D2246-01-02 DM3420 USER GUIDE

(4 to 20) mA

(0 to 20) mA

(0 to 10) mA

+-

+ -+

(0 to 1) V

(0 to 10) V

(1 to 5) V

TX

V

EXTERNAL

POWER SUPPLY

24 V MAXIMUM

(0 to 10) V

(1 to 5) V

CLAMPING SCREW

PANEL CLAMP

140.0

10 mm MAX PANEL THICKNESS

1.0 GENERAL

The unit is a highly accurate and stable digital process indicator that accepts all commonly

used process signals. The unit can be used "stand alone" or, with the Modbus serial

communications pod option, as part of a larger system.

The case design enables option Pods to be easily installed without the need for dismantling or

re-calibration. A range of Pods are available for:

•Relay outputs

•Isolated (4 to 20) mA re-transmission

•Modbus serial communication.

The diagram shows the rear panel positions for all electrical connections.

2.0 UNPACKING

Please inspect the instrument carefully for any signs of shipping damage. The packaging has

been designed to afford maximum protection, however, we cannot guarantee that mishandling

will not have damaged the instrument. In the case of this unlikely event, please contact your

supplier immediately and retain the packaging for subsequent inspection.

3.0 INSTALLATION

THIS SECTION FOR USE BY COMPETENT PERSONNEL ONLY

3.1 Safety Information

•WARNING READ SAFETY INFORMATION BELOW BEFORE

INSTALLATION

•WARNING Hazardous voltages may be present on the terminals - the

equipment must be installed by suitably qualified personnel and

mounted in an enclosure providing protection to at least IP20.

•ISOLATION The power supply terminals and associated internal circuitry are

isolated from all other parts of the equipment in accordance with BS

EN61010-1 for connection to a Category II supply (pollution degree

2)

Functional isolation (500V max) is provided between input and

output circuits, and between inputs and communications (where

fitted). Any terminals or wiring connected to the input, output

or communications terminals which are accessible in normal

operation must ONLY be connected to signals complying with

the requirements for Safety extra low voltage (SELV) circuits.

•WARNING If not installed in accordance with these instructions,

protection against electrical hazards may be impaired.

•Installation overvoltage category - 2 (as per BS EN61010-1)

•The Mains supply to the equipment must be protected by an external 1 Amp fuse and a

suitable switch or circuit breaker which should be near the equipment.

•The equipment contains no user serviceable parts.

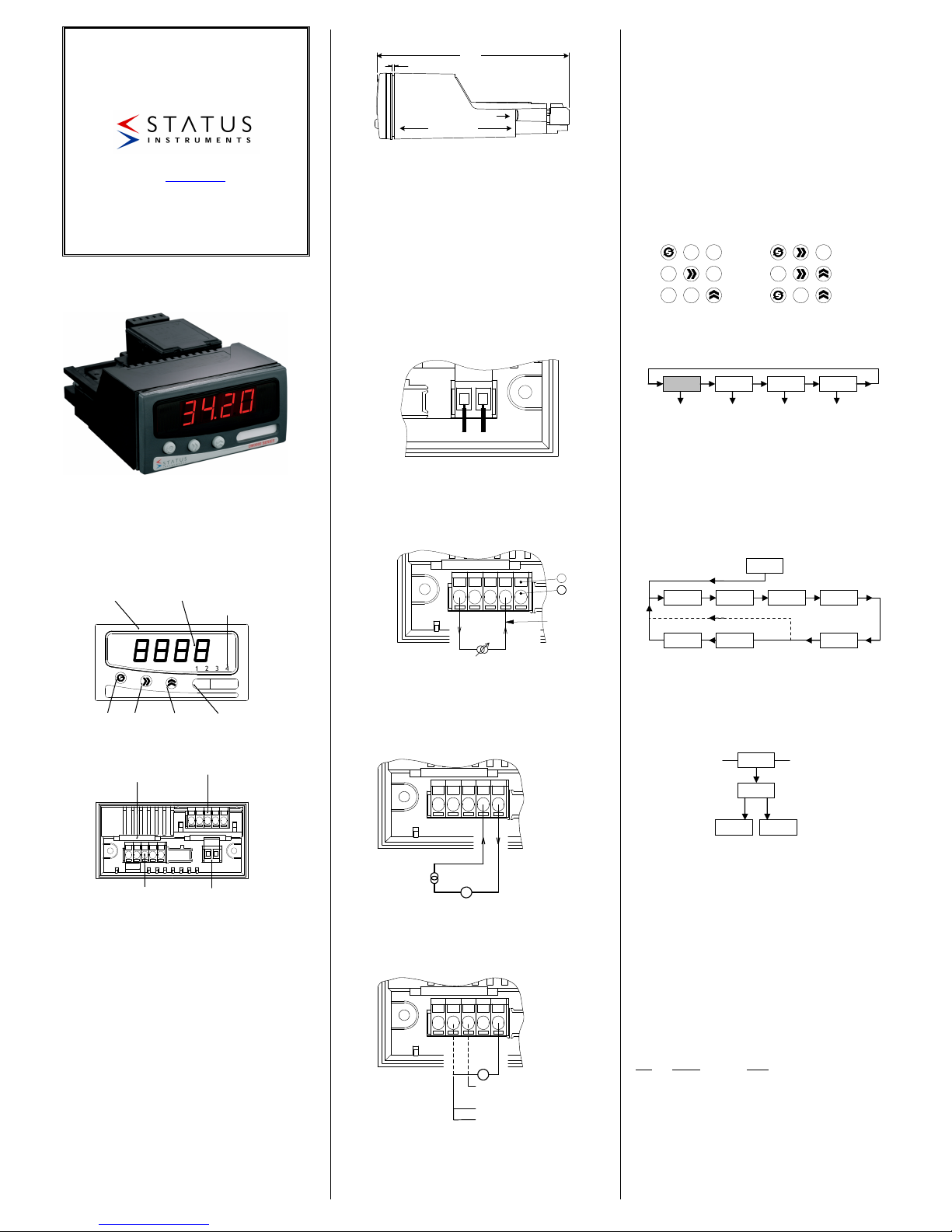

3.2 INSTALLING INTO A PANEL

(A dimensions in mm)

Cutout (92.0 / 92.8 x 45.0 / 45.6) mm (DIN43700)

Refer to section 8.0 for Mechanical Detail.

The maximum panel thickness is 10 mm. The instrument case has an integral gasket which

forms a seal when the instrument is tightened against the panel. The panel should be clean,

smooth and at least 1.6 mm thick for the seal to be effective.

•WARNING Use only the retaining screws provided to clamp the instrument to

the panel (screws must be tightened sufficiently to effect a seal but

must never be overtightened).

3.3 WIRING

All connections are made to sockets which are removable for ease of maintenance.

Installation should be undertaken in accordance with relevant sections of BS6739 -

British Standards code of practice for "Instrumentation in Process Control Systems:

Installation design and practice".

3.4 POWER SUPPLY

The Power supply rating will be indicated on the top of the instrument, ensure it is correct for

the application.

The Mains supply to the equipment must be protected by an external 1 Amp fuse and a

suitable switch or circuit breaker which should be near the equipment.

Wires are retained by screws. Ensure that the exposed section of the wire is fully inserted and

that no loose strands are exposed.

3.5 SENSOR CONNECTIONS

All sensor connections are made via the five way "fast wiring" socket at the rear of the unit.

Wire size (0.5 to 1.5) mm².

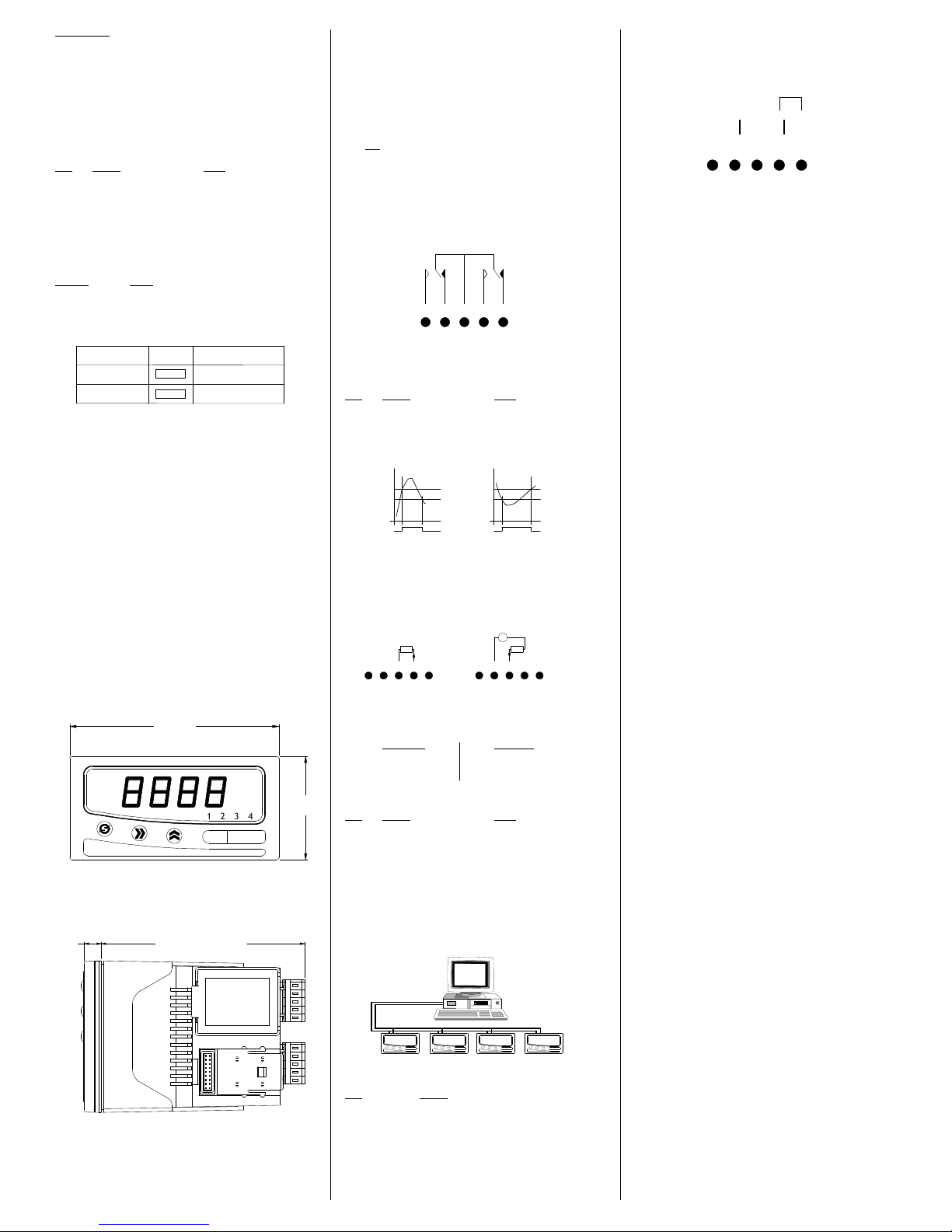

3.5.1 Current Measurement of an Internally Powered Loop

A 24V internal power supply is available to power external field transmitters.

To make a connection: Insert small screwdriver blade into tension clamp orifice, (1) push and

twist to deflect clamp into open position. Do not lever screwdriver thus forcing connector body

sideways. Insert conductor tail sufficiently into (2) then release screwdriver. Ensure no loose

wire strands protrude.

3.5.2 Current Measurement of an Externally Powered Loop

3.5.3 Voltage Connection

4.0 PROGRAMMING THE INSTRUMENT

The unit is a microprocessor based instrument enabling it to satisfy a variety of applications.

All programming is available from the front panel or via a PC using the RS485 Modbus

communications pod.

4.1 Programming Guide

The unit has three operating modes. These are :-

RUN (DISPLAYS PROCESS VARIABLE)

MENU

EDIT

RUN is the principal mode of operation, which displays the Process Variable from which all

other modes are accessed. The unit will always time-out back to this mode after one minute.

MENU mode provides access to the programmable parameters.

EDIT mode is entered from Menu Mode and allows the user to inspect and modify a

parameter.

4.2 Key Definitions

All programming is done using the three front panel keys, A, B and C are shown to assist the

tutorial.

CYCLE (A), SHIFT (B) and INC (C) keys are pressed singularly.

ESCAPE (A&B), ENTER (B&C) and CLEAR (A&C) are obtained by simultaneously pressing

the two keys.

4.3 Entering Menu Mode (START PROGRAMMING)

The Root Menu mode is accessed from "Run" by pressing ENTER (B&C) followed by CYCLE

(A). The display will now show "inPt". In order to understand what this means, the following

diagram shows where we are within the basic Root menu.

*Slot menus only appear when respective option pods are fitted.

4.3.1 Moving Around The Menu

You can browse through the Root menu by pressing CYCLE (A) which moves the menu

position from left to right (after reaching SYS, the menu position wraps around to the start).

4.3.2 Entering A Submenu

To enter a submenu, first cycle around the Root menu until the required submenu is displayed.

For the purposes of this tutorial press the CYCLE (A) key until “InPt” is displayed. Pressing

SHIFT (B) enters the Input Submenu. “tYPe” will now be displayed. The diagram shows our

position in relation to other items in the menu. Pressing CYCLE (A) moves left to right,

wrapping around at the end. The unit alters items in the menu list depending upon settings

made.

4.3.3 Editing A Parameter

The items displayed in the menu can either be submenus, parameters or numbers, most of the

items in the Inputs menu are parameters which can be edited.

Press the CYCLE (A) key until “tYPe” is displayed, then press SHIFT (B).

The current setting will now be shown flashing. This item is changed by pressing the INC (C)

key.

The choice of options available is as follows:

Press the INC (C) key until "crnt" is displayed.

Note that whilst the display is flashing, the option on the display has not been saved to

memory. To select an option, the ENTER key sequence is used. Press ENTER (B&C). The

display will stop flashing momentarily before returning to Menu mode. The system

automatically steps on to the next entry to speed the process of programming. This method of

editing parameters is repeated throughout the menu structure.

4.3.4 Returning From Submenus

To return up from the inPt menu to the root menu wait for 1 minute or press the ESCAPE

(A&B) key.

Pressing the ESCAPE key from our current position in the Inputs submenu takes us back to

the Root menu. The menu position will automatically step to the next menu item, if no pods

are fitted the unit will show SYS, if pods are fitted SLt1 or SLt2 will be shown.

The Root menu, as its name suggests is not a submenu. Pressing the ESCAPE (A&B) key

sequence whilst in the Root menu will take the user out of Menu mode and into Run mode.

Thus the process variable will be shown on the display. Refer to section 5.2 if an error code is

shown after programming in menu mode.

4.4 The Menus

4.4.1 The INPt (INPUT) Submenu

The INPt submenu is used to program all the characteristics of the input sensor and any signal

conditioning that may be required. The selection of an option in the list may affect items further

down. Therefore, during programming, the user should start at the top of the menu and work

down, to avoid setting an option which may later become obsolete. Short menu only items

shown in bold.

TITLE OPTIONS DETAIL

tYPE crnt, VoLt Set Current or Voltage

dP 888.8, 88.88, 8.888, 8888 Defines decimal point location

rngE 4-20, 0-20, 0-10 mA range setting, only for Current input

rngE 1-5, 0-1, 0-10 Voltage setting, only for Voltage input

Lo 000.0 Low engineering range, -999 to 9999

Hi 100.0 High engineering range, -999 to 9999

Lin nonE, Sqrt, cust Linearity: none, square root or custom *1

FiLt nonE, 2.5 s, Input filtering or smoothing

10 s, Adaptive

uSEr in 0..... in 9 out 0......out 9

DM3420

INTELLIGENT

PROCESS INDICATOR

Designed, manufactured and supported by:

Green Lane, Business Park, Green Lane

Tewkesbury Glos. G20 8DE. UK

Tel: +44 (0)1684 296818 Fax: +44 (0)1684 293746

Every effort has been taken to ensure the accuracy of this specification, however

we do not accept responsibility for damage, injury, loss or expense resulting from

errors and omissions, and we reserve the right of amendment without notice

Stock code: 52-314-2246-02

oC

2 3 41

Tag No.

FRONT PANEL

SEALED TO IP65

BRIGHT FOUR

DIGIT DISPLAY

DISCRETE LED

ALARM INDICATORS

CYCLE

KEY

SHIFT

KEY

INCREMENT

KEY

LEGEND

WINDOW

OPTION POD SLOT 2

(NOT SHOWN)

OPTION POD SLOT 1

PROCESS

INPUT

POWER

CONNECTION

(+) L N (-)

1

2

Current

Return

Tx

(4 to 20) mA

(0 to 20) mA

(0 to 10) mA

24 V

CYCLE

SHIFT

INC

ESCAPE

ENTER

CLEAR

B

C

AB

B C

AC

A