Steam Planet MA6023 User manual

1 | Page

Rev 10/2012

CONTEMPORARY STEAM ROOM

Installation & Operation Manual

Note: You must read all installation & operation instructions prior to assembly and use of this unit.

2 | Page

Rev 10/2012

Table of Contents

Notice to Installers ………………………………………….. 3

Packing List ………………………………………….. 3

Product Features Chart ………………………………………….. 4

Packing List ………………………………………….. 5

Rough-In Diagram ………………………………………….. 6

Water & Electric Requirements ………………………………………….. 7

Installation Instructions ………………………………………….. 8-11

Faucet Functions & Usage ………………………………………….. 11

Cleaning, Maintenance & Tips ………………………………………….. 12

BF1101 Main Control Panel Diagram …………………………………………. 13

Description of Functions ………………………………………….. 14

MID1101 Remote Control ………………………………………….. 15

Troubleshooting ………………………………………….. 16

Thank you forselecting Steam Planet Corp Computerized Steam Rooms.

In order to operate and use the product properly, please followall instructions providedin this User’s Manual. Our company reserves

the right to change the Manual at anytime. The manual takes effect the date it is published. This manual shall prevail if there is any

difference between this andprevious documents and manuals.

3 | Page

Rev 10/2012

NOTICE TO INSTALLERS

1) The distance from the ground to the ceiling has to be minimum of 3.9” higher than the height of the steam room.

2) The water pressure hasto be more than 3kg/cm2 (47-72 psi) and, if the pressure is lower than required, you

may install a booster to the water supply.

3) Please use a 20-amp 220V GFI breaker for the electrical connection.

4) We advised to have an accesspanel installed on theside of the electrical/water connections for maintenance

and service.

Manufacturer reserves the right to change specs or features at anytime. Please check to confirm details. 1-866-783-2661

PACKING NOTE:

(1) When first opening the boxes, please make sure everything is in good condition, especially if any visible damage has

been doneto the package, please contact Steam Planet immediately with photographic documentation of the damage.

(2) Make sure all water andelectrical components are up to local andnational standards.

(3)Two installers are required fortheseunits.

(4) Here are the tools you may needfor installation:

Rubber mallet wrench level tape measure screwdriver pencil 4mm allen wrench

4 | Page

Rev 10/2012

PRODUCT FEATURES

Model

Voltage

Power

Frequency

Length

Width

Height

MA6020

220V

3kW

50-60Hz

1090mm / 43 Inch

800mm / 31.5 Inch

2184mm / 86 Inch

MA6023

220V

3kW

50-60Hz

900mm / 35.4 Inch

900mm / 35.4 Inch

2184mm / 86 Inch

MA6027

220V

3kW

50-60Hz

1500mm / 59 Inch

813mm / 32 Inch

2184mm / 86 Inch

MA6028

220V

3kW

50-60Hz

1500mm / 59 Inch

1016mm / 40 Inch

2184mm / 86 Inch

DESCRIPTION

MA6020

MA6023

3kW Quick heating Self-Draining Steam Generator w/SteamAromatherapy Cup

Multiple Body Massage Jets

Hand-held Shower w/ Various watermassage settings & adjustable height bracket

8 inch wide water-drenching Rainfall Shower

Thermostatic / Anti-scald Faucet

“Special Process” Black Tempered Glass walls and front Clear Glass

Unique “Glass Touch” Control Panel

FM Radio

Wireless transmitter (optional extra) transmits from any electronic device

Hand held Remote control for entire panel control

“Chroma-therapy” LED multiple Color Lighting

Waterproof Oak Shower Grid

Removable Bench

Circulation Fan

Accessory Rack

Phone

Hinged door

Stone composite base included

Assembles from inside the unit

Left / Right Models Available

5 | Page

Rev 10/2012

PACKING LIST

Glass angle bracket installation instruction

Hinge installation instruction

A

.

Glass panel

B.Threaded Connector

C.Angle Bracket

D.Connecting Bolt

E.Bolt cap

A

.

Hinge

B.Glass door

C.Gasket

D.Screw

E.Allen wrench

SECTION PICTURE OF RUBBER SEAL

A.Half-moon shape seal B.Corner seal C.Magnetic seal D.Door bottom seal

GLASS

A:Glass A—Main Panel, Black

B:Glass B—Back Panel, Black

C:Glass C—Side Panel, Black

D:Glass D—Top, Black

E:Glass E—Front Clear Panel with Black Stripe

F:Glass F (M-A6027/6028 only)—Frontclear Panel with Black Strip

G:Glass G— Clear door, black strip on top.

*Diagram shows Right-hand unit, hingesare located on different side for differentmodels.

1-866-783-2661 Customer Service

A B C D

A

B

C

D

E

A

B

E

C

D

A

D

B

C

E

G

F

6 | Page

Rev 10/2012

ROUGH-IN DIAGRAMS

Note: All diagrams below are for right hand units only. Please reverse for left hand units.

M-A6020 (43×31.5×84in.)

M-A6023 (35.4×35.4×84in.)

M-A6028 (59×40×84in.)

M-A6027 (59×32×84in.)

A. Cold water in

B. Power jack(AC30A)

C. Hot water in

Rated voltage

Rated power

Rated frequency

AC220V 50/60Hz 3KW

7 | Page

Rev 10/2012

WATER AND ELECTRICITY INSTALLATION INSTRUCTION FOR ALL MODELS

(1) Water: Two water lines forcold and hot water respectively ½-inch National PipeThread(NPT).

(2) Power:Power requirement: Single-phase three-wire 220V power supply.

TECHNICAL INFORMATION

•Materials: Tempered Glass

•Power Supply: 3KW 20amp, 220V

•Steam Ready: 2-5 MIN

ELECTRICAL INFORMATION

•1 dedicated 12-2 line for steam (line 1, line 2, and ground)

•Single-phase three-wire 220 volt, 20 amp GFCI breaker

•The length of the wire for the machine is 1.5m (adjustable); it can be changed to a suitable length.

•Connect the overhead light, speaker, fan, CD, telephone according to the tags on the wires.

•Do not connect the wire “O3” to anything.

•Connect main power supply.

PLUMBING INFORMATION

•The unit is equipped with 3 ft. hot and cold, metal braided water supply hose with ½-inch national pipe thread to connect from

faucet/manifold (Manifold is located. 4 ft. high on rear of unit) to the shutoff valves (should be installed where they can be

accessed). Note: base edge sets directly against back and sidewall. Donot install any pipes along walls as to impede the

base from setting flush against them..

•Install hot and cold shutoffs with ½ -inch male national pipe thread (not included).Install shutoffs wherethey can be

accessible.

•Access panel near controls, pumps, and jets is recommended

•Drainage: It isadvised to have baseonsite before preparingdrain location. The diameter of the drain hole should be larger or

equal to Φ40mm (1.6 inches).

•Note: The flexible drain hose included with this unit is for installation into a floor drain only.

Substituting the existing drain setup for a setup of the installers’ choice will not void the warranty of

the unit as long as there is no evidence of misuse or damage to the base..

•All fixtures and fittings must be checked for tightness as they may have been loosened during transport

GENERAL INFORMATION

•Connect hot and cold supplies and make all electrical connections just before unit is set into place.

•Units come broken down in panels and are assembled with screws, nuts and bolts on site.

•This unit assembles from the inside for convenience.

•Note: All shower bases are a man made stone composite and may need to be set in mortar for leveling

purposes.

•It is advised to have base onsite before preparing drain location

•Access panel area recommended

•Manufacturer reserves the right to change specs or

features at anytime. Please check to confirm details.

1-866-783-2661

Caulk all needed seams and joints with 100%silicone caulk.

DRAIN INSTALLATION FOR ALL MODELS

For glass steam roomand shower room with 150mm shower tray:

A: Glass A

B: Steam Generator Drain

C: Shower Drain

D: Shower tray

8 | Page

Rev 10/2012

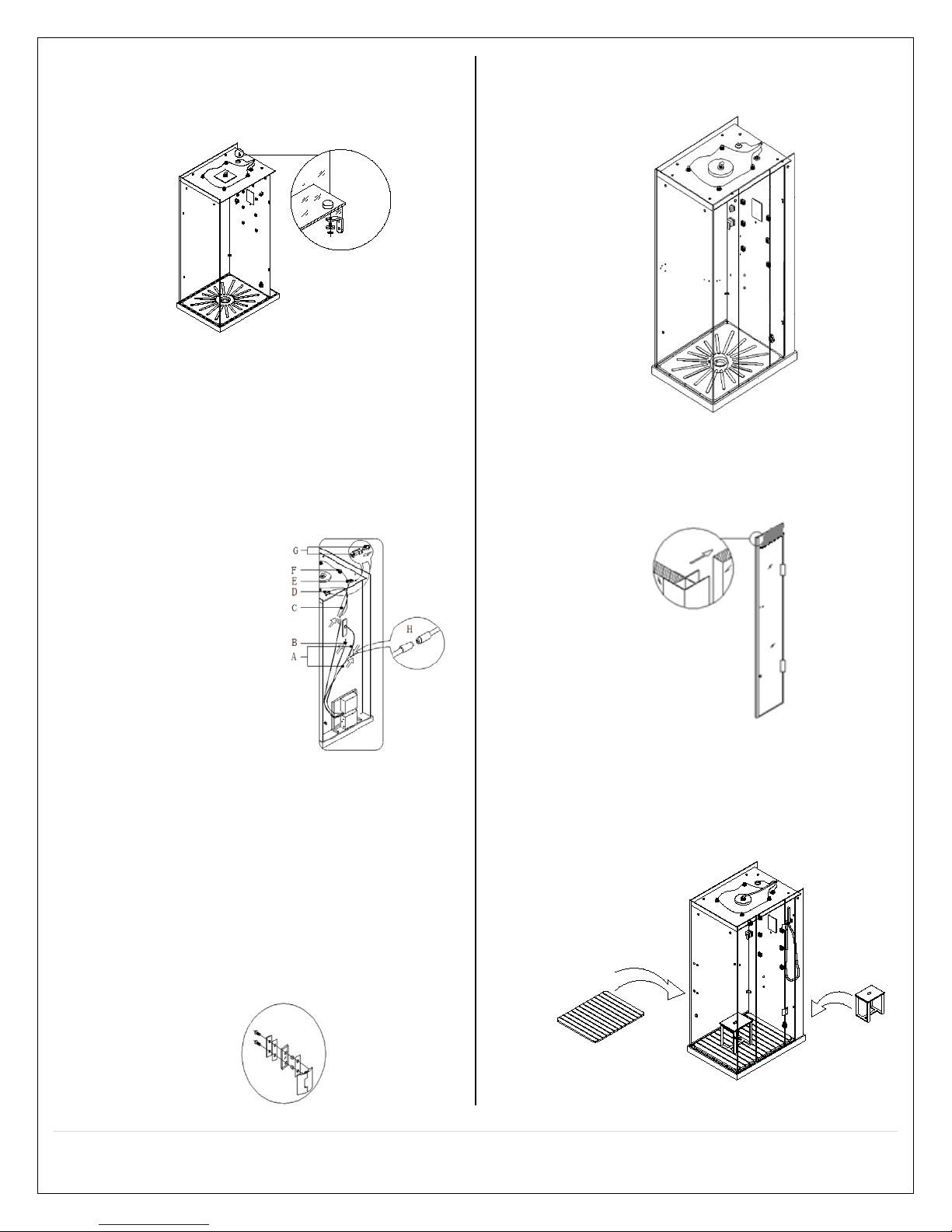

INSTALLATION INSTRUCTIONS FOR MA6020 & MA6023

Note: Silicone joints & seams where needed

Note: Determine the drain setup. There needs to be a 3/8inch

diameter hose connected from the steam box to the main drain.

1. Place shower tray in the corner where it will be

permanently located. Note: The handing (R/L) of your

unit determines which side the mounting plate goes (ie:

A right handed unit has themountingplate on the right

side)

2. Make sure the installation holes for the electric parts

and the steam generator arelined up with installation

holes; connect it with M6X25 Hex bolts.

3. Insert the half-moon shaped rubber seals (shown in

picture below) onto theleft, right and top edgeof glass

A.

4. Install angle brackets over the installation holes of

glass A, connect with connector bolts (make the

connection snug, but looseenough tomake

adjustments.) Connector bolt caps will be installed

when final tightening is complete. Connect water

supply lines and electrical lines.

5. Place bottom edge of glass A into the slot on the base

as shown. A small amount of soap or lubricant on the

gaskets will help with installation. Helpful hint: install

the shelf brackets to back panel before positioning in

base. See section 3.19 for more info.

9 | Page

Rev 10/2012

6. The wires for the fan, speaker, and light are labeled.

Make the corresponding connections from the

accessory to the wire coming from thecontrol box.

*Note: Be cautious when making this connection. The

pins of the connector can easily bendif connected

improperly!

A: Wire for control panel

B: Temperature Sensor

C: Wire for speaker/fan/light

D: Speaker

E: Fan

F: Lights

G: Connecting terminal for

light/fan/speaker

H: Control panel connecting

terminal

7. Install the angle bracket to the holeson glass B (black

back panel). Connect with screw. Tighten snugly,but

leave enough tension to adjust. Insert the corner seal

on the on the left side of glass B.

Note: Attach glass shelf brackets to back of panel

before proceeding.

8. (MA6020, MA6027& MA6028) NOTE: Attach glass

shelf brackets to the holes in glassB.

9. Place the bottom edge of glass B into the slot on the

base as shown below. Align the holes and connect

with angle brackets. Connect to glass A.

10. Insert the corner seal to the right edge of glass C, then

install angle brackets to the glass panel (C). Tighten

snugly, but leave enough tension to adjust. Refer to

picture below. Install glassshelf brackets on panel C

before moving forward

11. Place glass C into the slot onto the base and insert into

the corner seal of glass B. Note: Glass Bis the black

panel, and glass C is a black panel. Line upthe

installation holes and connect glass Band glass C.

12. Assemble the half-moon shaped seals on the sides a,

b, and c of glassD (top). Seeillustration below. Attach

angle brackets to glass panelD.

A

C

B

10 | Page

Rev 10/2012

13. Place glass D (top) on the top of the unit, align

connecting holes with glass D to glass panels A, B,

and C. Use M6X10 connector bolt to connect. Please

refer to illustration below

14. Connect the rainfall showerhead water line to faucet,

screw in. Also,connect the light, fan and radio. Then

locate the middle water pipe, which is under the faucet,

and connect it to the steam box water inlet. Secondly,

connect the black steam line,which is on the side of

the steam box, to the steam outlet. Connect steam box

drain line to the steam outletdrain. Finally, connect

the cold and hot water lines to the water manifold, the

red one is for hot water,

while the blue is for

cold.

A: Steam outlet

B: Main Control box

C: Black steamhose

(insulated)

D: Diverter

E: Rainfall shower head

supply

F: Hose clamps

G: M4×25 screw

H: Hose clamp

At this point, you should have all electric & water

features connected!

15. (M-A6020 & M-A6023 ONLY)Align glass E in slot of

base, align the installation holes of glass E to theholes

of Glass D and Glass A. Glass E has a black stripe

long the top and side. Use the Angle Bracket &

Connector Bolt; apply connector bolt caps after final

adjustments. Attach the DoorPanel G that has a black

stripe along the top.

16. (MA6027 & MA6028 ONLY) Attach glass panel E

which has a black stripe across the top andside to

glass panel D and A.

17. (M-A6027 & M-A6028 ONLY) Insert the corner seal

and corner brackets on the left side of glass F (will

have holes for door hinge) attach to panel D & C with

angle brackets and connector bolts. Attach door

hinges and door Panel G.

18. Put the wood floor grids in theshower trayand

benches in the unit. Attach flexible waterline to outlet

on panel A and the other end to the handheld shower

wand. Attach to the bracket. Note: the hex nut of the

water line goes on the panel outlet.

11 | Page

Rev 10/2012

19. Attach handle to the door andshelves to panels B and

C.

20. Steam Cup Connection Diagram

A: Steam outlet

B: Steam line Connector

C: Glass

D: Steam hose

FAUCET FUNCTION AND USAGE

•On/Off Control

oWhen the temperature is adjusted, the water flowcan be adjusted

through the handle in the middle section

oClockwise turns on, and counterclockwise turn off

•Water Diverter handle

oTurn the diverterhandle according to the signs marked on its face.

•When you use the hand held shower, turn the knob to the hand held shower

sign;

•When you use the massage jets, turn the knob to the back massage sign.

•When you use the rainfall shower head, turnthe knob to the rainfall shower

sign

•Cold Water and Hot:

oTurn the faucet to left and right to increase/decrease the water

temperature.

A

B

C

D

12 | Page

Rev 10/2012

CLEANING AND MAINTENANCE

1. Liquid detergents and soft cloth should be used. DO NOTclean with acetone andammonia detergents on fixtures. Do not

use detergents with formicacid or formaldehyde. Do not use any abrasive cleaners.

2. Mineral deposits/scaling onsurface can be cleaned by soft cloth with heatedvinegar.

3. After every 30 uses, we suggest you to clean the steam generator.

4. Make a solution mixed with 1.5-1.7 liter of warm water and5-10 grams of citric acid. Or, use straight whitevinegar. Pourthe

solution into thesteam generator through the cleaning valveon the inside of the shower. Turn it on after 8 to 10 hours; wait for

it to be discharged as steam.

General

1. User’s electric must meet national safety standard forvoltage and frequency. Power supply shall beconsistent withthe

parameters marked on theproduct.

2. The ground should always be connected to the system.

3. We advise to usea water filtration system for the steam generator unit. One Recommended filtration system is Whirlpool

WHKF-DWHV.

13 | Page

Rev 10/2012

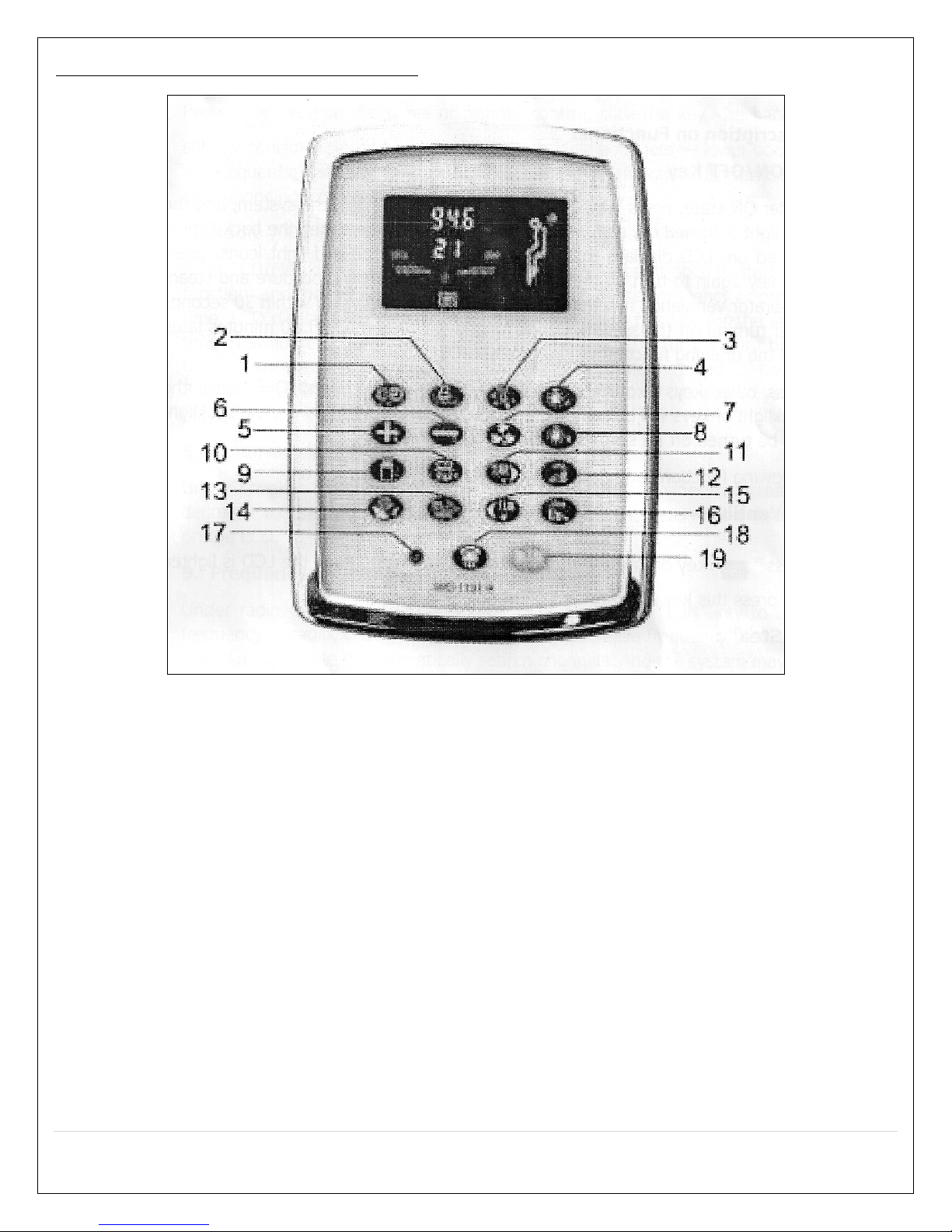

BF1101 CONTROL SYSTEM FOR MA602X SERIES

1. Time & Temperature setting

2. Rainfall shower

3. Body Massage Jets

4. Top light

5. Time / Temperature Increase

6. Time / Temperature Decrease

7. Circulation Fan

8. Back light (not active for this model)

9. Sauna (not active for this model)

10. Radio on/off and CD connection

11. Radio frequency -Up

12. Volume Increase

13. Radio frequency Memory

14. Steam ON/OFF

15. Radio frequency -down

16. Volume decrease

17. Remote sensor

18. Telephone

19. Power on/off

•Note: Sauna key does not have any functions for this model

•Note: Rainfall showerhead and body jets are controlled by manifold only

•Note: “B” light does not have any functions for this model

•Note: Rainfall shower and body massage jets are electronically controlled.

14 | Page

Rev 10/2012

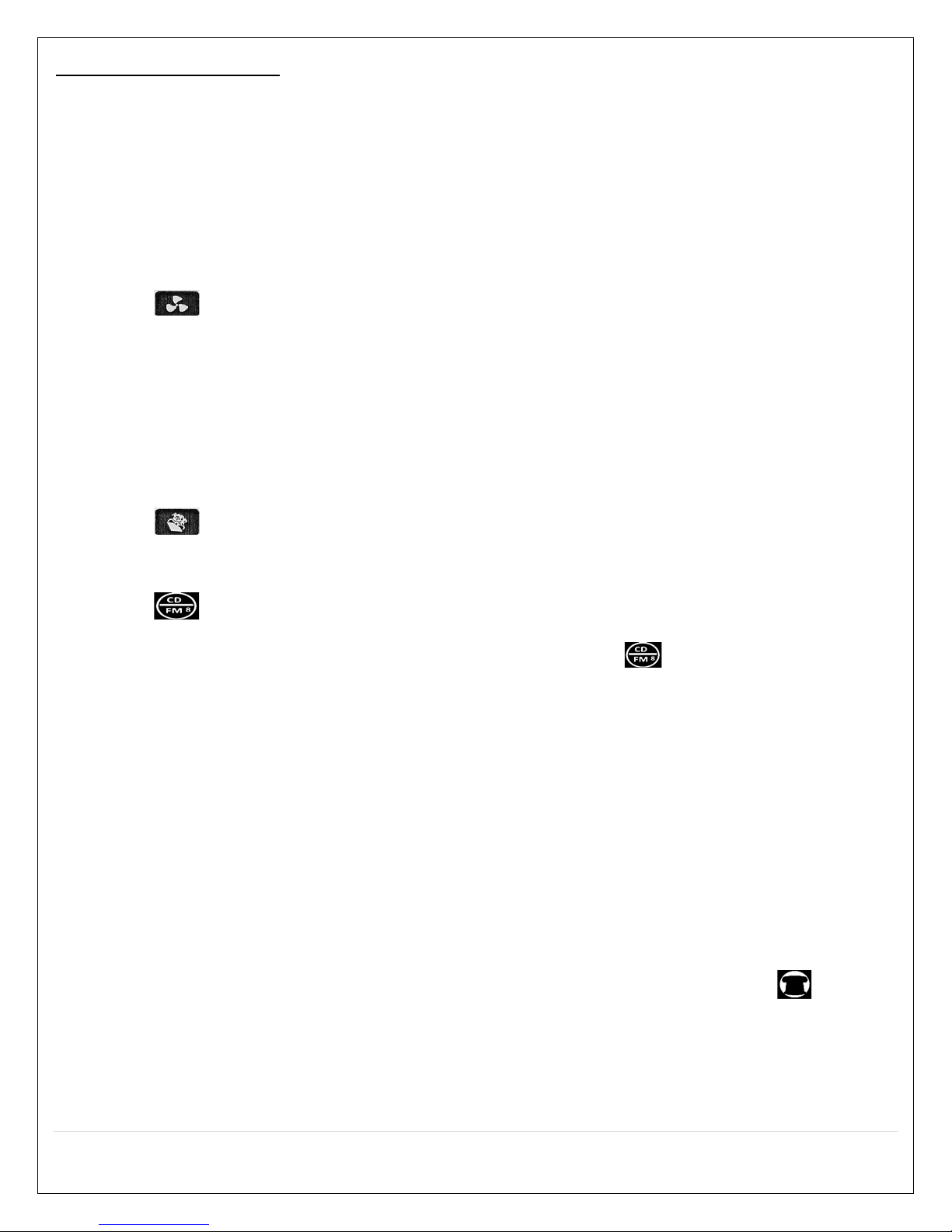

DESCRIPTION OF FUNCTIONS

Not in the same orderabove

1. ON/OFF Key

Under ON state, press “ON/OFF” Key on the panel tostart the system, and the top lightis turned on,all functions are

activated on the panel, the back light is on, LCD shows theambient temperature and all icons arelit; pressthe “ON/OFF” to

shut off the system.

Press other keys except “ON/OFF” key under standbyand OFF state, the backlight will come on,if the systems is not turned

on, the backlight will be turned off in 30 seconds.

Following functions are available when the system ison:

2. Circulation Fan:

Press key on the panel to start the fan the icon will light upon the LCD screen. Pressing the fan key again, will shut

down the circulation fan. This function circulates the steam throughout the enclosed shower space. No special exhaust

needed for this function.

3. Steam Temperature and Time Setting:

Press TIME & TEMPERATURE key on the panel so that temperature icon is on the screen, system will enter into steam

temperature setting state. Press “+” or “-“key to increase ordecrease temperature. The temperature rangeis 25-60°C (77-

140°F); pressthis key again to enter into time setting state. The time rangeis 1-99 minutes. If time or temperature is not

adjusted within 5 seconds, the system will automatically recover to display room temperature.

4. Steam:

Press key on the panel. The default steam time is 45 minutes, and the highest temperature is 45°C(113°F). By

pressing the steam key again, the steam system will shut off.

5. CD/FM Function:

Press key on the control panel or remote to activate the FM Radio, thecorresponding icon will light up on thecontrol

panel. The system will automatically switchto the previous frequency. Pressing this key the second time, will switch the

function to CD mode. The display will show thecorresponding icon. Pressing the again will shut off the system.

6. Volume Adjustment:

When the speaker is ON, pressing the “+”or “-“on the key panel to increase or decrease the volume. When changing the

volume, the LCD monitor will display the corresponding changes.

7. Frequency or Channel Adjustment:

When the radiois ON, press the “TUN” key to adjust the frequency (radio channels). Pressing the “+” or “-“ button once, will

increase or decrease the frequency by 0.1MHz, holding it for 1 minute will automatically search channels. The search will stop

once the next station is found,and the LCDpanel will display the correspondingchannel. When thesystem displays channel,

press “+” or “-“key to adjust channels, the range is 1-25 channels.

8. MEM, HZ, CH Selection Key:

When radio inON, press “MEM” key to select radio frequency (H) orchannel (CH). Hold this key tostore the correct

frequency into channel, LCD display will show“MEM” when stored.

9. Telephone Function (Operational only when is plugged in or available):

When there is an incoming call, telephone will ring, system will automatically shut off the radio/CD. Press key on the

panel to stop the ring and receive the phone call. LCD display will show the telephone icon; also, the shower functions will

automatically shut off. Pressphone key again to end the call. (You cannot dial out)

10. Mood Light:

Top light will turn on when thesystem is activated. Press theLight key onthe panelor remote control toturn on or turn off

the mood light.

15 | Page

Rev 10/2012

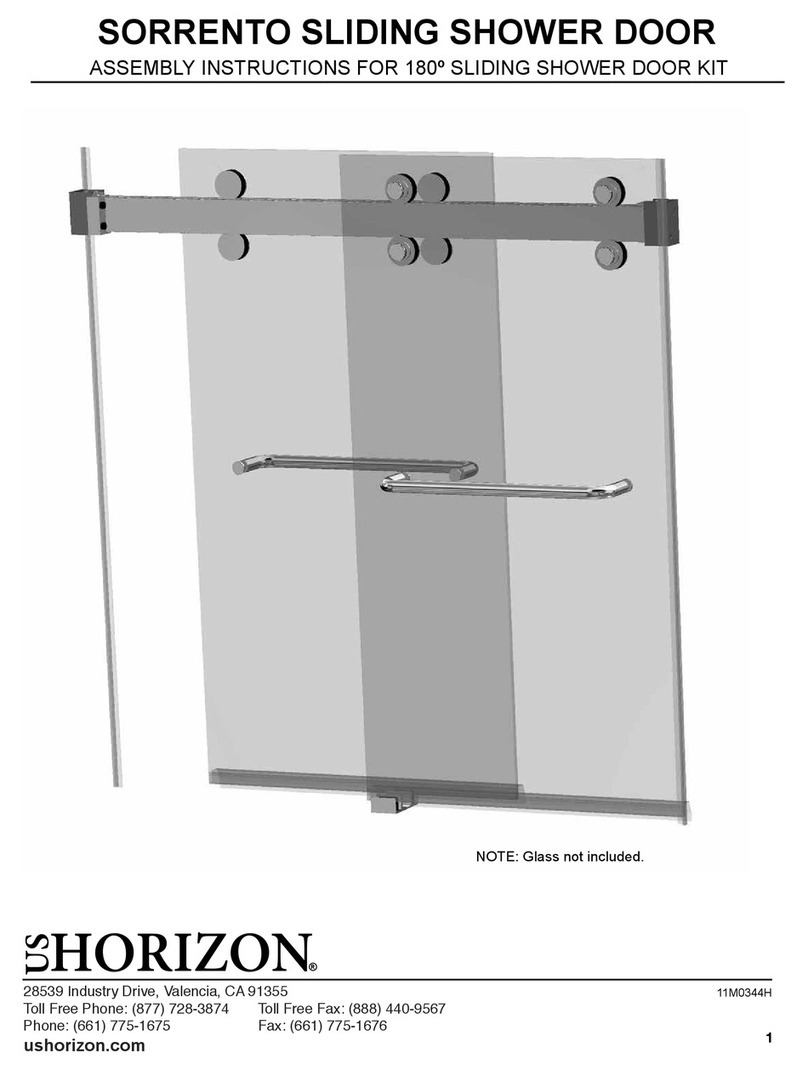

MID-1101 REMOTE CONTROL SYSTEM

•Note: Sauna key does not have any functions for this model

•Note: Rainfall showerhead and body jets are controlled by manifold only

•Note: “B” light does not have any functions for this model

•Note: Rainfall shower and body massage jets are electronically controlled.

16 | Page

Rev 10/2012

TROUBLESHOOTING

Problem Possible Reason Solution

Unit does not start

1.Power line is notconnected properly.

2.Insufficient power supply.

3.Fuse is damaged

4.Current circuit breaker is damaged.

1.reconnect the power supply

2.Power supply must reach 50/60Hz – 220V

3.Replace the 2A fuse

4.Replace the circuit breaker.

Switch failure

1.Current circuit breaker tripped or damaged

2.Short circuit

1.Replace the circuit breaker orreset.

2.Recheck the circuit.

Automatic shutdown

1.The intake valve or drain valve is damaged

2.The drain for the drain valve is jammed.

1.Replace the intake valve or drain valve.

2.Clear out the drain pipe.

1.Electric components weredamaged.

2.Electrical circuit is worn out.

1.Repair or replace the corresponding components.

2.Replace circuit breaker.

No steam

1.No water supply

2.Water pressure is too low

3.The heating element of the steam generator is

damaged

4.No water in steam generator

5.Steam pipe is jammed or broken

6.Heating time is not set

7.Temperature in the unit is higher than the set

steam temperature setting

1.Wait for the water supply to start

2.Install Pressure pump

3.Replace heating element

4.Check the water intake valve.

5.Clean out the jammed materials or replace the pipe.

6.Set Steam timer

7.Raise the temperature on the keypad/ remote

Automatic Protection

1.Water pressure is too high

2.Intake valve or drain valve isjammed

3.Drain pipes and drain is jammed

4.Steam pipes are jammed

1.Lower water pressure

2.Clear out jamming material in intake and drain valves

3.Clean out the drain pipe

4.Clear out the steam pipes

No sauna

1.Heating element is damaged

2.Circuit board or the component is damaged

1.Replace the heating element

2.Replace circuit board

Temperature is too

high

1.

Preset temperature is too high

2.Temperature sensor is damaged

1.

Adjust the temperature lower

2.Replace the sensor

Steam is Shutting off 1.Preset time ranout

2.Preset temperature is too low

3.Heating element is damaged

1.Reset the time

2.Increase the temperature onkeypad/remote

3.Repair or replacethe heatingelement

Water from steam

outlet

1.The water level sensor is damaged

2.The water levelcircuit is not working

1.Check the sensor

2.Check the water level circuit

Audio not working

1.No signal

2.Volume not high enough

3.Speaker is damaged

4.Antenna is loose/no signal

5.Circuit board is damaged

6.Circuit is loose, or there is no contact

1.Readjust for FM signal

2.Increase the volume

3.Replace the speaker

4.Connect the antenna and adjust the direction

5.Replace circuit board

6.Re-plug the circuit component or replace

Screen problem Problem with the control cable

Check the control cable, release and re-plug. Note:

align arrows and plug tightly

Water & Drain Valve

problem Water level control cable is not properly

connected

Check the water level control cablebetween steam

generator and the electrical box. Release the screw

and re-plug in the head.

This manual suits for next models

3

Table of contents

Other Steam Planet Shower Cabin manuals

Popular Shower Cabin manuals by other brands

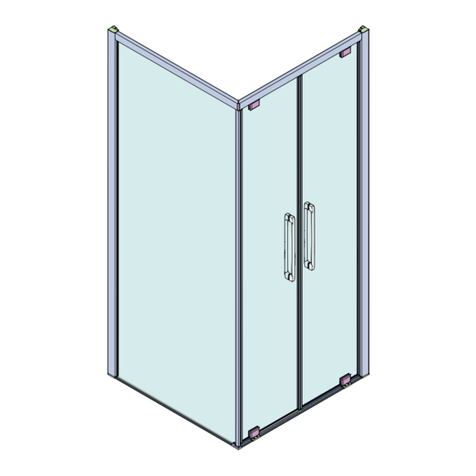

US HORIZON

US HORIZON SORRENTO Series Assembly instructions

Arblu

Arblu PERSEO ANGOLO Q-R 2SL+1LF Assembling instructions

ELEGANT

ELEGANT SPR870 quick start guide

RIHO

RIHO SCANDIC NXT X101 installation manual

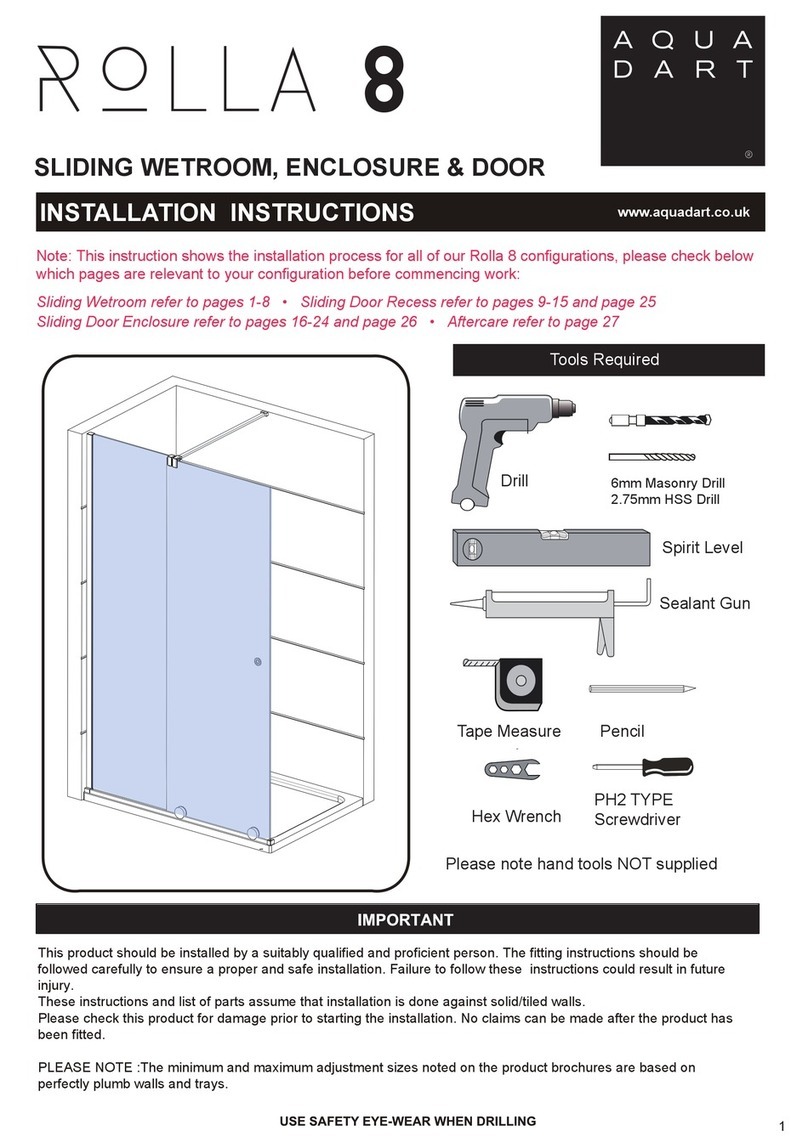

Aquadart

Aquadart Rolla 8 installation instructions

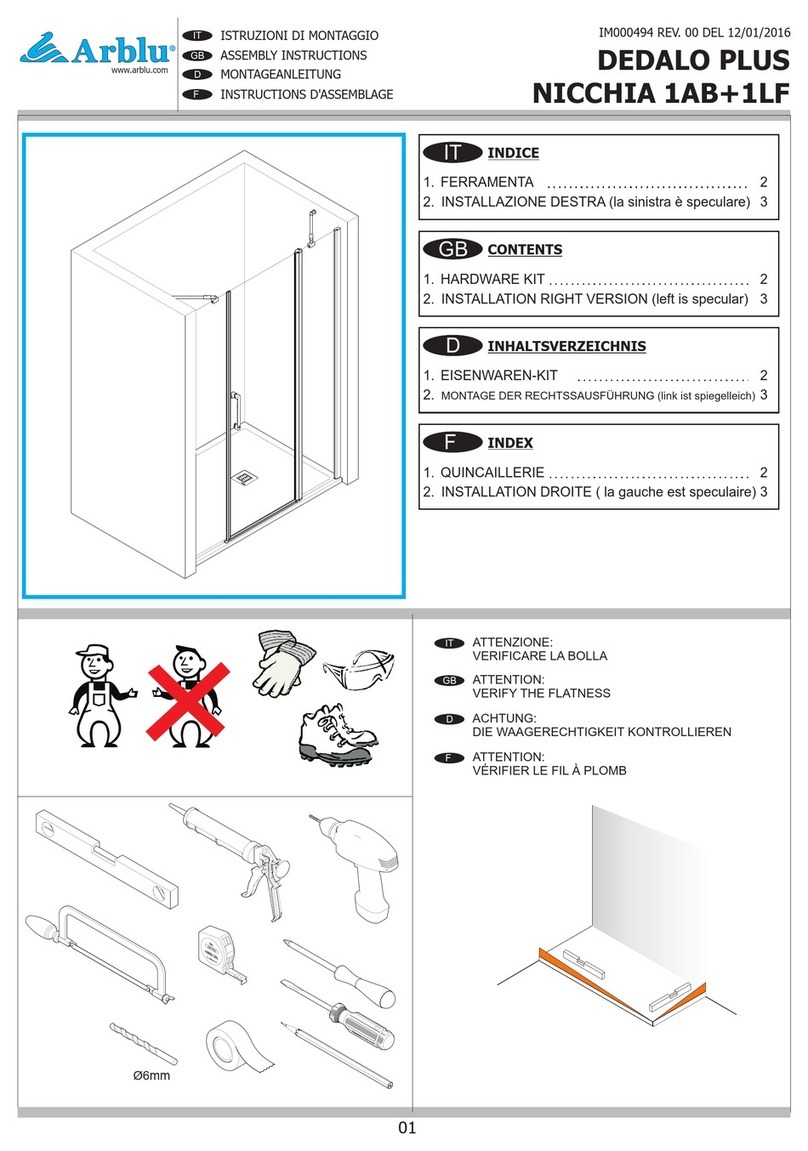

Arblu

Arblu DEDALO PLUS NICCHIA 1AB+1LF Assembly instructions