SteelMax SM-BM-21S User manual

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 4

2. SAFETY PRECAUTIONS.................................................................................................. 5

3. STARTUP AND OPERATION........................................................................................... 7

3.1. Preparing................................................................................................................... 7

3.1.1. Adjusting the bevel width and angle................................................................. 7

3.1.2. Using cutting fluid............................................................................................ 8

3.2. Operating................................................................................................................... 9

3.3. Beveling pipes...........................................................................................................11

3.4. Beveling larger pipes (only for optional equipment)...................................................13

3.5. Replacing the cutting inserts.....................................................................................13

3.6. Replacing the milling head........................................................................................15

4. WIRING DIAGRAM..........................................................................................................16

5. SPARE AND WEARING PARTS......................................................................................17

6. EXPLODED DRAWINGS AND PARTS LIST....................................................................18

7. DECLARATION OF CONFORMITY.................................................................................22

8. QUALITY CERTIFICATE..................................................................................................23

9. WARRANTY CARD..........................................................................................................24

SM-BM-21S

1. GENERAL INFORMATION

1.1. Application

The BM-21S Beveling Machine is designed to mill edges of plates and pipes made of

stainless steel. The machine allows beveling sheet edges and edges of pipes with

diameters from 150 mm (6’’) to 300 mm (12’’) at the angle of 0 to 60° and with the

maximum bevel width of 21 mm (13/16’’). The machine contains dampers to reduce

vibrations.

When equipped with an optional guide, the machine allows working on pipes with

diameters over 300 mm (12’’).

1.2. Technical data

Voltage

1~ 220–240 V, 50–60 Hz

1~ 110–120 V, 50–60 Hz

Power

1600 W (for 50 Hz)

1800 W (for 60 Hz)

Rotational speed

1360–1630 rpm (at 230 V)

1300–1560 rpm (at 115 V)

Protection level

IP 20

Protection class

I

Milling speed

270 m/min (900 ft/min, for 50 Hz)

320 m/min (1050 ft/min, for 60 Hz)

Maximum bevel width

b ≈ 21 mm (13/16’’, Fig. 1, Tab. 1)

Bevel angle range

0° ≤ ß ≤ 60° (Fig. 1)

Weight

23 kg (51 lbs)

Fig. 1. Bevel dimensions

β

0°

30°

45°

60°

b

21 mm

18.5 mm

21 mm

18.5 mm

Tab. 1. Maximum bevel width depending on the angle

SM-BM-21 Operator’s Manual

3

SM-BM-21S

1.3. Equipment included

The BM-21S Beveling Machine is supplied in a metal box with complete standard

equipment. The included equipment consists of:

Beveling machine with

a set of cutting inserts

1 unit

Metal box

1 unit

8 mm hex wrench

1 unit

6 mm hex wrench

1 unit

4 mm hex wrench

1 unit

12 mm flat wrench

1 unit

T15 torx screwdriver

1 unit

Oil for stainless steel

1 unit

Grease for screws

1 unit

Operator’s Manual

1 unit

441 mm (17.4’’)

339 mm (13.4’’)

366 mm (14.4’’)

SM-BM-21 Operator’s Manual

4

SM-BM-21S

2. SAFETY PRECAUTIONS

1. Before beginning, read this Operator’s Manual and complete proper occupational

safety and health training.

2. The machine must be used only in applications specified in this Operator’s Manual.

3. The machine must be complete and all parts must be genuine and fully operational.

4. Theelectricalsupplyspecificationsmustconformtothose specifiedontheratingplate.

5. The machine must be plugged into a properly grounded (earthed) socket-outlet.

6. Never pull the power cord as this may damage it and result in electric shock.

7. Untrained bystanders must not be present in the vicinity of the machine.

8. Before beginning, check the condition of the machine and electrical installation,

including power cord, plug, control panel components, and milling tools.

9. Keep the machine dry. Exposure to rain, snow, or frost is prohibited.

10. Keep work area well lit, clean, and free of obstacles.

11. Never use the machine in the vicinity of flammable liquids or gases, or in explosive

environments.

12. Never use dull or damaged tools.

13. Use only tools specified in this Operator’s Manual.

14. Mount the cutting inserts and the milling head securely. Remove adjusting keys

and wrenches from the work area before connecting the plug to the power outlet.

15. If the cutting edge of an insert is worn, rotate the insert in the socket by 90° or, if

all edges are worn, replace with new insert specified in this Operator’s Manual.

Always replace or rotate all inserts at the same time.

16. Before every use, inspect the machine to ensure it is not damaged. Check whether

any part is cracked or improperly fitted. Make sure to maintain proper conditions

that may affect the operation of the machine.

17. Always use eye and hearing protection, respiratory protective devices, non-skid

footwear, gloves, and protective clothing during operation. Do not wear loose

clothing.

18. Do not touch moving parts or metal chips formed during milling. Prevent objects

from being caught in moving parts.

19. After every use, remove metal chips from the machine, especially from the milling

head. Never remove metal chips with bare hands. Clean the machine with a cotton

cloth without using any agents.

SM-BM-21 Operator’s Manual

5

SM-BM-21S

20. Maintain the machine and tools with care. Cover steel parts with a thin grease

layer to protect them against rust when not in use for any extended period.

21. Maintain the machine and replace parts and tools only with the power cord

unplugged from the power outlet.

22. Repair only in a service center appointed by the seller.

23. If the machine falls on a hard surface, from height, is wet, or has other damage

that could affect the technical state of the machine, stop the operation and

immediately send the machine to the service center for inspection and repair.

SM-BM-21 Operator’s Manual

6

SM-BM-21S

3. STARTUP AND OPERATION

3.1. Preparing

3.1.1. Adjusting the bevel width and angle

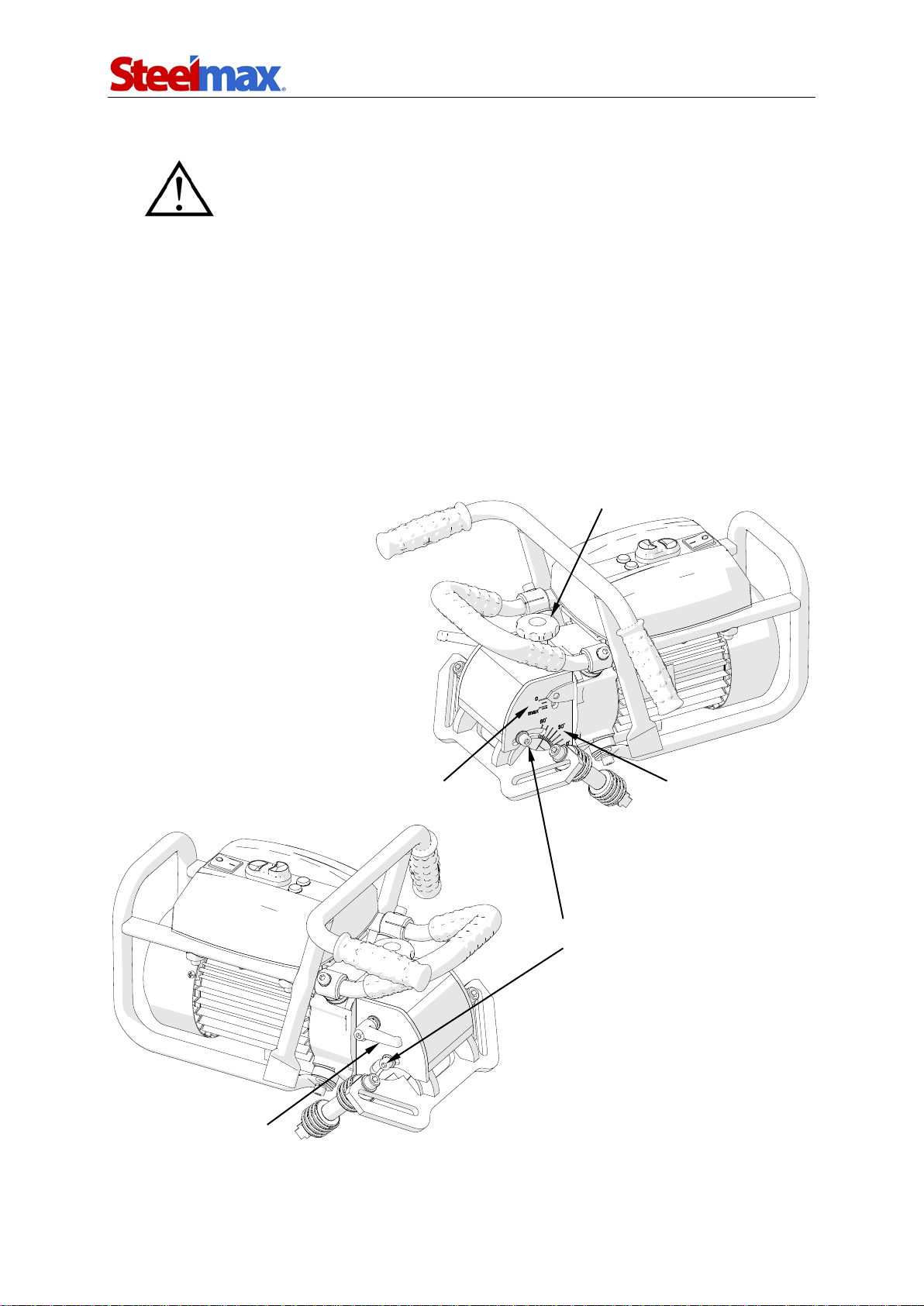

Before starting, set required bevel width and angle. First, with power cord unplugged

from the power outlet, set the milling head penetration to zero. To do this, loosen the

lever (Fig. 2) and rotate the adjusting knob to decrease the penetration of the milling

head into the workpiece by setting the indication ‘0’ on the width pitch.

Fig. 2. Adjusting the bevel width and angle

All safety precautions must be closely observed.

bevel width pitch

adjusting knob

screws locking the guide

securing lever

bevel angle pitch

SM-BM-21 Operator’s Manual

7

SM-BM-21S

To change the angle of the bevel, use the supplied 6 mm hex wrench to loosen

two side screws. Then, turn the guide in a way to set the required angle on the angle

pitch and tighten the screws afterward.

To adjust the bevel width, use the adjusting knob, proceeding as described before.

The width pitch is only an estimate, because the bevel width varies with angle. For

example, for the angle of 10° the maximum width ‘b’ (Fig. 1) is approximately equal

18 mm (11/16’’), while the width pitch indicates 9 mm (6/16’’). Increasing the

penetration at this angle will distort the bevel. The maximum bevel width (b ≈21 mm,

13/16’’) is obtained for the angle of 45°. The demanded bevel width for the required

angle must be determined experimentally by gradually increasing the milling head

penetration into the workpiece.

3.1.2. Using cutting fluid

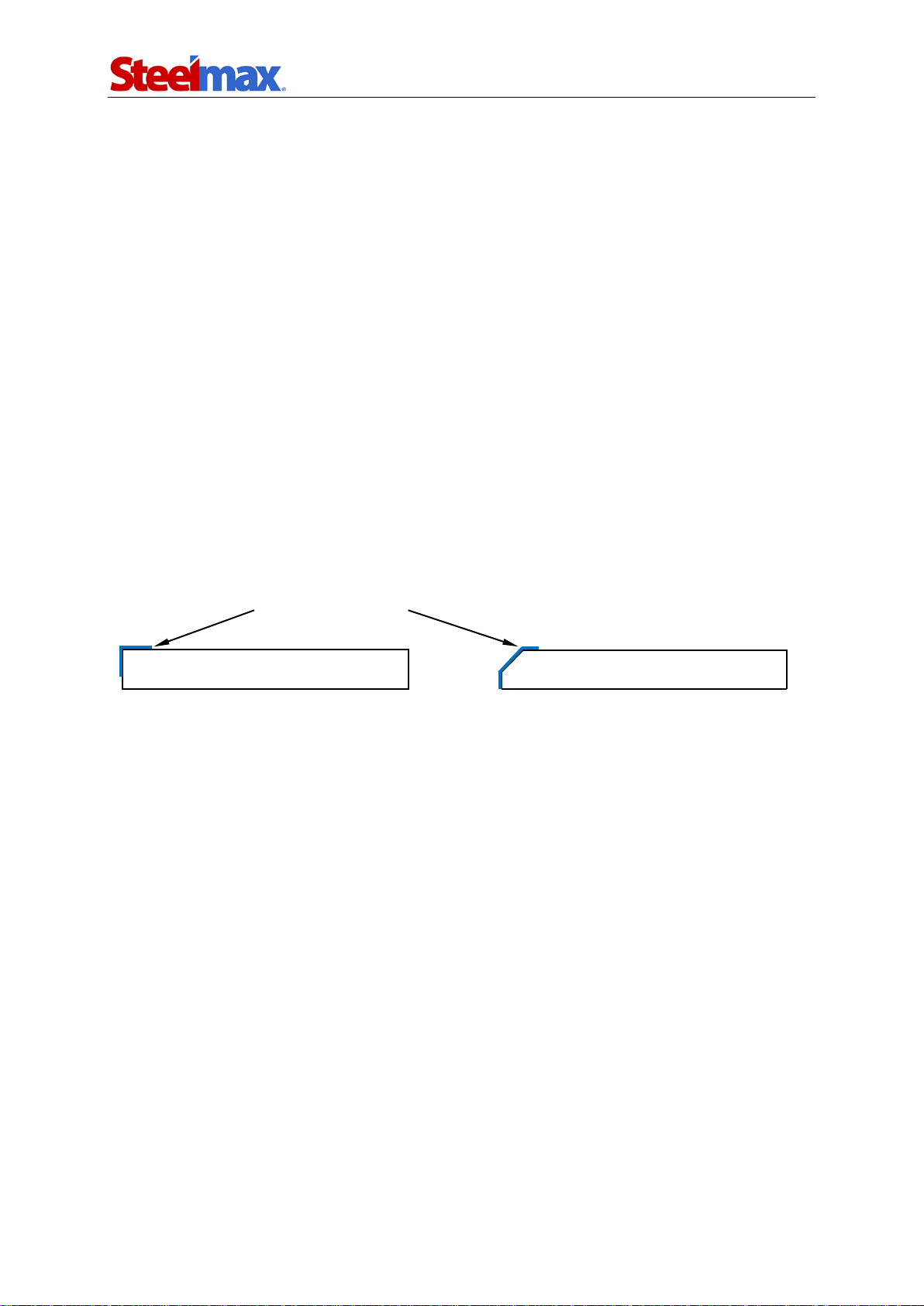

Before beveling stainless steel, cover the edges of the workpiece with the supplied oil

in the manner shown in Fig. 3.

Fig. 3. Preparing the edges for beveling stainless steel

oil for stainless steel

SM-BM-21 Operator’s Manual

8

SM-BM-21S

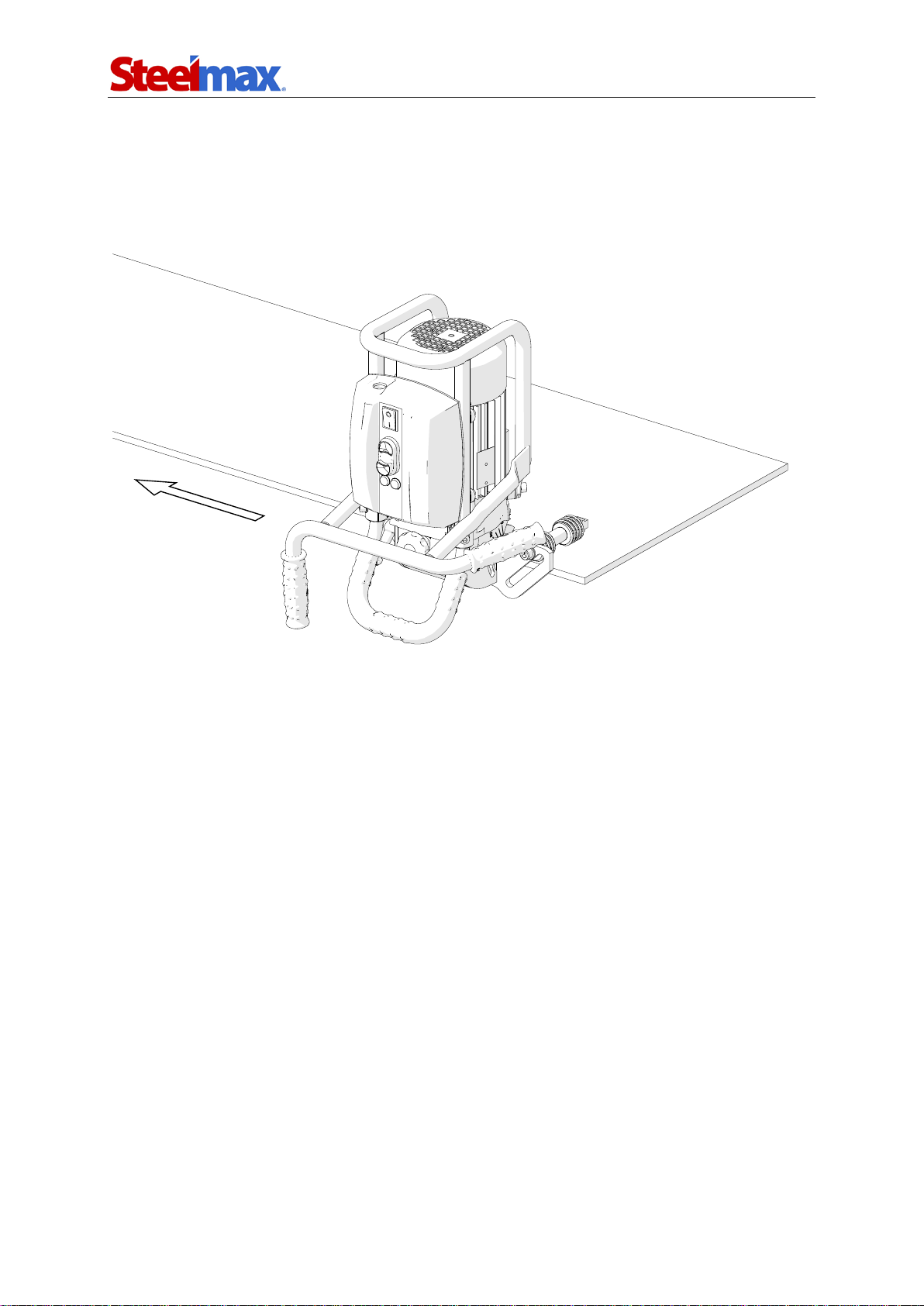

3.2. Operating

After setting the bevel width and angle, plug the machine into a properly grounded

power outlet. Then, place the machine vertically on the right side of the workpiece as

shown in Fig. 4 in a way that the milling head does not touch the working edge.

Fig. 4. Machine prepared for work on metal plates

Turn on the power, which will illuminate the power switch (Fig. 5). Then, turn on

the motor using the motor ON switch, press the guide to the plate, and slowly move

the machine close to the edge. Bevel by sliding the machine to the left. Beveling is

performed according to the counter-rotation. The proper feed direction is shown in

Fig. 4. The direction of the milling head rotation is indicated on the motor disk under

the milling head cover.

feed direction

SM-BM-21 Operator’s Manual

9

SM-BM-21S

Fig. 5. View of the control panel

The feed rate will depend on the profile and composition of the workpiece. You

can bevel the majority of steels capable of being welded in just one pass.

It is recommended that bevels wider than 12 mm (1/2’’) be accomplished in at

least two or three passes. In this case you use less effort and the process takes less

total time than for beveling in single pass.

To obtain the maximum bevel width (21 mm, 13/16’’) in two passes, the first pass

should be 14 mm wide (9/16’’), whereas for three passes the first one should be

12 mm wide (1/2’’) and the second one 16 mm wide (5/8’’).

If the feed is too fast, the red overload lamp illuminates, indicating motor overload.

Further increasing of the load will trigger the safety circuit and shut down the motor.

In this case, move the tool away from the beveled edge, toggle power switch to

position ‘0’, and after the red lamp turns off, turn on the power again. Operating with

the maximum permitted load (the red lamp flashing) is allowed, but the motor

temperature must not exceed 85°C (185°F). This type of motor can work under high

temperatures, but long-lasting overheating can permanently damage motor windings.

Therefore, after longer working under full load (up to 1 hour), stop the motor to cool it

for 10–15 minutes. Do not cool the motor by running it without load as it will become

heated even faster than when working with load.

power switch

motor ON switch

motor OFF switch

overload lamp

lamp indicating motor

operation

SM-BM-21 Operator’s Manual

10

SM-BM-21S

Once the work is finished, press the motor OFF switch to stop the motor, and

toggle the power switch to position ‘0’ to turn off the power. Use petroleum ether to

clean the oil remainder from the workpiece.

Clean the machine with a cotton cloth without using any agents.

3.3. Beveling pipes

The guide with rollers supplied in standard equipment allows beveling pipes with

diameters of 150–300 mm (6–12’’).

To prepare the machine for work on pipes, use the supplied 6 mm hex wrench to

unscrew two screws locking the guide (Fig. 6). Then, take out the guide set, rotate it

by 180° around the vertical axis, mount again, and secure with the screws.

Fig. 6. Preparing the machine for work on pipes

Use the supplied 8 mm hex wrench and the 12 mm flat wrench to unscrew the

screws securing the rollers. Then, move rollers from the opening (Fig. 7a) to the slot

(Fig. 7b) by placing the T-nut into the slot.

2

1

3

4

5

SM-BM-21 Operator’s Manual

11

SM-BM-21S

Fig. 7. Moving the rollers from the opening to the slot

Use the adjusting knob to set the indication ‘0’ on the width pitch. Move the

rollers away from each other and place the machine as shown in Fig. 8, with the

guide touching the pipe. Then, move the rollers symmetrically to touch the pipe,

secure with the screws in this position, and set the required bevel width and angle.

Fig. 8. Machine prepared for work on smaller pipes (∅150–300 mm, 6–12’’)

screw securing

the roller

a)

b)

SM-BM-21 Operator’s Manual

12

SM-BM-21S

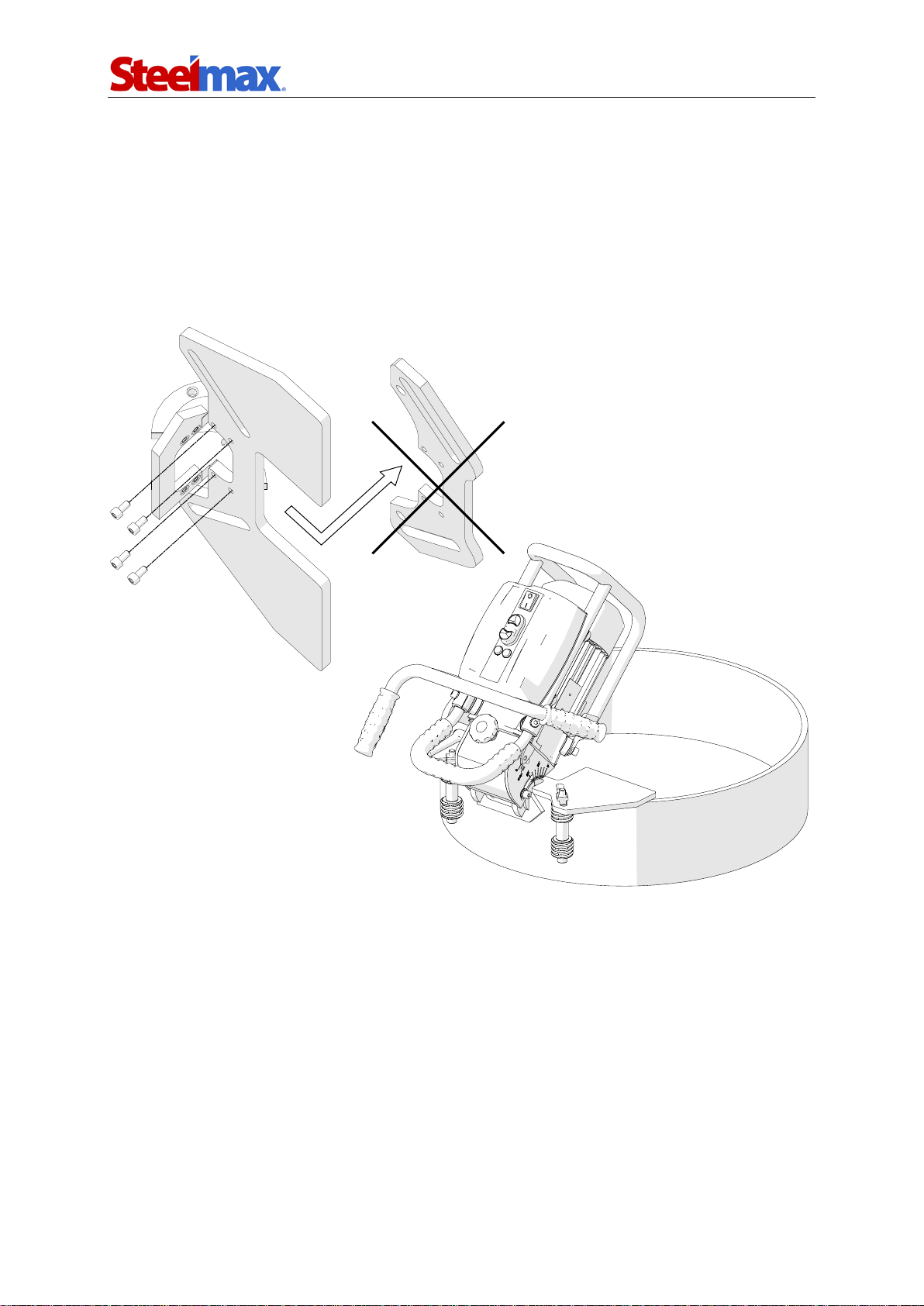

3.4. Beveling larger pipes (only for optional equipment)

An optional guide allows beveling larger pipes with diameters from 260 mm to 600 mm

(10–24’’). To prepare the machine for work on larger pipes, disassemble the guide set

as shown in Fig. 6. Use the supplied 4 mm hex wrench to unscrew the standard guide

and mount the guide for larger pipes (Fig. 9), then screw in the screws and mount the

rollers as shown in Fig. 7b.

Fig. 9. Machine prepared for work on larges pipes (∅260–600 mm, 10–24’’)

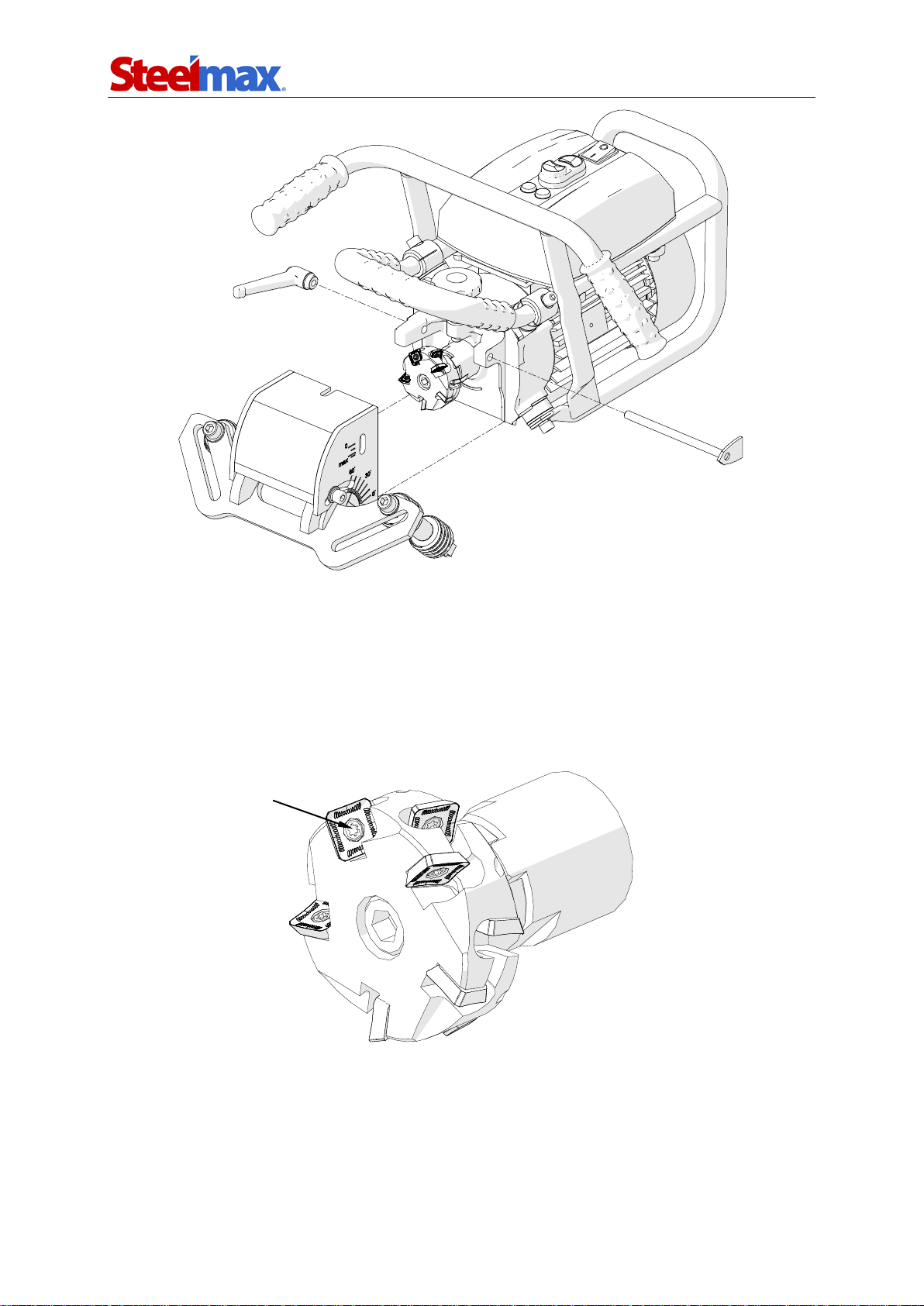

3.5. Replacing the cutting inserts

The machine is equipped with an uniform milling head that contains two insert rings,

each holding five cutting inserts made of carbide, for a total of 10 inserts. The inserts

can be replaced or rotated. Perform this work only with the power cord unplugged

from the power outlet. To replace or rotate an insert, unscrew the lever (Fig. 10),

remove the pitch, and take out the milling head cover.

Part number:

PRW-0505-03-00-00-0

SM-BM-21 Operator’s Manual

13

SM-BM-21S

Fig. 10. Dismantling the milling head cover

Use the supplied screwdriver to unscrew the set screw (Fig. 11), then remove the

external insert, and clean the socket. Next, place the rotated insert again or replace

with a new one if all four edges are worn out. To replace an insert from the internal

ring, remove the external insert first.

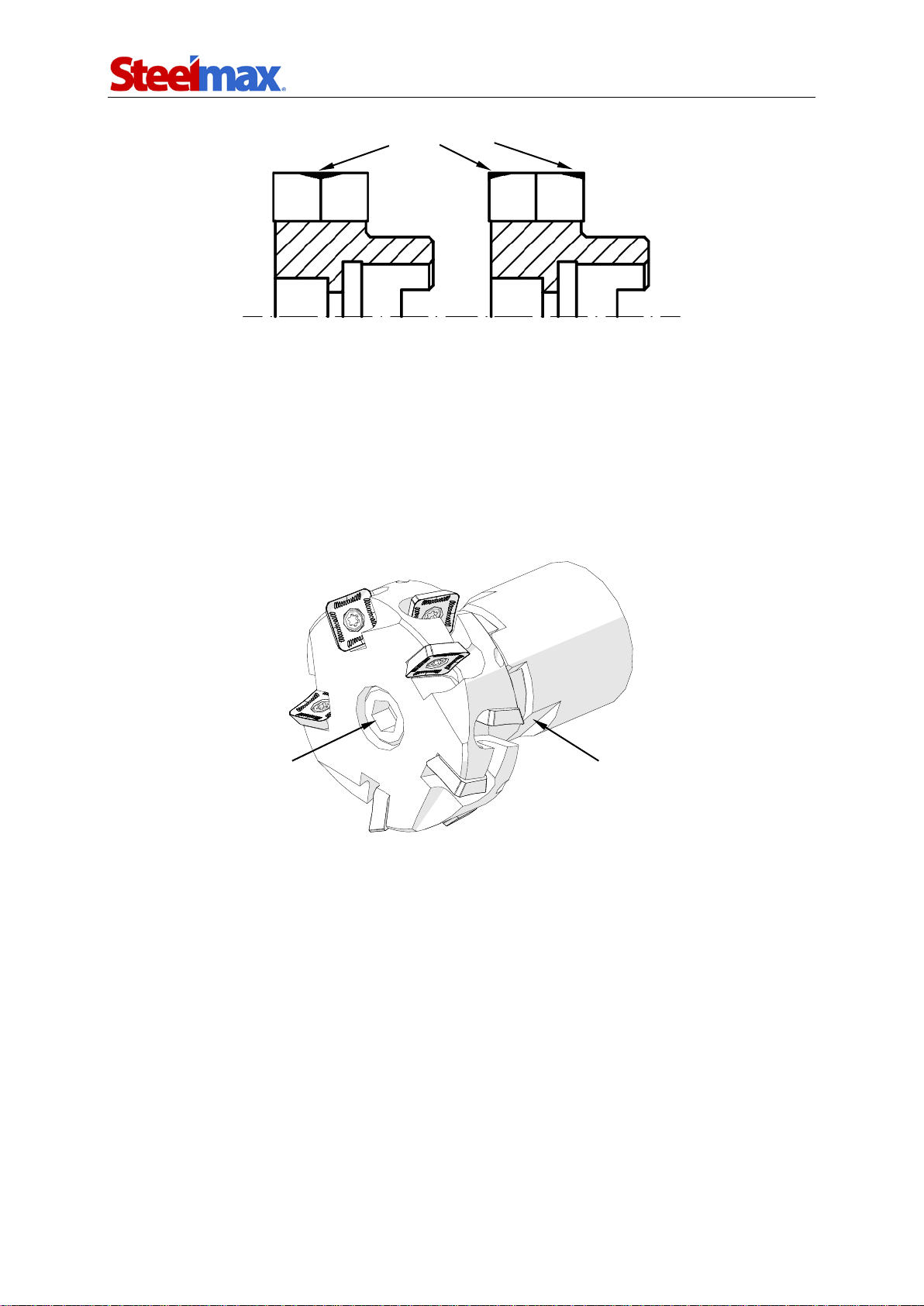

Fig. 11. Replacing the cutting inserts

If the width of established bevels is low, the cutting inserts wear only on one, internal

corner. Then, the good action is to change the inserts between the rings (Fig. 12),

which will extend the life of the inserts.

2

1

3

set screw

SM-BM-21 Operator’s Manual

14

SM-BM-21S

Fig. 12. Changing the cutting inserts between rings

3.6. Replacing the milling head

To replace the milling head, remove its cover in the manner shown in Fig. 10. Then,

place the 32 mm flat wrench on the driving ring (Fig. 13) to lock the spindle rotation,

use the supplied 8 mm hex wrench to unscrew the screw, and remove the milling

head. The 32 mm flat wrench is not included in standard equipment.

Fig. 13. Replacing the milling head

worn out corners

screw securing the head

driving ring

SM-BM-21 Operator’s Manual

15

SM-BM-21S

4. WIRING DIAGRAM

SM-BM-21 Operator’s Manual

16

SM-BM-21S

5. SPARE AND WEARING PARTS

Name

Number

Milling head (including mounting screws,

screwdriver, and grease) GLW-0461-03-00-00-0

Cutting insert

PLY-000282

Mounting screw for inserts

SRB-000311

T15 torx screwdriver for mounting screws

WKT-000004

Grease for screws (5 g, 0.17 oz)

SMR-000005

Oil for stainless steel (0.5 kg, 1.1 lbs)

OLJ-000004

SM-BM-21 Operator’s Manual

17

SM-BM-21S

6. EXPLODED DRAWINGS AND PARTS LIST

46

59

36

58

51

47

32

35

49

53

13

38

40

38 52

43

43

1

46

28

38

16

29

57

45

15

44

49

56

14

3

38

17

19

23

18

21

22

60

48

5

4

30

31

37

41

39

20

34

54

12

50

11

8

50

12

24

7

9

38 33

10

34

55

6

SM-BM-21 Operator’s Manual

18

SM-BM-21S

ITEM PART NUMBER DESCRIPTION Qty

1

PWD-0461-17-00-00-0

POWER CORD 230V

1

1

PWD-0461-17-00-00-1

POWER CORD 115V

1

1

PWD-0461-17-00-00-2

POWER CORD 230V (AU)

1

3

SLN-0505-01-00-00-2

MOTOR ASSY 230V

1

3

SLN-0505-01-00-00-3

MOTOR ASSY 115V

1

4

ZBI-0461-02-00-00-0

DRIVING RING

1

5

PKT-0461-04-00-00-0

KNOB

1

6

OSL-0461-05-00-00-0

MILLING HEAD COVER

1

7

PRW-0505-02-01-00-0

VERTICAL GUIDE

1

8

PRW-0505-02-02-00-0

HORIZONTAL GUIDE

1

9

OBS-0461-06-03-00-1

GUIDE HOLDER I

1

10

OBS-0461-06-04-00-1

GUIDE HOLDER II

1

11

OSK-0461-06-05-00-0

PIVOT

2

12

RLK-0505-02-03-00-0

ROLLER

4

13

RMK-0461-07-00-00-0

FRAME

1

14

RKJ-0461-08-00-00-0

FRONT HANDLE

1

15

MDL-0461-09-02-00-0

ELECTRONIC MODULE ASSY 230V

1

15

MDL-0461-09-02-00-1

ELECTRONIC MODULE ASSY 115V

1

16

PLY-0461-09-03-00-0

BOTTOM PLATE

1

17

PKR-0461-09-04-00-0

CONTROLLER HOUSING COVER

1

18

KON-0461-09-10-00-0

RED LAMP

1

19

KON-0461-09-11-00-0

YELLOW LAMP

1

20

WSK-0461-11-00-00-0

PENETRATION INDICATOR

1

21

LCZ-0461-12-00-00-1

LINK

1

22

USZ-0461-13-00-00-0

RUBBER SEAL

1

23

WBR-0461-14-00-00-0

DAMPER

4

24

GLW-0461-03-00-00-0

MILLING HEAD WITH SCREWS

1

28

NKR-000014

HEX. NUT M4

2

29

NKR-000032

NUT SHORT M4

2

30

NKR-000082

T-NUT

2

31

NIT-000010

ROUND HEAD RIVET 2x6

2

32

PDK-000021

ROUND WASHER 6.4

4

33

PDK-000022

ROUND WASHER 8.4

3

34

PDK-000026

ROUND WASHER 10.5

4

35

PDK-000175

SADDLE WASHER

4

36

PDK-000060

EXTERNAL TOOTH SPRING WASHER 4.3

6

37

PDK-000052

SPRING WASHER 10.2

2

38

PDK-000051

SPRING WASHER 8.2

8

39

PLY-000282

CUTTING INSERT

10

40

RKJ-000010

HANDLEVER

1

41

SRB-000311

MOUNTING SCREW

10

43

WKR-000183

SCREW M4x10 PHCRMS

4

44

KND-000114

CAPACITOR 30uF 240V

1

44

KND-000115

CAPACITOR 80uF 110V

1

45

NKR-000040

STRAIN RELIEF NUT

1

46

PDK-000043

SPRING WASHER 4.1

6

47

PDK-000046

SPRING WASHER 6.1

4

48

PNK-000013

POWER SWITCH

1

SM-BM-21 Operator’s Manual

19

SM-BM-21S

ITEM PART NUMBER DESCRIPTION Qty

49

LCZ-000007

MOTOR ON/OFF SWITCH

1

50

SRB-000075

HEX SOCKET HEAD CAP SCREW M5x10

8

51

SRB-000124

HEX SOCKET HEAD CAP SCREW M6x40

4

52

SRB-000141

HEX SOCKET HEAD CAP SCREW M8x14

2

53

SRB-000156

HEX SOCKET HEAD CAP SCREW M8x35

2

54

SRB-000046

HEX SOCKET HEAD CAP SCREW M10x25

1

55

SRB-000309

HEX SOCKET HEAD CAP SCREW M10x120

2

56

SRB-000148

HEX SOCKET HEAD CAP SCREW M8x20

2

57

WZK-0461-09-07-00-0

STOP BUTTON WIRE SET

1

58

WZK-0461-09-08-00-0

CONTROLLER PLATE GROUNDING WIRE

1

59

WZK-0461-09-09-00-0

MOTOR GROUNDING WIRE

1

60

WKR-000446

CROSS RECESSED SCREW M4x20

2

61*

SKR-0461-15-00-00-0

METAL BOX

1

62*

KLC-000011

8 MM HEX WRENCH

1

65*

KLC-0461-16-00-00-0

6 MM HEX WRENCH – MODIFIED

1

66*

WKT-000004

TORX SCREWDRIVER T15x100

1

67*

KLC-000032

12 MM COMBINATION WRENCH

1

68*

KLC-000007

4 MM HEX WRENCH

1

69*

SMR-000005

GREASE FOR SCREWS

1

70*

OLJ-0505-05-00-00-0

OIL FOR STEEL

0.5 kg

71*

OLJ-0505-06-00-00-0

OIL FOR STEEL

1 kg

72*

OLJ-0505-07-00-00-0

OIL FOR STEEL

5 kg

73*

OLJ-0505-08-00-00-0

OIL FOR STEEL

30 kg

* not shown on the drawing

SM-BM-21 Operator’s Manual

20

Other manuals for SM-BM-21S

1

Table of contents

Other SteelMax Power Tools manuals