SteelMax SM-BM-21S User manual

15335 E. Fremont Drive, Centennial, CO 80112

1–87STEELMAX, FAX 303 –690 –9172

www.steelmax.com [email protected]

OPERATOR’S MANUAL

S

SM

M-

-B

BM

M-

-2

21

1S

S

BEVELING MACHINE

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Dimensions................................................................................................................ 4

1.4. Design ....................................................................................................................... 5

1.5. Equipment included ................................................................................................... 6

2. SAFETY PRECAUTIONS.................................................................................................. 7

3. STARTUP AND OPERATION........................................................................................... 9

3.1. Preparing................................................................................................................... 9

3.1.1. Adjusting the bevel angle and width................................................................. 9

3.1.2. Using the cutting fluid.....................................................................................10

3.2. Adapting for 150–300 mm pipes ...............................................................................11

3.3. Adapting for 300–600 mm pipes (option)...................................................................14

3.4. Operating..................................................................................................................15

3.5. Replacing the cutting inserts.....................................................................................17

3.6. Replacing the milling head........................................................................................18

4. SPARE AND WEARING PARTS......................................................................................19

5. ACCESSORIES...............................................................................................................20

5.1. Guide for 300–600 mm pipes....................................................................................20

5.2. Cutting tools..............................................................................................................20

6. WIRING DIAGRAM..........................................................................................................21

7. EXPLODED DRAWINGS AND PARTS LIST....................................................................22

8. DECLARATION OF CONFORMITY.................................................................................26

9. WARRANTY CARD..........................................................................................................27

SM-BM-21S

SM-BM-21 Operator’s Manual

3

1. GENERAL INFORMATION

1.1. Application

The BM-21S is a beveling machine designed to bevel stainless steel. The machine

can bevel plates, as well as pipes with outer diameters of 150–300 mm (6–12″), at an

angle of 0–60° and with the bevel width of up to 21 mm (13/16″). Also, the machine

contains dampers to reduce vibrations.

When equipped with an optional guide, the machine can bevel pipes with outer

diameters of 300–600 mm (12–24″).

1.2. Technical data

Voltage

1~ 220–240 V, 50–60 Hz

1~ 110–120 V, 50–60 Hz

Power

1600 W (for 50 Hz)

1800 W (for 60 Hz)

Rotational speed

1360–1630 rpm (at 230 V)

1300–1560 rpm (at 115 V)

Protection level

IP 20

Protection class

I

Milling speed

270 m/min (900 ft/min, for 50 Hz)

320 m/min (1050 ft/min, for 60 Hz)

Maximum bevel width (b)

21 mm (13/16″, Fig. 1)

Bevel angle (ß)

0–60° (Fig. 1)

Weight

23 kg (51 lbs)

Fig. 1. Bevel dimensions; maximum bevel width depending on the angle

β

0°

30°

45°

60°

b

21 mm

18.5 mm

21 mm

18.5 mm

SM-BM-21S

SM-BM-21 Operator’s Manual

4

1.3. Dimensions

441 mm (17.4″)

339 mm (13.4″)

366 mm (14.4″)

SM-BM-21S

SM-BM-21 Operator’s Manual

5

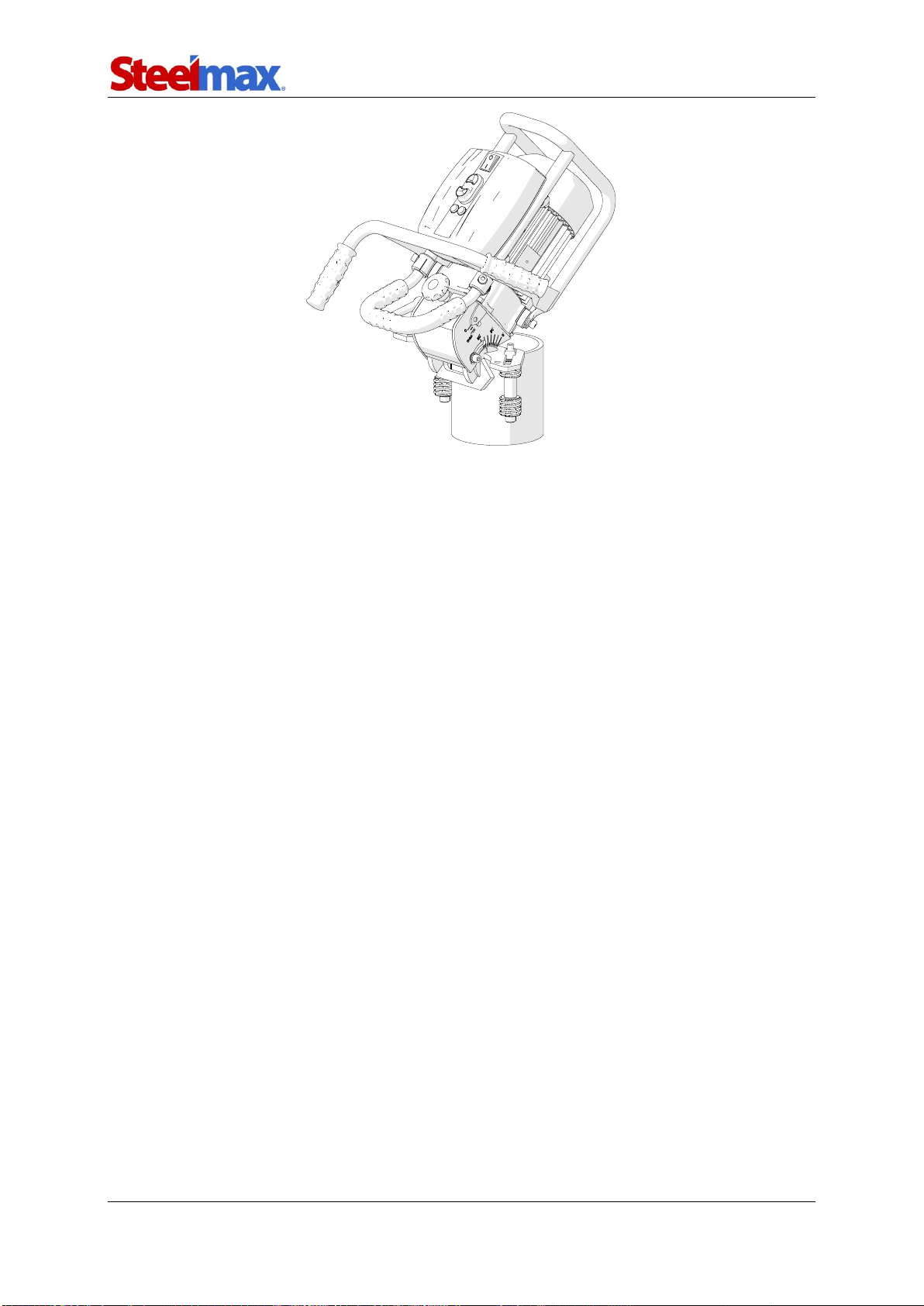

1.4. Design

Fig. 2. View of the machine and the control panel

Depth knob

Bevel width scale

Bevel angle scale

Screws locking the bevel angle

Depth lock lever

Power switch

START

STOP

Operating

mode

lamp

Overload lamp

Guide set

Milling

head

Milling

head

cover

SM-BM-21S

SM-BM-21 Operator’s Manual

6

1.5. Equipment included

1

Beveling machine

1 unit

2

Cutting insert

10 units

3

Metal box

1 unit

4

8 mm hex wrench

1 unit

5

6 mm hex wrench

1 unit

6

4 mm hex wrench

1 unit

7

12 mm flat wrench

1 unit

8

T15P torx screwdriver

1 unit

9

Oil for stainless steel

1 unit

10

Grease for screws

1 unit

–

Operator’s Manual

1 unit

1

2

4

5

6

7

8

9

3

10

SM-BM-21S

SM-BM-21 Operator’s Manual

7

2. SAFETY PRECAUTIONS

1. Before use, read this Operator’s Manual and complete a training in occupational

safety and health.

2. Use only in applications specified in this Operator’s Manual.

3. Make sure that the machine has all parts and they are genuine and not damaged.

4. Make sure that the specifications of the power source are the same as those

specified on the rating plate.

5. Connect the machine to a correctly grounded power source.

6. Do not pull the cord. This can cause damage and electric shock.

7. Keep untrained bystanders away from the machine.

8. Before each use, ensure the correct condition of the machine, power source,

power cord, plug, control parts, and milling tools.

9. Before each use, make sure that no part is cracked or loose. Make sure to

maintain correct conditions that can have an effect on the operation of the

machine.

10. Keep the machine dry. Do not expose the machine to rain, snow, or frost.

11. Keep the work area well-ventilated, well-lit, clean, and free of obstacles.

12. Do not use near flammable materials or in explosive environments.

13. Use only tools specified in this Operator’s Manual.

14. Do not use tools that are dull or damaged.

15. Make sure that the cutting inserts and the milling head are correctly attached.

Remove wrenches from the work area before you connect the machine to the

power source.

16. If the cutting edge of an insert is worn, rotate all inserts by 90°. If all edges are

worn, install new inserts specified in this Operator’s Manual.

17. Use eye protection, ear protection, respiratory protective devices, non-skid

footwear, gloves, and protective clothing. Do not use loose clothing.

18. Do not touch chips or moving parts. Do not let anything catch in moving parts.

19. After each use, clean the machine and the milling head with a cotton cloth and no

chemical agents. Do not remove chips with bare hands.

20. If you are not going to use the machine for an extended period, put anti-corrosion

material on the steel parts.

SM-BM-21S

SM-BM-21 Operator’s Manual

8

21. Maintain the machine and install/remove parts and tools only after you unplug the

machine from the power source.

22. Repair only in a service center appointed by the seller.

23. If the machine falls, is wet, or has any damage, stop the work and promptly send

the machine to the service center for check and repair.

SM-BM-21S

SM-BM-21 Operator’s Manual

9

3. STARTUP AND OPERATION

3.1. Preparing

3.1.1.Adjusting the bevel angle and width

Unplug the machine from the power source. Start with setting the bevel width to zero.

To do this, loosen the lock lever (Fig. 3), rotate the knob to set ‘0’ on the bevel width

scale, and tighten the lever.

Fig. 3. Initial setting the bevel width to zero

To set the required bevel angle (Fig. 4), use the 6 mm hex wrench to loosen two side

screws. Rotate the guide set to get the required angle on the scale, and tighten the

screws in this new position.

Fig. 4. Setting the bevel angle (45° is set on the drawing)

SM-BM-21S

SM-BM-21 Operator’s Manual

10

After you set the bevel angle, use the depth knob to adjust the bevel width. The width

scale shows only a rough value because the bevel width varies with the angle. For

example, for 10° the maximum width b(Fig. 1) is about 18 mm (11/16″), while the

width scale shows about 9 mm (6/16″). Increasing the depth at this angle will distort

the bevel. The maximum bevel width (b = 21 mm, 13/16″) is for 45°. Find the required

bevel width for the required angle in practice. To do this, gradually increase the

penetration of the milling head into the workpiece.

3.1.2.Using the cutting fluid

Before you bevel stainless steel, put the supplied oil onto the workpiece as shown in

Fig. 5.

Fig. 5. Preparing the edges for beveling stainless steel

Oil for stainless steel

SM-BM-21S

SM-BM-21 Operator’s Manual

11

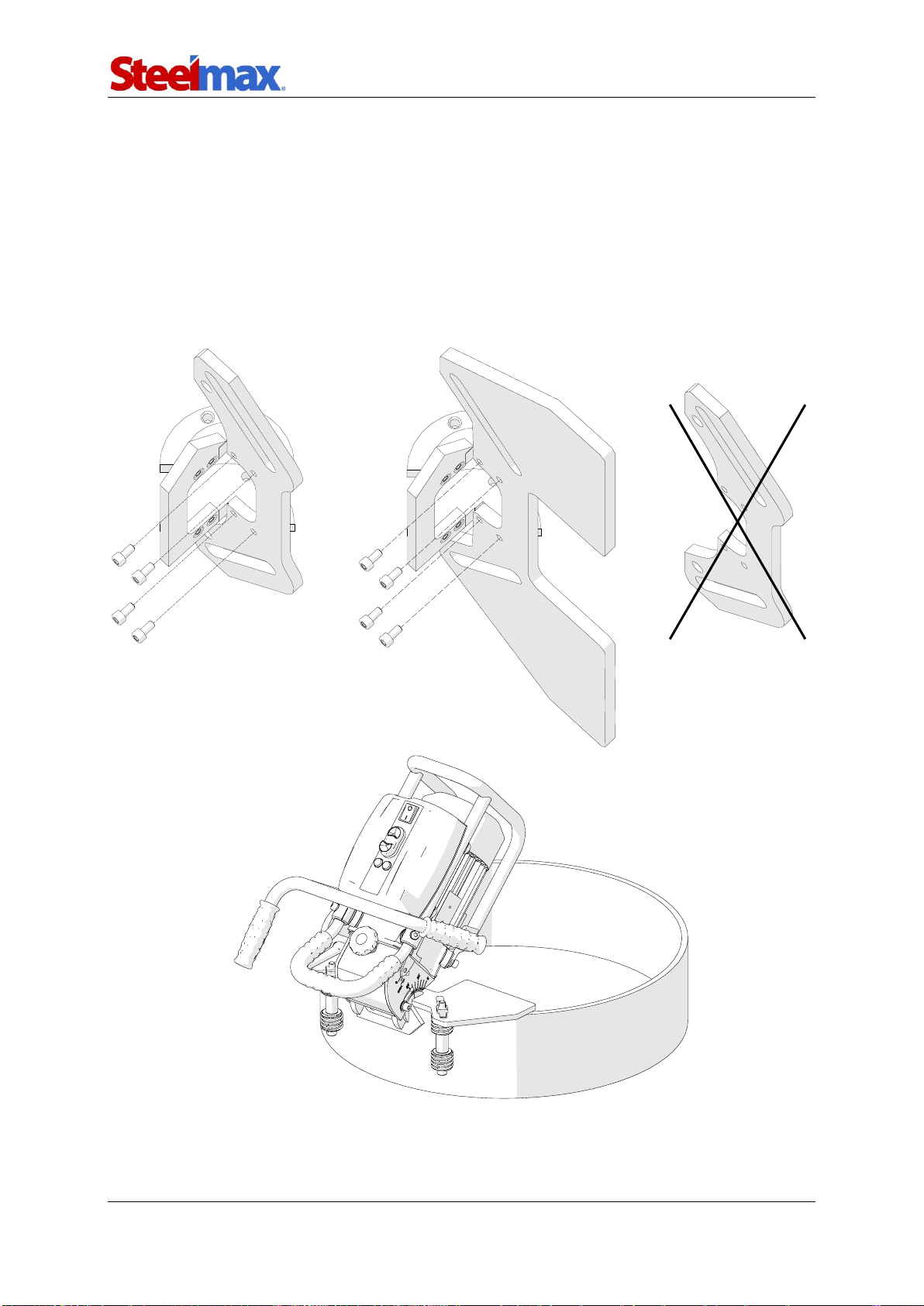

3.2. Adapting for 150–300 mm pipes

To bevel pipes with diameters of 150–300 mm (6–12″), assemble the standard guide

set in a different way. To do this, use the 6 mm hex wrench to remove two side

screws (1, Fig. 6) and remove the guide set (2). Remove the set by 180° around the

vertical axis (3), install again (4), and attach with the screws (1).

Fig. 6. Rotating and installing the guide set

Use the 12 mm flat wrench to prevent the turn of the T-nut and use the 8 mm hex

wrench to remove the roller screw. Next, move the rollers from the hole (Fig. 7a) to

the slot. Install the rollers as shown in Fig. 7b and put the T-nut into the slot.

1

2

4

3

1

SM-BM-21S

SM-BM-21 Operator’s Manual

12

Fig. 7. Moving the rollers from the hole to the slot

Loosen the depth lock lever (Fig. 8) and rotate the depth knob to set ‘0’ on the bevel

width scale. Then, move the rollers away from each other as far as possible.

Fig. 8. Initial setting the bevel width to zero and separating the rollers

Put the machine on a vertical pipe so that the surfaces of the guide set are in contact

with the face and side of the pipe. Then, move the rollers symmetrically to make

them contact the pipe (Fig. 8) and tighten them in this position. Set the required bevel

angle and width as described before.

Roller screw

a)

b)

SM-BM-21S

SM-BM-21 Operator’s Manual

13

Fig. 9. Machine prepared for work on pipes with diameters of 150–300 mm (6–12″)

SM-BM-21S

SM-BM-21 Operator’s Manual

14

3.3. Adapting for 300–600 mm pipes (option)

To bevel pipes with diameters of 300–600 mm (10–24″), assemble the guide set by

using an optional guide. To do this, remove the guide set (1, 2, Fig. 6) and use the

4 mm hex wrench to remove the standard guide. Then, assemble the guide for 300–

600 mm pipes (Fig. 10) and tighten with the screws. Install the rollers and adjust the

required bevel angle and width as described before.

Fig. 10. Machine prepared for work on pipes with diameters 300–600 mm

Part number:

PRW-0505-03-00-00-0

SM-BM-21S

SM-BM-21 Operator’s Manual

15

3.4. Operating

After you set the bevel angle and width, connect the machine to a correctly grounded

power source. Put the machine on the right so that the rollers are on the plate. Keep

a gap between the milling head and the plate (Fig. 11).

Fig. 11. Machine correctly put on the workpiece

Set the power switch to ‘I’ and press the green START button to start the motor.

Move the machine to the plate and bevel by moving the machine to the left.

Constantly press the machine to the plate.

Beveling is done according to the counter-rotation. The rotation direction of the

milling head is marked on the motor disk under the cover of the milling head.

The feed rate depends on the profile and composition of the workpiece.

Most steels capable of being welded can be beveled in one pass. However,

make bevels wider than 12 mm (1/2″) in at least two passes. This will require less

effort and time than if you bevel in a single pass.

To get the maximum bevel width (21 mm, 13/16″) in two passes, make the first

bevel width of about 14 mm (9/16″). For three passes, make the first bevel width of

about 12 mm (1/2″) and the second of about 16 mm (5/8″).

If an overload occurs because of, for example, too fast feed, the red overload

lamp comes on. If you continue work in such a case, the motor stops. Then, move

the machine away from the plate and set the power switch to ‘O’ to turn off the

power. Next, wait until the overload lamp comes off, and turn on the power again.

STOP

Feed direction

Power switch

START

Start the motor and move to the plate

SM-BM-21S

SM-BM-21 Operator’s Manual

16

You can work near the overload (when the red lamp flashes), but do not let the

motor temperature increase more than 85°C (185°F). This can lead to damage of the

motor windings. After each hour of work under full load, stop the motor for 10–

15 minutes. Do not try to decrease the motor temperature by working without load.

The motor will then get hotter than when working with load.

After the work is finished, press the STOP button to stop the motor. Then, set the

power switch to ‘O’. Use petroleum ether to clean oil from the workpiece.

Clean the machine with a cotton cloth and no chemical agents.

SM-BM-21S

SM-BM-21 Operator’s Manual

17

3.5. Replacing the cutting inserts

Unplug the machine from the power source. Remove the lever (1, Fig. 12), the

indicator (2), and the milling head cover (3).

Fig. 12. Removing the milling head cover

Use the supplied T15P screwdriver to remove the fixing screw (Fig. 12), remove the

insert, and clean the socket. Rotate the insert by 90° and install again or replace to a

new one if all four edges are worn. To replace an insert from the internal ring, first

remove the insert from the external ring.

Fig. 13. Replacing the cutting inserts

2

1

3

Fixing screw

SM-BM-21S

SM-BM-21 Operator’s Manual

18

When you make bevels of low width, the cutting inserts wear only on one, inner

corner. Then, the good thing is to change the inserts between the milling cutters

(Fig. 7). This will extend the life of the inserts.

Fig. 14. Changing the cutting inserts between rings

3.6. Replacing the milling head

Remove the milling head cover as shown in Fig. 12. Use the 32 mm flat wrench to

prevent the turn of the spindle (Fig. 15). Then, use the 8 mm hex wrench to remove

the screw, and remove the milling head. The 32 mm flat wrench is not included in

standard equipment.

Fig. 15. Replacing the milling head

Worn corners

SM-BM-21S

SM-BM-21 Operator’s Manual

19

4. SPARE AND WEARING PARTS

Name

Number

Milling head (including fixing screws and screwdriver;

10 inserts required)

GLW-0461-03-00-00-0

Cutting insert (sold 10 per box)

PLY-000282

Fixing screw for inserts

SRB-000311

T15P torx screwdriver for fixing screws

WKT-000005

Grease for screws (5 g, 0.17 oz)

SMR-000005

Oil for stainless steel (0.5 kg, 1.1 lbs)

OLJ-0505-09-00-00-0

Oil for stainless steel (1 kg, 2.2 lbs)

OLJ-0505-10-00-00-0

Oil for stainless steel (5 kg, 11 lbs)

OLJ-0505-11-00-00-0

SM-BM-21S

SM-BM-21 Operator’s Manual

20

5. ACCESSORIES

5.1. Guide for 300–600 mm pipes

5.2. Cutting tools

Part number

Part name

PLY-000591

Cutting insert (10 required, sold 10 per box)

Part number:

PRW-0505-03-00-00-0

Other manuals for SM-BM-21S

1

Table of contents

Other SteelMax Power Tools manuals

Popular Power Tools manuals by other brands

Omer

Omer D.18 Roll Use, maintenance and spare parts manual

Würth

Würth ANG 310 Original operating instructions

SCOPREGA

SCOPREGA TURBO MAX 12 V instruction manual

Powerfix Profi

Powerfix Profi Z16531 Operating and safety notes

Weidmuller

Weidmuller Crimpfix universal operating manual

Everwin

Everwin FCN90 Operation and maintenance manual

Metabo

Metabo WR 18DH Safety instructions and instruction manual

Chicago Pneumatic

Chicago Pneumatic CP0456 Series instruction manual

Fein

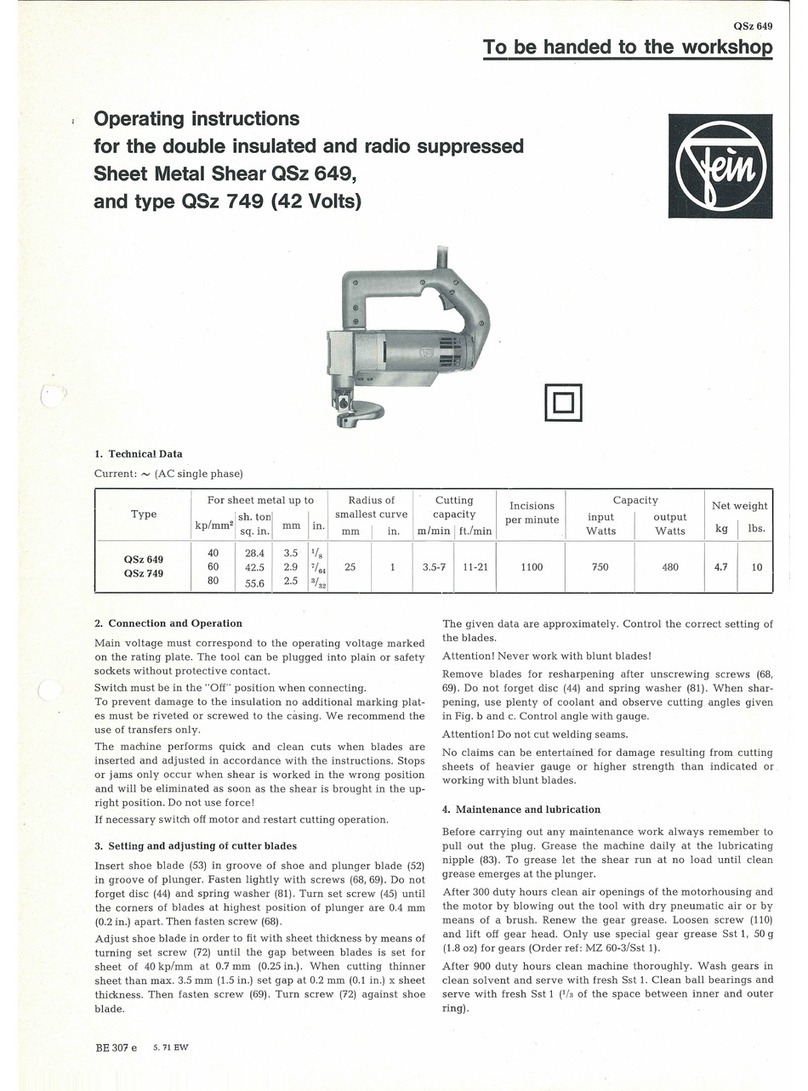

Fein QSz 7 49 operating instructions

Atlas Copco

Atlas Copco EP7PTI55 HR10-MT Product instructions

Bosch

Bosch GOP Professional 250 CE 300 SCE Original instructions

Miller

Miller S-52A owner's manual