Star Meter CYYZ61 User manual

An instruction manual

CYYZ61 Hygienic pressure transmitter

星仪传感器

STAR METER

4. Product Features

a) Using diaphragm isolation technology

b) Integrated chip, wide range of supplied voltage

c) Easy to clean up,Compact structure, easy installation

d) Frequency cutoff design, strong anti-interference ability,

lightning protection

e) Current limiting, voltage limiting, reverse connection

protection(limiting current output)

f) High accuracy, good stability, fast response

5.Technical parameters

Measuring media : Liquid or gas(compatible with contact media)

Overall material: Diaphragm 316L stainless(contacted)

Process connection 316L stainless(contacted)

Casing 316L stainless

Display case ABS engineering plastic(digital tube display)

Hessman connector ABS engineering plastic

Pressure range: 0~10kPa~4MPa (read the range selection form

for details)

P r e s s u r e m o d e : Gauge pressure

Output signal: 4~20mA、RS485 (Standard Modbus-RTU protocol),

(0~10VDC、0~5VDC、1~5VDC、0.5~2.5VDC customized)

Supply voltage: 12~36VDC Normal

15~36VDC Normal(with display or output 0~10VDC)

3~5VDC Customized (Output 0.5~2.5VDC/RS485)

Accuracy class: 0.1%FS (range≥100kPa customized)

0.25%FS(range≥100kPa customized)

0.5%FS (10kPa≤range<100kPa default)

Device display accuracy class of 0.5, shown by (LED) digital tube

Working conditions: contact media temperature -40~130℃

Ambient temperature-40~85℃

Ambient humidity 0%~95%RH(no condensation,no condensing)

Temperature compensation: -10-70 ℃ (accuracy of 0.25% FS, 0.5% FS, 1% FS)

-40-80 ℃ (accuracy of 0.1% FS)

Seismic performance : 10g(20...2000Hz)

Overload capacity: 200% full scale or 120MPa(minimum value)

Response frequency: analog signal output≤500Hz, digital signal output ≤5Hz

Stability : ±0.1% FS/year

Temperature drift: ±0.01%FS/℃(within the temperature compensate range)

Overall weight : no display ≈190g display ≈270g

Protection lever: IP65(no display)IP54(display)

Note: The above protection level refers to the level

achieved after the electrical connection is complete.

Power range : Current type≤0.02Us(W)

Digital type≤0.015Us(W)

Voltage type≤0.008Us(W)

Voltage type(output 0.5~2.5)≤0.001Us(W)

Note:Us=Supplied voltage

Load characteristics : Current type load ≤{(Us-7.5)÷0.02(Us=supply

voltage)}Ω voltae type load ≥100kΩ

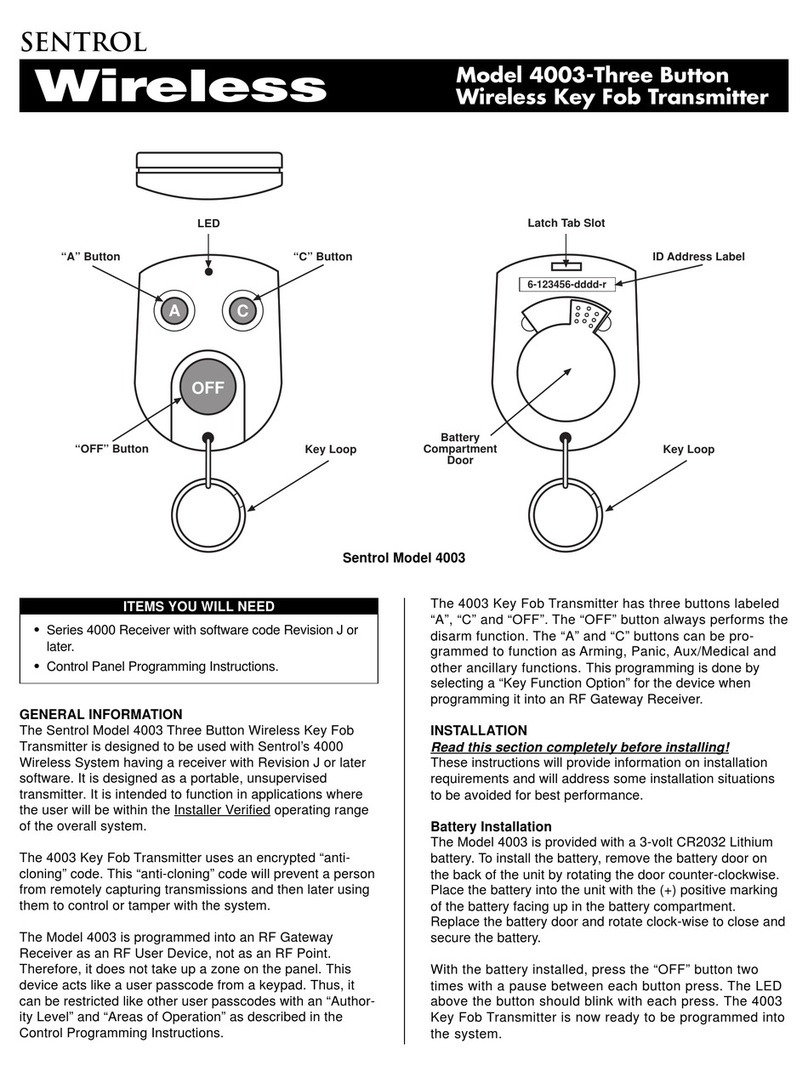

6.Dimensions

Figure 6-3 display clamp interface

Figure 6-4 display Threaded interface

6mm

60mm

φ

27mm

φ50.5mm

100mm

48mm

145mm

SENSORS

48mm

6mm

φ50.5mm

PG9

PG9

PG9

PG9

! Note: The total length of the digital signal output

is increased by 33mm.

Figure 6-1 no display Clamp interface

Figure 6-2 no display Threaded interface

Note 2: The marked place can be rotated 360°

medical technology

Pharmaceutical industry

Food and beverage industry

Typical application

76mm

12mm

116mm

φ

27mm

S=27

SENSORS

S=27

12mm

48mm

48mm

76mm

φ

27mm

161mm

version number20.4.23

1.Overview

1.1 Safety guidance

This operational manual contains important information on how to use the

transmitter correctly. The installation personnel of the transmitter should

read this manual carefully before operation. In case of further explanation

or special questions, which cannot be addressed in this manual, please

contact our company for assistance on necessary information.

Please pay attention to the warning signs on the manual! Do not use

crystallized or solidified measure medium, to avoid damaging of the sensor.

The operator must strictly follow the safety instructions and user’s

manual during operation. Furthermore, the operator should comply with the

occupational safety rules, the accident prevention guidelines, the national

standards and engineering specifications as well.

Please keep this manual in a safe place near the transmitter for easy

access.

The copyright of this operational manual is protected. This version of

operational manual was edited according to the functions of corresponding

products, the product functions and operation procedures are described as

complete as possible. If there is any error, please don’t hesitate to

contact us. The company is not responsible, in regard of any fault

description or its possible consequences.

–The right to modify the technical parameters is retained–

1.2 Icon description

Danger! - Hazard that may result in death or serious injury.

Warning!- Potential hazard that may result in death orserious injury.

Cautious!-Potential hazard that may cause minor injury.

Reminder!-Potential hazard that may result in personal injury.

Tips!-Tips and information for smooth operation of the equipment.

1.3 Manual user

Warning! This manual is suitable for technicians.

1.4 Limit of liability

The company will not be held responsible nor provide any warranty

service, in case of transmitter damages caused by failure to follow the

instruction manual, inappropriate use, self-modification or destruction.

1.5 Instructions for use

CThe pressure transmitter CYZ61 series is suitable for pressure

measurement in liquid or gas and process industries. Operators are

responsible for checking whether the equipment is suitable for operating

conditions. If you have any questions, please contact our sales department

to ensure the correct application of the transmitter. The Company shall not

bear any responsibility for the influence caused by improper selection.

The purchased model is suitable for certain gas or liquid medium as

described in the measurement samples. The user must ensure the

compatibility of contact media and transmitter.

Warning!

Inappropriate use may lead to danger!

2.Product overview

CYYZ61 series pressure transmitters adopt OEM pressure sensor with

stainless steel diaphragm as signal measuring element. After automatic

testing by computer, temperature compensation of zero point and sensitivity

in wide temperature range is carried out by laser resistance adjustment

technology. The amplification circuit is located in the stainless steel

case, which converts the sensor signal into standard output signal, giving

full play to the technical advantages of the sensor, so that the CYZ61

series pressure transmitter has excellent performance. It is easy to clean,

anti-interference, small temperature drift, high stability, and has high

measurement accuracy. It is an ideal pressure measuring instrument in

pharmaceutical, food and other industries.

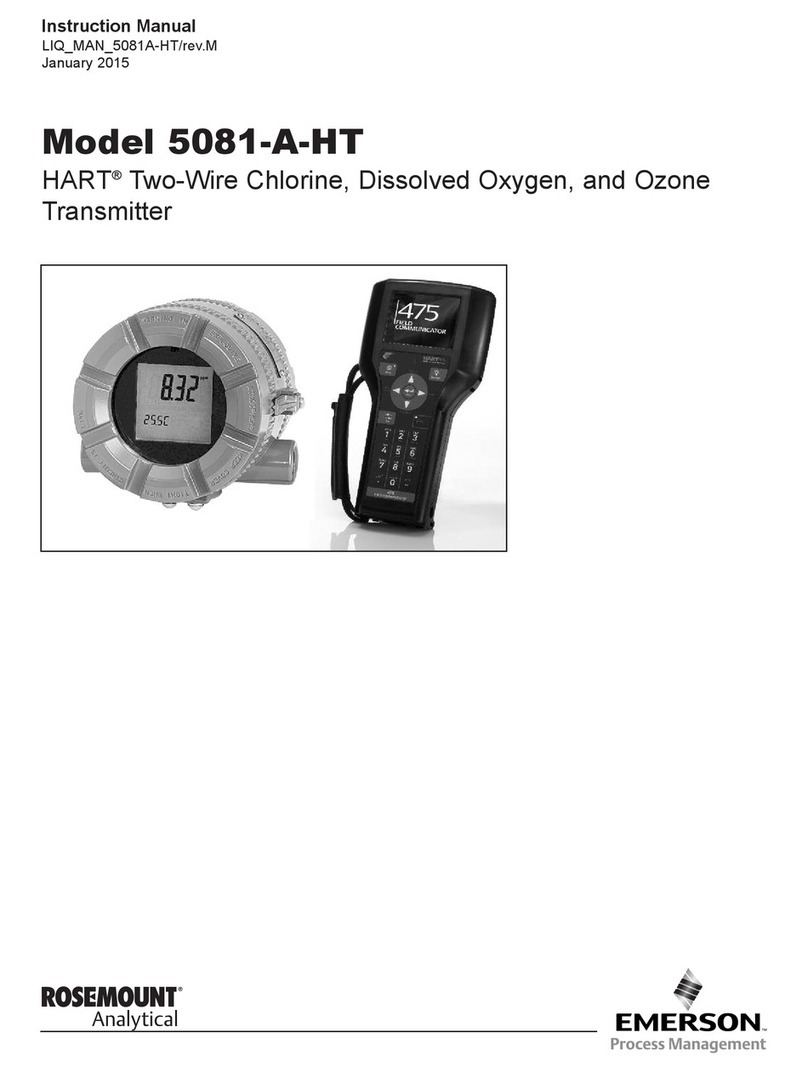

3.Working principle

The pressure sensors diffuses a wheatstone electric bridge on

mono-crystalline silicon, and stressed by the measuring media (liquid or

gas)to cause change of the bridge wall resistance value(piezoresistive

effect). In result, a differential voltage signal will be generated, which

converts the signal corresponding to the range into standard analog

signal(as shown in Figure 3-1)or digital signal.

!

!

!

!

!

!

Figure 3-1

Pressure

source Sensor

Signal

processing

circuit

Output

analog

quantity

or

digital

signal

Customer

collecting

device

1200

1000

800

600

400

200

107.5 15 20 Working volt

25 30 36

RL(Ω)

Loading resisitance (4~20)mA DC

Us(VDC)

Working zone

Figure5-1

Note1: The total length of the digital signal output

is increased by 33mm.

7.Installation and precautions

Warning!

a)Installed without pressure nor power supply.

Warning!

b)Transmitter should be installed by technician who read and

understood this operational manual.

Danger!

c)The transmitter uses diffused silicon oil-filled core, which may

cause explosions if in-properly handled. Do not measure oxygen for sake

of he safety.

Danger!

d) This product is not explosion-proof, using in explosive area may

cause serious injury and significant loss.

Warning!

e) It is prohibited to measure media that is not compatible with

the transmitter.

f) Please check if the package is in good order when receiving

the product, confirm the transmitter model and specifications.

!g) To avoid the damage of diaphragm, please unpack the package

and protective cap before starting the equipment. Please keep the

protective cap of the product. When the equipment is dismantled,

please put on a protective cap for the pressure interface immediately.

Be extra careful when handling unprotected diaphragms, because

unprotected diaphragms are very sensitive and easily damaged.

!h)Handle with care, do not throw, do not force during

installation of transmitter.

i)Vertical installation is applicable when pressure is below

0.03MPa (except for gas),to avoid affecting themeasurement accuracy.

Others can be installed at any angle. In case the interface size does not

match, it is allowed to make connecting adaptor.

j)During installation, attention should be paid to the upward

installation of the pressure interface of the equipment (for gas

emission).

k)If the pressure interface is upward or lateral when the

transmitter is installed, it is necessary to ensure that there is no

liquid flowing in the equipment shell, otherwise moisture and dirt

will block the air outlet near the electrical connection, or even

cause equipment failure. It is necessary to ensure that there is no

dust and dirt residue on the edge of threaded connection of electrical

connection.

l)It is recommended to install at minor temperature gradient variations zone.

m)It is recommended to adopt lightning protection and over

voltage protection facility between power distribution box or power

supply and the transmitter, for the fact that there will be danger if

the transmitter is installed in a harsh area.

n)While measuring high temperature media, please ensure the

media temperature is not higher than the maximum work temperature of

transmitter. If necessary, it is required to install a cooling device.

o)Install a pressure cutoff valve between the transmitter and

media, to inspect and avoid interference with measurement accuracy

caused by pressure port clogging.

p)During the installation, use a wrench to tighten the transmitter

from the hexagonal nut at the bottom, to avoid wire disconnection caused

by direct rotation of the upper part of the device.

!q) This product is a light current device, it must be laid

separately from high current cables during wiring, and comply with

relevant national wiring standard (GB/T50312-2016).

!

!

!

!

!

STAR METER

24-hour service hotline:400-600-4496 Executive standard JB∕T 10726-2007www.star-sensor.com

1

9.Specification selection

▲0~20 kPa

0~0.4MPa

0~1.6MPa

05

09

13

06

10

14

0~100kPa

07

▲ accuracy level 0.5; no mark accuracy level default 0.25, level 0.1 can be customized.

67 Custom

04 ▲0~10kPa ▲0~50kPa

08 0~200kPa 0~0.5MPa 11 0~0.6MPa

12 0~2.5MPa 15 0~4MPa

0~1MPa

Range Selection Schedule

Code Range Code Range Code Range Code Range

CYYZ61 Hygienic pressure transmitter selection table

CYYZ

Clamp(50.5)

35

61 H12 A1 14 B G

For example: CYZ61-H-12-A1-14-B-G (Hygienic Pressure Transmitter, Hessman Lead (No Display),

Range 0-1 MPa, Output 4-20 mA, Connection M20*1.5, Accuracy 0.25, Power Supply 12-36 VDC).

Note 1: The output is 0.5-2.5 VDC/RS485, which can not be displayed.

61

H

X

CYYZ

Pressure transmitter

Transmitter type

Code

Hygiene type (default no connection)

With or without display

Code

Without display (Hausman lead)

Display (Hausman lead)

Range

Code

See range selection table attached

Signal output

4-20mA Two-wire systme

RS485 communication interface

(standard M odbus-RTU protocol) four-wire system

Custom

Code

A1

RS

DZ

Custom

M20*1.5 External thread

G1/2 External thread

44

14

19

Accuracy level

0.1%FS Customization (range ≥100KPa)

0.25%FS Regular (range ≥100KPa)

0.5%FS Regular ( range <100kPa)

Code

S

B

C

Supply voltage

12-36VDC Regular

15-36VDC

Regular (with display or output 0~10VDC)

3-5VDC Custom (Note 1)

Custom

Code

G

G2

G3

DZ

Custom

Other custom requirements

Regular

Code

D

No

Example of selection

Connection type

Code

version number20.4.23

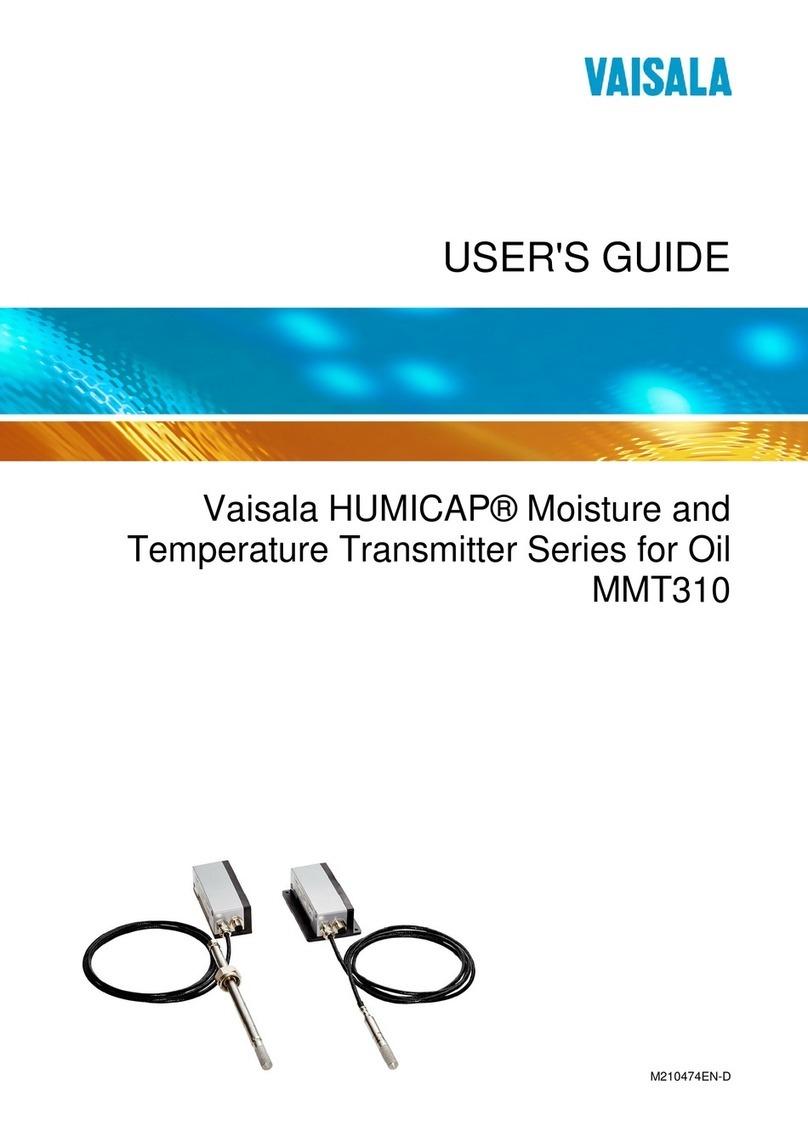

8.wiring installation

c)Remove wire holder from dismantle notch with flat screw driver.

d)Lay shielded cable through the wire hole as figure8-3 after removing,

connect wire at the terminal behind the wire holder as instructed in the

figure, restore and screw the wire holding cap tightly.

After wiring is completed, the wire outgoing direction can be changed by

the direction of wire holder

It is required to ensure the outer diameter of the cable used is within

the allowable range of the guard staple. And the cable must be fitted in the

guard staple firmly and without clearance. The diameter of wire holding cap

is 4~6mm.

The plug must be correctly and properly installed to ensure the protection level.

Wire holding cap

Figure 8-3

VDE

lift 1

3

2

GDM

+S

10A

250V

~

Dismantle notch

Plug case Wire holder

Wire hole

Figure8-1 Figure8-2

b)Remove plastic plug units indicated

in the figure above.

a)Unscrew the star type M3 screw

Plastic pug unit

8.1 Wiring

Pull out the terminal block which is inside the casing of plug to

connect the wire, wiring steps areas shown in the following figure.

r) Ensure that the power supply voltage meets the requirement

of the transmitter. And make sure the maximum voltage of the pressure

source is within the range of the transmitter.

s)Increase pressure and reduce pressure very slowly during the

pressure measurement, to avoid instantaneous high voltage or low

voltage.

Warning!

t) Make sure the pressure source and power are disconnected

before disassembling the transmitter, to avoid accidents in result of

media ejection.

u) Do not disassemble during usage, and do not touch the diaphragm,

!

8.2 Wiring diagram

Voltage output wiring figure 8-5 (three-wire system)

Current output wiring diagram 8-4 (two-wire system)

P

Transmitter

Blue line(V-)

Red line(V+)

Collecting device

Power supply(VDC)

Pressure input

U

+ -

A

P

Transmitter

Red line(V+)

Blue line(V-)

Yellow line(OUT)

Pressure input

V

U

+ -

Collecting device

Power supply(VDC)

3

2

1

1、Positive power supply(V+)

2、Positive output (OUT)

3、Negative power supply(V-)

、Earthing

3

2

1

1、Positive power supply(V+)

2、Negative power supply(V-)

、Earthing

Representing the shielded wire, all marked grounding points

must be effectively grounded.

The transmitter casing defaults to be ground, all field devices

are required to be effectively grounded.

Only the current output has reverse connection protection

(no damage but does not work), current limiting and voltage limiting

protection. Reversed connection of all other output signals can cause

damage to the transmitter.

1、Positive power supply(V+)

2、RS485A(A)

3、Negative power supply(V-)

、RS485B(B)

3

2

1

RS485 (digital signal) 8-6 output wiring diagram (four-wire system)

P

Transmitter

Red line(V+)

Blue line(V-)

Yellow line(A)

White line(B)

PC

device

U

+ -

Pressure input

Collecting device

Power supply(VDC)

10.Protocol Description

(limited to RS485 signal output 485 all product addresses default to 01)

10.2.Modbus-RTU Read Data 03 Command Description(Data is hexadecimal)

10.1.Basic technical parameters of the transmitter

(This protocol complies with the Modbus communication protocol, and uses a subset

of the Modbus protocol which is RTU mode. RS485 half-duplex working mode)

a)Output signal: RS485 (Maximum distance can be up to 1000 meters. Maximum connection 32 channels)

b)Standard Modbus-RTU protocol

(03 function reads data, 06 function inputs setting data)

c)Data format: 9600, N, 8, 1 (9600bps, no parity, 8 data bits, 1 stop)

d)Measurement range: 0-X (MPa, kPa....)

e)Resolution: 0.05%

f)Output data: 0...2000 (other range customize)

g)Response frequency: ≤ 5Hz

h)Response speed: ≥10ms

Protocol format description

Host command

Return from

machine

Device address

Device address

Address

Address

Data address

00 00

02*CN

Data byte

Function code

Function code

03

03

Number of read data

CN

Sensor data

S_HN ,S_LN

16CRC code(low before high after)

16CRC code(low before high after)

CRC0 CRC1

CRC0 CRC1

Communication example(reading a sensor signal):

The sensor communication device address of 0-1.6 MPa is set to 01, ie

[Address]=01 (Address range 01-254);

And, CRC0=84, CRC1=0a. Then send and return data should be as follows:

Send: 01 03 00 00 00 01 84 0A

Back: 01 03 02 02 AC B9 59

02AC is hexadecimal, converted to decimal 684;

Data output: 0-2000 corresponds to 0-1.6 MPa, so the current pressure is

P=1.6*684/2000=0.5472MPa

Calculation formula: (range upper limit - range lower limit) ÷ 2000 *

current data + range lower limit = current pressure value

Query example(read the current device address, only to be completed

independently by a single sensor)

Send:FF 03 00 0F 00 01 A1 D7

Back:FF 03 02 00 01 50 50

Then: the address of this device is 01 (hexadecimal)

Example of modification

For example, change 01 address to 09 address:

Send 01 06 00 0F 00 09 79 CF

Retun 01 06 00 0F 00 09 79 CF

Then the original address 01 is modified to 09 successfully, and the

modification of address can be done offline or online. It can work

directly without re-powering at completion.

10.3. Modbus-RTU input 06 command detailed description

(data is hexadecimal)

Protocol format description

Host command

Return from

machine

Device address

Device address

Address

Address

Data address

Data address

00 0F

00 0F

Function code

Function code

06

06

New address

New address

H L

H L

16CRC code (low before high after)

16CRC code (low before high after)

CRC0 CRC1

CRC0 CRC1

10.5. 16CRC verify

The 16CRC verification is a standard error check method used by the

Modbus protocol. Generally, it has detailed descriptions and procedures,

which is not explained here.

10.4.Precautions for use

a)Single RS485 bus must adopt a “hand-to-hand” bus structure. Do

not use a star connection or a fork connection. The address code is set

from near to far, that is, the management computer is connected to the

No. 1 controller, No. 2 is connected to No. 1, No. 3 is connected to No.

2, and so on...

Warning!

b)The AC power supply and the case of the equipment must be grounded

properly and well. There are many places where there are triangular sockets

which in fact, have no grounding at all. Be alerted. When the grounded

properly, the equipment to release the energy by combining with the

lightning protection design when struck by the lightning surge and the

static electricity, to protect the RS485 bus equipment and related chips

from damage. Do not use the RS485 bus if there is no grounding or not

properly grounded, to avoid equipment burnout and casualties.

c)Wire must use multi-strand shielded twisted pair cable with diameter of

more than 0.3 mm2 (multiple strands are for spare). Use PVC pipe separately to

avoid lining with strong current to avoid interference from strong current.

d)485 (A) and 485 (B) must be twisted together, because 485

communication uses differential mode communication principle, and twisted

pair anti-interference performance is good. It is wrong not to use twisted

pairs, and other types of cables.

e)Connect the RS485 converter and the reference ground GND (power

supply negative) of all access controllers, and use the remaining one or all

of the multiple twisted pair cables for the series GND; if the reference

ground is not connected, it will also affect the communication time.

Nowhere, high frequency radiation, mainly from distributed capacitance and

inductance, produces a common mode effect.

f)The shield of the network communication line is grounded. It is

required for grounding, otherwise the potentially danger of the bus is

unknown.

g)If multiple machines or cables are too long for communication, add

120 ohm matching resistors between 485 (A) and 485 (B) at the head and end

of the 485 bus, to improve the communication performance quality. (Must be

pair twisted)

h) The transmission rate, number of load nodes and transmission

distance should be reasonably arranged, to achieve remote low-node for

low-speed, short distance multi-node for high-speed principle.

i)The data communication shall be verified to protect the transmission

accuracy. Generally, the Modbus-RTU is verified by the crc-16 verification

mode, and the error rate is less than 1/1billion.

j)If necessary, choose the company's isolated type model 485, the price

is generally higher.

!

STAR METER

24-hour service hotline:400-600-4496 Executive standard JB∕T 10726-2007www.star-sensor.com

2

version number20.4.23

Warning!

a)Before starting, it is a must to check if the transmitter is

installed correctly, and if there is any obvious damage.

Warning!

b)The transmitter must be operated by professional technicians who

read and understood this operating manual.

Warning!

c)The transmitter is only suitable for working conditions that

meet the technical requirements!

11.Initial start

12.After sales service

a)The company is responsible for all the maintenance costs during

the warranty period, after inspected by the technician of the company and

confirmed there is quality failure.

Warning!

b)Please clean the residual media before returning, especially

substances that is harmful to human health, such as corrosive, toxic,

carcinogenic or radioactive substances;

c)Please keep the warranty card and certificate in a safe place,

and return with the product when there is need of repairing;

d)If there is any faulty with the transmitter, please contact our

after-sales service. If you need to send the transmitter back to the

company for repair after confirming the problem. Please attach the

following information:

Description of the site environment;

Fault phenomenon;

Delivery address and contact information;

!

!

!

!

If the fault phenomenon does not fall within the above range, please

contact our after-sales.

Fault phenomenon

·The transmitter

has no output signal.

·Output irregular jumps

whenthe pressure is constant

·The corresponding output

value is incorrect when

transmitter is not connected

to pressure media

·The transmitter output does

not match with the measured

pressure

·The supply voltage is

incorrect

·The external load is too large

·Whether it is within the

power supply range

·Adjust the external load

·The transmitter is not

operating in required

environment

·Move the transmitter to

the specified environment

or take action to ensure

that the environment meets

the requirements

·The transmitteris not

grounded

·Strong RF interference on

site

·No shielded cable applied

·Use shielded cable and

ground the shield

·The transmitter is

properly connected

to the earth

·The transmitter

is not powered.

·Fault connection.

·Supply power to transmitter

correctly according to

the wiring diagram.

Cause analysis Elimination method

12.1Common fault analysis and elimination

12.2 Calibration

13. Transportation and storage

The transmitter should be kept in a sturdy cardboard box (large device

requires a wooden box), free move in the box is not allowed,be careful when

handling, do not handle with roughly. Store area .

should meet the following conditions:

Zero and full-scale drift may occur during the use of the transmitter.

If the above phenomenon occurs after long time use,it is recommended to send

the transmitter back to us for calibration to ensure high accuracy.

a) Protect from rain and moisture.

b) Free from mechanical shock or shock.

c) Temperature range -20 ~ 55 °C.

d) The relative humidity is not more than 80%.

e) No corrosive gas in the environment.

a) After unpacking, check the packing list to confirm if the documents

and accessories are complete.

The packed documents are:

A copy of the instruction manual.

A product certificate.

A warranty card.

b) Observe if there is any damage caused during transportation, for

proper following up.

c) We hope that the user can safely keep the “warranty card”, please

don’t misplace it, otherwise you can’t return to the factory for free repair!

Warning!

When purchasing the pressure transmitter, the user should select the appropriate

model to make sure it meets specifications of the contact media ,such as the

pressure , temperature , protection level and environmental conditions

14.Unpacking precautions

15.Instructions for ordering

!

STAR METER

24-hour service hotline:400-600-4496 Executive standard JB∕T 10726-2007www.star-sensor.com

3

Other Star Meter Transmitter manuals