used to pull a load. When lifting a

load, the area below the lift should be clear of personnel.

All personnel must maintain a safe distance away from

danger area should a failure occur.

Caution:

1. Risks are high for serious injury or death when

working around suspended loads. The operator must

avoid carrying the load over people and it is best to

have a 10 foot clear radius. This requires that no one

is allowed to be within 10 feet of the area in which the

load would fall if a failure occurred.

2. Do not allow anyone to ride on the truss boom nor on

the load being carried.

3. Do not make any repairs or modications to the

Truss Boom without written authorization from the

manufacturer. Replacement of pintle-hitch and decals

does not require authorization.

Safety Precautions:

1. Before elevating the load, make sure the telehandler

boom is level - not leaning to the right or left. Do not

use the Truss Boom when operating on a side slope.

2. Before the load is raised make sure slings, chains,

or straps are properly secured and are not twisted

around each other or entangled.

3. The load must be picked up so that it is equally

balanced and hangs level.

4. When lifting a load, guard against shock loading by

taking up the slack in slings or straps slowly. Prevent

jerking at the beginning of the lift, and accelerate or

decelerate slowly.

5. Do not use the Truss Boom to drag or pull a load.

6. Do not leave suspended loads unattended.

7. Take care that the load does not swing or come in

contact with an obstruction.

8. Keep all personnel clear while the load is being raised,

moved, or lowered. Telehandler operator should be

watchful of the load at all times, especially when it is

in motion.

9. Never allow more than one person to give signals to

the telehandler operator except to warn of a hazardous

situation.

10. Never raise or carry the load higher than necessary.

11. Never allow anyone to work under a suspended load

12. Never exceed rated capacity of any part of the lifting

system.

13. Never allow anyone to ride on Truss Boom or on the

load being carried.

14.Telehandler operator must be properly trained

and have required certications.

15.Before using the Truss Boom check to see that it is

properly secured to the telehandler as described

in the installation section.

16.Determine that the loads to be handled are within

the capabilities of the forklift. Keep in mind that

rated capacities will likely decrease when the

boom is in a raised position, or when the boom is

extended.

17.When using the Truss Boom it should be level or

tipped upward (never down below level).

18.Do not pull loads – it is designed for vertical lift

only.

19.The load should always be carried low and kept

from swinging using tag lines as necessary. Any

time a load is raised, extreme caution should be

exercised as the telehandler is far more vulnerable

to tipping with a raised load.

20.Any time the load is raised make sure the

telehandler is on level, rm footing.

21.Refer to the telehandler operator’s manual for

more information on handling elevated loads as

well as information for safe and proper telehandler

operation.

22.Always comply with all local, state, and federal

Safety regulations.

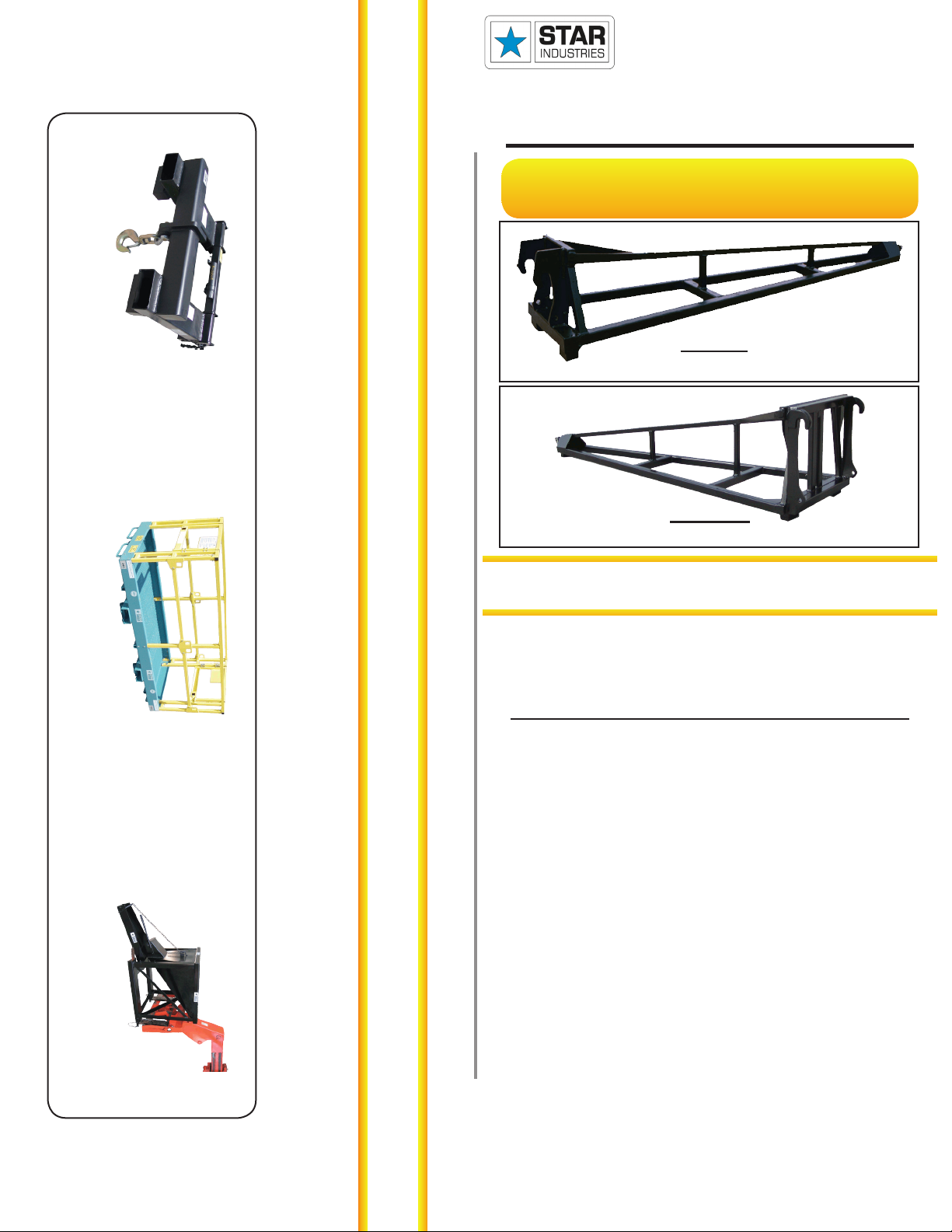

Model List

1310 10’ 2,000 lbs 480 lbs.

1320 12’ 2,000 lbs 560 lbs.

1330 15’ 2,000 lbs 640 lbs.

1325* 12’ 2,000 lbs 690 lbs.

1335* 15’ 2,000 lbs 795 lbs.

“A” Effective Length

Model 1320 Low Profile 12 ft. Truss Boom

(Models 1310 & 1325 similar)

“Low Profile” Truss Boom

Rear View

“C”

“B”

“A” Effective Length

Model 1330 Low Profile 15 ft. Truss Boom

(Model 1335 similar)

“Wide Back” Truss Boom

Rear View

“C”

“B”

This manual suits for next models

4

Other STAR INDUSTRIES Forklift manuals