STAUFF SPR-PRC-POC User manual

Operating instructions

Translation of the

original operating instructions

Machine for cutting ring

pre-assembly and final assembly

SPR-PRC-POC

R3.0, valid from firmware 3.6.x, 6010014620 22-10-2020

To avoid injuries and damage, read these operating instructions thoroughly

and attentively. Retain it for further reference.

SPR-PRC-POC

www.stauff.com

3 / 72

Table of contents

Table of contents

1

Information about the instructions ........................................................ 6

1.1 Target group of the operating manual ............................................6

1.2 Structure of warnings......................................................................6

1.3 Structure of instructions..................................................................7

1.4 Structure of additional information..................................................7

1.5

Structure of references ...................................................................7

2

For your safety .........................................................................................8

2.1 General safety instructions .............................................................8

2.2 Intended use...................................................................................9

2.3 Tasks and obligations of the operating company........................... 9

2.4 Personnel qualification .................................................................10

2.5 Personal protective equipment.....................................................10

2.6 Safety labels .................................................................................11

2.7 Safety devices ..............................................................................12

2.8

Securing the machine against reactivation...................................13

3

Machine description ..............................................................................14

3.1 Machine overview.........................................................................14

3.2 Technical data ..............................................................................15

3.3 Function ........................................................................................15

3.4 Tools and product.........................................................................15

3.5 Type plate .....................................................................................16

3.6

Spare parts and wear parts ..........................................................17

4

Transport and storage...........................................................................18

4.1 Safety............................................................................................18

4.2

Transport ......................................................................................18

5

Installation ..............................................................................................19

5.1 Safety............................................................................................19

5.2 Installing the machine...................................................................20

5.3 Attaching supply connections.......................................................20

5.4

Establishing readiness for operation ............................................20

6

Operation ................................................................................................21

6.1 Safety............................................................................................21

6.2 Switching on the machine.............................................................22

6.3 Establishing readiness for operation after emergency stop .........25

6.4 Warming up the machine..............................................................26

6.5

Setting up the machine.................................................................28

6.5.1

Language setup.................................................................28

Table of contents

Machine for cutting ring pre-assembly and final assembly

4 / 72

www.stauff.com

6.5.2 Setting up the system properties ...................................... 29

6.6

Setting up the tool ........................................................................ 33

6.7

Setting the operating mode .......................................................... 36

6.7.1

Setting automatic mode .................................................... 36

6.7.2

Setting button mode.......................................................... 36

6.7.3

Setting button mode with foot switch ................................ 38

6.8

Setting up the job ......................................................................... 41

6.8.1

Setting the assembly type................................................. 42

6.8.2

Setting the material ........................................................... 43

6.8.3

Setting the production quantity ......................................... 43

6.8.4

Setting the pressure for manual pressure......................... 44

6.9

Preparing the workpiece............................................................... 46

6.10

Assembling a cutting ring ............................................................. 48

6.10.1

Assembling a cutting ring in automatic mode ................... 48

6.10.2

Assembling a cutting ring in Manual Pressure mode........ 49

6.10.3 Assembling a cutting ring in button mode ......................... 50

6.10.4 Assembling a cutting ring in button mode with foot switch 52

6.11 Checking the product ................................................................... 53

6.12 Completing the job ....................................................................... 54

6.13 Final assembly in the fitting body ................................................. 55

6.14 Cleaning the machine................................................................... 55

6.15 Switching off the machine ............................................................ 56

7

Troubleshooting

............................................................................... 57

7.1

Safety ........................................................................................... 57

7.2

Troubleshooting............................................................................ 58

7.3

Malfunctions/error messages ....................................................... 59

7.3.1

Pressure: “Ultimate pressure out of limit” ......................... 59

7.3.2

Pressure:

“

Set pressure too high. Displayed value is

max. pressure. Confirm by entering new value.”.............. 60

7.3.3

Path: “Position detection”.................................................. 61

7.3.4

Light curtain: “Light curtain” .............................................. 62

7.3.5

Tube not pressed on ......................................................... 63

7.3.6

Piston not retracted........................................................... 63

7.3.7

Tool not detected .............................................................. 63

7.3.8

Reference run interrupted ................................................. 65

7.3.9

Wrong turning direction..................................................... 65

7.3.10

Other faults........................................................................ 66

8

Maintenance

...................................................................................... 67

8.1

Safety ........................................................................................... 67

8.2

Inspection and maintenance ........................................................ 67

8.3

Checking the emergency stop...................................................... 67

8.4

Checking the light curtain............................................................. 67

SPR-PRC-POC

www.stauff.com

5 / 72

Table of contents

9Decommissioning............................................................................. 68

9.1

Safety............................................................................................ 68

9.2

Dismantling................................................................................... 69

9.3

Disposal........................................................................................ 69

10

EC Declaration of Conformity...............................................................70

Index ...................................................................................................... 71

1 Information about

the instructions

Machine for cutting ring pre-assembly and final assembly

6 / 72

www.stauff.com

1 Information about the instructions

1.1 Target group of the operating manual

The operating personnel tasked with the following work has to read and

observe this operating manual:

• Installation

• Operation

• Malfunction

• Maintenance

See “Personnel qualifications” chapter 2.4, p. 10.

1.2 Structure of warnings

Coloured signal word boxes emphasise the warnings. Always read the full

warning text for effective protection against hazards!

The different colours and signal words of the following boxes designate

various hazard levels:

DANGER

Ignoring this warning results in serious or lethal injuries.

WARNING

Ignoring this warning can result in serious or lethal injuries.

CAUTION

Ignoring this warning can result in minor or moderate injuries.

ATTENTION

Ignoring this warning can result in damage.

SPR-PRC-POC

www.stauff.com

7 / 72

1 Information about

the instructions

Warnings always have the same structure. They include the signal word,

hazard type and source, consequences of ignoring them and steps to

avert/avoid hazards.

Example:

WARNING

Risk of shearing off and crushing fingers

►Ensure before start-up that all safety equipment is properly installed

and in working order.

►Ensure your fingers are not in the assembly area when

operating the machine!

1.3 Structure of instructions

Instructions are a direct request to carry out a task. They are structured in

line with the operation involved. Always carry out the operating steps in the

prescribed sequence.

The instructions are structured as follows and marked with the

appropriate symbols:

Objective of the instructions

1. Action step

Effect of the action step to check if the step has been

executed correctly.

2. Additional action step

Result of the overall instruction

1.4 Structure of additional information

Text marked with an information symbol provide

additional information and tips.

1.5 Structure of references

References are shown in this manual as follows:

Example:

“… only operate the machine as intended

chapter 2.2, p. 9.“

2 For your safety

Machine for cutting ring pre-assembly and final assembly

8 / 72

www.stauff.com

2 For your safety

To avoid accidents and injuries, …

• follow all safety instructions and warnings in these operating instructions

• observe hazard, prohibitory and instruction signs

• follow the accident prevention regulations and directives applicable at

the place of operation

• observe all inspection and maintenance intervals

• ensure to comply with the intended use

2.1 General safety instructions

Safety instructions help you in avoiding injuries and damage. Ensure

that you have read and understood all the safety instructions in these

operating instructions.

Safe working entails doing more that just reading the general safety

instructions in this chapter. Also read and follow the specific safety

instructions in each chapter affecting your work. Also observe

information in the referenced product documents.

The following general safety instructions apply to all work undertaken

on the machine:

• Observe the applicable national and international health and

safety regulations.

• Only operate the machine …

– in a technically satisfactory condition

– taking into account safety and hazards

– according to the intended use

– in compliance with this operating manual and

– with all safety devices unchanged, properly installed and

functional

• Wear the appropriate personal protective equipment for all work

on the machine chapter 2.5, p. 10.

• Observe all safety markings affixed to the

machine chapter 2.6, p. 11.

• Work on electrical equipment may only be carried out by

Walter Stauffenberg GmbH & Co. KG.

• Immediately eliminate any malfunctions which affect your safety

and/or reliable operation of the machine. Take the machine out

of service until the fault is rectified.

• Components – except tools – may only be replaced by

Walter Stauffenberg GmbH & Co. KG.

SPR-PRC-POC

www.stauff.com

9 / 72

2 For your safety

• Keep away from moving parts. Wear close-fitting clothes. Tie long hair

back to prevent it from being drawn into the machine. Remove any rings

and necklaces before the work.

• Be aware of the presence of residual energies in mechanical,

hydraulic and electrical components.

2.2 Intended use

The machine for cutting ring pre-assembly and final assembly is intended

exclusively for machine pre-assembly and final assembly of cutting rings on

tube ends in the Light and Heavy Series for outer tube diameters between

6 mm and 42 mm.

The machine is used together with assembly studs and counter

retaining plates specially designed for machine assembly.

The assembly parameters stored in the machine apply solely to the use of

an original STAUFF cutting ring FI-DS-.. in combination with the selected

tube material and the original STAUFF union nut. .

The machine may only be used within the specifications provided in the

chapter “Technical data” chapter 3.2, p. 15 and in compliance with the

maintenance instructions and other instructions in this manual and in the

referenced documents.

No changes, attachments or conversions may be carried out without

consulting the manufacturer. Such modifications could limit the operating

safety of the machine and are considered to be a violation of intended use.

Any use other than the intended use is not permitted.

2.3 Tasks and duties of the operating company

In addition to the instructions and information in these operating instructions,

the general, statutory and other mandatory regulations on accident

prevention and environmental protection also have to be observed.

To ensure safe machine operation, the operating company has to

at least …

• ensure that the machine is only operated as intended, in

proper condition, with all safety devices fully installed and

without damage

• establish the area of application and prepare the corresponding

operating instructions

• always keep the safety markings attached to the machined in a

complete and legible condition

• make the operating instructions available in a complete and legible

form at the operating location of the machine at all times

• instruct the personnel in safe working

Machine for cutting ring pre-assembly and final assembly

10 / 72

www.stauff.com

2 For your safety

• acquire the regulations applicable to the machine in their most recent

version and to familiarise personnel working on the machine with these

• provide personnel with the required personal protective equipment

• carry out a safety instruction

• ensure sufficient ventilation and lighting of the work areas

• collect any floor contamination using suitable means and dispose of

these observe the safety data sheet for the production equipment

used

2.4 Personnel qualification

Any work on the machine may only be carried out by qualified and

authorised personnel. Personnel instructed, trained or briefed in the work

involved is considered to be qualified. This has to be backed up by

appropriate certificates and records.

A distinction is made in this manual between the following groups

of persons:

• Operating personnel are those who have been verifiably briefed in

the operation and function of the machine. They input the data

required for the operation and carry out the required operating steps to

operate the machine. They are also responsible for simple

maintenance work and troubleshooting as specified in the inspection

and maintenance schedule and in the troubleshooting instructions.

• Personnel learning on the job may only work on the machine under

the constant supervision of personnel qualified for this work.

2.5 Personal protective equipment

The following personal protective equipment is mandatory for those

working on the machine:

Wear close-fitting work clothes!

Wear safety boots!

Machine for cutting ring pre-assembly and final assembly

12 / 72

www.stauff.com

2 For your safety

2.7 Safety devices

Safety devices protect operating personnel against hazards.

Before each startup of the machine, all safety devices have to be fitted

correctly and in working order.

Safety devices may only be removed when the machine has stopped and is

protected against being accidentally switched on again by means of a

padlock or a similarly suitable measure.

The following safety devices are attached to the machine or have to be

fitted by the operating company:

Electrical main switch

The electrical main switch is located at the

front of the machine. The electrical main

switch de-energizes the entire machine

(position: 0). The electrical main switch is

secured against reactivation chapter 2.8,

p. 13.

Light curtain

Light curtains prevent personnel from

reaching into the hazard area of the

machine. If anyone reaches into the hazard

area during operation, the respective light

curtain will trigger an emergency stop. This

stops all machine movements.

Emergency stop button

Pressing the emergency stop button

triggers an emergency stop resulting in all

machine movements being stopped.

To reactivate the machine, the triggered

emergency stop has to be unlocked

(Establishing readiness for operation after

emergency stop).

1

Light curtain

1

2 3

2

Electrical main switch

3

Emergency stop button

Fig. 1: Safety devices

SPR-PRC-POC

www.stauff.com

13 / 72

2 For your safety

2.8 Securing the machine against reactivation

Secure the machine against reactivation:

1. Ensure that …

a padlock is available for securing the machine against reactivation

(not included in the delivery).

2. Switch off the machine as described.

3. Secure the electrical main switch with a padlock.

Fig. 2: Electrical main switch protected with padlock

The machine is secured against reactivation

3 Machine description

Machine for cutting ring pre-assembly and final assembly

14 / 72

www.stauff.com

3 Machine description

3.1 Machine overview

Fig. 3: Overview

No. Designation Description

1Assembly area Machine workpiece

2Electrical main switch Switch on the machine

3“Ready/Process

runs” lamp

Machine ready for operation, machine running

4Operating panel Setting up the machine

5Enable Enable the machine

6Emergency stop button

Stop machine in an emergency

Optional foot switch Enable the machine

RJ45 interface PC connection;

At the rear of the machine

Power supply At the rear of the machine

Foot switch connection At the rear of the machine

Optional tool holder Tool holder offset to the top

1

2

3

4

5

6

3 Machine description

SPR-PRC-POC

www.stauff.com

15 / 72

3.2 Technical data

General data

Dimensions (W x D x H) 780 mm x 650 mm x 305 mm

Weight incl. oil: 95 kg

Electrical power

Electrical connection: 400 V / AC3 / 50Hz

460 V / AC3 / 60Hz

Current consumption: 2.7 A

Hydraulic energy

Oil capacity: 4 litres

Max. operating pressure: 450 bar

Installation requirements

Ambient temperature: Dry between 15 °C and 35 °C

Position Horizontal

Sound pressure level

in acc. with EN ISO 11202:2009: 68 dB(A)

3.3 Function

The machine mechanically mounts cutting rings onto tube ends. Tubes

from the Light and Heavy Series with tube diameters between 6 mm and

42 mm can be used. Pre-assembly mode and final assembly mode are

available.

For more information on final assembly, please follow the detailed

instructions in the assembly instructions in the STAUFF Connect product

catalogue.

The machine is used together with assembly studs and counter-

retaining plates specially designed for mechanical mounting.

3.4 Tools and product

The machine for cutting ring pre-assembly and final assembly mounts

cutting rings onto tube ends. They form the basis for cutting ring fittings.

Fig. 4: Product

3 Machine description

Machine for cutting ring pre-assembly and final assembly

16 / 72

www.stauff.com

1

Assembly stud

2Cutting ring

3Union nut

4Counter retaining

plate

Fig. 5: Components

The assembly stud and counter retaining plate are labelled with the

size:

• The number corresponds to the external tube diameter

• LL stands for the Extra-Light Series

• L stands for the Light Series

• S stands for the Heavy Series

Please refer to the STAUFF Connect product catalogue for additional

information on selecting the size.

3.5 Type plate

The type plate is located on the side of the machine.

Fig. 6: Type plate

The serial number is stamped into the frame at the front right.

3 Machine description

SPR-PRC-POC

www.stauff.com

17 / 72

3.6 Spare and wear parts

ATTENTION

Replacing components

Machine damage, malfunctions, faults

►Only Walter Stauffenberg GmbH & Co. KG may carry out work which

involves opening up the machine!

►Only authorised setup and maintenance personnel may carry

out maintenance work!

►Only use suitable tools in proper condition!

►Replace components only with genuine spares or those authorised

by the manufacturer.

Lists of authorised spare and wear parts can be obtained from

Walter Stauffenberg GmbH & Co. KG.

4 Transport and storage

Machine for cutting ring pre-assembly and final assembly

18 / 72

www.stauff.com

4 Transport and storage

4.1 Safety

WARNING

Lifting loads

Serious or lethal injuries from falling/suspended loads

►Secure all moving components before raising the load.

►Only use undamaged lifting equipment which is approved for the weight

of the load to be lifted.

►Attach load attachment gear only at the indicated attachment points.

►Never leave loads suspended in the lifting devices without supervision.

►Never stand underneath suspended loads.

WARNING

Transporting the machine

Serious or lethal injuries from tilting or slipping loads

►Before transporting the machine, secure all its moving components.

►Secure the machine against overturning or slipping out of position

during transport.

►Only use transport vehicles which are suitable for the weight of the

machine.

4.2 Transport

Information on dimensions and weight can be found in

chapter 3.2, p. 15.

Note the following during transport:

• The attachment points are the side bars/grips of the machine.

• Keep the machine horizontal during all transport. Note that the centre of

gravity is in the installation area.

• Transport may only be carried out by an authorised specialist company

or by qualified personnel.

• Dispose of all packaging material in a proper and environmentally

compatible manner after transport.

5 Installation

SPR-PRC-POC

www.stauff.com

19 / 72

5 Installation

5.1 Safety

WARNING

Lifting loads

Serious or lethal injuries from falling/suspended loads

►Secure all moving components before raising the load.

►Only use undamaged lifting equipment which is approved for the weight

of the load to be lifted.

►Attach load attachment gear only at the indicated attachment points.

►Never leave loads suspended in the lifting devices without supervision.

►Never stand underneath suspended loads.

WARNING

Carrying out installation work

Serious or lethal injuries or machine damage due to incorrect installation

►Installation work may only be carried out by authorised specialist

personnel.

►Only use suitable tools in proper condition!

►Wear your personal protective equipment for all work.

WARNING

Connecting the machine to the power supply

Serious or lethal injuries from dangerous voltage

►Work on electrical equipment may only be carried out by qualified

electricians.

►Work on live parts is only permitted under supervision of a second

person.

WARNING

Risk of shearing off and crushing fingers

►Ensure before start-up that all safety equipment is properly installed and

in working order.

►Ensure your fingers are not in the assembly area when operating the

machine!

5 Installation

Machine for cutting ring pre-assembly and final assembly

20 / 72

www.stauff.com

CAUTION

Working on the hydraulic system

Eye injuries from ejected hydraulic oil

►Depressurise the machine!

►Only Walter Stauffenberg GmbH & Co. KG may carry out work

which involves opening up the machine!

►Wear your personal protective equipment including safety goggles

for all work undertaken on the hydraulic system!

5.2 Installing the machine

The machine is assembled ready for operation by the

manufacturer and delivered with the control unit set up.

Control unit updates can be requested from the

manufacturer. Note the following before the installation:

• Set up the machine on a sturdy base.

• Set up the machine so there is space to work around it.

• Inspect the machine for any signs of damage.

5.3 Attaching supply connections

Attach the machine to the following supply connections:

• Power supply

5.4 Establishing readiness for operation

A visual check and function test has to be carried out on the

machine before startup. Ensured that …

• all parts are mounted correctly, are undamaged and in full

working order

• all outer fittings are installed and fully tightened

• all safety devices are functioning chapter 8.3, p. 67 and

chapter 8.4, p. 67.

Table of contents

Other STAUFF Cutter manuals

Popular Cutter manuals by other brands

Far Tools

Far Tools TC 180B Original manual translation

FLORABEST

FLORABEST FGs 72 a1 original operation manual

Central Pneumatic

Central Pneumatic 69473 Part list manual

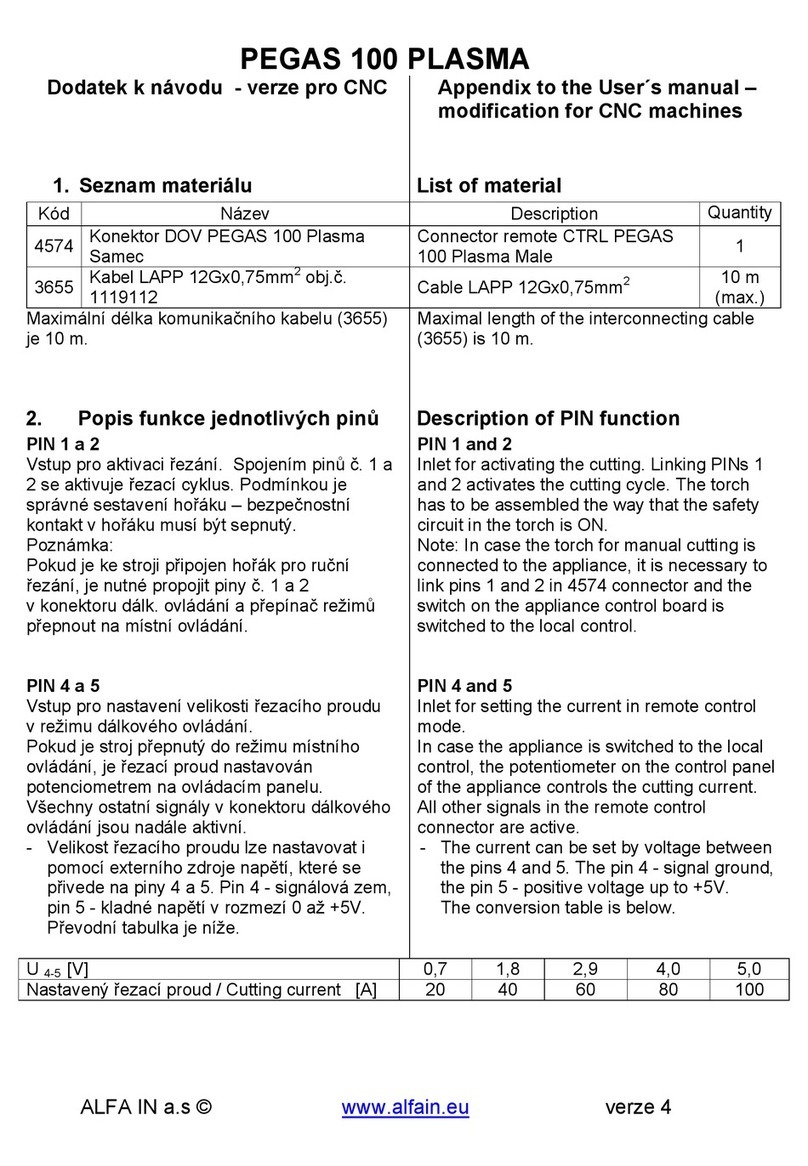

Alfain

Alfain PEGAS 100 PLASMA Appendix to the User's manual

Rtech

Rtech CNC Assembly instructions

Central Pneumatic

Central Pneumatic 05490 Assembly and operating instructions

KMT

KMT Streamline SL-V Plus series Operation and maintenance manual

FLETCHER

FLETCHER 3100 owner's manual

Dremel

Dremel 678-01 Operating/safety instructions

Husqvarna

Husqvarna K650 Operator's manual

Cedima

Cedima CF-12.4 E-TR Operating manual and safety instructions

LEM

LEM 685 Use and maintenance instructions