Steamist HC-9 User manual

80 100

120

140

60

40

20

0psi

Table of Contents

10/08 Pub. No. 600-A

Table of Contents

I. Important Steam bath Safety Guidelines.......................................................................

II. Warning Sign Installation...............................................................................................

III. Pre-Installation...............................................................................................................

IV. Rough-In........................................................................................................................

V. Installation......................................................................................................................

VI. Digital Command Center Installation..............................................................................

VII. Digital Commercial Control Package Operation.............................................................

VIII. Warranty information......................................................................................................

List of Illustrations

Warning Sign..............................................................................................................................

Figure 1 - Dimensional Drawing for Heavy Commercial Steam Generator

(HC-9 thru HC-18).....................................................................................................................

Figure 2 - Cables......................................................................................................................

Figure 3 - Typical Steam Generator Installation........................................................................

Figure 4 - Sensor Installation (Inside Steam Room).................................................................

Figure 5 - User Control Panel...................................................................................................

Figure 6 - Main Control Panel...................................................................................................

Programming Examples............................................................................................................

Specifications Chart..................................................................................................................

Wiring Diagram.........................................................................................................................

Page

1

1

2

3

4

5

6

12

Page

1

2

3

3

5

6

7

8

10

11

10/08 Pub. No. 600-A

- 1 -

Important Steam Bath Safety Guidelines

I. Important Steam Bath Safety Guidelines:

A) Do not permit children to use the steam bath unless

they are closely supervised at all times.

B) Wet surfaces of the steam enclosures may be

slippery. The floor should be skid resistant. Bathers

should use care when entering and leaving.

C) The steam head is hot. Bathers should not touch

the steam head and avoid contact with steam near

the steam head.

D) Prolonged use of the steam bath can excessively

raise the internal human body temperature and

impair the body’s ability to regulate its internal

temperature (hyperthermia). Limit the use of steam

to 10 – 15 minutes until you are certain of your

body’s reaction.

E) Excessive temperatures have a high potential for

causing fetal damage during the early months of

pregnancy. Pregnant or possibly pregnant women

should consult a physician regarding correct expo-

sure. Obese persons and persons with a history of

heart disease, low or high blood pressure, circula-

tory system problems, or diabetes should consult a

physician before using the steam bath.

F) Persons using medication should consult a physi-

cian before using a steam bath since some medica-

tion may induce drowsiness while other medications

may affect heart rate, blood pressure and circula-

tion.

G) The Facility manager should fully understand the

causes, symptoms, and effects of hyperthermia

which may be described as follows: Hyperthermia

occurs when the internal temperature of the body

reaches a level several degrees above the normal

body temperature of 98.6° F. The symptoms of

hyperthermia include an increase in the internal

temperature of the body, dizziness, lethargy, drowsi-

ness, and fainting. The effects of hyperthermia

include:

1) Failure to perceive heat.

2) Failure to recognize the need to exit the steam

bath.

3) Physical inability to exit the steam bath.

4) Unawareness of impending risk.

5) Fetal damage in pregnant women.

6) Unconsciousness.

WARNING: The use of alcohol, drugs, or medication can

greatly increase the risk of hyperthermia.

II. Warning Sign Installation:

The warning sign shown below and provided with the

generator MUST be permanently installed on the steam

room door or the wall immediately adjacent to the steam

room.

WARNING

1. EXIT IMMEDIATELY IF UNCOMFORTABLE, DIZZY, OR SLEEPY. STAYING TOO LONG INA

HEATEDAREAIS CAPABLE OF CAUSING OVERHEATING.

2. SUPERVISE CHILDRENATALLTIMES.

3. CHECK WITH DOCTOR BEFORE USE IF PREGNANT, DIABETIC, IN POOR HEALTH, OR

UNDER MEDICALCARE.

4. BREATHING HEATEDAIR IN CONJUNCTION WITH CONSUMPTION OFALCOHOL, DRUGS,

OR MEDICATION IS CAPABLE OF CAUSING UNCONSIOUSNESS.

5. DO NOT CONTACT STEAM HEAD OR STEAMATTHE STEAM HEAD.

REDUCE THE RISK OF OVERHEATING AND SCALDING

REDUCE THE RISK OF SLIPPING AND FALL INJURY

1. USE CARE WHEN ENTERING OR EXITING THE STEAM ROOM, FLOOR MAY BE SLIPPERY.

NOTE: FORADDITIONAL SAFETYCONSIDERATIONS SEE OWNERS MANUAL.

!

17"

80 100

120

140

60

40

20

0psi

19"

7¾"

2¾" 1¼"

9"4½" 7"

5½"

2⅜"

15psi

Safety Valve

¾" NPT Outlet

Water

Column

Sight

Glass

Assembly

Steam Outlet

½" NPT

Electrical

Power box

Indicator

Light

Operating

Pressure

Cotnrol

Pressure

Gage

Water Solenoid,

Valve ¼"

Drain Valve ½" NPT

when with manual

drain, 1” when with

optional Auto Drain

Water Inlet,

Strainer

½" NPT

Auxiliary Manual Reset

Pressure Cutoff

Pre-Installation

10/08 Pub. No. 600-A

- 2 -

The Heavy Commercial steam generator (HC-9 thru

HC-18) comes from the factory assembled, carefully

wired, and tested. Please read all instructions before

installing or servicing.

IMPORTANT:

1. All Plumbing and Electrical work must conform to local

and national codes.

2. All power must be OFF to the steam generator when

installing or servicing the unit.

3. Do not use or install unauthorized components,

accessories or products on the generator or its' piping.

III. Pre-Installation:

The following general information should be used in

conjunction with your architect, designer and contractor

in providing a suitable and safe steam room environment

for the steam bathers.

A) Insure that the model steam generator unit

purchased is sized adequately for your steam room.

IMPORTANT: Refer to the specification plate affixed

to the cabinet of the steam bath generator.

B) Be sure to have the proper electrical supply. Deter-

mine proper size of wire, voltage, amperage, and

phase for the steam generator based on the specifi-

cation plate attached to the generator and the chart

in the back of this manual.

C) Provide an inline fuse/circuit breaker as required

sized in accordance with specification plate. Do not

install a GFI Ground Fault Interrupter to this equip-

ment.

D) Select a location to install the generator to allow

sufficient room (See Access Area Requirements) for

access to the unit in the event service is required.

Select a clean dry indoor location protected from

freezing. Do not store flammable materials such as

gasoline, thinners, paints, etc. in the same area as

the steam generator. Do not store corrosive materi-

als such as chlorine near the steam generator.

E) For safe low temperature draining (blow down) of

the steam generator it may be necessary to drain

into an ASME blow down tank. If required additional

space for the tank will be necessary. Consult with

your architect or licensed plumber. The blow down

process can potentially dump boiling water down

the drain and damage the drainage system.

F) The steam generator should be located as close as

possible to the steam room. If the steam generator

is more than ten feet from the steam head, insulate

the steam pipe with appropriate pipe insulation

rated for a minimum of 212ºF.

G) The serial number plate should be visible.

H) The steam room must be completely sealed on all

sides, top and bottom. Floor, walls, and ceiling

should be completely covered with waterproof

material. Floor and bench materials must be slip

resistant.

I) Provide a floor drain inside the steam room for

condensate run-off and steam room cleaning.

J) Only water tight lighting fixtures approved for the

application should be used.

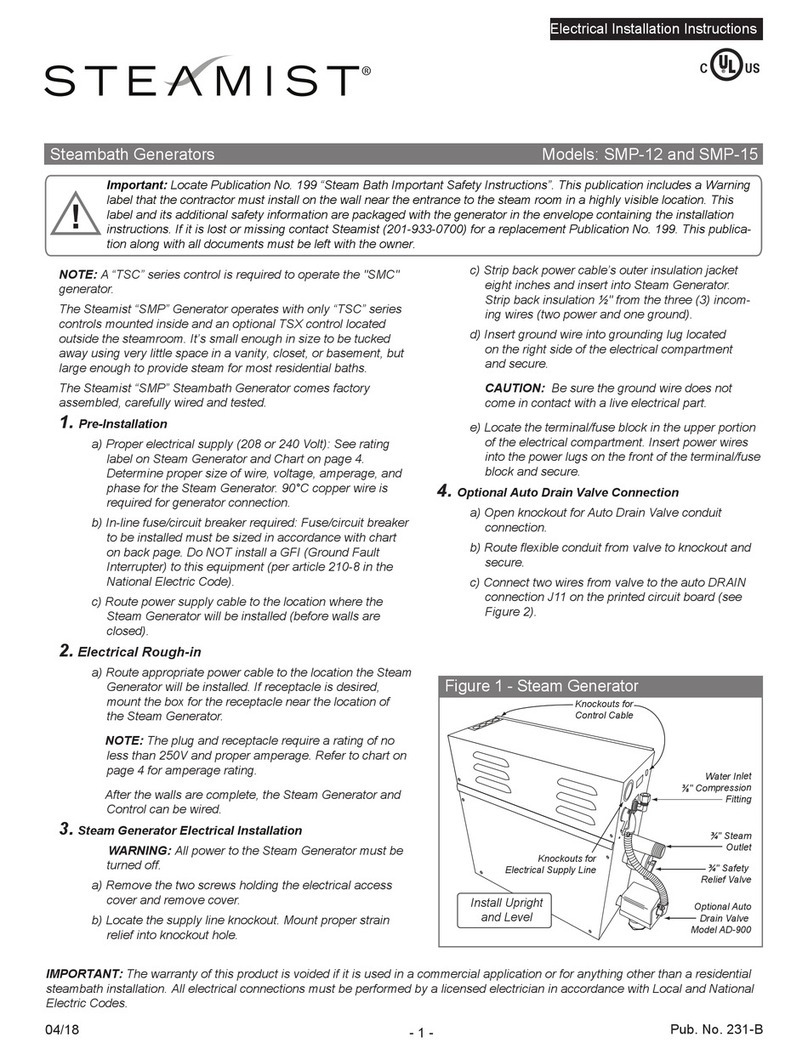

Figure 1 - Dimensional Drawing for Heavy Commercial Steam Generator (HC-9 thru HC-18)

18"

Water Line, ½" NPT - Run

from a cold water pipe.

Provide a local shut-off valve.

Motorized Drain Valve

(Optional) - Use a 1" pipe routed

to an indirect waste line to be

used for the drain.

Safety Relief Valve, ¾" NPT -

Connect to indirect waste or as

required by local codes

Commercial HC Stand

(Optional)

Product Number 68005

Temperature Sensor -

Single tier seating 6 feet

above floor or Double tier

seating 7 feet from the floor

Digital Command Center -

Cable supplied is 50’ in

length. 100’ cable is

available by special order.

Maximum functional cable

length is 100 feet.

User Bypass Control -

Cable supplied is 50’ in length.

100’ cable is available by special

order. Maximum functional cable

length is 100 feet. Steam Outlet,

¾" NPT

Utility RoomSteam Room

Steam Line,

¾" Copper

User Bypass Control Cable

(6-pin Connector)

Digital Command Center Cable

(4-pin Connector)

Female End

To Generator

Female End

To Generator

Male End

To Control

Male End

To Control

Figure 2 - Plumbing Diagram

Rough-In

IV. Rough-In:

A) Plumbing Rough-In:

The heavy Commercial “HC” Steam Generator

requires the following connections: 1/2" NPT piping

for the water inlet, 3/4" copper tubing for steam

outlet, and 3/4" NPT safety valve should be piped to

an indirect waste line. A ½” drain line for a manual

drain or a 1” drain line for an optional auto blow

down assembly must be provided to route to an

indirect waste.

1) Rough-in a ½" water line from a cold water pipe.

Provide a local shut-off valve.

2) Rough-in the steam line using 3/4" copper

tubing. Do NOT use iron or galvanized pipe, it

will rust and discolor wall of steam room. For a

steam line that is longer than 10 feet use an

appropriate pipe insulation rated for a minimum

of 212ºF. The steam head should be located

approximately 18" above the floor and as far

from the bather as possible. Do NOT install

shut-off valves in this line. Do NOT create traps

or valleys in this line which would trap conden-

sation and block the flow of steam.

3) Rough-in a ½” drain line for a manual drain or a

1” drain line for an optional auto blow down

assembly and provide for an indirect waste, to

be used for draining steam generator.The

indirect drain must be in accordance with local

plumbing codes.

4) Rough-in a drain line using ¾" pipe routed to an

indirect waste from the Safety Relief valve. The

discharge end of this pipe must not be

restricted in any way. It must be piped in a way

that would safely discharge steam and/or

boiling water in the event of a failure. Always

follow local plumbing codes.

B) Electrical Rough-in:

1) Route power supply cable to the location where

the steam generator will be installed.

2) Route control cables as described in the Digital

Command Center.

10/08 Pub. No. 600-A

- 3 -

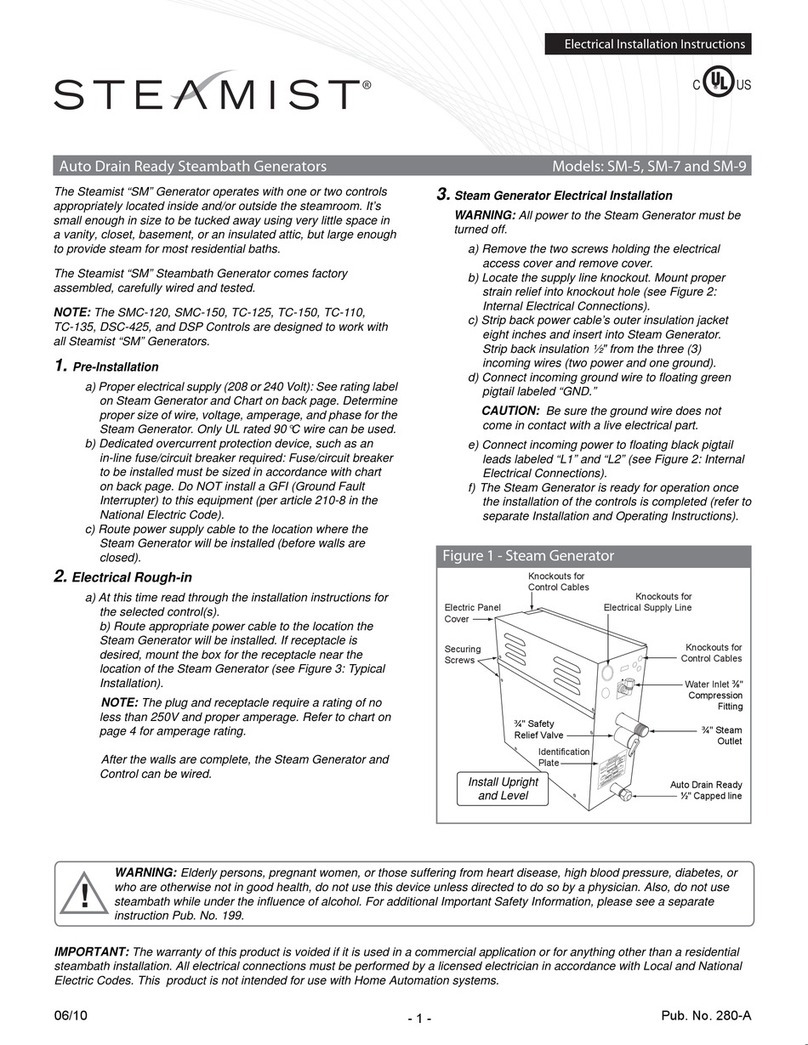

Figure 3 - Typical Steam Generator Installation

Figure 2 - Cables

Rough-In / Installation

C) Digital Commercial Control Package rough- in:

The DCCP is factory wired for either one or two

steam rooms. The following installation instructions

are typical for both room installations. IMPORTANT:

The command center cable, USER BYPASS

CONTROL cable and sensor cable are not the

same and must not be confused. Also the cables

must be routed in the proper direction.

1) Digital Command Center rough-in: Route the

command center cable in the proper direction

from the generator to the selected dry mounting

location convenient to the facility operator.

Make sure the generator end of the cable is

located near the generator mounting location

and the control end is located near the control

mounting location. Important: the cable is 50’

long. 100’ cable is available by special order.

Maximum functional cable length is 100 feet.

2) USER BYPASS CONTROL: Route the USER

BYPASS CONTROL cable in the proper

direction from the generator to the selected

location outside the steam room door. Make

sure the generator end is located near the

generator mounting location and the control

end is located near the control mounting

location. Important: the cable is 50’ long. 100’

cables are available by special order. Maxi-

mum functional cable length is 100 feet.

3) Room Temperature Sensor: Route the tempera-

ture sensor cable in the proper direction from

the generator to the selected location inside the

steam room. For sensor installation and

location, see Figure 3. Make sure the generator

end is located near the generator mounting

location and the sensor end is located near the

sensor mounting location. Important: the cable

is 50’ long. 100’ cables are available by special

order. Maximum functional cable length is 100

feet.

10/08 Pub. No. 600-A

- 4 -

V. INSTALLATION

A) Plumbing Installation: Care must be taken when

installing the steam generator. Leave proper access

for servicing (See Installation Area Requirements).

(Refer to Figure 2 for typical steam generator

installation.) CAUTION: The steam generator is

designed to be used ONLY in an upright and level

position; to do otherwise would damage the unit and

void the warranty. For convenient access mount the

steam generator on the optional Steamist stand

designed specifically for the steam generator.

1) Water supply: Purge the water supply line

before connecting to the steam generator. In

areas where high water pressure may be a

problem a water hammer arrestor should be

installed.

2) Steam line: Connect the steam line from the

previously roughed-in location to the steam

solenoid valve on the generator marked “steam

outlet.” If the generator is equipped to provide

steam to two rooms care must be taken to

make sure the proper steam solenoid is piped

to the proper room.

3) Safety Line: Connect the 3/4" NPT safety valve

into the previously installed indirect waste line.

4) Optional automatic blow down: Pipe into the

3/4" indirect waste line.

5) In the steam room, place the center of the

escutcheon onto the steam pipe and screw the

steam head into place. Care must be taken not

to scratch the steam head or escutcheon with a

wrench. Be sure the steam slot in the steam

head is facing down.

6) The steam, safety, and drain pipes become hot

during operation and should be insulated with

appropriate rated pipe insulation to protect

against accidental contact.

B) Electrical Installation: WARNING ALL POWER TO

THE STEAM GENERATOR MUST BE TURNED

OFF.

1) Locate and remove six (6) screws securing the

access cover to the gray electrical power box.

(See Figure 1.)

2) Locate appropriate knockout found on top of the

gray electrical power box. Mount a proper strain

relief into knockout hole.

3) Strip back the power cable’s outer insulation

jacket twelve inches and insert into gray

electrical power box. Strip back insulation 1/2"

from the incoming wires: single phase (two

power and one ground). 3 phase (three power

and one ground).

4) Insert ground wire into grounding lug located on

the left side wall of the gray electrical power

box. CAUTION: insure ground wire does not

come in contact with live electrical connections.

5) Locate power block found in upper part of gray

electrical power box. Insert power wires into

proper power lug terminals on top of the block

and secure.

ENOCILIS

R

A

EL

C

.Z

O.L

F

2/1

t

eN 02

5

13

.

o

N

m

e

tI

.A

.

S.U

N

I

E

DAM

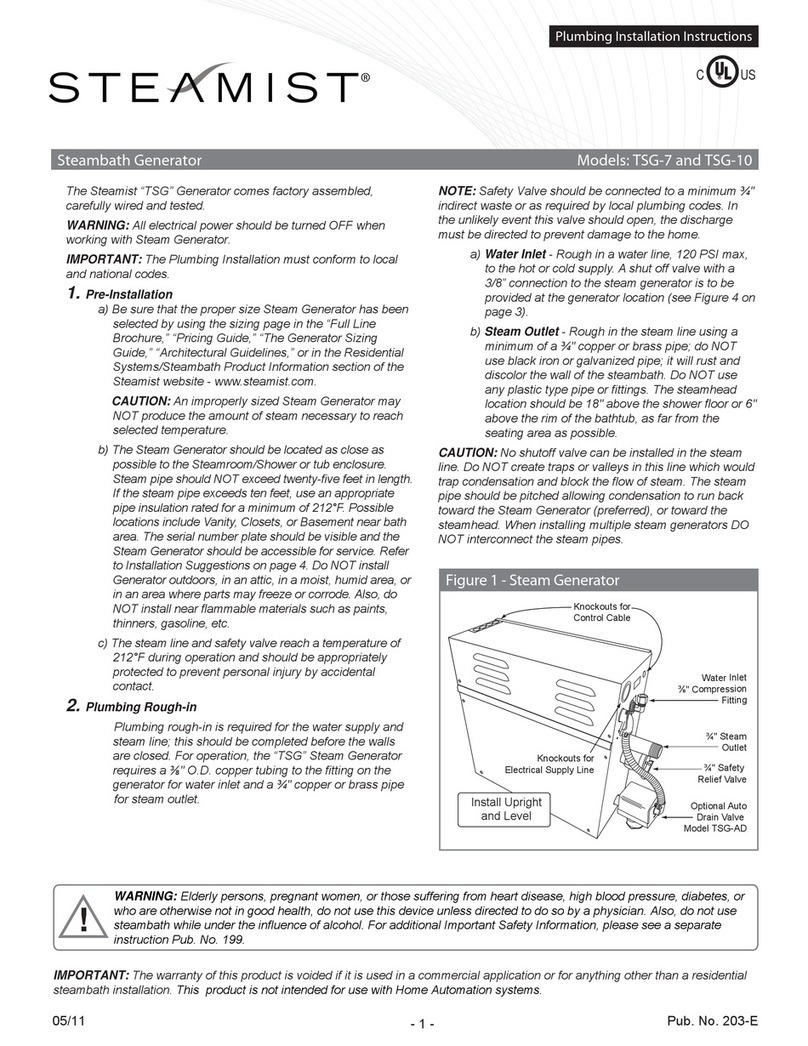

NOTE: Location of the sensor is as follows:

a) Single tier seating - 6 feet above floor.

b) Double tier seating - 7 feet above floor.

No. 8 Plastic

anchors

5/8” Hole

Cable to

Steam Generator

Temperature

Sensor and Housing

(Shipped Assembled)

No. 8 Screws

1” Long

2

3

4

5

STEPS TO INSTALL SENSOR:

1) Take new sensor assembly and connect to 50’

sensor cable. Please observe polarity of the 50’ cable.

Make sure the male end of the cable is routed toward

the sensor in the steam room.

2) Peel off adhesive backing from sensor.

3) Carefully apply silicone sealant around rear edge.

4) Feed wires back into wall and press sensor firmly to

wall (be careful to align plate holes with anchor holes).

5) Install screws, and snap chrome cover back into

place.

6) Temperature sensor assembly must form a 100%

water tight seal to the wall using silicone supplied.

1

50 Foot Sensor Cable

Male end

to Sensor

Female end

to Generator

50’ sensor cable

Figure 3

10/08 Pub. No. 600-A

- 5 -

Digital Command Center Installation

VI. Digital Command Center Installation:

WARNING: All the electrical power to the steam genera-

tor MUST be turned OFF before proceeding with instal-

lation.

A) CONTROL MODULE comes factory wired for either

one or two steam rooms. The following installation

instructions are typical for both room installations.

The configuration for one or two room is set at the

factory. When the generator is configured for two

rooms (SRP-Second Room Package must be

ordered) it will have 2 room temperature sensors

(one per room), two electric steam valves, two

USER BYPASS CONTROLs, and two steam heads.

The electric steam valves will be labeled 1 and 2.

The connections for the sensors, USER BYPASS

CONTROL(s), and aroma pumps, will all be labeled

for room 1 and room 2. It is very important to pay

special attention not get the connection to room 1

and room2 crossed. This will be very difficult to

troubleshoot. If the generator is configured for one

room there will not be any special markings.

B) USER BYPASS CONTROL(s): The USER BYPASS

CONTROL should be located outside the steam

room door convenient to the bather. This control

gives the bather limited control of the steam room.

The system will operate without this control but this

function is lost. See the operating instructions for

further information on this function. Route the USER

BYPASS CONTROL wire from the selected mount-

ing area to the control module on the steam genera-

tor. The USER BYPASS CONTROL mounts to

2-1/8” or 55 mm round hole in the wall.

C) DIGITAL COMMAND CENTER is intended to be

used solely by the manager. It should be located at

a convenient height for programming. It may be

mounted on the wall of the utility room near the

steam generator, in the manager’s office, or the

front desk. The factory supplied wire is 50 feet long,

therefore DCC must be located within its reach.

IMPORTANT: The digital command center is unique

and not to be confused with the USER BYPASS

CONTROL wires or the sensor wires. The Digital

Command Center uses a 4 wire connector, the

USER BYPASS CONTROL uses a 6 wire connector

and the room sensor uses a 2 wire connector.

Route the Digital Commander Center wire from the

selected mounting location to the control module

located on the steam generator. The Digital Com-

mand Center mounts to a hole in the wall 2-1/2”w x

7-7/8”h.

D) Room Temperature Sensor(s): The room tempera-

ture sensor is required for operation. The sensor

must be located in the steam room approximately

six feet above the floor and never closer than one

foot to the ceiling or the corner of the room. Route

the cable from this location to the control module on

the steam generator. The sensor mounts to a 5/8”

hole in the wall.

Figure 4 - Sensor Installation - Inside Steamroom

User Idle/Max Display

Idle/Max Button

Digital Commercial Control Package Operation

VII. Digital Commercial Control Package Operation:

This control is designed to maximize energy savings by

allowing the facility manager set a lower operation

temperature called IDLE TEMP and also satisfy the

steam bather with the ability to by-pass this feature on

demand by pressing the USER BYPASS CONTROL

button. Unlike a typical 24 /7 timer which has only an ON

or OFF mode, the Digital Command Center has three

modes MAX, IDLE and OFF. MAX is the normal ON

mode reserved for peak hours of use when the steam

room is held at the optimum steam bath temperature.

IDLE mode is the energy saving mode. IDLE is set

below the MAX temperature and provides a significant

energy savings. As needed, the steam bather can easily

switch to the MAX setting by pressing the button on the

USER BYPASS CONTROL.

A) USER BYPASS CONTROL: The USER BYPASS

CONTROL button is only functional during the IDLE

mode. In the IDLE mode the USER BYPASS

CONTROL, typically mounted at the entrance to the

steam room, is waiting for the user to press the

button and select the MAX mode. IDLE mode is

indicated on the USER BYPASS CONTROL by one

lit bar. Pressing the USER BYPASS CONTROL

button starts the MAX CYCLE TIMER and immedi-

ately begins to heat the room to the MAX setting.

This temporary MAX CYCLE TIMER is program-

mable up to 60 minutes by the facility manager.

MAX TEMP mode is indicated by all bars lit. When

the Digital Command Center is set to MAX TEMP

the USER BYPASS CONTROL icon displays max

(all bars lit). In the MAX TEMP mode the USER

BYPASS CONTROL buttons do not function. When

the DIGITAL COMMAND CENTER is in the OFF

mode the USER BYPASS CONTROL icon will be off

(no bars lit) and the user buttons do not function.

B) Programming the DIGITAL COMMAND CENTER

can be broken down into 3 separate sections, SET

EVENT, SET VALUE, and SET CLOCK. The

buttons on the control are grouped accordingly. SET

EVENT is used to set the time and day that a

particular mode (MAX, IDLE, or OFF) is to begin.

SET VALUE is intended to set the MAX and IDLE

temperature as well as the MAX CYCLE TIMER.

The SET CLOCK section is only for adjustment of

the current time and day. The DIGITAL COMMAND

CENTER display light comes on when any button is

pressed. The light will remain on for 5 minutes after

the last button is pressed.

1) SET CLOCK: The SET CLOCK section of the

Digital Command Center is used exclusively for

setting the current time and day. It is a conve-

nient place to make changes for daylight

savings time without having to reprogram other

settings. The clock has a battery backup in the

Control Module that will keep time for up to one

year with no power.

(a) DAY Setting: Press the lower DAY button

to toggle the current day of the week.

(b) HOUR Setting: Press the lower HOUR

button to select the current AM or PM hour

and the correct hour will be displayed.

(c) MINUTE setting: Press the Lower MINUTE

button until the correct minute is displayed.

2) SET VALUE: The SET VALUE section of the

keypad is used to program the following 4

parameters:

(a) MAX1 TEMP is used to set the maximum

desired operating temperature of the

steam bath. It is set by pressing the button

until the preferred maximum temperature is

displayed. Note: The MAX TEMP cannot

be set lower than the IDLE TEMP. Selec-

tion of the MAX TEMP setting is at the

discretion of the facility manager.

(b) MAX2 TEMP (only available with SRP) is

used to set the desired operating tempera-

ture of a second steam room. It is

programmed the same as MAX1 TEMP.

(c) IDLE TEMP is used to program a lower

temperature setting during periods of less

frequent usage. It is set by pressing the

button until the desired set-back tempera-

ture is displayed. The feature can be

disabled by setting it to 00.The IDLE TEMP

cannot be set higher than the lowest MAX

TEMP value.

10/08 Pub. No. 600-A

- 6 -

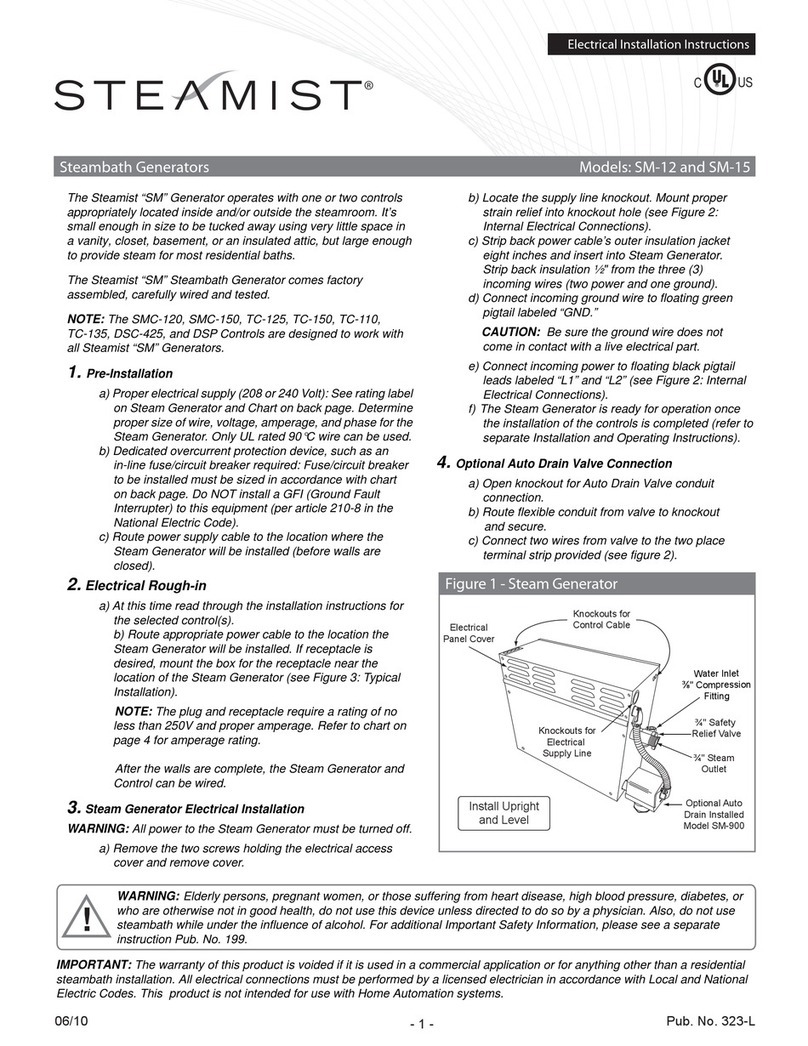

Figure 5 - User Control Panel

Daily Program Number

Keypad lock

Clock

Max Temperature/Current

Temperature for Room 1

Idle Temp

24/7 Event Programming

buttons

Timer/Temperature setting

buttons

Lock Button

Time of day setting

Max/Idle/Off mode indicator

Day of the week indicator

AM/PM indicator

Max Temperature/Current

Temperature for Room 2

0-60 Minute Max Cycle Timer

Digital Commercial Control Package Operation

3) SET EVENT: Before programming the SET

EVENT, it is necessary to determine the hours

the steam bath will operate and in which mode.

Each day of the week can have up to six events

programmed. The chart on the following page

will help organize your plan for the SET EVENT

function. The top 2 sections of the chart are

filled in with 2 examples

10/08 Pub. No. 600-A

- 7-

(d) MAX CYCLE TIMER is used to set the

duration that the system will be in MAX

TEMP mode after the USER BYPASS

CONTROL button is pressed in. It is set by

pressing the corresponding button on the

Digital Command Center. Each time the

button is pressed the minutes will increase

in one minute increments from “:00” to

“:60”. If the MAX CYCLE TIMER is

programmed to “:00”, this feature will be

disabled and the USER BYPASS

CONTROL(S) will be disabled.

(e) Degree °C or °F change is made by

placing a jumper over the CN109 pins for

°C or by removing it for °F (Jumper not

included). The power must be OFF when

making this change. See Command

Module on Wiring Diagram page 11.

Figure 6 - Main Control Panel

10/08 - 8 -

Digital Commercial Control Package Operation

Pub. No. 600-A

EXAMPLE 1 shows the club opening at 7AM. Assuming

it is not busy the first hour so the mode is selected as

IDLE. Then at 8AM it gets busy and the program

switches to MAX. At 10AM it slows down again and the

control switches back to IDLE. Then at 3PM it gets busy

again and switches to back to MAX. At 7PM we switch

back to IDLE and 10PM the club closes.

EXAMPLE 2 shows the club opening a 7AM and set to

IDLE all day until 10PM when the club closes. This

would yield maximum energy savings and is the recom-

mended program.

At any time the system is in IDLE mode the user can

activate the MAX TEMP mode by pressing the USER

BYPASS CONTROL button.

Photo copy the chart and use it as a work sheet to plan

you settings:

PROG # 1 2 3456

EXAMPLE 1 MAX

IDLE

OFF XXXXXX

TIME 7:00AM 8:00AM 10:00AM 3:00PM 7:00PM 10:00PM

PROG # 1 2 3456

EXAMPLE 2 MAX

IDLE

OFF XX

TIME 7:00AM 8:00AM 10:00AM 3:00PM 7:00PM 10:00PM

TU

MAX

IDLE

MAX

IDLE

FR OFF

OFF

TIME

SU MAX

IDLE

OFF

MAX

OFF

TH

IDLE

MO

WE

SA MAX

IDLE

OFF

PROG # 1 2 3456

TIME

TIME

TIME

TIME

TIME

TIME

MAX

IDLE

OFF

MAX

IDLE

OFF

Digital Commercial Control Package Operation

10/08 Pub. No. 600-A

- 9 -

4) Programming SET EVENT: To program the

SET EVENT section, first press the PROG#

button on the Digital Command Center. The

display will flash the current program number

and show the start time of that program. The

program can only be changed while flashing. To

enter a new program, first press the DAY button

in the upper SET EVENT section to choose the

individual day or a block of days (i.e. M-TU-W-

TH-F, or SU-M-TU-W-TH-F-SA). With the

proper day(s) selected, set start time for

program 1 using the upper HOUR and MIN

buttons. Be sure to select the proper AM or PM

hour. Then press the MAX/IDLE/OFF button to

choose the mode for program 1. Program 1 is

complete. Press PROG# button to get to

program 2. Enter the start time of program 2

and select the mode. You are only program-

ming the start time of each program. The end

time is automatically the start time of the next

program. The last program entered is limited to

11:59PM. If the facility operates beyond

midnight, program 1 of the next day must be

set to 12:00 AM for continuous operation.

Follow the same process for all the programs

and days of the week. To exit the programming

mode, press the ENTER button or wait 30

seconds and it will stop blinking and your

changes will be saved. The DIGITAL COM-

MAND CENTER needs a minimum of two

programs per day to function as shown in

EXAMPLE 2. The first must be IDLE or MAX

and the last program must be OFF mode. Note:

Programs 1 through 6 are sequential and

therefore it will not be possible to set a new

program before the end of the previous

program.

(a) Programming Tip: To modify an existing

program press the PROG# button and the

upper DAY button to get to highlight the

program you want to change. Then modify

the setting with the appropriate button.

Entries will be saved automatically in 30

seconds or by pressing the enter button.

(b) Programming Tip: If the facility operates

on nearly the same schedule every day, it

may be easier to program all seven days to

the same common program and then go

back and program Sunday to be off if the

facility is closed that day.

(c) Programming Tip: You can review your

program by pressing the PROG# button

and toggling through the programs and

toggling through the days of the weeks,

and observing the time settings. If you

made no changes simply press the enter

button to return to normal or it will return in

30 seconds.

(d) Programming Tip: When reviewing the

program and a block of days are selected,

if all the individual programs for those days

do not match, the clock will display --:--.

This is normal and any adjustments made

at this time will reprogram all days selected

to match the new entry.

5) Manager lock function: The Digital Command

Center has a locking feature that prevents any

setting to be changed when locked. To lock the

control, press the lock button, the lock icon will

flash for up to 30 seconds. While the icon is

flashing, press any three consecutive buttons,

and then press the lock button again to confirm.

The three consecutive buttons pressed are the

password. The system control will be locked

and the lock icon will be on steady. To unlock,

press the lock button and then press the same

three consecutive buttons as the previous

password, the system will be unlocked and the

lock icon will disappear. If the password is lost

or forgotten, it can be reset. This will require

two people. Turn off the main power (circuit

breaker), have a second person then press and

hold the lock button on the Digital Command

Center while the first person turns the power

back on. The system will be unlocked. Also see

the reset section for an alternate method (step

11).

6) Temporary Mode setting: By pressing

IDLE/MAX/OFF button on the Digital Command

Center you can temporarily change the current

mode (IDLE/MAX/OFF). This is only a tempo-

rary change until the next programmed event.

7) Auto-Blow Down: The optional auto-blow down

becomes active in the OFF mode. When first

entering OFF mode, the steam valves will

deactivate and the generator will continue to

maintain normal pressure. After 5 minutes the

generator will shut down and the drain will

open. Boiling water will exit under pressure and

the water valve will turn on to help flush the

generator. After 2 minutes the drain will close

and the generator will refill. After a total of 7

minutes the generator is ready to start a new

cycle. If the facility is operated 24 hours a day,

a 7 minute OFF mode should be programmed

in to allow for a proper drain cycle. In areas

where the water is hard, a second drain cycle

can be programmed by adding an extra 7

10/08 Pub. No. 600-A

- 10 -

Digital Commercial Control Package Operation

minute OFF mode during an “Off-Peak” daytime

period. IMPORTANT: Due to possible code

violations or damage to the building drainage

system the hot boiling water exiting in this

process may require a Blow-Down Tank.

Consult with your licensed contractor. Blow-

Down tanks may be purchased separately.

8) Steam Control: The steam valve(s) are

controlled according to the room temperature

sensor(s) and the programmed mode. When

the room temperature is lower than the set

temperature by one degree the steam valve will

turn on. When it reaches the set temperature it

turns off. If for some reason the room tempera-

ture exceeds the MAX TEMP setting (of either

room) by more than 10 degrees the Digital

Command Center will turn off the generator

until that room temperature drops to 1 degree

below the set temperature.

9) Aroma Control: There are two aroma control

relays (one for each room) located in the

Command Module on the generator. These

relays can be used with most aroma pumps

available. The relays are programmed to

conserve aroma therapy oil. The relays are only

on when the following conditions are met. The

program for that room must be in the MAX

mode, the steam valve for that room must be

on and the temperature in that room must be

above the IDLE setting. When all these condi-

tions are met, then the aroma relays will

energize.

10) Fahrenheit and Celsius: The Fahrenheit or

Celsius temperature can be selected by

changing a jumper in the Command Module

(CN109). When it is not connected (open

circuit), it will be Fahrenheit. When it is

connected, it will be Celsius. The Jumper must

be switched with power off (See wiring diagram

on page 11).

11) Reset Feature: If it is ever necessary to reset

all the programs and start over press and hold

the PROG# button and the lower MIN button for

five seconds simultaneously. This will reset

every setting in the Command Center. This

process can also be used to unlock the control

if the password is lost or forgotten.

Model

No. Product

No. KW

Volts/

Phase/

Amps

Wire Size

90ºC

Copper AWG

Shipping

Weight

HC-9

HC-12

HC-15

HC-18

Specifications Chart

60900

60901

60902

60903

60904

61200

61201

61202

61203

61204

61500

61501

61502

61503

61504

61800

61801

61802

61803

61804

9

12

15

18

Max.

Cu. Ft.

400

500

620

740

240/1/38

208/1/43

240/3/22

208/3/25

480/3/11

240/1/50

208/1/58

240/3/29

208/3/33

480/3/15

240/1/63

208/1/72

240/3/36

208/3/42

480/3/18

240/1/75

208/1/87

240/3/43

208/3/50

480/3/22

8

6

10

8

14

6

4

8

8

12

4

4

8

6

10

3

3

6

6

10

Water

Inlet Steam

Outlet

Dimensions

22-1/2”x19”x28”

22-1/2”x19”x28”

22-1/2”x19”x28”

22-1/2”x19”x28”

140 lbs.

150 lbs.

150 lbs.

150 lbs.

1/2” NPT

1/2” NPT

1/2” NPT

1/2” NPT

3/4” NPT

3/4” NPT

3/4” NPT

3/4” NPT

Line

Fuse

50

60

30

35

15

70

80

40

45

20

80

90

45

60

25

100

110

60

70

30

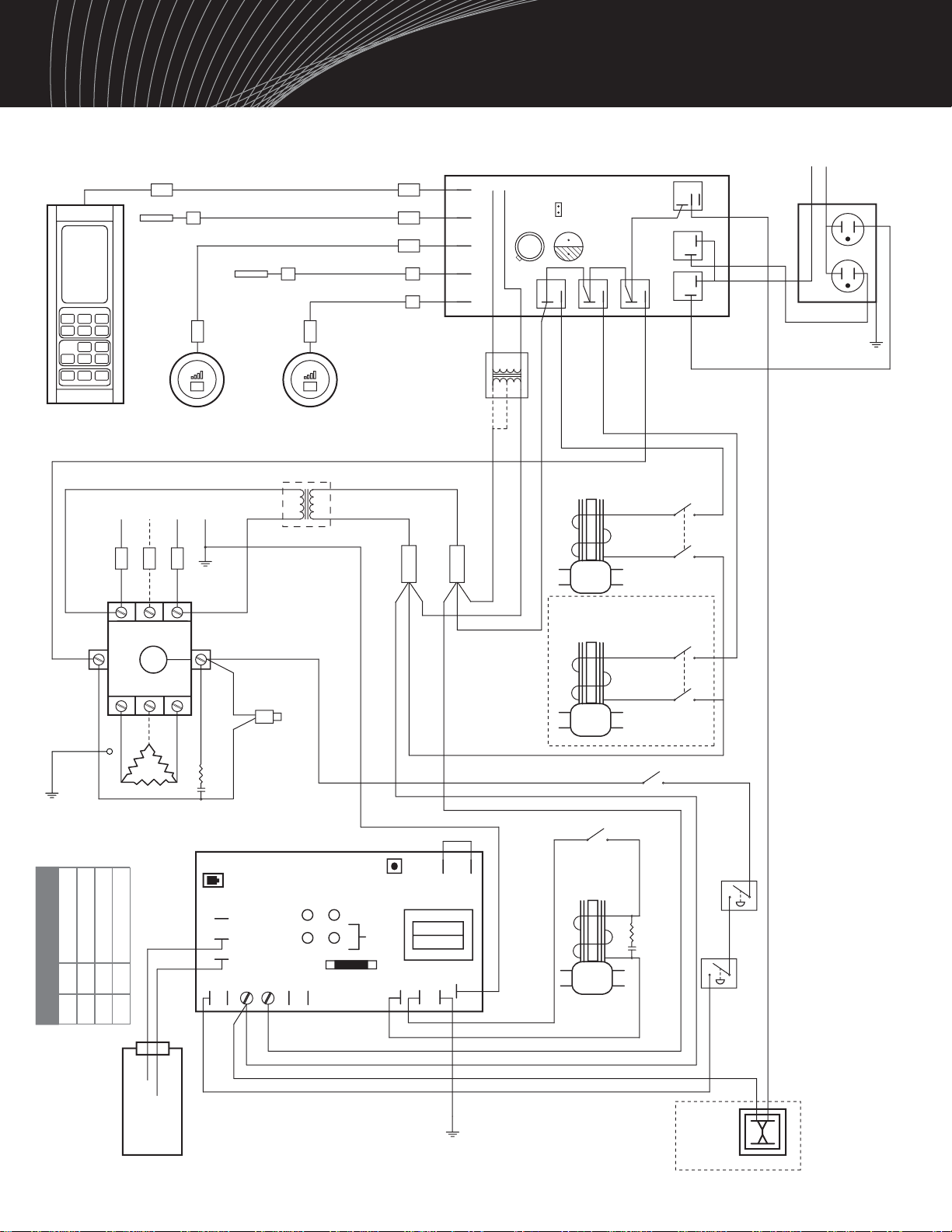

LLC-1300-6 Circuit Board

P14

P12

P11

P10

P1

P2

P6

P8

P7

P9

P4

P3

P5

L

H

XL

P18 P17

DS1

DS2

DS3

DS4

See

Chart

Test

Switch

Fuse 0.15 AMP

L1

L3

L2

T2

T1

T3

COIL

50’ Cable

50’ Cable

Digital

Command

Center

User

Bypass

Control 2

User

Bypass

Control 1

Room

Sensor 1

Room

Sensor 2

Transformer

For 480V Units

Steam Solenoid

Valve 1

Optional

Steam Solenoid

Valve 2

12V Class 2

Transformer

Steam

Switch 1

Steam

Switch 2

Incoming

Power

Fuses

Contactor

Red Heat

Light Heater Switch

Water Switch

Water

Solenoid

Pressure

Control

Optional

Auto

Blowdown

Water

Sensor

Tube

Command Module

Control

Fuses

YL

GN

GN

BN

BK

BK

RD

RD

BK

RD

OR

VT

YL

RD

GY

VT

BN

BN BK

BL

BL

RD

BK

BL

BN

BK

RD

WT

GY

Steam1

Steam2

Heater

Aroma1 Aroma2

Drain

120V, 15AMP

Branch Circuit

HN

1

2

BK14

WT14

RD14

RD14

Pressure

Limit

Control

F2 F1

50’ Cable

50’ Cable

50’ Cable

CN102

CN105

CN103

CN106

CN104

*CN109

Back up

Battery

*Note: CN109 Jumper open = F° Jumper closed = C°

Turn OFF power if making this change

RDRD

BK

BK

BN

Note: All factory wires are 18AWG unless otherwise noted.

Power and heater wire gauge are set by the factory.

BK14

CN101 12VAC

YL

YL

RD

BK

BL

**

** Note: Select

BL for 240V

RD for 208V

GN12

Note: Ground

must be on a

heater flange bolt

GN

BK14

Snubber

Snubber

10/08 Pub. No. 600-A

- 11 -

Wiring Diagram

DS1

DS2

DS3

DS4

GRN

YEL

AMB

RED

TIMER ON

HEAT ON

WATER FILL ON

POWER ON

LED Color Chart

Other manuals for HC-9

2

This manual suits for next models

23

Table of contents

Other Steamist Iron manuals