Star Meter KPE 9039G User manual

Installation instructions

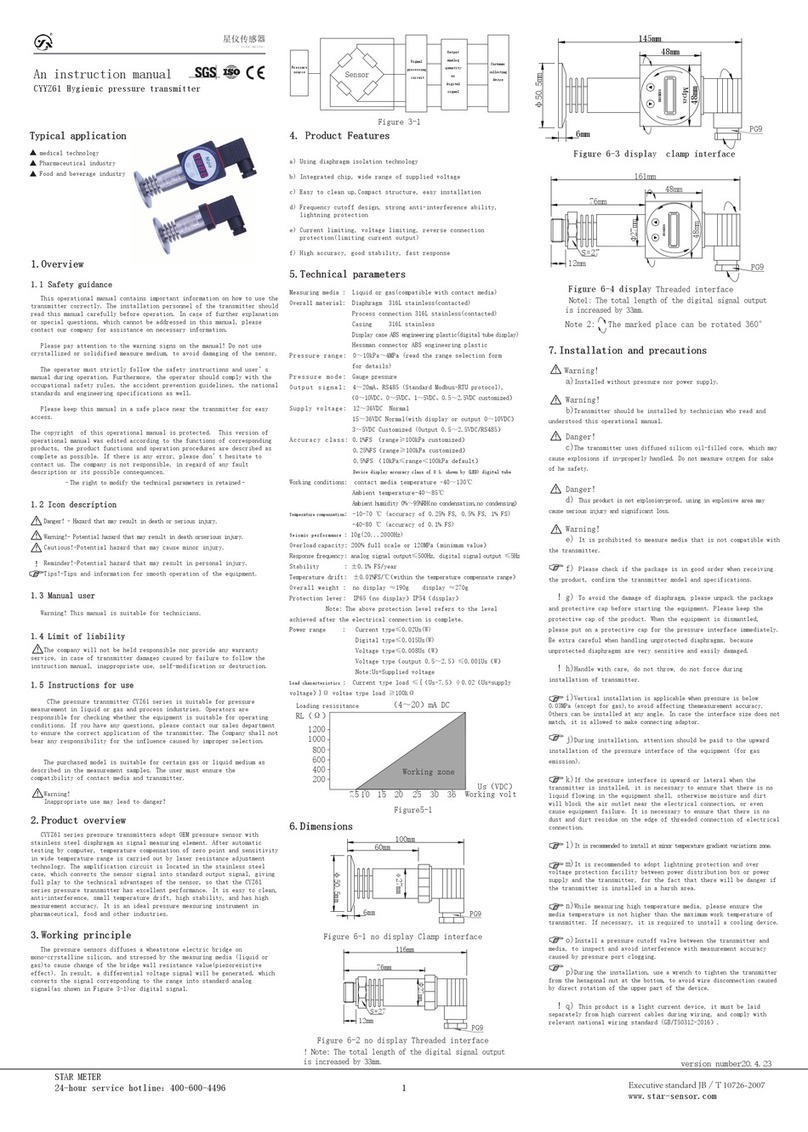

CYYZ92 Exquisite Pressure Transmitter

星仪传感器

STAR METER

星仪传感器

24小时服务热线:400-600-4496 执行标准JB/T 10726-2007www.star-sensor.com

1

版号23.06.27

DANGER!

The transmitter adopts diffused silicon oil filled core, and improper

use will cause explosion accidents. To ensure safety, it is strictly

prohibited to measure oxygen.

DANGER!

This product is not explosion-proof, and its use in explosion-proof

area will cause serious personal injury and material loss.

!

!

a) After unpacking, check whether the documents and accessories

are complete according to the packing list.

Packing documents: one copy of operation manual.

One product certificate.

A warranty card.

b) When receiving the product, please check whether the package is

intact, and check whether the transmitter model and specification are

consistent with the product you choose.

c) Observe whether the transmitter is damaged due to transportation

for proper treatment.

d) The user is expected to keep the "warranty card" properly and do

not lose it, otherwise it cannot be returned to the factory for free

maintenance!

Unpack

Identification

Precautions for use

Summary

Safety guidance

These installation instructions contain important information on how to

use the transmitter correctly. The transmitter installer shall

carefully read the installation instructions before operating the

transmitter. In case of further understanding or special problems,

which are not described in detail in this operation manual, please

contact our company to obtain necessary information.

Please pay attention to the warning signs on the instructions!

Operators must strictly follow the safety instructions in the

installation instructions. In addition, occupational safety rules,

accident prevention guidelines, national installation standards and

engineering specifications must be observed.

Please keep this instruction properly and store it in a convenient

place near the transmitter.

The copyright of these installation instructions is protected. The

installation instructions of this version are written according to the

functions that can be realized by the corresponding product during

printing, and describe the product functions and operation steps as

detailed and complete as possible. If you find mistakes, you are

welcome to criticize and correct them. The company is not responsible

for the possible wrong description and possible consequences.

– reserve the right to modify the technical parameters –

Icon description

Danger! – A dangerous situation that could result in death or

serious injury.

Warning! – A potentially hazardous situation that could result in

death or serious injury.

Be careful! – A potentially hazardous situation that may result

in minor injury.

Reminder! – A potentially hazardous situation that may cause

personal injury.

Tips! – Tips and information to ensure trouble free operation of

the equipment.

User

Warning! These installation instructions are for technicians.

Limitation of liability

If the transmitter is damaged due to non-compliance with the operation

and installation instructions, improper use, self modification and

destruction, the company will not be liable for compensation and will

not provide warranty service.

!

!

!

!

!

model

range

output

power supply

accuracy

protect

Product number

Product certification

Wiring definition

PRESSURE Sensor

St ar Me ter

model:

:

:

:

accuracy :

protect :

Tel:400-600-4496

Opening

Select the opening position

according to the medium, with gas

at the top and liquid and steam

at the side or bottom.

It is recommended to install a pressure stop valve before the

pressure measuring point to facilitate the maintenance and disassembly

of the transmitter. In addition, it can reduce the pressure impact

during the initial installation of pressure measurement.

Installation precautions

After the pressure in the pipeline stabilizes, slowly open the

stop valve to start measurement.

In the hydraulic system, pay attention to the upward installation

of the pressure interface of the equipment (for gas discharge).

If the transmitter is installed in a harsh site and will encounter

dangerous damage such as lightning stroke or overvoltage, we recommend

that the user carry out lightning stroke and overvoltage protection

between the distribution box or power supply and the transmitter.

In order to avoid liquid flowing along the cable, causing liquid

accumulation at the waterproof joint or entering the junction box,

a U-shaped ring shall be configured between the threading box and the

pressure transmitter as shown in the figure, and the bottom of the

U-shaped shall be lower than the pressure transmitter. It is considered

that sufficient length of electric cable shall be reserved for

maintenance and replacement.

A pulse buffer is installed inside the sensor. If the liquid

contains particles, the pressure hole may be blocked. Installing the

sensor in a vertical position can effectively avoid the blockage of

the pressure hole. After the pressure tap hole is blocked, the pulse

buffer can be removed with a 2.5 hexagonal wrench, cleaned and then

reassembled( Do not use hard objects to poke the pressure sensing

film inside the pressure hole during disassembly)

Try to install it in the place with small temperature gradient

change.

Warning!

The equipment must be installed without pressurization and power supply.

!

Install

Do not weld the base with pressure

transmitter! The deformation of the

base caused by welding shall be

avoided, and the waste slag shall be

cleaned to avoid scratching the

measuring diaphragm( (accessories to

be purchased separately)

PWarning!

Do not measure media with incompatible materials in contact with the

transmitter.

! No modifications or changes can be made on the equipment.

! Handle with care and do not throw it at will. Please do not use

brute force when installing the transmitter.

! This product belongs to weak current equipment, which must be

laid separately from strong current cables, and shall be wired in

accordance with relevant national wiring standards (GB / t50312-2016).

Ensure that the power supply voltage meets the power supply

requirements of the transmitter. Ensure that the high pressure of the

pressure source is within the range of the transmitter;

During pressure measurement, pressurize and relieve pressure

slowly to avoid instantaneous increase to high pressure or decrease to

low pressure;

Please do not disassemble or touch the diaphragm when using, so

as not to damage the product.

!

fuel damper

Installation steps for connection with clamp or KF

The thread length of the

pressure transmitter must be

greater than the thread depth of

the base to ensure the effective

sealing of the end gasket.

The thread length of the

pressure transmitter must be

less than the thread depth of

the base to ensure effective

sealing of the root gasket.

Raw tape or sealant is used.

After locking, a small part of

the thread of the pressure

transmitter is surplus.

-Select appropriate sealing accessories according to the measured medium

and input pressure

-Put the seal into the installation position of the corresponding

connection

-Place the clamp connection or KF connection in the center with sealing

device

-Then lock the hoop

-Use a wrench to tighten the transmitter from the hexagonal nut at the

bottom of the transmitter to avoid directly turning the upper part of

the equipment and causing the disconnection of the connecting line.

The recommended installation torque is as follows:

Recommended

installation

torque (nm)

55~60

40~45

30~35

20~30

15~16

Interface

type

G1/4

G1/2

7/16UNF

1/2NPT

1/4NPT

1/8NPT

Interface

type

M27*2

M20*1.5

M14*1.5

M12*1.5

M10*1.0

Recommended

installation

torque (nm)

30~35

45~50

16~20

2~3TFFT

2~3TFFT

2~3TFFT

Installation torque

Note: tfft is the number of turns the tool is tightened after

hand tightening

Installation steps for threaded connections

-Select appropriate sealing accessories and sealing positions according

to the measured medium and input pressure

Installation steps for flange connection

-Select appropriate sealing accessories according to the measured

medium and input pressure(e.g. gasket)

-Place the seal between the equipment flange and the counter flange

-Install the equipment on the corresponding flange connection through

4-8 groups of bolts (according to the flange model)

Installation steps for connection of pagoda mouth or fast interface

-Check whether the size of air pipe and interface match

-After the air pipe is directly inserted into the interface, pull it

slightly by hand to check the reliability, that is, the connection is

completed

-Ensure that the sealing surface connected to the equipment is smooth

and flat

Pedestal

Face seal

Root seal

Thread seal

Transmitter

valve

Welded base

星仪传感器

STAR METER

接线示意

Represents a shielded wire, and all marked grounding points must

be effectively grounded. It is recommended to choose shielded twisted

pair signal cables. In order to avoid grounding circuits, the shielding

layer adopts single ended grounding, insulated floating grounding at

the pressure transmitter end, and grounded at the control cabinet end.

The transmitter casing is grounded by default, so it is required

that the on-site equipment be effectively grounded. If the on-site

equipment cannot be grounded, the indicated grounding point must be

effectively grounded.

wire

星仪传感器

24小时服务热线:400-600-4496 执行标准JB/T 10726-2007www.star-sensor.com

2

星仪传感器制造有限公司

Star sensor manufacturing Co., Ltd

Tel:400-600-4496

www.star sensor.com

厂址:燕郊经济开发区 天山国际创业基地 20号

Star MeterR

更多资料请扫码

前往官网获取

Disassembly and assembly steps of aviation plug

(without connecting wire)

12

3

4

a) Rotary lock nut and

compression bolt

c) Connect the wiring at the wiring terminal according to the wiring

diagram, restore it after wiring, and lock the compression bolt.

b) Separate the components

Lock nut

Subject

Terminal block

Hold down bolt

Hold down ring

Rubber ring

The user must ensure that the outer diameter of the cable used is

within the allowable range of the ferrule. In addition, ensure that

the cable is firmly installed in the ferrule without gap. The locking

diameter of the compression bolt is 4 ~ 5mm.

Be sure to install the socket correctly and properly to ensure the

degree of protection.

Warning!

a) Before startup, the user must check whether the transmitter is

installed correctly and whether there is obvious damage.

Warning!

b) The transmitter must be started and operated by professional

technicians who read and understand this operation manual.

Warning!

c) The transmitter is only applicable to the working conditions

that meet the technical requirements!

EMC statement

Applicable Directive: electromagnetic compatibility Equipment Directive

2014 / 35 / EU.

CE marking indicates that the product meets the requirements of applicable

EU standards.

The user must ensure that the whole equipment meets all use standards.

First start-up

!

!

!

Common fault analysis and troubleshooting

If the fault phenomenon does not fall within the above scope,

please contact our after-sales department,

400-600-4496

Fault phenomenon

·The transmitter

has no output signal

·When the differential

pressure is constant,

the output jumps irregularly

·When the transmitter is not

connected to the pressure,

the corresponding output value

is incorrect

·The transmitter output is

inconsistent with the measured

differential pressure

·Incorrect supply voltage

·Excessive external load

·Mechanical overload caused by

overvoltage

·Compliance with power supply scope

·Adjust external load

·When the transmitter is not

connected to the pressure,

the corresponding output value

is incorrect, and the transmitter

does not work in its required

environment

·Observe the humidity and

temperature allowed by the

environment

·The transmitter is not grounded

·Strong RF interference on site

·Shielded cable not used

·Use shielded cables and the

shielding layer is grounded

·The transmitter is reliably

connected with the earth

·Transmitter not powered

·Wiring error

·Power the transmitter correctly

according to the wiring diagram

Cause analysis Solution

Disassembly and after sales

Warning!

When disassembling the transmitter, ensure that the pressure source

and power supply of the transmitter have been disconnected to avoid

accidents caused by medium ejection;

During the warranty period, the products are detected by our

technicians as quality problems, and the company shall bear all

maintenance costs;

Warning!

Please clean up the residual media before returning, especially the

substances harmful to human health, such as corrosive, toxic,

carcinogenic or radioactive substances;

Please keep the warranty card and certificate, and return with the

product during maintenance;

If the transmitter fails, please contact our after-sales service.

After confirming the problem, you need to send the transmitter back to

our company for maintenance. Please attach the following information:

Description of site environment;

Fault phenomenon;

Receiving address and contact information;

Maintenance and cleaning

No maintenance is required to maintain the pressure transmitter.

Maintenance may only be performed by the manufacturer.

Before cleaning, the pressure transmitter needs to be relieved

and powered off.

Wipe the transmitter surface with a soft damp cloth.

!

!

Adjustment

maintain

Wrong detergent

Correct detergent

-Clear water

-Traditional detergent

-Using the wrong detergent will damage the label of the product.

-Do not use irritant cleaners.

-Do not use harmful or sharp sanitary ware.

-Do not use abrasive rags or sponges.

clean

Cleaning products

Zero and full scale drift may occur during the service life of the

transmitter. If the above phenomena occur after long-term use, it is

recommended to send the transmitter back to our company for calibration

to ensure high accuracy.

Transportation, storage and transportation

The transmitter shall be packed in a strong carton (wooden case

is required for large instruments). It is not allowed to move freely i

n the carton. It shall be handled with care and rough loading and

unloading is not allowed. The storage location shall meet the

following conditions:

a) Rain proof and moisture-proof.

b) Free from mechanical vibration or impact.

c) Temperature range - 30 ~ 70 ℃.

d) The relative humidity shall not be greater than 90% (no condensation).

e) The environment does not contain corrosive gases.

21

34

red

yellow

blue

white

ID Two wire three wire

1/red Power supply+ Power supply+

2/yellow OUT+

3/blue Power supply- Power supply-

4/white

Aerial insertion straight head strip line

21

34Note: Lock wire diameter 4-5mm

Aerial insertion straight head

ID Two wire three wire

1/red Power supply+ Power supply+

2/yellow OUT+

3/blue Power supply- Power supply-

4/white

21

34

Aviation elbow

Note: Lock wire diameter 4-5mm

ID Two wire three wire

1/red Power supply+ Power supply+

2/yellow OUT+

3/blue Power supply- Power supply-

4/white

21

34

Aerial insertion elbow strip line

red

yellow

blue

white

ID Two wire three wire

1/red Power supply+ Power supply+

2/yellow OUT+

3/blue Power supply- Power supply-

4/white

ID Two wire three wire

1/red Power supply+ Power supply+

2/yellow OUT+

3/blue Power supply- Power supply-

4/white

red

yellow

blue

white

Direct outgoing line

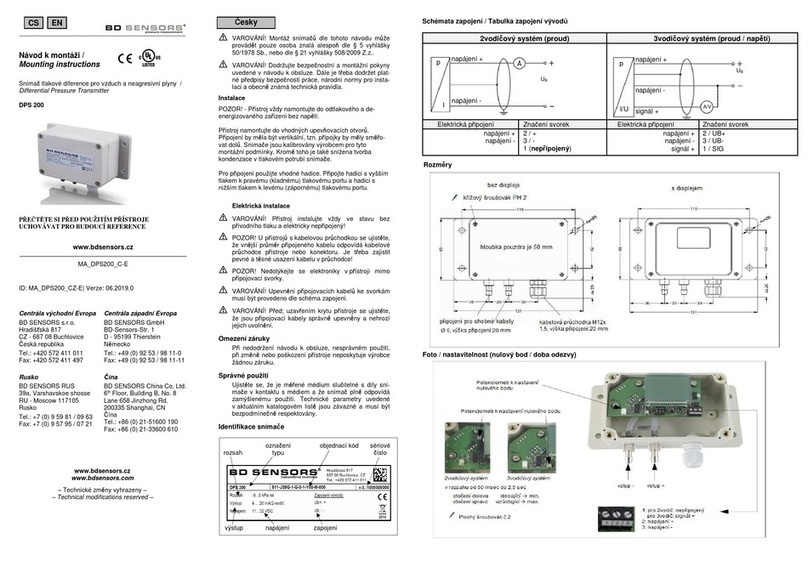

Current output wiring diagram (two wire system)

transmitter

P

Blue line (V-)

Red line (V+)

collecting device

Power supply (VDC)

Pressure

input

U

+-

A

Voltage output wiring diagram (three wire system)

transmitter

P

Red line(V+)

Blue line(V-)

Yellow line(OUT)

Pressure

input

V

U

+-

collecting device

Power supply (VDC)

Other Star Meter Transmitter manuals

Popular Transmitter manuals by other brands

Air Monitor

Air Monitor AUTO-purge III Installation, operation and maintenance manual

Vega

Vega VEGABAR 81 operating instructions

Dwyer Instruments

Dwyer Instruments CDT Series Installation and operating instructions

Comrex

Comrex ACCESS manual

Suntor

Suntor ST6210SH user manual

ABB

ABB TGS 40 operating instructions