SteelMax PB-5 User manual

The tools of innovation.

15335 E. Fremont Drive, Centennial, CO 80112

1–87STEELMAX, FAX 303–690–9172

www.steelmax.com [email protected]

OPERATOR’S MANUAL

P

PB

B-

-5

5

/

/

P

PB

BE

E-

-5

5

/

/

P

PB

BC

C-

-5

5

PIPE BEVELING MACHINE

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 4

1.4. Dimensions................................................................................................................ 5

1.5. Design ....................................................................................................................... 7

2. SAFETY PRECAUTIONS.................................................................................................. 8

3. STARTUP AND OPERATION..........................................................................................10

3.1. Installing the jaw blocks and tool bits ........................................................................10

3.2. Installing (removing) the mandrel and adjusting the clearance..................................11

3.3. Installing the motor....................................................................................................12

3.4. Clamping the machine into the pipe..........................................................................13

3.5. Preparing the air (for machine with air motor) ...........................................................14

3.6. Operating..................................................................................................................14

3.7. Troubleshooting the electric motor............................................................................16

3.8. Troubleshooting the battery motor.............................................................................16

3.9. Replacing the spindle disk ........................................................................................17

3.10. Facing and beveling at the same time.....................................................................18

4. ACCESSORIES...............................................................................................................19

4.1. Tool bits for carbon steel...........................................................................................19

4.2. Tool bits for stainless steel........................................................................................21

4.3. Air motor...................................................................................................................22

4.4. Electric motor............................................................................................................22

4.5. Battery motor ............................................................................................................22

4.6. Air preparation unit....................................................................................................23

4.7. 5.2 Ah battery ...........................................................................................................23

4.8. Battery charger .........................................................................................................23

4.9. 75 mm spindle disk...................................................................................................24

4.10. 140 mm spindle disk set..........................................................................................24

4.11. Ratchet wrench.......................................................................................................25

4.12. Small expanding mandrel........................................................................................26

4.13. Coolant ...................................................................................................................26

5. EXPLODED DRAWINGS AND PARTS LIST....................................................................27

6. DECLARATIONS OF CONFORMITY...............................................................................30

7. WARRANTY CARD..........................................................................................................33

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

3

1. GENERAL INFORMATION

1.1. Application

The PB-5 / PBE-5 / PBC-5 is apipe beveling machine designed to mill pipes made of

carbon and stainless steel, aluminum alloys, and copper-nickels. Depending on the tool

bit used, the machine allows external beveling, internal beveling, J-beveling, internal

calibration, and facing pipes from inner diameters of 32 mm (1.26″)to outer diameters

of 114 mm (4.49″). You can install up to three tool bits at the same time.

An optional 140 mm spindle disk set allows the machine to bevel pipes with outer

diameters up to 140 mm. Using an optional 75 mm spindle disk, ratchet wrench, or

both, helps working in places hard to reach. An optional small expanding mandrel

allows machining pipes with inner diameters from 25 mm to 33 mm (0.98–1.30″).

1.2. Technical data

PB-5

PBE-5

PBC-5

Pressure

0.6 MPa (87 psi)

–

–

Voltage

–

1~ 110–120 V, 50–60 Hz

1~ 220–240 V, 50–60 Hz

18 V DC, 5.2 Ah

Air motor

Modec

NT10RT0851FCA1F-CO

–

–

Electric motor

–

Metabo

SBEV 1100-2 S

Metabo

BS 18 LTX Impuls

Connection

CEJN 410 DN 10.4

R 1/2″BSPT fitting for

quick-coupling

Electrical plug

Battery connection

Air consumption

1400 l/min (50 CFM)

–

–

Power

800 W

1100 W

–

Pipe diameter

32 mm ID to 114 mm

OD (1.26–4.49″)

32 mm ID to 114 mm

OD (1.26–4.49″)

32 mm ID to 114 mm

OD (1.26–4.49″)

Maximum pipe

wall thickness for

outer diameter

up to 114mm

12 mm (0.47″)

12 mm (0.47″)

12 mm (0.47″)

114–124mm*

10 mm (0.39″)

10 mm (0.39″)

10 mm (0.39″)

124–132mm*

8 mm (0.31″)

8 mm (0.31″)

8 mm (0.31″)

132–140mm*

6 mm (0.24″)

6 mm (0.24″)

6 mm (0.24″)

Rotational speed without load

180 rpm

–

0–50 rpm (gear 1)

0–180 rpm (gear 2)

Nominal rotational speed

90 rpm

0–113 rpm (gear 1)

0–318 rpm (gear 2)

–

Protection class

–

II

–

Required ambient temperature

0–40°C (34–104°F)

0–40°C (34–104°F)

0–40°C (34–104°F)

Weight with motor

10 kg (22 lbs)

11 kg (24 lbs)

10 kg (22 lbs),

includes battery

* Available with the optional 140 mm spindle disk set.

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

4

1.3. Equipment included

1

Beveling machine (without tool bits)

1 unit

2

Metal box

1 unit

3

Jaw blocks (number 1, 2, 3, 4, 5, 6)

3 sets

4

Coolant container

1 unit

5

Tool container

1 unit

6

13 mm socket wrench

1 unit

7

6 mm hex wrench

1 unit

8

5 mm hex wrench

1 unit

9

4 mm hex wrench with handle

1 unit

10

3 mm hex wrench with ball end

1 unit

11

Air motor

Option

12

Electric motor

Option

13

Battery motor

Option

–

Operator’s Manual

1 unit

1

2

3

4

5

6

7

8

9

10

11

12

13

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

5

1.4. Dimensions

380 mm (15″)

232 mm (9″)

539 mm (21″)

577 mm (23″)

433 mm (17″)

232 mm (9″)

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

6

434 mm (17″)

468 mm (18.4″)

232 mm (9″)

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

7

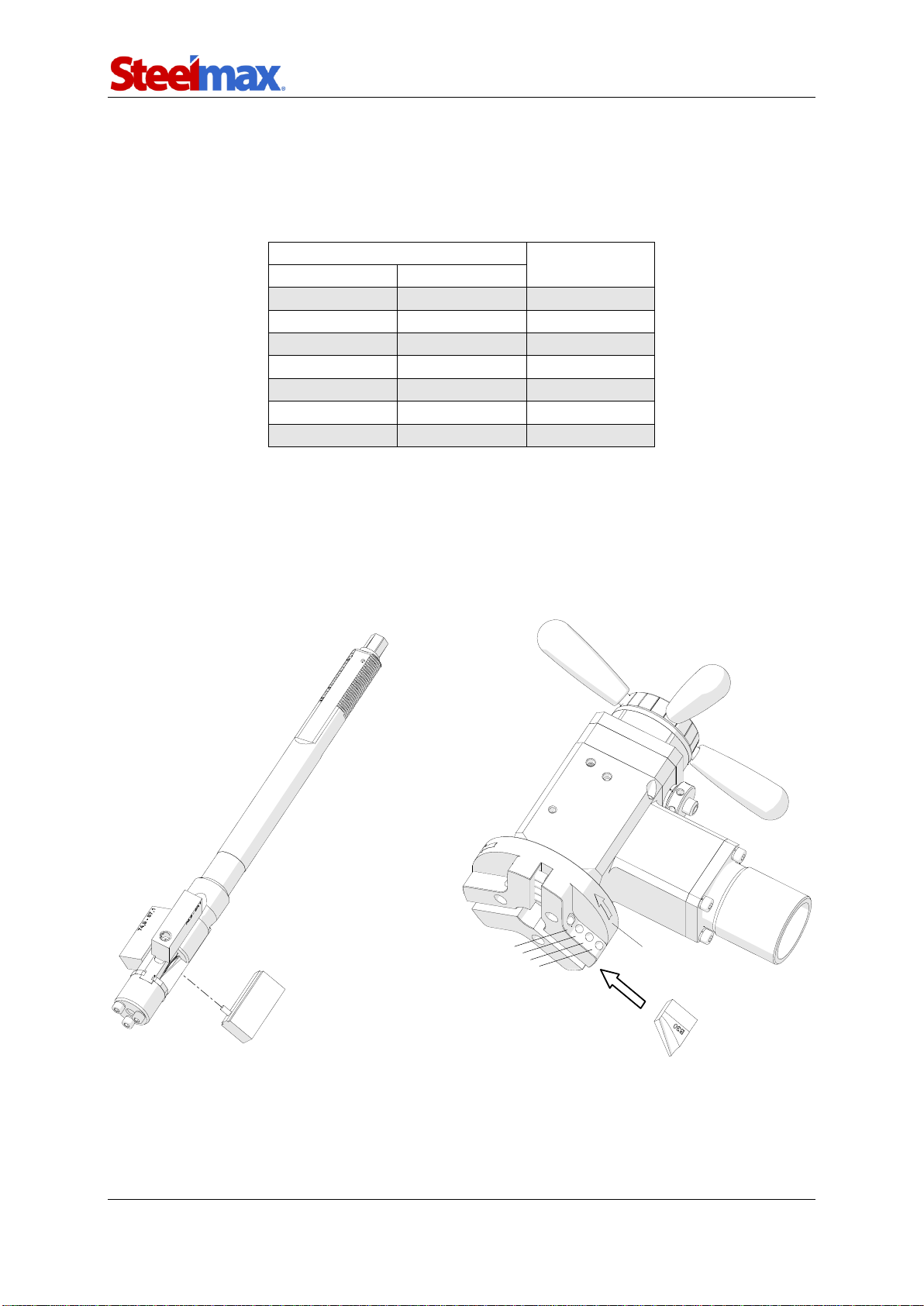

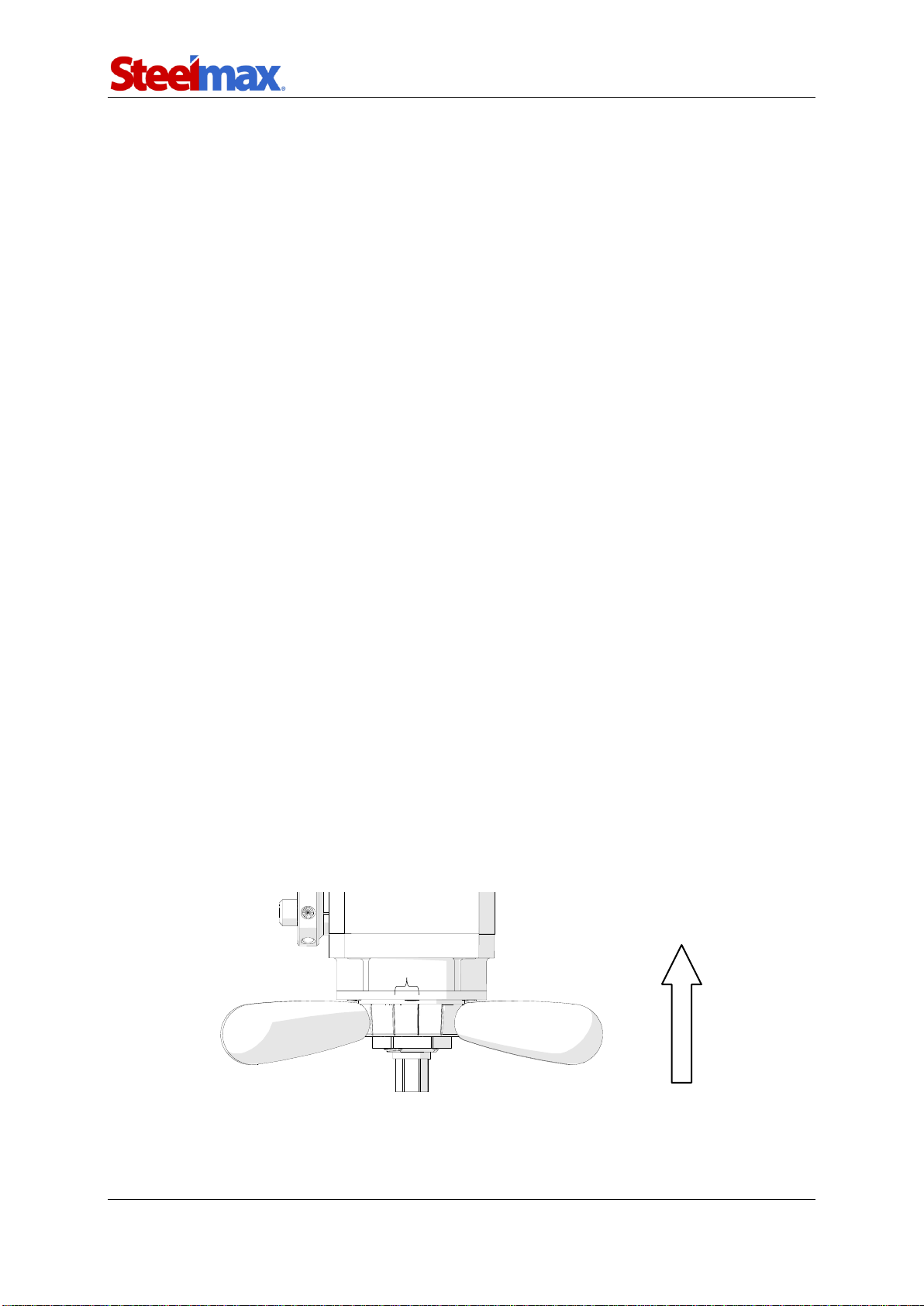

1.5. Design

Fig. 1. View of PB-5 and of PBE-5 electric motor and PBC-5 battery motor

Handle

Clearance

adjustment

unit

Expanding mandrel

118 mm spindle disk

Air motor

ON/OFF lever

Air connection

Draw nut

Feed

indicator

ON switch lock

ON/OFF switch

Rotation direction switch

(must be set as shown)

Gear switch

Speed adjustment dial / LED

Rotation direction switch

(must be set as shown)

ON/OFF switch

with speed adjustment

Gear switch

Torque adjustment dial

Battery

LED activation button

LED

Operation mode switch

(must be set as shown)

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

8

2. SAFETY PRECAUTIONS

1. Before use, read this Operator’s Manual and complete a training in occupational

safety and health.

2. Use only motors specified in the technical data.

3. Use only in applications specified in this Operator’s Manual.

4. Make sure that the machine has all parts and they are genuine and not damaged.

5. Make sure that the specifications of the air (power) source are the same as those

specified on the rating plate.

6. Supply themachine with air motor only with clean and lubricated air. Make sure

that the air source has an air preparation unit that contains a filter, regulator, and

lubricator.

7. Do not pull the hose (cord). This can cause damage and serious injury.

8. Keep untrained bystanders away from the machine.

9. Before each use, ensure the correct condition of the machine, air (power) source,

supply hose (power cord, battery), quick coupling (plug), control parts, and tool bits.

10. Before each use, make sure that no part is cracked or loose. Make sure to

maintain correct conditions that can have an effect on the operation of the

machine.

11. Avoid accidental starts. Do not put the machine so that the motor will start. Do not

carry the machine with air motor by holding the ON/OFF lever.

12. Keep the machine dry. Do not expose the machine to rain, snow, or frost.

13. Keep the work area well-lit, clean, and free of obstacles.

14. Do notuse nearflammable materials, orin explosive environments.

15. Attach the pipe so that it will not fall or roll.

16. Use only tool bits specified in this Operator’s Manual.

17. Do not use tool bits that are dull or damaged.

18. Attach the tool bits with two screws. Remove wrenches from the work area

before you connect the machine to the air (power) source.

19. Use eye and ear protection, protective footwear, and protective clothing. Do not

use loose clothing.

20. Use an electric/battery motor only after you set the rotation direction switch and the

operation mode switch as shown in Fig. 1. Using left rotation or impulse mode (the

switches set to the opposite positions) can damage the machine.

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

9

21. Do not touch chips or moving parts. Do not let anything catch in moving parts.

22. After each use, clean the machine with a dry cotton cloth and no chemical

agents. Do not remove chips with bare hands.

23. Maintain the machine and install/remove parts and tool bits only after you unplug

the machine from the air (power) source or remove the battery.

24. Repair only in a service center appointed by the seller.

25. If the machine falls, is wet, or has any damage, stop the work and immediately

send the machine to the service center for check and repair.

26. Do not leave the machine when it operates.

27. If you are not going to use the machine, remove the tool bits from the sockets.

Then, remove the machine from the work area and keep it in a safe and dry

place.

28. If you are not going to use the machine for an extended period, put anti-corrosion

material on the steel parts.

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

10

3. STARTUP AND OPERATION

3.1. Installing the jaw blocks and tool bits

Use the table that follows to select the correct jaw blocks for the diameter of the pipe.

Pipe inner diameter

Jaw blocks

number

[mm]

[inch]

32–43.5

1.26–1.71

–

43–55

1.69–2.17

1

54–66.2

2.13–2.61

2

64.7–76.9

2.55–3.03

3

74.9–87.1

2.95–3.43

4

85.2–97.4

3.35–3.83

5

94.8–107

3.73–4.21

6

Use the 3 mm hex wrench to attach the jaw blocks to the expanding mandrel (1,

Fig. 2). Then, select up to three tool bits suitable to planned use, and put them in the

sockets. Point the blades in the rotation direction (2). Next, use the 4 mm hex wrench

and two of the screws (3)to attach each tool bit. Make sure that the pressing

surfaces of the screws are in full contact with the tool bits.

Fig. 2. Installing the jaw blocks and tool bits

1

2

3

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

11

3.2. Installing (removing) the mandrel and adjusting the clearance

Loosen the nut and use the 6 mm hex wrench to loosen the set screw (1, Fig. 3), and

put the mandrel into the machine (2). Make sure that tool bits installed are not in

contact with the mandrel. Next, rotate the handles to the right (3) by at least 10 turns

until the mandrel engages with the machine fully. Tighten the set screw (4)and check

if you can easily rotate the handles in both directions. If the screw is too tight, loosen it

lightly. Finally, tighten the lock nut (5).

Fig. 3. Installing the mandrel into the machine

If the mandrel becomes loose causing vibrations of the tool bits during machining, do

the above actions without removing the mandrel from the machine.

To remove the mandrel, loosen the nut and use the 6 mm hex wrench to loosen

the set screw (1,Fig. 3) by at least one turn. Then, rotate the handles to the left to

remove the mandrel.

1

2

4

5

3

3

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

12

3.3. Installing the motor

When you use the air motor, put it into the machine (1, Fig. 4) so that the arbor is in

the socket (2). Then, rotate the motor to the left (3) to tighten.

To attach the electric/battery motor, put the clamping ring (4) onto the machine.

Attach the correct driver (5) to the motor. Put the motor into the machine (6) so that

the arbor is in the socket (2). Then, use the 6 mm hex wrench to tighten the clamping

ring (7).

In the electric motor, set the rotation direction switch as shown in Fig. 1. In the

battery motor, set the rotation direction switch and the operation mode switch as

shown in Fig. 1.

Fig. 4. Installing the air, electric, and battery motor

1

2

3

5

5

6

7

5

4

5

5

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

13

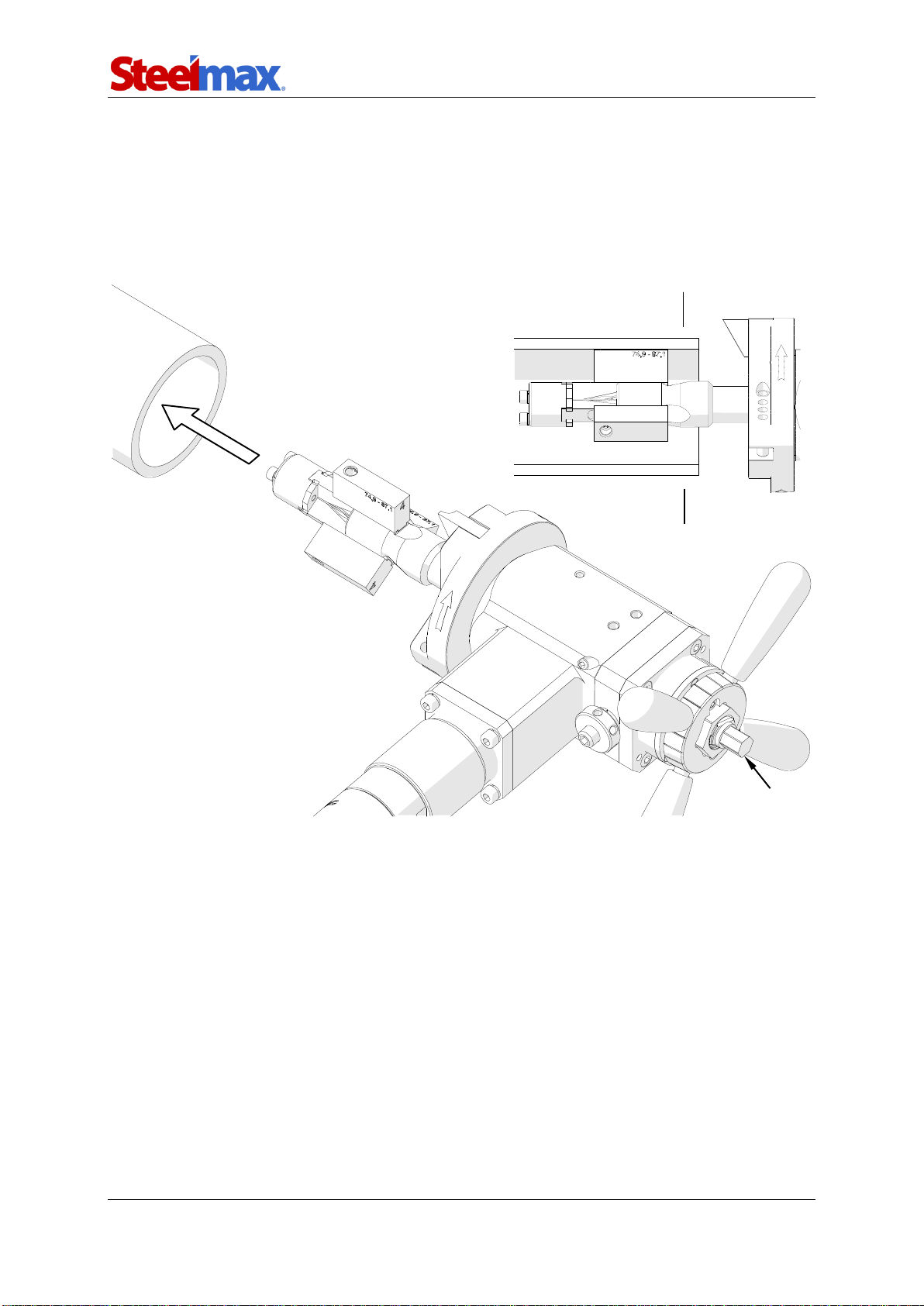

3.4. Clamping the machine into the pipe

Put the machine into the pipe (1, Fig. 5) to set the tool bits at least 3 mm (0.12″) from

the pipe end. Then, use the 13 mm socket wrench to rotate the draw nut (2) to the

right to expand the jaw blocks and clamp the machine into the pipe. Make sure that

the jaw blocks are put further than the surface after machining (3).

Fig. 5. Clamping the machine into the pipe

2

1

3

3

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

14

3.5. Preparing the air (for machine with air motor)

Connect the machine to a correctly prepared air source of sufficient purity. Make sure

that all inner diameters of the air source (including the supply hose and fittings) are of

at least 10 mm (0.4″). Make sure that the air source has an air preparation unit that

contains a filter, regulator, and lubricator (FRL).

Maintain the FRL unit as required. Keep the water trap drained, filter cleaned,

and the lubricator oil reservoir filled so that there is a drop of oil every 2–5 seconds.

Use oil whose ignition temperature is more than 260°C (500°F). If you are not going

to use the machine for at least 24 hours, increase the supply of oil and let the motor

operate for 2–3 seconds. This will prevent rusting and degrading of the rotor vanes.

3.6. Operating

After you connect the machine to the correct supply, press the ON/OFF lever to start.

In the electric motor, set the gear 1. In the battery motor, set the gear 1 and the

maximum torque. Then, press and hold the ON/OFF switch. To lock the switch in the

position ON (not available in the battery motor), press the ON switch lock before you

release the ON/OFF switch. To adjust the speed, use the dial or, in the battery motor,

change the force that you apply on the ON/OFF switch.

Apply the coolant on the working edge. Then, rotate the handles to the right to

bring the tool bits close to the pipe. If the pipe end is not perpendicular to the pipe

axis, the tool bit will cut only a small part of the pipe during initial rotations. Thus, use

a low feed rate until the tool bit is in continuous contact with the pipe during at least

one rotation. The feed is 0.11 mm (0.004″) per graduation (Fig. 6) or 2 mm (0.08″) per

one full turn of the handles.

Fig. 6. View of the feed indicator

Rotate the handles to the right to continue machining. Use such a feed rate so

that the chip is continuous. If the feed rate is too low, only small chips are removed.

Feed direction

0.11 mm (0.004″)

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

15

If the feed rate is too high, machining is difficult and the chips are rough or torn.

Do not allow the tool bit to burnish the surface. If chatter problems occur, decrease

the feed rate and the speed. Then, make sure that the tool bits that you use are

sharp and are of correct type for the material. Stainless steel can harden during work.

Thus, cut stainless steel with a high enough feed, 0.08–0.15 mm (0.003–0.006″) per

rotation, to cut under the hardened surface.

If the electric motor becomes overloaded, the motor shuts off. However, do not let

the motor overload. If possible, cuthardmaterials with a low feed rate and speed.

After the pipe end is machined fully, stop rotating the handles and allow several

more turns of the spindle to improve the finish of the surface. Then, use the ON/OFF

lever/switch to turn off the motor, and wait until the rotation stops. Rotate the handles

to the left to move the tool bits away from the pipe end to at least 3 mm (0.12″). Then,

rotate the 13 mm socket wrench to the left to loosen the draw nut and release the

clamping, and remove the machine from the pipe.

Clean the pipe with petroleum ether.

Clean the machine with a dry cotton cloth and no chemical agents.

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

16

3.7. Troubleshooting the electric motor

If the LED is on, the motor power has been decreased. This prevents overheating of

the motor as a result of frequent overload. To decrease the temperature of the motor,

let the motor operate with no load at the maximum speed.

If the LED flashes fast, the automatic restart has been prevented after a power

failure. Then, to start the motor, turn it off and on.

If the LED flashes slow, the carbon brushes are almost worn and the motor

has been shut off. Replace the brushes with new ones specified by the manufacturer

of the motor.

3.8. Troubleshooting the battery motor

If the motor is frequently overloaded for extended periods, it will be shut off. To stop

the beeping signal, release the ON/OFF switch. If you feel that the motor or the

battery is warm, before use wait until its temperature decreases. To decrease the

temperature more quickly, let the motor operate with no load at the maximum speed.

The motor can also shut off if the machine jams in the workpiece. To continue

work, release the ON/OFF switch and press it again. Do not let the machine jam in

the workpiece.

If the LED flashes, the battery is almost discharged. To check the charge level,

press the LED activation button. If the battery is discharged fully, charge the battery

or replace to a fully charged.

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

17

3.9. Replacing the spindle disk

Loosen the nut and use the 6 mm hex wrench to loosen the set screw (1, Fig. 7) by

at least one turn. Then, rotate the handles to the left (2) to remove the mandrel (3).

Fig. 7. Removing the mandrel from the machine

Use the 5 mm hex wrench (1, Fig. 8) and remove the spindle disk (2). Then, install

the new disk (3) onto the pin (4) and tighten with the same screws.

Fig. 8. Replacing the spindle disk

1

2

3

4

1

2

3

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

18

3.10. Facing and beveling at the same time

When you face and bevel at the same time, use short or long beveling tool bit

depending on the pipe diameter (Fig. 9).

Fig. 9. Positioning the facing tool bit and a short or long beveling tool bit

F0-30 facing tool bit

Short tool bit

Long tool bit

Short tool bit

Short or long

tool bit

Long tool bit

Long tool bit

Short or long

tool bit

Short tool bit

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

19

4. ACCESSORIES

4.1. Tool bits for carbon steel

NOZ-000031

F0-30

0° facing tool bit

NOZ-000032

B30

30° beveling tool bit*

NOZ-000033

B30d

30° beveling tool bit**

NOZ-000036

B375

37.5° beveling tool bit*

NOZ-000037

B375d

37.5° beveling tool bit**

NOZ-000040

B45

45° beveling tool bit*

NOZ-000041

B45d

45° beveling tool bit**

* For diameters over 56 mm, if works together with 0° facing tool bit.

** For diameters under 83 mm, if works together with 0° facing tool bit.

PB-5 / PBE-5 / PBC-5

PB-5 / PBE-5 / PBC-5 Operator’s Manual

20

NOZ-000052

IC15-40 –on the left

15° internal calibration tool bit

NOZ-000053

IC15-40 –on the right

(for diameters over 56 mm)

15° internal calibration tool bit

NOZ-000087

IB12-60

12° internal beveling tool bit

NOZ-000058

J10-R6

10° J-beveling tool bit

NOZ-000057

J15-R2

15° J-beveling tool bit

NOZ-000059

J20-R8

20° J-beveling tool bit

NOZ-000088

J20-R1

20° J-beveling tool bit

This manual suits for next models

2

Table of contents

Other SteelMax Power Tools manuals