Always wait until the machine has come to a complete

stop before placing it down. The tool insert can jam and

leadtolossofcontroloverthepowertool.

Before any work on the machine (e. g., maintenance,

tool change, etc.) as well as during transport and

storage,settherotationaldirectionswitchto thecentre

position. Unintentional actuation of the On/Off switch can

leadtoinjuries.

Protectthe power tool against heat, e. g., against

continuous intense sunlight, fire, water, and

moisture.Dangerofexplosion.

In case of damage and improper use of the battery,

vapours may be emitted. Provide for fresh air and seek

medical help in case of complaints. The vapours can

irritatetherespiratorysystem.

SafetyWarningsforbatterychargers

Keep the battery charger away from rain or

moisture.Penetrationofwaterinthebatterycharger

increasestheriskofanelectricshock.

Do not charge other batteries. The battery charger is

suitable only for charging STAYER lithium ion batteries

withinthelisted voltagerange. Otherwise thereisdanger of

fireandexplosion.

Keep the battery charger clean. Contamination can lead

todangerofanelectricshock.

Before each use, check the battery charger, cable and

plug. If damage is detected, do not use the battery

charger. Never open the battery charger yourself. Have

repairs performed only by a qualified technician and

only using original spare parts. Damaged battery

chargers, cables and plugs increase the risk of an electric

shock.

Do not operate the battery charger on easily

inflammable surfaces (e. g., paper, textiles, etc.) or

surroundings. The heating of the battery charger during

thechargingprocesscanposeafirehazard.

Children should be supervised to ensure that they do

notplaywiththebatterycharger.

Before any work on the machine (e. g., maintenance,

tool change, etc.) as well as during transport and

storage,settherotationaldirectionswitchto thecentre

position.

Unintentional actuation of the On/Off switch can lead to

injuries.

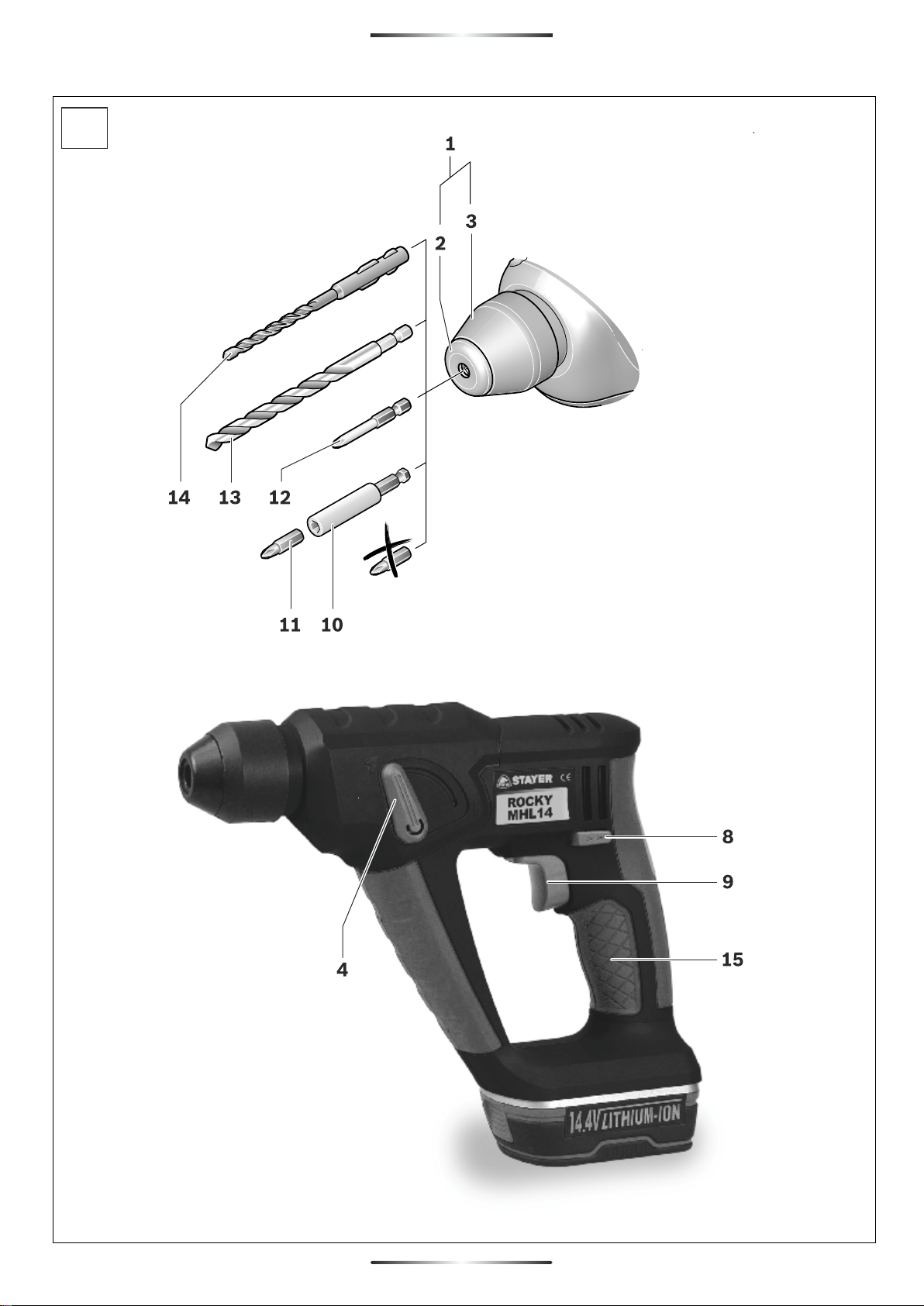

3.Instructionsforuse

3.1PlacementTool

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

resultinelectricshock,fireand/orseriousinjury.

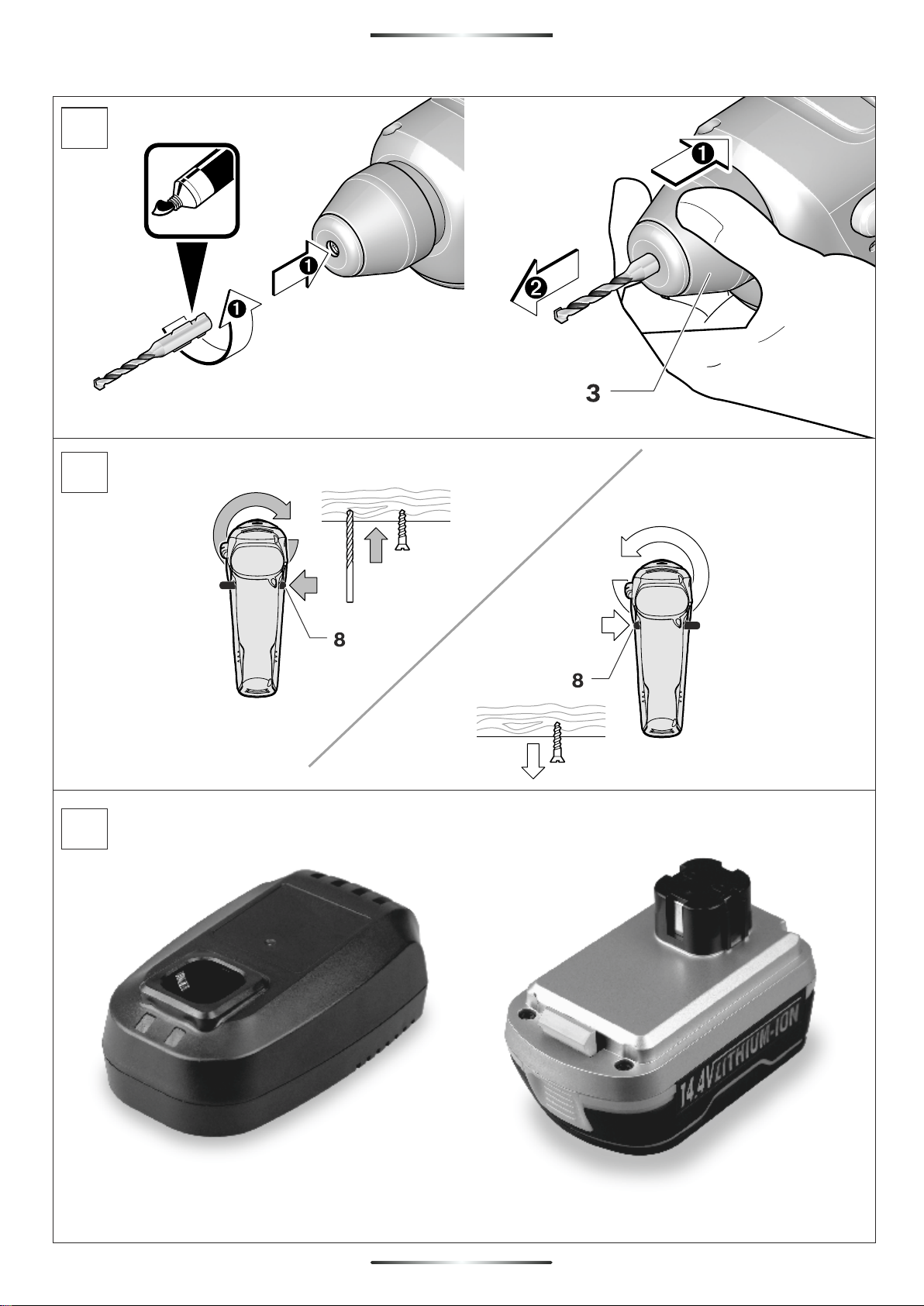

3.2Assembly(Fig.B)

The machine is intended for hammer drilling in concrete,

brick and stone. It is also suitable for drilling without impact

in wood, metal, ceramic and plastic. Machines with

electronic control and right/left rotation are also suitable for

screwdriving.

Usethebatterychargeronlywhenyoufullyunderstandand

can perform all functions without limitation, or have

receivedappropriateinstructions.

Wear hearing protection. Exposure to noise can cause

hearingloss.

Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

or fastener may contact hidden wiring. Cutting

accessory and fasteners contacting a “live” wire may make

exposed metal parts of the power tool “live” and could give

theoperatoranelectricshock.

Use appropriate detectors to determine if utility lines

are hidden in the work area or call the local utility

company for assistance. Contact with electric lines can

leadtofireandelectricshock.Damagingagaslinecanlead

to explosion. Penetrating a water line causes property

damageormaycauseanelectricshock.

Switch off the power tool immediately when the tool

insert jams. Be prepared for high reaction torque that

cancausekickback.Thetoolinsertjamswhen:

—thepowertoolissubjecttooverloador

—itbecomeswedgedintheworkpiece.

Secure the workpiece. A workpiece clamped with

clamping devices or in a vice is held more secure than by

hand.

Keep your workplace clean. Blends of materials are

particularly dangerous. Dust from light alloys can burn or

explode.

1. Contents page

2.Specific safety instructions......................................15

3.Instructionsfor use....................................................15

3.1 Placement Tool.............................................................15

3.2 Assembly......................................................................15

3.3Electricalconnection.............................................16

3.4Illustrateddescription............................................16

4.Operating instructions..............................................16

4.1Placement and testing..........................................16

4.2General instructions for use..................................17

4.3Tool change..........................................................17

5.Maintenance and service instructions.....................17

5.1Cleaning...............................................................17

5.2Repairservice.......................................................18

5.3 Warranty...............................................................18

5.4 Disposal and recycling..........................................18

6.Regulations................................................................18

6.1Technical Data......................................................18

6.2 EU declaration of conformity.................................19

2.Specificsafetyinstructions

ENGLISH

5

5