Sencon SI9550 User manual

MANUAL NO 092-41020-00

REVISION 0

LANGUAGE ENGLISH

Hoverprobe

Refurbish ent

Instructions

2 Hoverprobe Refurbishment

1.

RECOGNIZING THE TWO MODELS ........................................................................... 3

2.

PACKING LIST .......................................................................................................... 4

3.

HOVERPROBE REFURBISHMENT INSTRUCTIONS ..................................................... 5

3.1

S

WITCH ASSEMBL

.................................................................................................... 9

3.1.1

SI9650 ........................................................................................................... 9

3.1.2

SI9550 ......................................................................................................... 10

3.2

F

INAL ASSEMBL

..................................................................................................... 12

4.

HOVERPROBE TEST ............................................................................................... 14

5.

REVISION LIST ....................................................................................................... 15

6.

FAX BACK SUGGESTION PAGE ............................................................................... 16

.

CONTACTS DETAILS FOR SENCON ......................................................................... 1

It is strongly advised that you

watch the enclosed video CD prior

to carrying out this refurbishment.

Hoverprobe Refurbishment 3

1. Recognizing the two models

SI9550 Hoverprobe – old version

SI9650 Hover probe - current version

Foot

s

witch socket only on SI9550 version

4 Hoverprobe Refurbishment

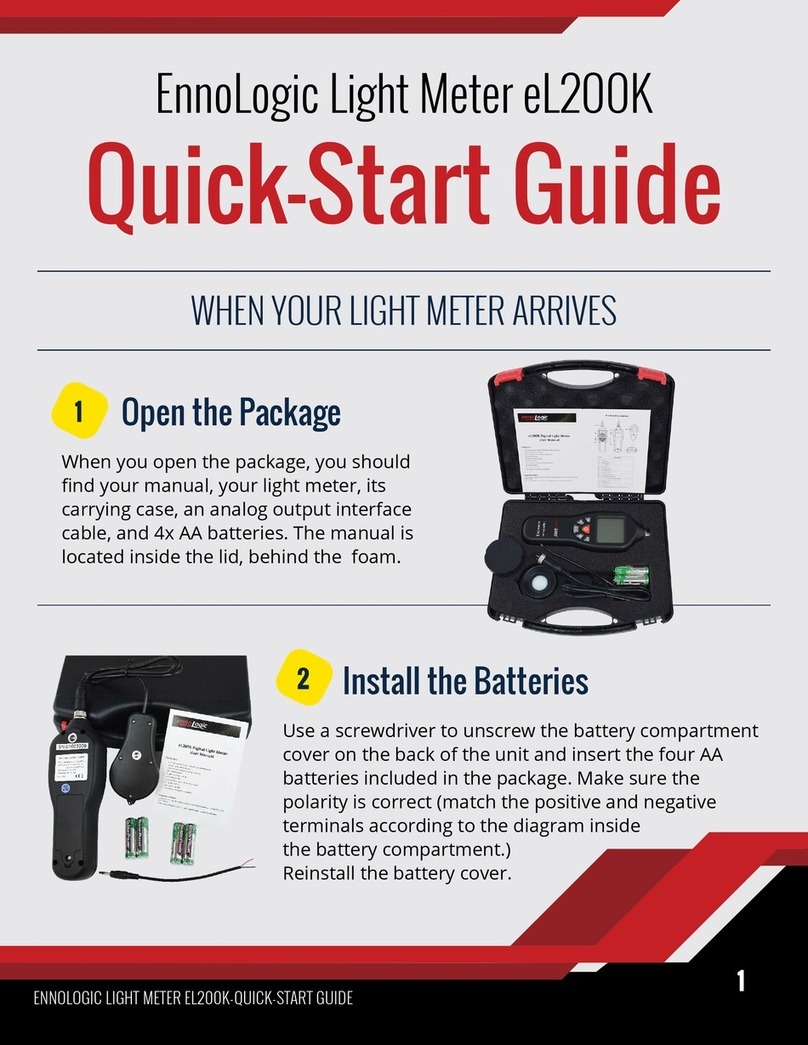

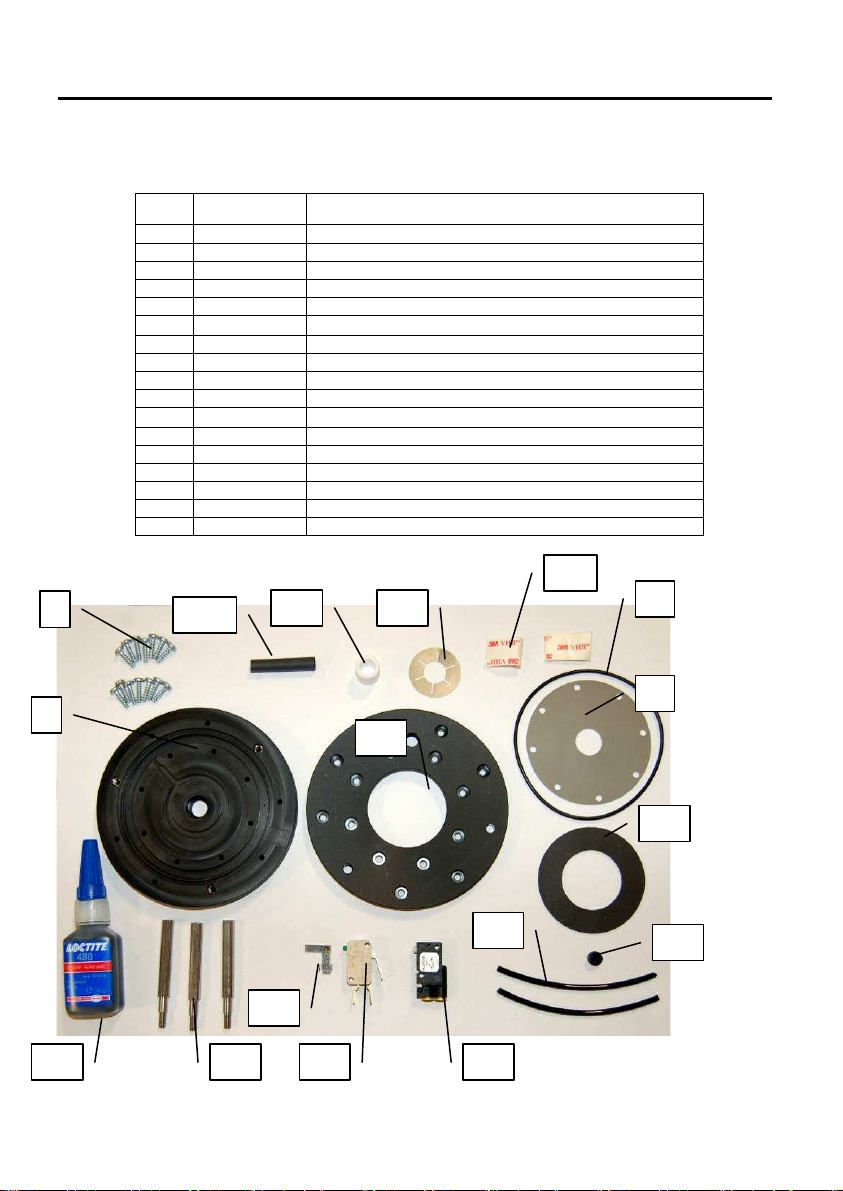

2. Packing List

ITEM QTY DESCRIPTION

1 1 Hoverplate

3 1 Gasket

4 1 O Ring, 98*2.5, NBR70

5 1 Airplate

6 14 Screw torx LN1442, K40x14 stainless steel

8 3 Pillar, M5x70mm long, male to female, stainless steel

9 1 Probe tip

13 1 Weight cushion

14 1 Bearing

15 1 Bearing holder

22 100mm Plastic air pipe, polyurethane, 4mm pipe in o/d 4mm

25 1 2 pole lever – ONLY REQUIRED FOR SI9550

28 1 Microswitch – ONLY REQUIRED FOR SI9550

29 1 Micro air valve

29A 2 x 15 mm Heat shrink 6/2 adhesive black – ONLY REQUIRED FOR SI9550

30 2 x 30 mm VHB tape Acrylic foam – ONLY REQUIRED FOR SI9550

31 1 Loctite 480 glue – ONLY REQUIRED FOR SI9550

1

6

29 14 4

15

3

13

9

22

28 29

22

25

8 31

30

Hoverprobe Refurbishment 5

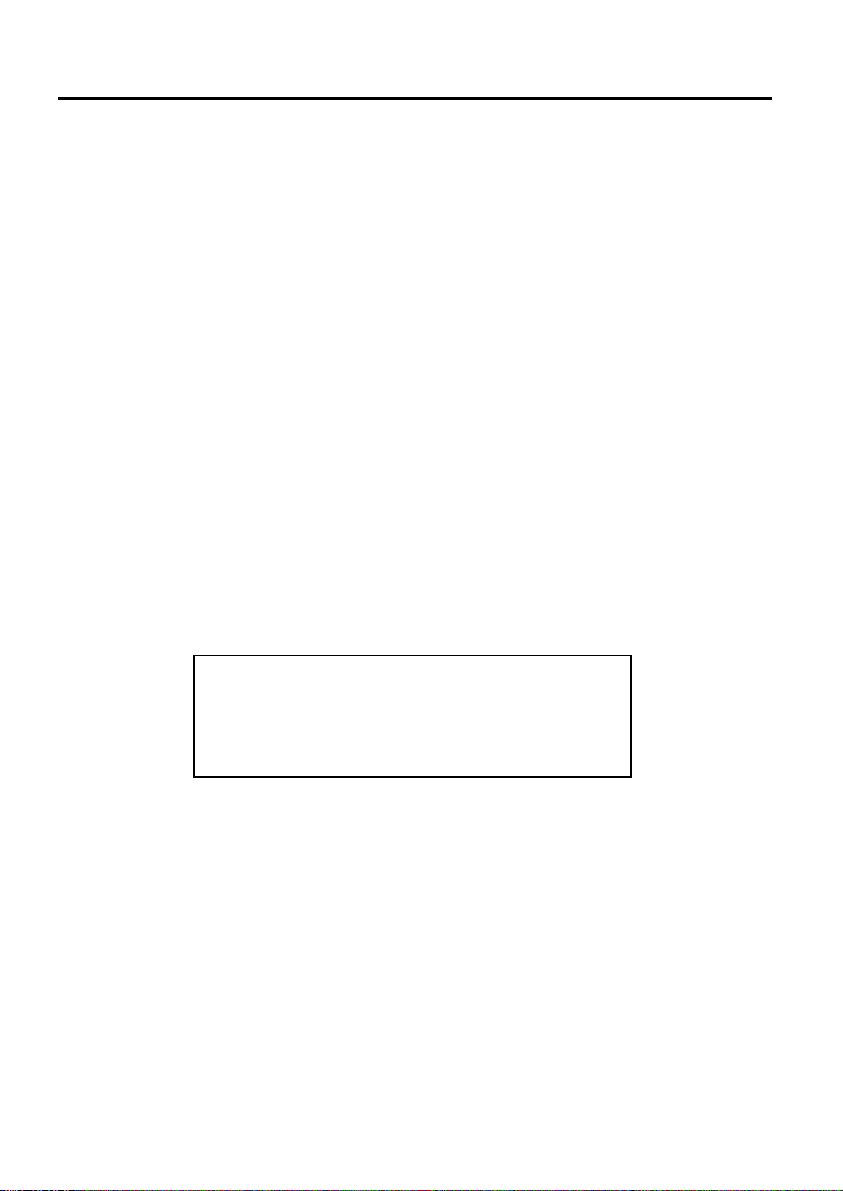

3. Hoverprobe Refurbishment instructions

4

1

3

6

5

7

8

9

10

11

12

13

14

16

19

17

18

20

22

21

23

34

24

15

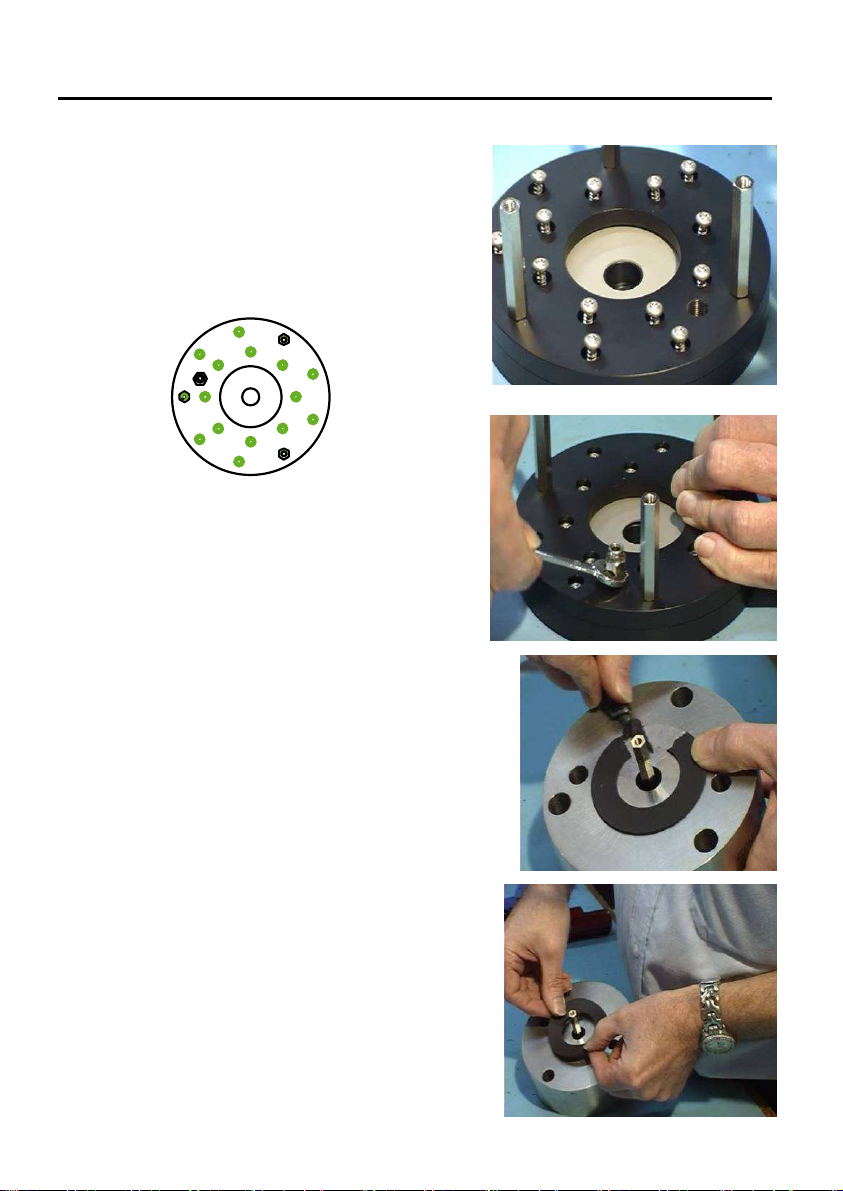

Countersinkholes up

Centralise on weight.

Press holder over ea ring top

in groove. Keep holder as fl at

as possi l e.

1. Disassemble the Hoverprobe down to the hoverplate (1).

In the process, cut the wires to the micro-switch just above the switch and

unscrew the old switch from the top plate (only necessary if Hoverprobe is of

old type SI9550)

2. Place a new O ring (4) and

a new gasket (3) in place

on the new hoverplate (1).

6 Hoverprobe Refurbishment

3. Screw Pillars (8) down to fasten the new

airplate to the hoverplate (1). The pillars

are supposed to have a tight fit in the

holes. The curved surface of centre hole

on airplate must be downwards

4. Tighten screws (6), with torque of 1.4Nm,

in sequence as shown in 'Top View'.

5. Take the air-fitting (7) out of the old

airplate (5) and mount it in the new

airplate (5)

6. Remove old weight cushion from weight

using a sharp knife.

7. Stick new weight cushion (13) onto weight

as central as possible.

2

11

414 7

12

8

10

9

513

3

T

op view of ase

6

1

T

o

r

que 1

N

m

Hoverprobe Refurbishment

8. Insert the new probe tip (9) in probe

tip holder (10).

9. Fit bearing holder spring plate (15)

on to the bearing (14). Take care it

doesn’t deform! Keep holder as flat

as possible. To aid you use a cylinder

or similar with a hole slightly bigger

than the bearing.

10. Place bearing (14) with bearing holder

(15) in to the weight assembly (12).

The longer part of the bearing goes

into the weight

8 Hoverprobe Refurbishment

11. Lock centre pillar (17) in the probe tip holder (10) with threadlocker (Loctite 242

or similar).

12. Place weight (12) over pillars (8).

13. Place the top plate (16) over the

weight (12).

Hoverprobe Refurbishment 9

3.1 Switch assembly

3.1.1 SI9650

14. Replace air valve (29) on bracket (24).

15. Connect the plastic air pipe (22) to

the air-valve and the external air

fitting.

16. Press the copper pipe (19) in to the

air-valve (29).

19

22

10 Hoverprobe Refurbishment

3.1.2 SI9550

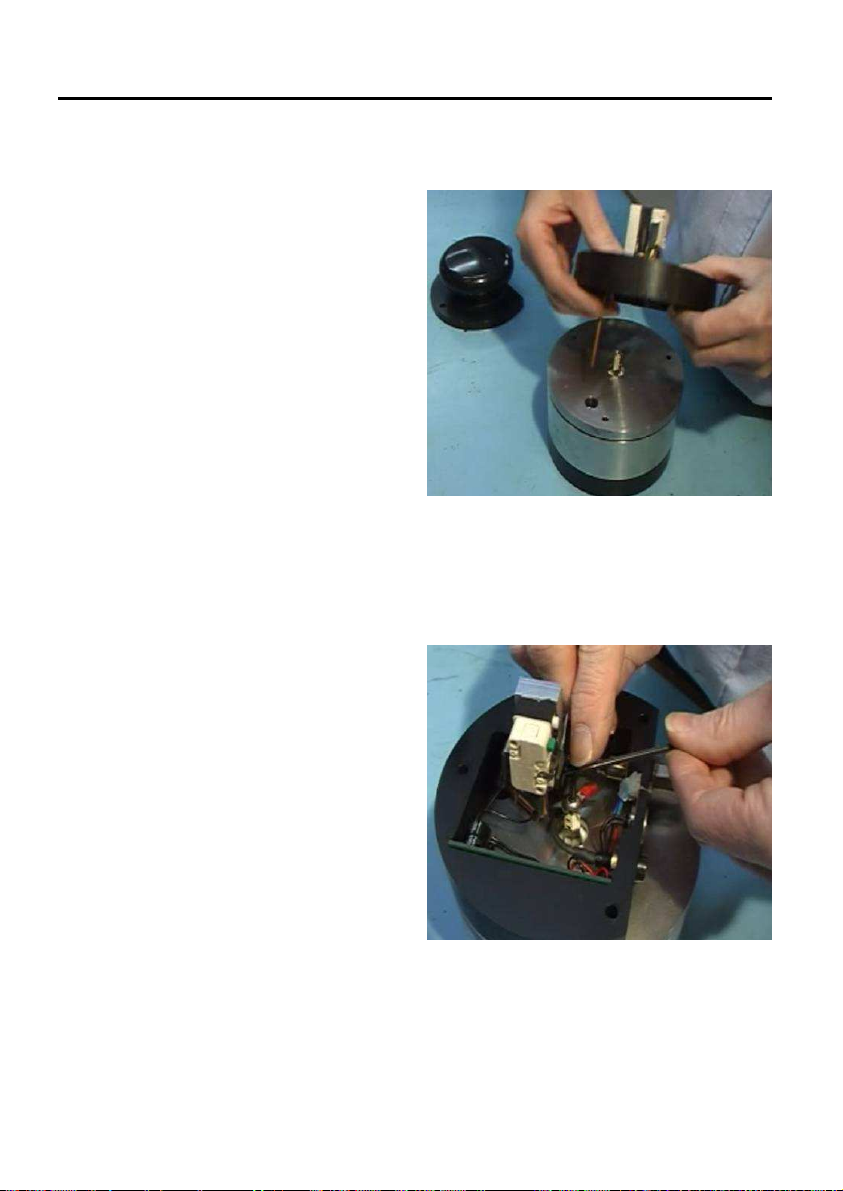

17. Remove old micro switch and air valve

from bracket (24).

18. Clean the bracket (24) and flatten both

sides of the new air-valve (29) with

sanding paper.

19. Stick 30mm VHB tape (30) onto the

bracket (24), put some drops of glue (31)

on the tape to hold the plastic valve.

20. Stick the air-switch (29)

onto the bracket (24) as

high as possible and equal

with the front surface, but

make sure there is no leak.

21. Place whole assembly in a

vice to set for 5 minutes.

Do NOT over tighten the

vice!

Hoverprobe Refurbishment 11

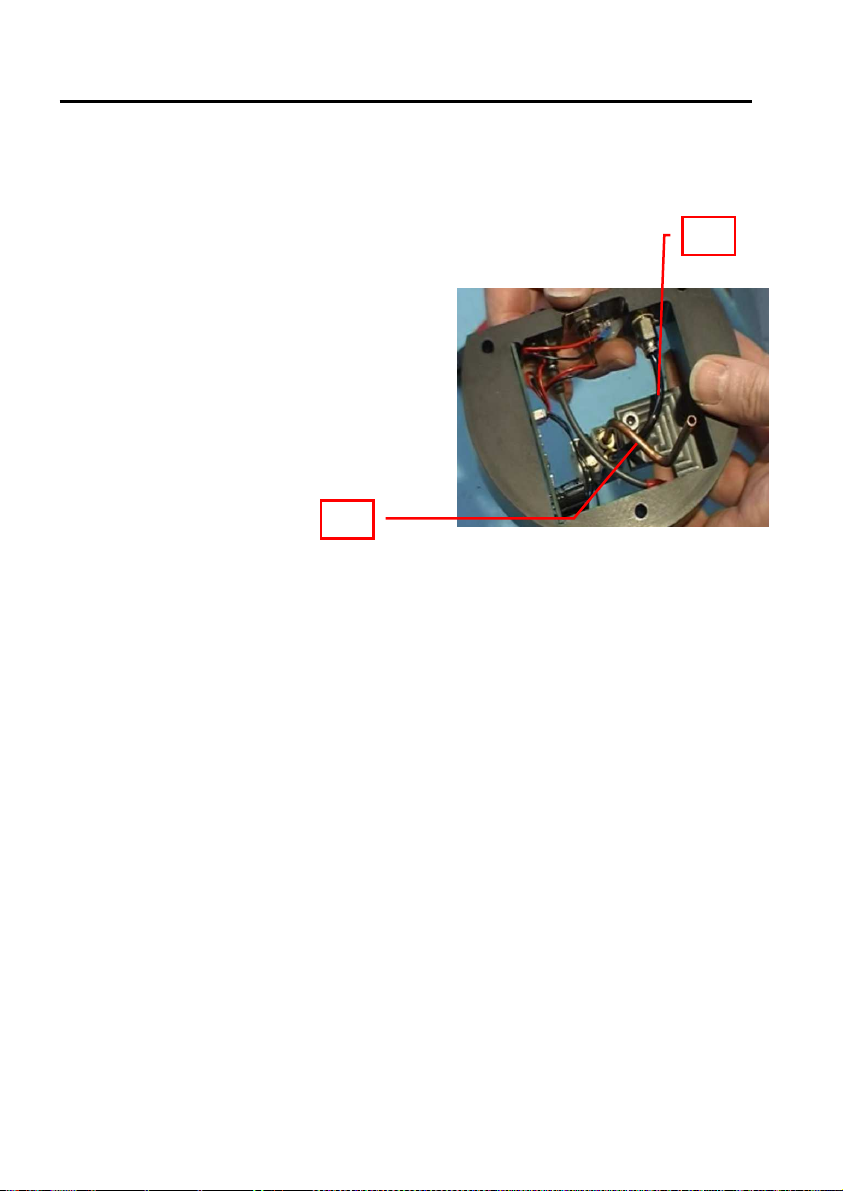

22. Connect the plastic air pipe

(22) to the air switch and

the external air fitting.

23. Press the copper pipe in to

the air-valve (29).

24. Position the copper pipe

(19) as shown to allow easy

alignment to the air fitting.

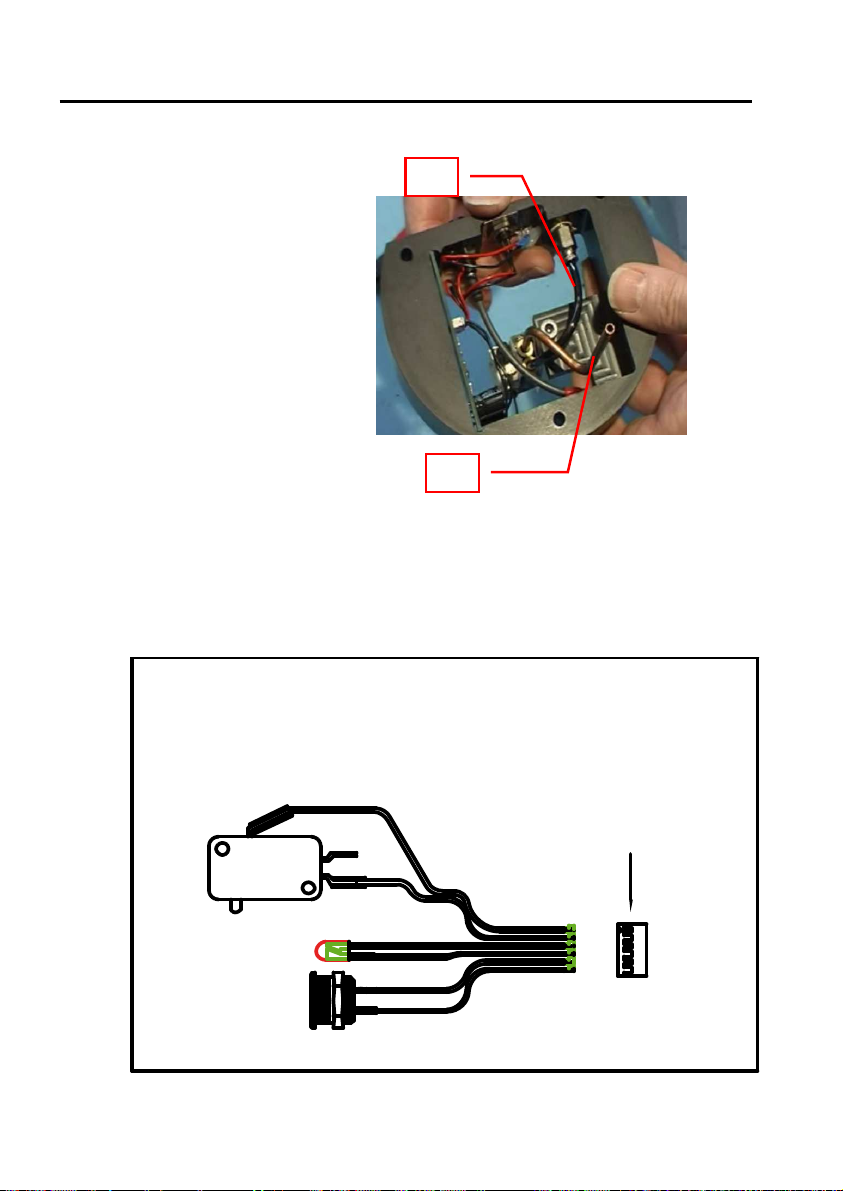

25. Put the PCB in the slot. DO NOT PULL THE WIRES!

26. Solder the wires on to the new micro switch according to the drawing.

Remember to cover the terminals with heat shrink (30).

Detail wire connections

Check th at the lack wi re is at the

flat side of the LE D.

Flat side LED =

CONNE C TION 1: 5

CONNE C TION 2: 6

ANODE: 4 RED

CATHODE: 3 BL ACK

2

1

5

6

3

4

2

1

Pin rem oved y ca refully

sk ipping kni fe under tu

on shell , if needed

19

22

12 Hoverprobe Refurbishment

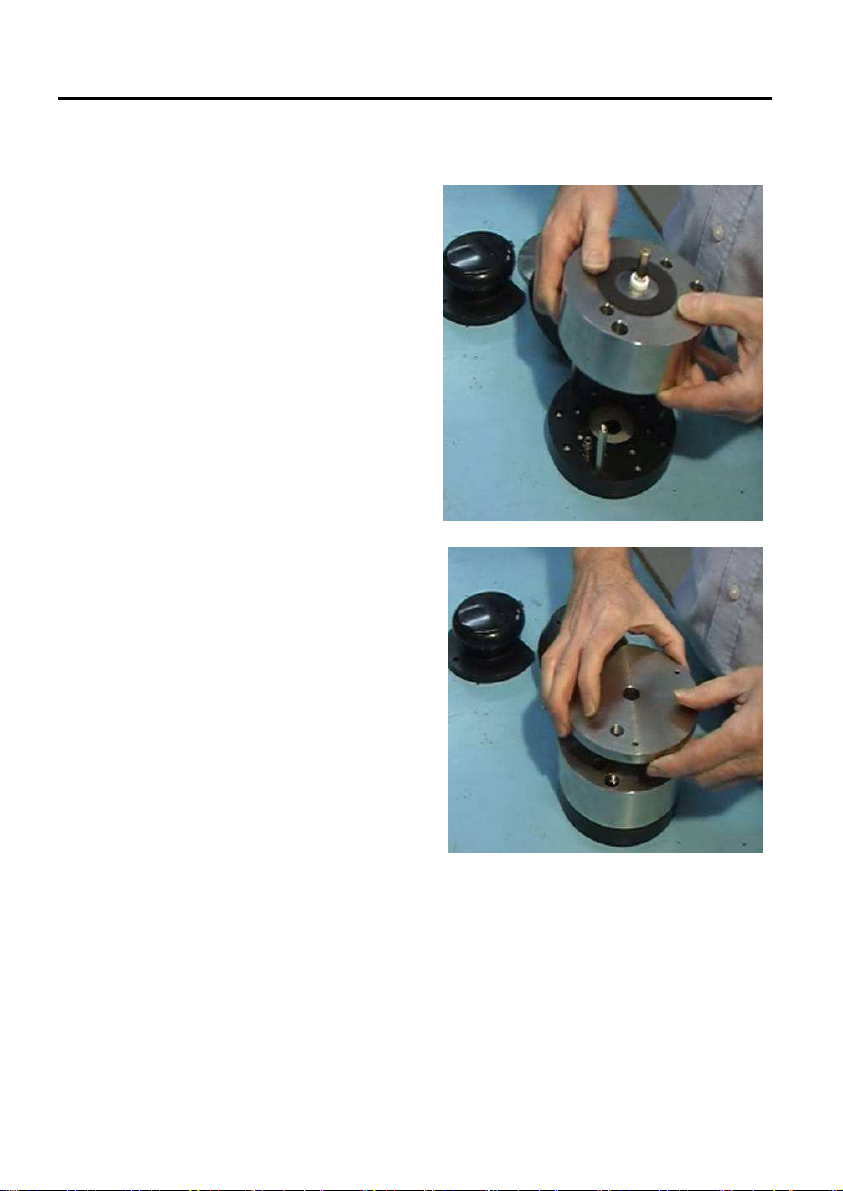

3.2 Final assembly

27. Place copper pipe (22) through

the weight and in to the air plate

air fitting (7).

28. Make sure the copper pipe (22) is

still connected to the air-valve

(29) without side tension.

29. Make sure that the micro switch is triggered before the air-valve is triggered.

30. Connect the banana plug wire to

the centre pillar (17) and tighten

the screw (18) gently.

Hoverprobe Refurbishment 13

31. Place handle assembly onto

enclosure (21), holding the

whole Hoverprobe

backwards so that the lever

is resting on the buttons

and tighten everything with

the 3 bolts (34).

32. Make sure the weight (12) can be lifted and twisted freely (a few millimetres)

and the switches are triggered. Check that the weight does not stick or slides

down to rest slowly.

14 Hoverprobe Refurbishment

.

Hoverprobe Test

33. There should be no interference to the weight when lifting it up by hand.

34. Connect the probe to the Film Weight Gauge and supply the air pressure = 5 bar

(75 psi). Check that there is no unusual noise which may indicate a leak in the air

system.

Note: the air switch is designed to constantly bleed a small amount of air.

35. The little holes in the hoverplate should be clean and the base of the hoverplate

should be flat.

36. When hovering, with 5 bar (75 psi), over a flat sheet and pressing down on the

hoverprobe no friction with the sheet should be felt.

37. Clean the probe tip by hovering it on to a clean A4 sheet of paper and release it.

Now slowly pull out the sheet out to take off any impurities on the probe tip.

38. SI9550 ONL : Check for lightening of LED and the 5 second time delay. Press the

button on the Hoverprobe. The LED should go red. Now release the button.

After approximately 5 sec. the LED should turn off and the display on the gauge

should either flash once or a bar should appear underneath the reading to

indicate a reading has been taken.

39. Carry out a function test on the Hoverprobe with a sheet with a known film

weight.

Hoverprobe Refurbishment 15

5. Revision list

Revision

Number

Raised

By

Description Change

note No

Date Approved

16 Hoverprobe Refurbishment

6. Fax back suggestion page

Sencon products are designed to a great deal of care and input from users.

If you have a suggestion to improve this product or its user manual please photocopy this

page, write your suggestion and fax the copy to Sencon.

To: Sencon

Fax: +34 93 754 96 87

From: ………………………………..

Company: ……………………………

Model: Hoverprobe refurbishment kit

Suggested improvement

………………………………………………………………………

……………………………………………………………………….

………………………………………………………………………

………………………………………………………………………

………………………………………………………………………

………………………………………………………………………

Hoverprobe Refurbishment 1

7. Contacts Details for Sencon

NORTH, CENTRAL & SOUTH AMERICA

Sencon Inc.

6385 W. 4th Street

Bedford Park, IL 60638. USA

Tel: +1 08 496 3100

Fax: +1 08 496 3105

EUROPE - MIDDLE EAST - ASIA

Sencon (UK) Ltd.

Stonebridge Cross Business Park

Droitwich WR9 0LW. UK

Tel: +44 1905 82 800

Fax: +44 1905 958 6

EUROPE (3-PIECE)

Sencon Europe Ltd.

C/ Gran Via de Lluís Companys, 168 1º 2ª

08330 Premià de Mar (Barcelona)

Spain

Tel: +34 93 54 95 26

Tel: +33 1 6 64 12 8

Tel: +49 30 8 333 380

Fax: +34 93 54 96 8

ASIA (3-PIECE)

Sencon Asia Inc

808 Citystate Center Building

09 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 696 6965

Fax: +63 2 696 6159

www.sencon.com

This manual suits for next models

1

Table of contents

Other Sencon Measuring Instrument manuals