4520362-1/0606

Page i - 2 - Description

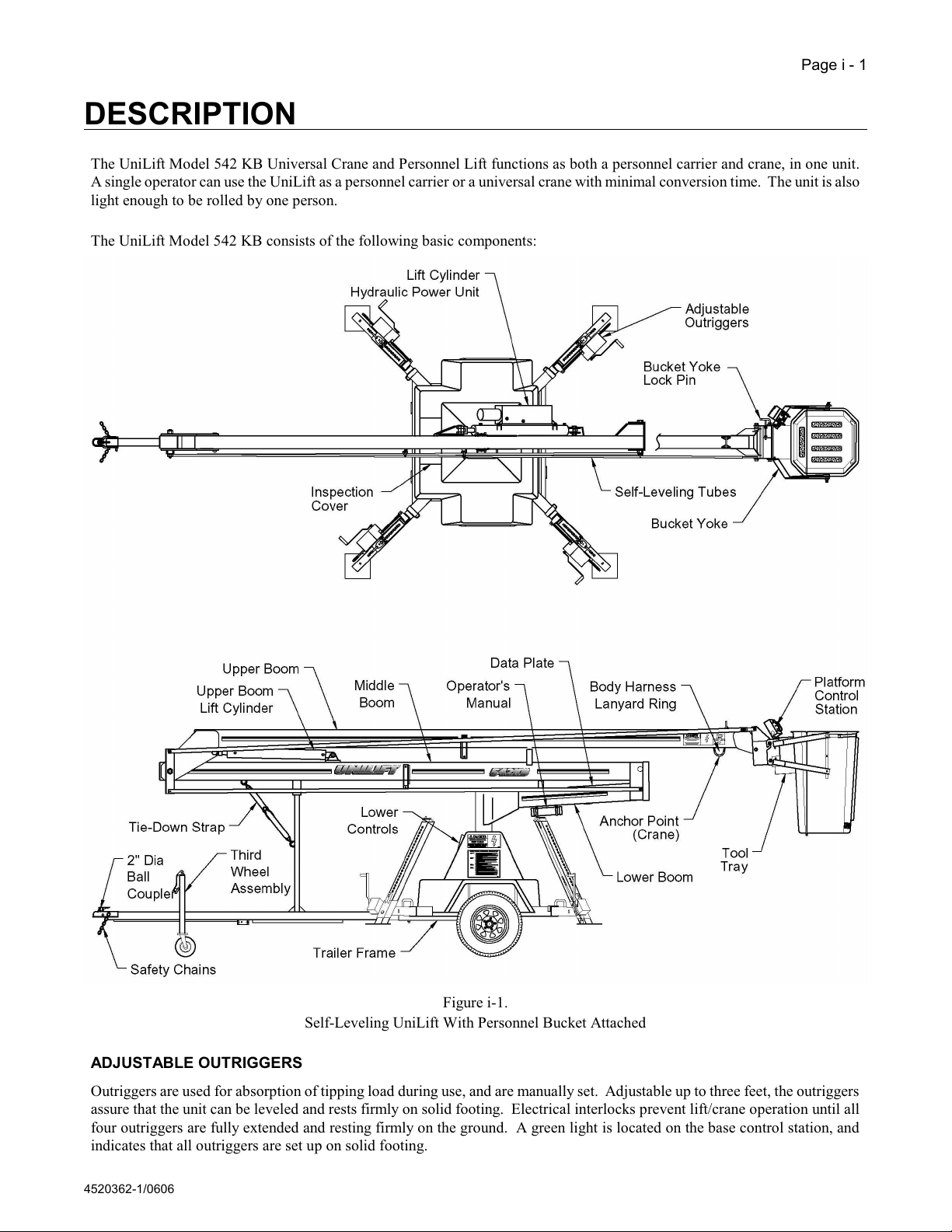

SINGLE AXLE TRAILER FRAME WITH 2" (50.8 mm) BALL COUPLER WITH SURGE BRAKES, AND

THIRD WHEEL

A torsion bar type of axle, rated at 3500 pounds (1589 kg), is used for road stability while towing. The 2" (50.8 mm) diameter

ball coupler with surge brakes, and third wheel assembly are provided as standard equipment, allowing the unit to be transported

to a job site and unhitched. WARNING: DO NOT ATTEMPT TO TOW THIS LIFT WITH A MULTI-PIECE HITCH

BALL OR A HITCH BALL OTHER THAN 2" (50.8 mm). Safety chains are also provided and shall always be attached when

the unit is to be transported. Tire size is P205/75R14 with a max load rating of 1532 Lbs. (696 kg) at 35 psi (241 kPa).

PLATFORM AND LOWER CONTROLS

Full controls are provided at both the bucket and the base. The DOWN OVERRIDE-OFF-ENABLE switch (Platform Control

Station), and the PLATFORM CONTROL/LOWER CONTROL switch (Lower Control Station) are used to enable each station.

A key switch is provided at the Lower Control Station for security. Emergency lowering controls are also provided at the end of

the upper boom, and inside the base assembly.

POWER REQUIREMENTS AND CHARGING CAPABILITIES

The unit is powered by two, 6-VDC deep-cycle batteries connected in series, yielding 12 VDC for approximately eight hours of

operation under typical use. A built-in 12-VDC, 30-amp battery charger is provided to restore charge to the batteries, and is

equipped with automatic cutoff when full charge is reached. The battery cutout relay also permits operation while the unit is

plugged in and the batteries are recharging. (See the section on Inspection and Maintenance for more details on battery system.)

HYDRAULIC LIFT CYLINDERS

Aerial lift is provided by two 3-1/2 inch (88.9 mm), double-acting cylinders: the lower lift cylinder is attached to the lower and

middle booms. The upper lift cylinder is attached to the upper and middle booms. Hydraulic power is provided by a 12-VDC

hydraulic system, connected to the lower lift cylinder.

SURGE BRAKES

Hydraulic brakes are standard equipment. They are surge activated and use a standard 2-inch (50.8 mm) diameter ball coupler.

Breakaway chains are provided for emergency stopping.

OVER-CENTER SAFETY SWITCH

An over-center safety switch is mounted to the upper boom. This switch continuously monitors the angle of the upper boom, and

prevents it from going into an over-center position.

PERSONNEL BUCKET

The fiberglass personnel bucket is self-leveled by the linkage which is connected to the boom structure. Older models were gravity

leveled and hydraulically dampened with a positive work-position locking handle. The bucket is made removable for crane

operation if required. Travel limits prevent continuous rotation of the booms and bucket. A body harness is provided with each

unit and shall be worn at all times when operating unit from the bucket.

LEVELING SAFETY SWITCH (OPTION)

The leveling safety switch continuously monitors the trailer for an unsafe tilt condition (exceeding 5°) during set-up and operation.

The green Trailer Level Indicator Light is lit when the trailer tilt is within the 5° range. If the tilt exceeds the limit during set-up,

the controls will not operate. If an unsafe condition occurs during operation, only the boom DOWN functions will work.

110-VAC ACCESSORY POWER OUTLET (OPTION)

A 110-VAC outlet, 15 amps maximum capacity, is available at the bucket to power accessory tools.

Courtesy of Crane.Market