thermopatch.com

8

• Labels and emblems

Shrinkage, nishes and coatings on the textile can inuence the heat sealing result in a

negative way.

Pre-heating can oer a solution in some cases.

If it appears that there is not a complete adhesion, it is recommended to re-seal another 10

seconds.

Remark:

Some modern fabrics cannot withstand the heat sealing temperature of 204 °C. If you

cannot be sure of the result, use a sample of the same fabric, if possible, to establish

its heat resistance. Also care labels in garments can inform you of their heat resistant

properties (iron ability). When it is necessary to lower the temperature, it is necessary to

press for a longer time.

How to remove heat sealed Thermopatch labels:

Because Thermopatch labels must be wash resistant to all industrial washing processes, it

is not easy to remove heat seal products.

When necessary you can try following procedure:

• Put the garments with the label to be removed under the press for about 7 seconds. The

glue layer will melt again.

• Leave the garment on the plate and remove the label, if necessary by means of a blunt

scraper or tweezers.

• Please note: Heating plate and labels are hot!!

• Repeat this procedure if you are not successful the rst time trying.

Interrupting the heat sealing cycle:

You can interrupt the operation at any moment by unlocking the arm of the closed heat seal

machine during the press cycle.

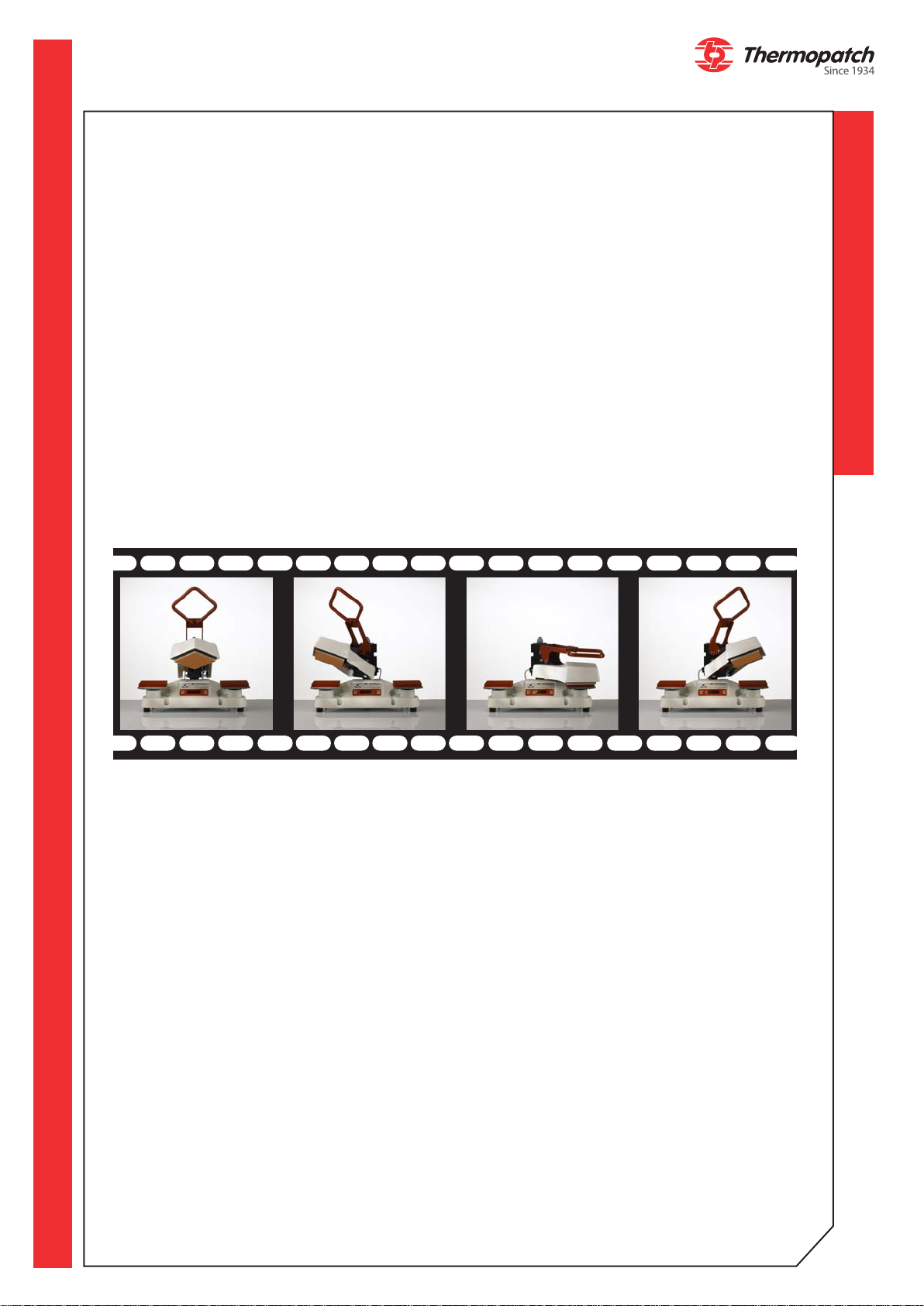

When you wish to shut down the machine, switch the main switch to o. It is located on the

right side of the machine.

The indicators on the control panel are then turned o.

Trouble shooting:

Some problems and failures that can occur, are listed below.

After describing each problem, the possible cause (sometimes more than one) is given, as

well as a possible solution.

If the described solution cannot solve the problem, please contact the service department

of your distributor.

Heat sealing problems:

Insucient adhesion of the glue layer

• Press time too short.

• Increase the time in steps of 2 seconds and try again.

• Temperature too low.

• Check with Thermolabels and increase the temperature, if necessary.

The pressure is not sucient.

• The silicone rubber sealing pads are worn out: replace when worn.

• The sealing pressure is set in the factory and cannot be adjusted.

• The teon self-adhesive coating of the press element is dirty or worn-out.

• Clean with a damp cloth and replace it, if necessary. When replacing the old teon, it is

very important that adhesive residue is removed from the heating element. To do this it

is necessary to heat up the machine, scrape o the glue remains by using a blunt edged

scraper. It is important to avoid scratching the metal of the heating plate.

• After this is done, degrease the heating element and apply the self-adhesive teon

cover.

Glue layer becomes too thin, causing adhesion problems

• Sealing time too long.

• Lower the time in steps of 2 seconds and try again.

• Temperature too high.

Check with Thermolabels and lower the temperature, if required.