Star 106 User manual

USER MANUAL

Model 106-106C

Star Universal (Gosport) Ltd

Unit 2, Clarence Wharf, Mumby Road, Gosport, Hampshire, United Kingdom, PO12 1AJ

Tel: + 44 (0) 23 9258 2857 Fax: + 44 (0) 23 9251 1731

Email: sales@staruniversal.com

Web: www.staruniversal.com

2

Star Universal (Gosport) Ltd

Unit 2, Clarence Wharf

Mumby Road

Gosport

Hampshire

PO12 1AJ

Telephone Number: 023 9258 2857

Fax Number: 023 9251 1731

Website: www.staruniversal.com

All rights reserved. Nothing from this edition is allowed to be copied and/or made public by means of print, photocopy or any other way without previous written permission

of Star Universal (Gosport) Ltd

Star Universal (Gosport) Ltd reserves the right to change spare parts and/or specifications without previous notice. Contents of this manual can also be changed without

previous warning.

Star Universal (Gosport) Ltd cannot be held responsible for eventual damage caused by specifications deviating from the standard model.

Although extreme care has been exercised during the writing of this manual, Star Universal (Gosport) Ltd will not accept any liability for eventual errors in this manual and/or

for the consequences of (mis)interpretation of the contents.

Star Universal (Gosport) Ltd is not responsible for damage or problems which result from the use of other than the original spare parts.

If this manual has not been supplied with instructions for certain repairs, adjustments and maintenance, you should contact Star Universal (Gosport) Ltd

3

Contents

1Introduction and check list 3

2Safety 4

3Machine Settings 5-6

4Fault Finding 7

5Machine Operation 7-8

6Maintenance Calendar 8

7Jaw Maintenance and Service Spares 9-10

8Thermocouple Replacement 11

9Jaw Assembly Diagram 12

10 Service Replacements 13

11 Electrical Parts List 14

12 Wiring Diagrams 15&16

13 Inside the Machine 17

14 Technical Specification 18

15 Environmental Policy 18

16 Warranty Policy 19

1 INTRODUCTION

With the purchase of this heat sealing machine you will be able to pack a great variety of

products. To use the heat sealer, Star Universal (Gosport) Ltd has ensured that all the machines,

from the smallest to the largest model, fulfil the greatest demands. All the machines are built

in-house to the highest standard and undergo vigorous testing, complying with all regulations.

Unpacking

The heat sealing machine is packed in either a box or pallet. We recommend you keep the

box/pallet so you can transport the heat sealer safely in the future, if ever required.

Use the following list to check the contents of the box/pallet:

Manual

✓

Spares Kit

Additional spares (if applicable)

4

2 SAFETY

2.1 SAFETY INSTRUCTIONS FOR HEAT SEALER OPERATION

WARNING this manual should be read in full prior to operating this heat sealing

machine. Ensure all the operators are aware of how to use it safely.

All users of this product are requested to follow all warnings and instructions contained in this

manual. In addition, all warnings and instructions affixed to the machine should be followed.

This heat sealer is supplied with a 3 wire power cable and a moulded 13 amp fused plug (UK). A

secondary fuse is located on the circuit board for additional protection. Increased user safety

can be achieved by the provision of a residual current device (RCD) being used on the supply

circuit to the machine.

The machine is not rated for direct water contact unless otherwise stated.

Ensure the power is switched off and the plug removed from the socket prior to carrying out any

service work.

The machine should be regularly serviced using genuine Star parts and is subject to the portable

appliance test regulations.

When not in use switch the machine off.

The sealer is designed to be installed on a flat level surface to ensure stability during operation.

The sealer is a heavy unit, take extra care when moving the machine using appropriate methods

and equipment. For machine weights and dimensions see later in the manual.

Heat sealers are not designed to be used in flammable or explosive environments.

With repeated cycling residual heat can build up on the sealing jaws. Avoid touching them

wherever possible.

Keep hands clear of the sealing jaws when operating the machine.

Always use heat sealers in a ventilated environment as sealing certain plastics may create fumes.

Check with your bag/material manufacturer.

Star Heat Sealers meet the health and safety requirements of The Supply of Machinery (Safety)

Regulations 1992 No. 3073 and The Machinery Directive 2006/42/EC. The CE mark will be affixed

to the product where applicable.

A request is made that any known incidents that result in injury to an operator from the

legitimate use of this heat sealer is reported to Star Universal Technical Department. Tel: 02392

582857 e mail: info@staruniversal.com

!

5

3 MACHINE SETTING

106/106C

Weld Control Keypad Locked Cool Control

Power On Indicator Alarm Indicator

SETTING THE WELD AND COOL TIMES/TEMPERATURES.

Set the weld and cool times as below. Place some of the material you wish to seal between the

sealing jaws, close them and cycle the machine by pressing the foot switch/push button. When

the cycle finishes open the jaws, if the material has not welded increase the weld and cool times.

If the weld looks molten decrease the weld and cool times. Repeat the above process until you

achieve a flat strong weld.

Weld Time/Temperature

With the machine turned on press the weld control ▲or ▼key and release, the amber weld

indicator will flash. To increase the weld time/temperature press the weld control ▲key, to

decrease press the weld control ▼key. As a starting point use 0.7/80. After 5 seconds the screen

will default back and save the figure entered.

Cool Time/Temperature

With the machine turned on press the cool control ▲or ▼key and release, the blue cool

indicator will flash. To increase the cool time press the cool control ▲key, to decrease press the

cool control ▼key. Cool time should be approximately 3 times weld time. After 5 seconds the

screen will default back and save the figure entered. Certain bag materials may require more or

less cool time than advised above, adjust this as required.

SETTING THE COMPENSATION, KEY LOCK AND JAWS TIMEOUT

During machine operation a residual heat build-up can affect the quality of the weld. To try and

minimise this the sealer has built in compensation which you can set. Firstly, set the weld and

cool times as above from a cold start then repeat the steps as below to achieve consistent weld

quality.

6

Heating Compensation (time control only)

This relates to the amount of time the controller reduces the weld time after each operation to

compensate for residual heat. A value of 0 indicates that heating compensation is disabled. A

low value will reduce the weld time by a small amount and is suitable for a machine that warms

up very slowly. A high value will reduce the weld time by a larger amount and is suitable for a

machine that warms up very quickly.

To adjust the value, with the machine turned on, press both of the weld control ▲and ▼keys

for 2 seconds and release when hc appears on the screen. To increase or decrease the figure use

the heat ▲or ▼key. After 5 seconds the screen will default back and save the figure entered.

Cycle the machine 15-20 times weld one of your bags. If the seal fails decrease the figure, if it is

molten increase the figure.

Cooling Compensation (time control only)

This relates to how quickly the controller increases the weld time when the machine is idle,

compensating for the machine cooling down when not being used. A value of 0 indicates that

cooling compensation is disabled. A low value will increase the weld time by small amount and

is suitable for a machine that cools down very slowly. A high value increases the weld time by a

larger amount and is suitable for a machine that cools down more rapidly.

To adjust the value, with the machine turned on press both of the cool control ▲and ▼keys

for 2 seconds and release when cc appears on the screen. To increase or decrease the figure use

the cool ▲or ▼key. After 5 seconds the screen will default back and save the figure entered.

Cycle the machine 15-20 times, allow it to cool for a few seconds and weld one of your bags. If

the seal fails decrease the figure, if it is molten increase the figure.

Key Lock

To prevent unauthorised alteration, the Star MkVI has a control lockout. If the green keypad

locked light is on the feature is not engaged. To engage or disengage press the cool ▲or ▼key

and release to display the cool time, the blue indicator will flash. Press and hold both of the weld

▲and ▼keys for 2 seconds. The green keypad locked light will come on or go off once the two

seconds is up. Release the keys and wait for the screen to go back to default.

Jaws Timeout

This is the time allowed for the jaws to close, jaws to open or automatic knife to complete its

travel before the alarms engage. To alter press the cool ▲key and weld ▼key for 2 seconds

until the display shows 2 digits with a decimal point between them. To alter this figure, use the

weld ▲and ▼keys. After 5 seconds the screen will default back and save the figure entered.

7

4 ERRORS AND FAULT FINDING (To reset the machine after an error, turn the power off for 5 seconds and then turn on again)

5 MACHINE OPERATION

106-106C

SETTING THE MAXIMUM VACUUM LEVEL

1) Cover the vacuum probe with one of your bags.

2) Close the clamp jaws to start the pump, the probe should be blocked and the vacuum gauge

should show a reading.

3) Increase or decrease the vacuum level using the vacuum regulator to achieve the required

maximum level and use the locking screw on the regulator to lock it in position

PROBE BLOCKING

As you draw vacuum, so atmosphere will act on the outside of your bag and this may block the

vacuum probe.

If this happens, try to position your product closer to the probe in order to ‘shield’ it.

Alternatively, gently tension the bag by pulling it away from the probe to relieve the blocking

effect.

Error

Possible Cause

Solution

The machine doesn’t turn on

•The plug is not inserted into the plug socket

•Fuse blown

•Internal error

•Check machine is plugged in

•Replace fuse, external/internal

•Contact Star Universal

E1

(power detected across

elements when the machine

is not cycling)

•Power relay stuck on

•Board fault

•Replace relay

•Replace board

E2

(Jaws failed to close after

start signal received)

•Jaws timeout too low

•Board fault

•Increase jaws timeout (see p6)

•Replace board/contact Star universal

E3

(no power detected across

the element when the

machine is running a weld

cycle)

•Broken element

•Power relay stuck off

•Board fault

•Transformer blown

•Replace element

•Replace power relay

•Replace board/contact Star Universal

•Contact Star Universal

E4

(Jaws Failed to open after

cycle)

•Jaws timeout too low

•Relay stuck on

•Board fault

•Increase jaws timeout (see p6)

•Replace tapes (leaving loose)

•Replace board

E5

(Knife failed)

•Link on KNIFE I/P broken

•Replace link

E6

(Temperature rise in element

not sensed within timeout)

•Timeout not set right

•Broken element

•Power relay stuck off

•Board fault

•Transformer blown

•Adjust timeout (see p6)

•Replace element

•Replace power relay

•Replace board/contact Star Universal

•Contact Star Universal

E7

(Over Temperature)

•Thermocouple not connected

•Thermocouple broken

•Power relay stuck on

•Board fault

•Check thermocouple is connected to board

input

•Check thermocouple is in the correct

position on jaw (see p)

•Replace thermocouple

•Replace power relay

•Replace board/contact Star Universal

8

MACHINE OPERATION

Once the vacuum level, weld and cool times have been set, along with the compensation if

required, the sealer is ready to use.

The operation involves placing the bag to be sealed between the jaws with the open end round

the vacuum probe, closing the clamp jaw until enough vacuum has been applied, pressing the

foot switch, the top jaw descends automatically and runs through a weld and cool cycle,

releasing on completion.

IMPORTANT –ONCE THE SEALING JAWS HAVE CLOSED RELEASE THE CLAMP JAW OR THE CLAMP

JAW RUBBER CAN BE DAMAGED BY THE PROBE RETURNING.

When operating the machine ensure your hands or anyone else’s are not between the jaws. Try

and avoid touching the jaws if possible as they can become warm with continuous use.

6 MAINTENANCE

WARNING! Unplug machine before any maintenance is carried out

DAILY MAINTENANCE

Visually check barrier tape

Change tapes if there are any burn marks, rips OR

damage.

Jaws move freely

Before turning machine on, manually shut jaws and

ensure they move freely.

MONTHLY MAINTENANCE

Sealing jaws

Change tapes, element and rubber if necessary. Check

end blocks are not damaged.

Clamp bars

Change tape and sponge if necessary.

Clean filters

If applicable.

Cutter rail

Check condition - free from any excessive wear.

Change if necessary.

6 MONTH MAINTENANCE

Repeat monthly maintenance

A 6-month maintenance kit can be ordered from Star

Universal.

Internal inspection

Visually check power relay - if discoloured replace.

Lubricate solenoids using graphite powder.

YEARLY MAINTENANCE

Contact Star Universal

You can request an onsite visit or send the machine to

Star Universal (Gosport) Ltd.

!

9

7 JAW MAINTENANCE AND SERVICE SPARES

Under normal operating conditions it will be necessary to replace certain expendable items that

are readily available from our spares department. Use of non-Star genuine parts or the incorrect

part number can cause damage to the machine and invalidate the warranty.

Before replacing any sealing jaw items ensure the machine is switched off and unplugged.

Replacing consumable items

To gain access to carry out a service on the fixed jaw it is necessary to remove the fixed clamp

jaw. This is done by unscrewing the two Allen bolts that hold it to the sealing jaw, being careful

not to lose the spacer washer.

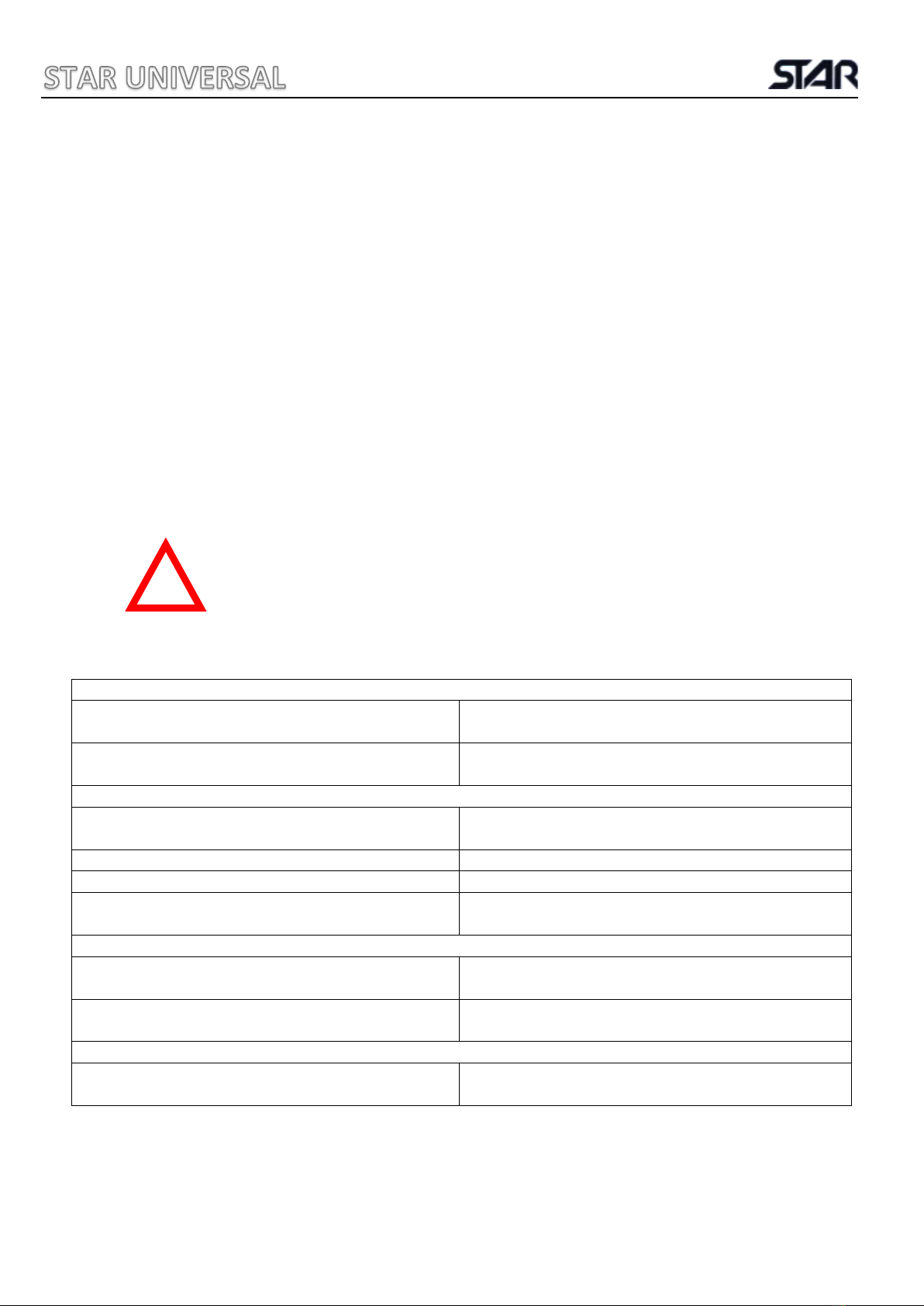

Barrier Tape: The barrier tape is a brown Teflon coated cloth designed to prevent plastic sticking

to the element ribbon. If this becomes burnt or damaged peel the old tape off, removing any

excess adhesive from the jaws. Take a length of new tape, remove one of the adhesive strips

and stick it to the front of the jaw, remove the other adhesive strip and stick to the back of the

jaw. The tape should be applied loosely so it is not in contact with the element ribbon when the

jaws are open.

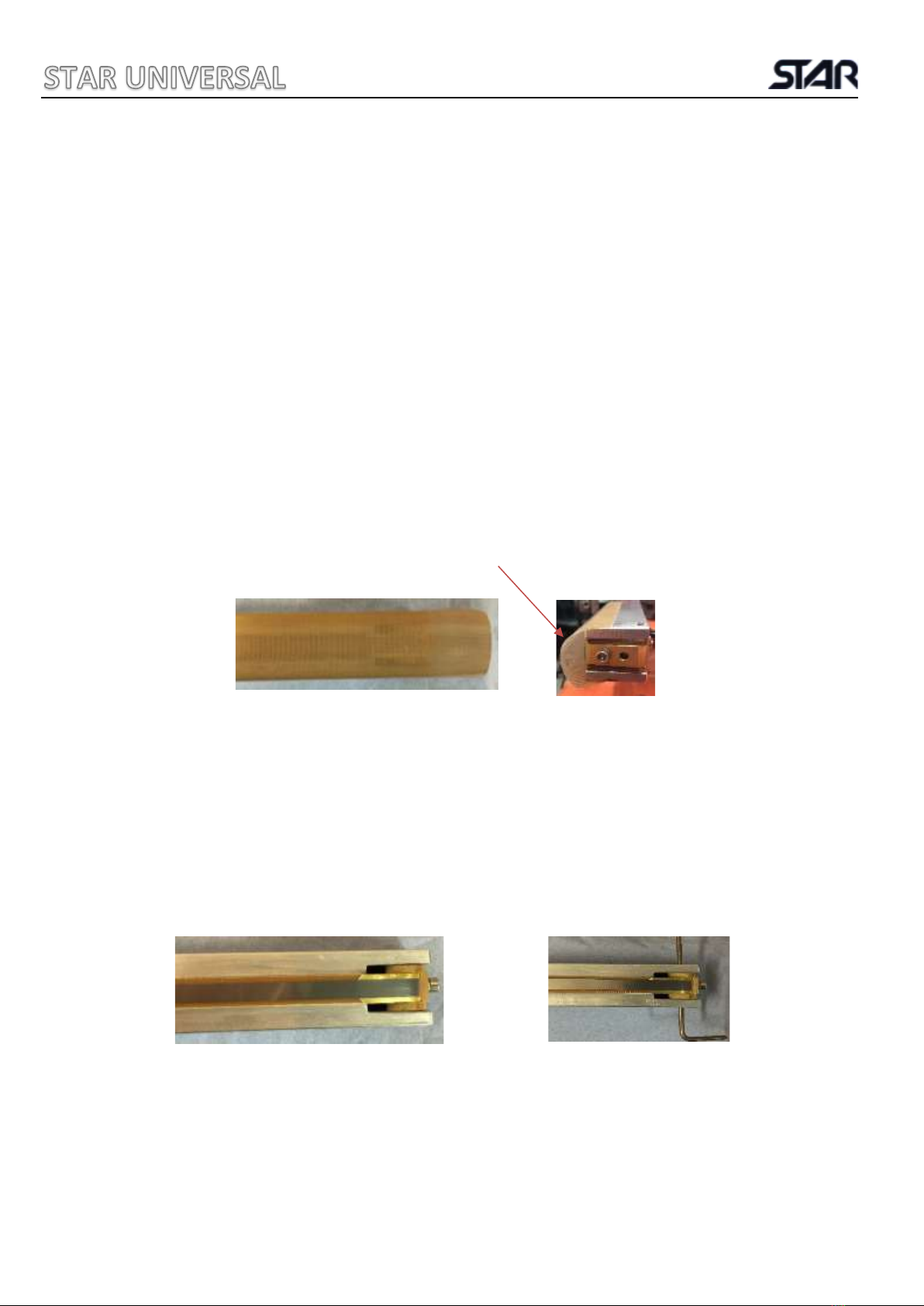

Element Ribbon: Remove the barrier tape as above. Place the loading pins through the

expansion blocks and holes in either end of the jaw to keep the springs under compression and

loosen the Allen key bolt. Remove the old ribbon. Cut a length of new element ribbon slightly

longer than the jaw and fold one end back on itself by about 5mm. Place this end in one of the

expansion blocks and tighten the Allen bolt. Measure the length of ribbon required to fit into

the other expansion block, cut to length and fold the end back 5mm. Fit in the other expansion

block and tighten the Allen bolt. Remove the loading pins and re-cover with barrier tape. Ensure

on double heat machines that the two elements line up to produce a good seal.

10

Brass Shim: Remove barrier tape and element ribbon as above. Remove the brass clamp by fully

unscrewing the Allen bolt. Replace the brass shim, attach the brass clamp and re fit the ribbon

and tape as above.

Silicone Rubber/Sponge –Heated Jaw: Remove the barrier tape and element ribbon as above.

Peel the silicone rubber away from the aluminium sealing jaw and clean any residual adhesive

left behind. Apply a NARROW bead of silicone adhesive to the channel, cut a piece of silicone

rubber to length and press into the channel ensuring a smooth surface. Replace the sealing

ribbon and barrier tape as above.

Clamp Bar Rubber: Remove the old barrier tape and rubber and clean the aluminium where it

was mounted. Apply a bead of silicone adhesive to the aluminium and stick the new rubber on.

Replace the barrier tapes over the rubber. To allow the adhesive to set fasten the top and

bottom clamp jaws together for around 2 hours.

Compression Spring and Ball Bearing: Remove barrier tape and element ribbon as above,

remove loading pin taking extra care due to the spring being under tension. Replace

Compression spring and ball bearing. Refit element ribbon and tape as above.

11

8 THERMOCOUPLE REPLACEMENT

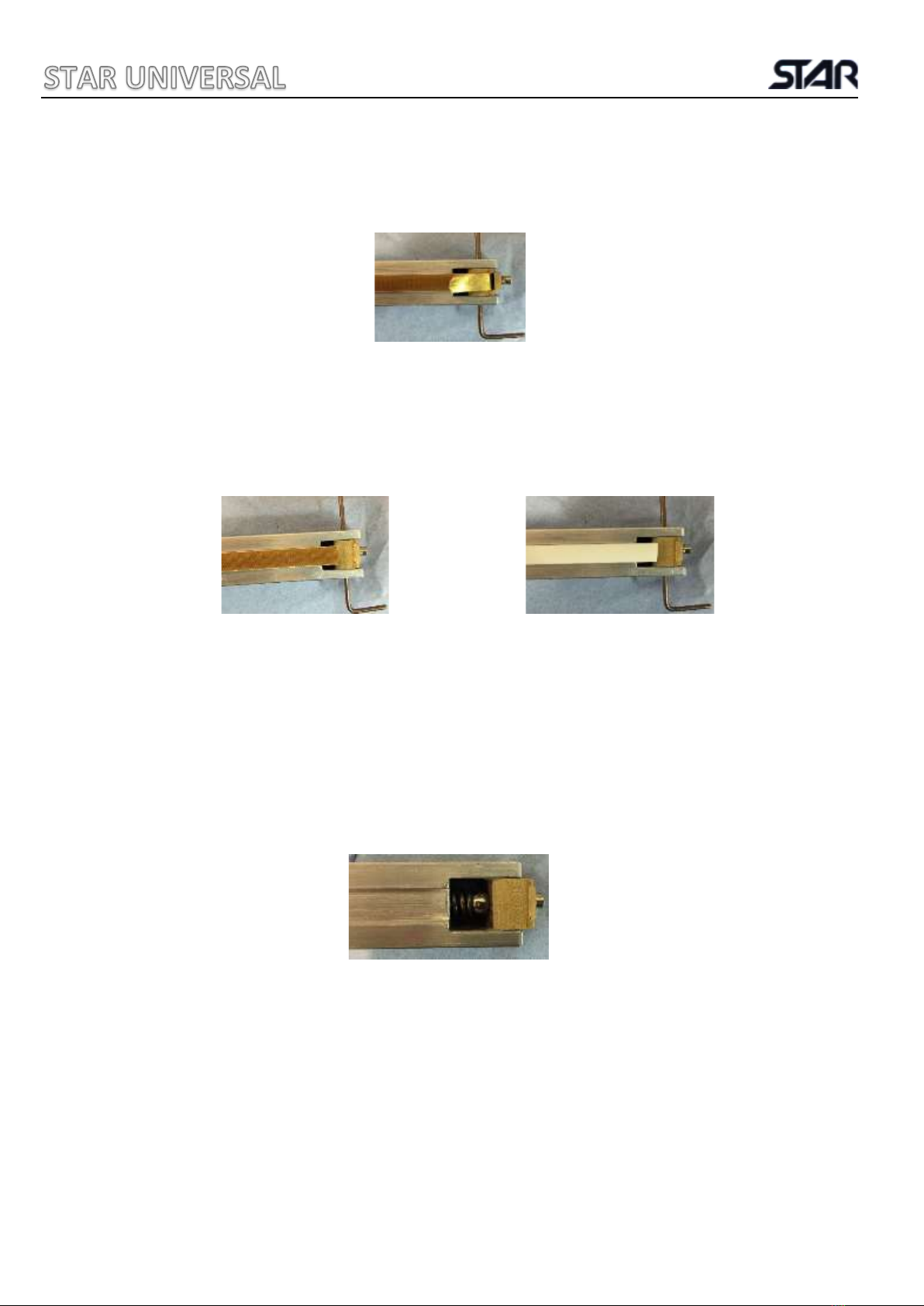

Thermocouple: If the silicone has been replaced cut a shallow V in it just deep enough for the

thermocouple wire to sit flush with the rubber, the tip/disc should be sat on top of the rubber.

Place the thermocouple through the hole and fasten in place with thermocouple adhesive strip.

The tip of the thermocouple should be in the centre of the silicone. The backing tape should be

applied to cover the thermocouple.

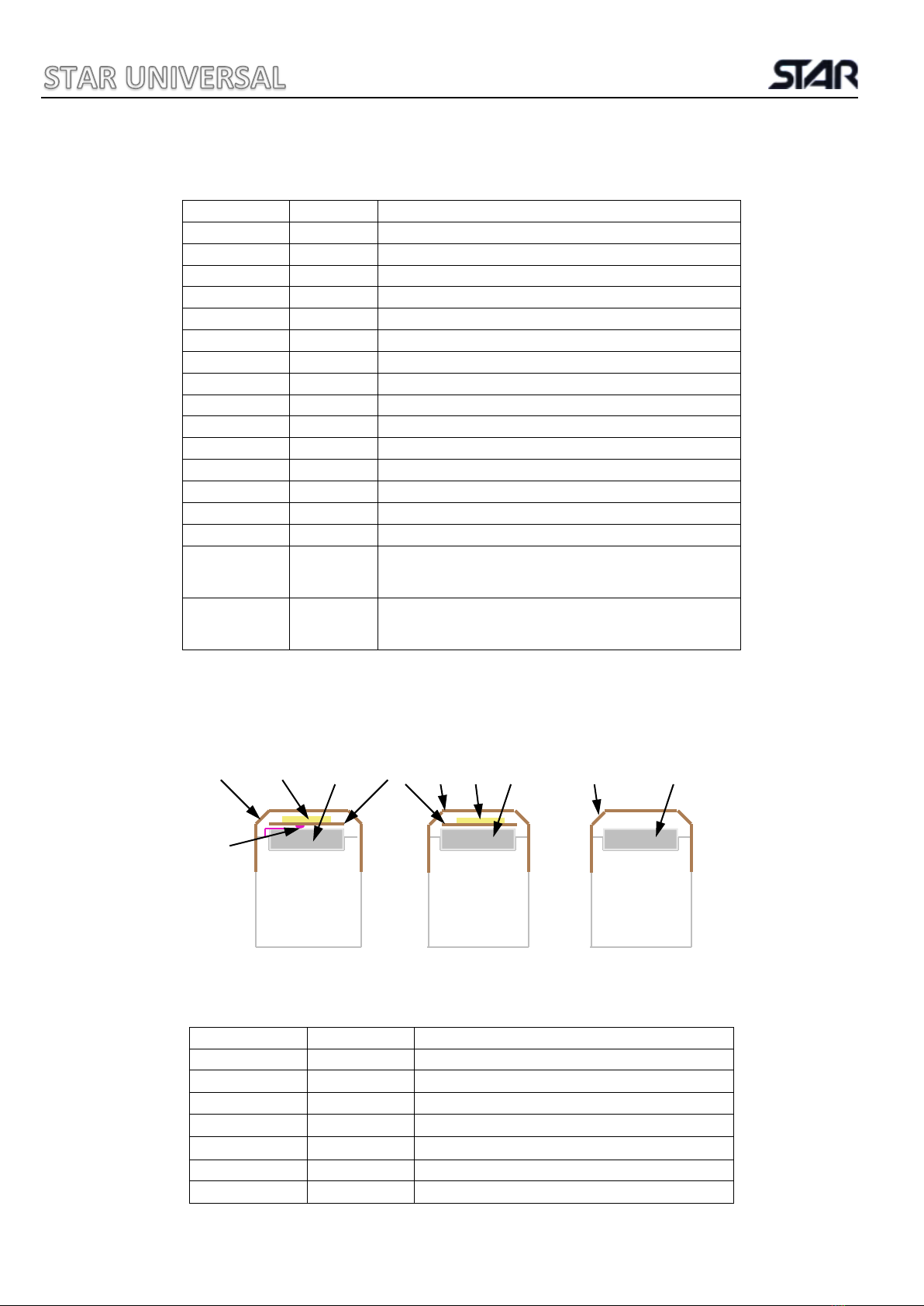

1. Cut V shape into rubber:

2. Place thermocouple through hole in jaw:

3. Secure thermocouple using the thermocouple adhesive strip:

4. Place backing tape over length of rubber and replace the element ribbon:

12

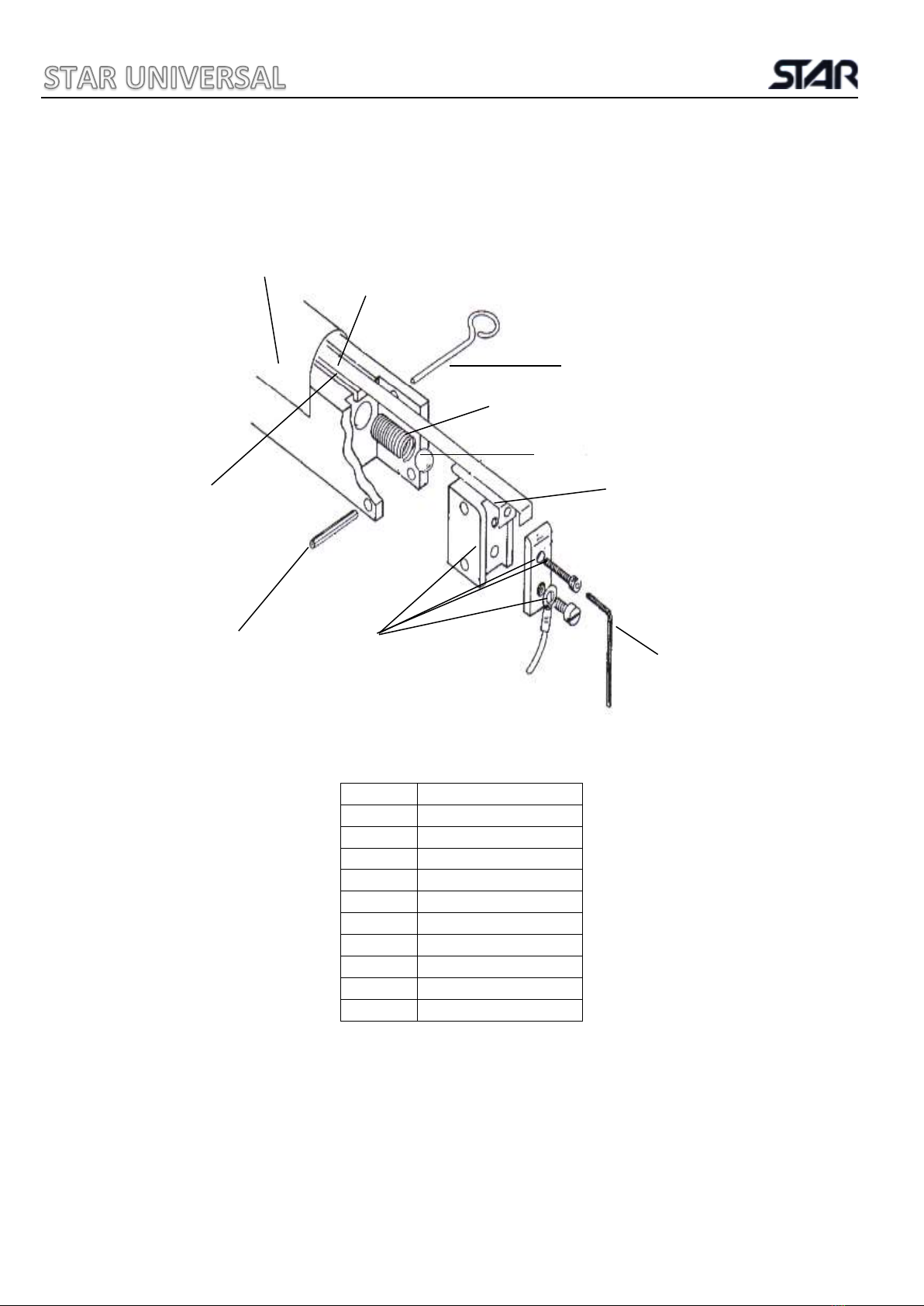

9 HEATED JAW TENSION ASSEMBLY

Diag No

Description

1

barrier tape

2

element ribbon

3

silicone rubber

4

Expansion block

5

Brass Shim

6

Compression spring

7

Ball bearing

8

25mm Roll Pin

9

Allen key

10

Loading pin

1

2

3

4

8

5

6

7

9

10

13

10 SERVICE REPLACEMENTS & JAW ASSEMBLIES

Part No

Diag No

Description

B018003

1

50mm barrier tape

E024002

2

6mm element ribbon

B017002

3

1m 9.5mm silicone rubber

M202005

4

15.5mm Expansion block (Pair)

M202004

5

9.5mm Brass Shim

B021005

6

Compression spring

B022002

7

Ball bearing

B023002

8

25mm Roll Pin

B029002

9

Allen key

M202009

10

Loading pin

B018007

NA

65mm barrier tape for fixed clamp jaw

B018022

NA

9mm PTFE backing tape

B017012

NA

D Section Silicone Sponge

B017014

NA

Silicone Rubber Compound (85g)

B029003

NA

Clamp Jaw allen key

S001001

NA

Spares Kit inc P&P

Comprises of 10m element ribbon, 10m barrier tape, 3m silicone

rubber/sponge & 1 tube silicone rubber compound

S001005

NA

Star 106 Spares Kit inc P&P

Comprises of 10m element ribbon, 10m 50mm barrier tape, 3m

silicone rubber, 3m D section sponge & 1 tube silicone adhesive

JAW ASSEMBLIES

HEATED JAW WITH HEATED JAW UNHEATED JAW

THERMOCOUPLE

Part No

Diag No

Description

B018003

1

50mm Barrier Tape

E024002

2

6mm Element Ribbon

B017002

3

9.5mm Silicone Rubber

B017007

4

9.5mm Silicone Sponge

B018022

11

9mm S/A Backing Tape

E019006

12

Thermocouple

B017014

NA

85g silicone rubber adhesive

1

1

2

2

3

11

3

12

4

1

14

11 ELECTRICAL PARTS LIST

Part No

Diag No

Description

E010001

E010036

SW1

On/Off Switch

Rocker Switch Cover IP65 (Stainless Steel model)

E017003

F2

Mains Fuse

E017008

F1

Solenoid Fuse

E003008

R1

Weld Relay

E022002

D1

Rectifier Diode

E021003

S

Supressor

E010005

E010006

SW2

Standard Foot Switch

Heavy Duty Foot Switch (Stainless Steel Model)

E011011

RS1

Safety Micro Switch

E005001

E005028

TH126

MKVI Controller

MKVI (C) Controller (MKVI C Model)

B014002

Membrane Keypad

E001001

TR1

Transformer

E002001

E002002

E002005

SOL

Solenoid Complete

Cone Solenoid Complete

Solenoid Plunger

E011014

SW3

Vacuum Pump Switch

P201001

VP

Vacuum Pump

E013005

E013006

SKT

3 Pin Socket

3 Pin Plug

B022001

Probe Roller Bush

B021004

Clamp Jaw Return Spring Right

B021008

Clamp Jaw Return Spring Left

P203006

Vacuum Regulator

P202001

Vacuum Gauge

M105008

Vacuum Probe

E019006

TC

Thermocouple (MKVI C Model)

E013016

Mains Lead & Plug

B021006

Solenoid Return Spring

M202007

Solenoid Pin

M102008

Brass Link

B016001

Jaw Arm Gaiter (Pair) (If IP rated)

ALL PARTS QUOTED IN THIS MANUAL ARE CORRECT

AT THE TIME OF PUBLICATION E&OE

STAR UNIVERSAL RESERVE THE RIGHT TO REVIEW

AND ALTER THE PARTS AS NECESSARY

COMPONENTS AND LAYOUT MAY VARY FROM THOSE PICTURED

15

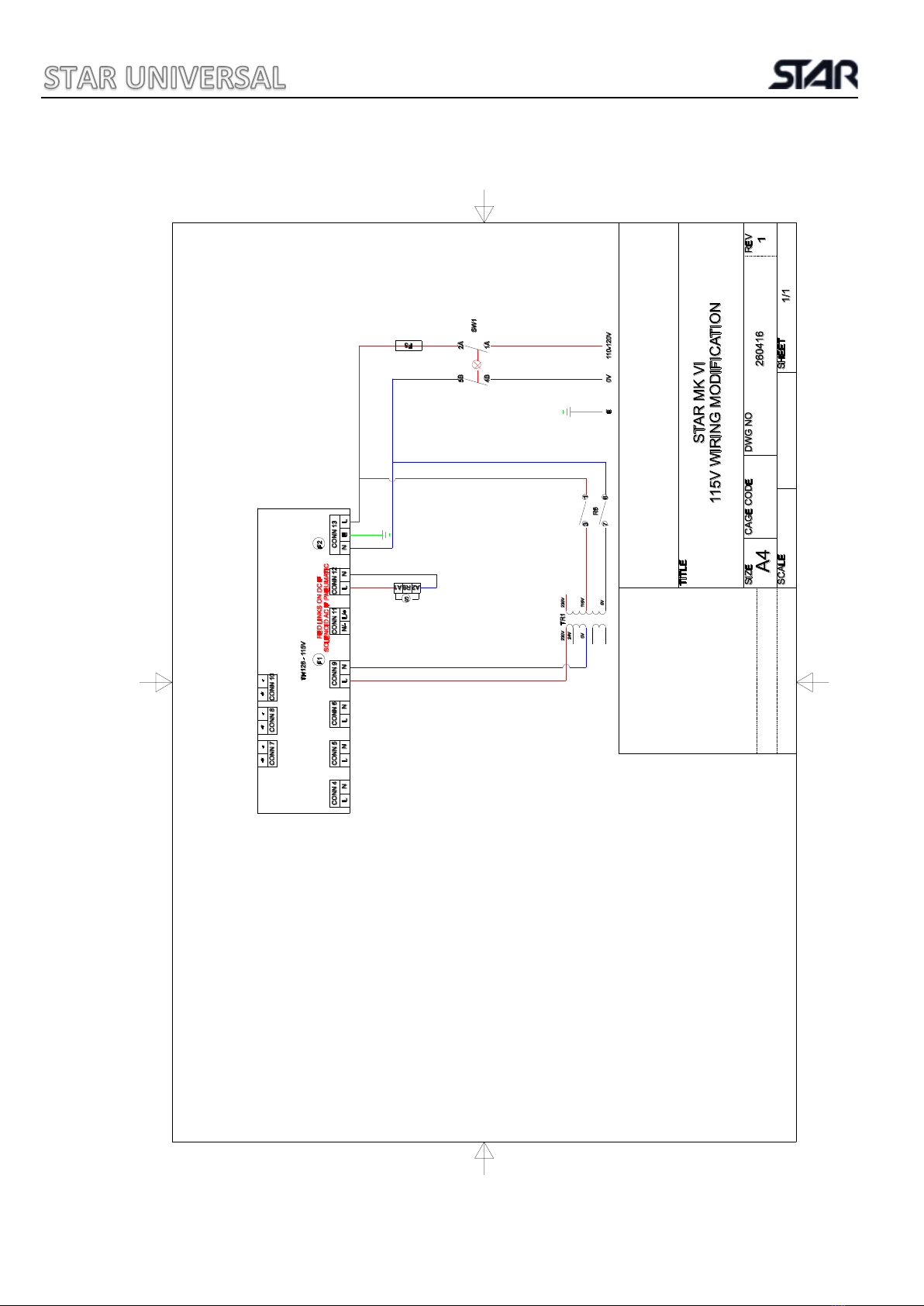

SW1 ON/OFF SWITCH

SW2 TRIGGER

SW3 VACUUM PUMP SWITCH

SKT 3 PIN PLUG/SOCKET

VP VACUUM PUMP

R1 POWER RELAY

SOL SOLENOID

D1 DIODE

RS1 JAWS CLOSED MICRO SWITCH

TR1 MAIN TRANSFORMER

TH126 CIRCUIT BOARD

F1 SOLENOID FUSE

F2 MAIN FUSE

TC THERMOCOUPLE

N/A

STAR UNIVERSAL (GOSPORT) LTD

R1

12 WIRING DIAGRAMS

STAR 106 - 106C SOLENOID

(No connection 3 if it’s not a STAR 106C)

16

STAR 106 115V

F5 10a AS FUSE

R6 11 PIN RELAY 115V

S SUPPRESSOR

TH126 - 115V CONTROL BOARD 115V

N/A

STAR UNIVERSAL (GOSPORT) LTD

17

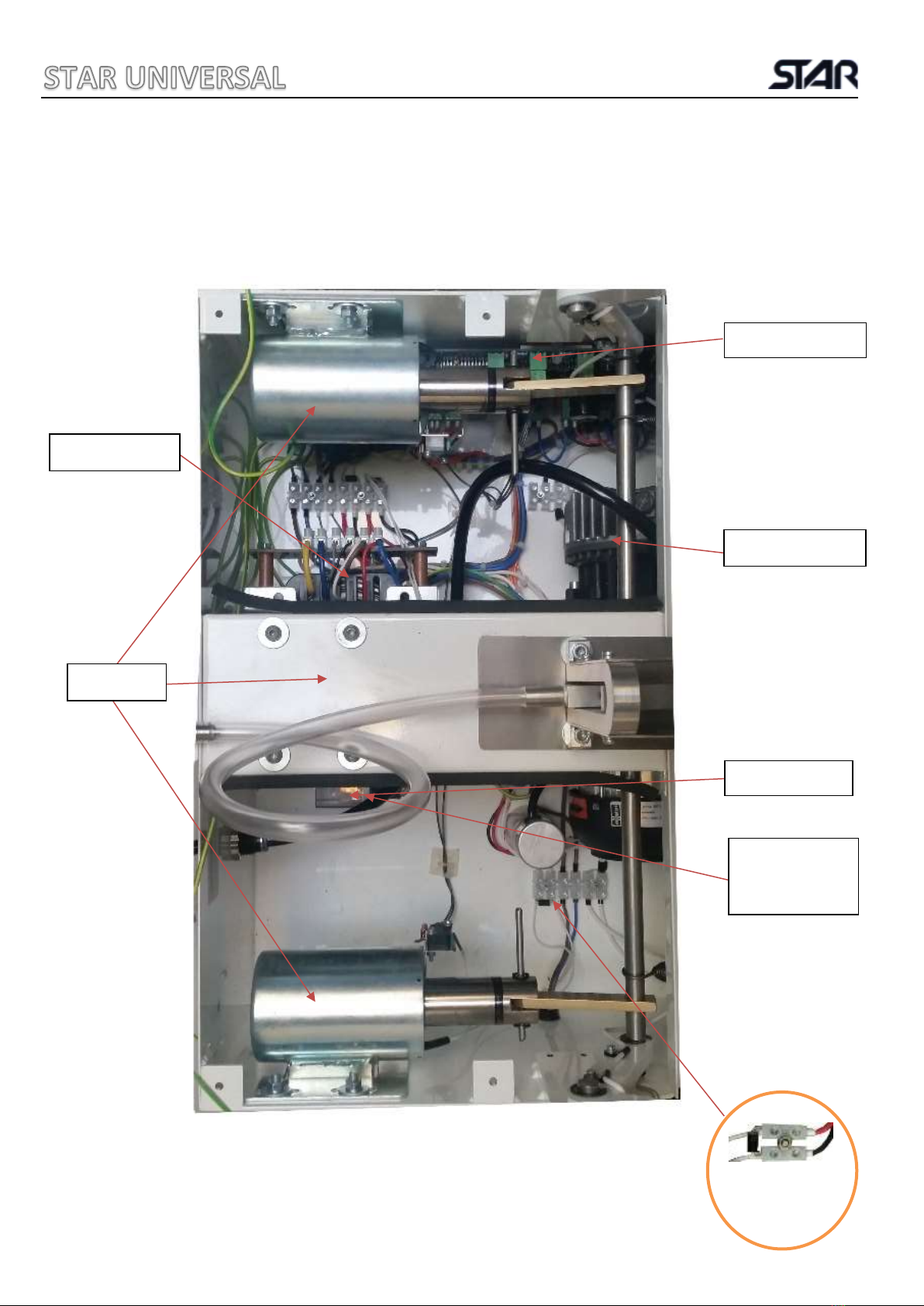

13 INSIDE THE MACHINE

STAR 106-106C

Transformer

Circuit Board

Solenoids

Power Relay

Vacuum Pump

Suppressor

across both

orange wires

Grey Strip on diode

to the red wire

18

14 TECHNICAL SPECIFICATION

STAR 106-106C

All the above weights and dimensions are approximate and based on the standard machine E&OE.

Star Universal reserves the right to change the above specifications without prior notice.

15 ENVIRONMENTAL RESPONSIBILITY

MACHINE RECYCLING

As this machine contains electrical and electronic components it must be disposed of correctly

and not in general land fill.

As Star Universal only build industrial equipment to individual customer requirements the

responsibility for the disposal lies with the end user.

Star Universal will offer a collection service for machines we have built at the end of their

useful life for recycling.

Please contact us for prices stating the machine model and serial number.

Producer Registration No. WEE/MM7018AA

Seal Length

500mm

600mm

750mm

900mm

Seal Width

6mm Standard, 2.5mm, 9.5mm 12.5mm and 20mm options

Jaw Opening

Solenoid approx. 30mm

Max Material thickness

1000µm approx. (4000g)

Sealing Cycle Time

Typically, 4-10s

Vacuum Cycle Time

Typically, 2-20s Dependent on size of pack and vacuum level required

Power Supply

230V 50/60Hz Single Phase, 115V Optional

Average Power Consumption / Cycle

0.02kWh

Average Power

Vacuum 160W, Weld 1730W, Cool 250W, Standby 25W

Jaw Length

565mm

665mm

815mm

965mm

Machine Body length

500mm

500mm

500mm

500mm

Depth

415mm

Overall Height

430mm

Weight Solenoid Machine

46kg

48kg

50kg

53kg

19

16 STAR UNIVERSAL WARRANTY POLICY

The Company provides a 1-year warranty from the date of delivery on all Star Heat Sealing

machines. If any part is found defective due to faulty manufacture, Star Universal will affect the

repair or replacement to the customer free of charge providing:

a) The fault is reported directly to the Service Department.

b) The fault is not caused by misuse, neglect or faulty adjustments by the operator.

c) The machine failure has not occurred through normal wear and application usage.

d) The machine has not been serviced or repaired by any person not authorised by Star

Universal during the warranty period.

e) The machine is returned to Star Universal at the address below.

Expendable items like the jaw barrier tape and heating elements are not covered by the

warranty but are readily available at a charge from the Service Department.

Travel time to attend a machine on site may be charged at the current applicable rates.

This warranty is additional to the normal customer statutory rights.

20

Star Universal (Gosport) Ltd

Unit 2, Clarence Wharf, Mumby Road, Gosport, Hampshire, United Kingdom, PO12 1AJ

Tel: + 44 (0) 23 9258 2857 Fax: + 44 (0) 23 9251 1731

Email: sales@staruniversal.com

Web: www.staruniversal.com

This manual suits for next models

1

Table of contents