Steens Industrier AS 2010 mk IV User manual

R

R

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

MANUPED

Art.no.: 373 100

Model 2010 mk IV

I-nr.: 109 200

Ellingsrud Industrifelt, Verkstedveien 25

Post box 254, N-1401 SKI

Phone: +47 64 91 47 00 - Fax: +47 64 87 65 47

e-mail: post@steens-industrier.com

Home page: www.steens-industrier.com

Adjustable resistant

Adjustable height (angle)

Digital counter

speed•

distance•

watch•

Chair-/wheel plates included

U S E R M A N U A L

R

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

Warranty

Steens Industrier AS does not have any responsibilty for faults in the content

of this material, for accusingly damage in relations with delivering, use or

recycling of this material.

Steens Industrier AS does not have any responsibility or any guaranty if the

use of this apparatus is not in conjunction with the field of use and meaning.

Technical specifications can be changed with out notice.

© Copyright 2008 - 2010

Steens Industrier AS claims all the rights to this document on the base of

Norwegian law. Reuse, copying complete or fragmentally, may not be done

without our confirmation.

Steens Industrier AS have the right to change the information in this document

without notice.

Publications:

Fil: 373 100 BM manuped 06 EN net.---

First issue: March 2008

Second issue; February 2010

Ellingsrud Industrifelt, Verkstedsveien 25

Post box 254, N-1401 SKI

Phone: +47 64 91 47 00 - Fax: +47 64 87 65 47

e-mail: post@steens-industrier.com

Home page: www.steens-industrier.com

CONTENT

• Foreword

Important symbol•

• Receiving and check out

• Content in the box

• Assembling, preparation and test of functions

• Parts and definitions

Fields of use•

• Product description

• Rules for use

Safety•

• Positions and adjustments

Use of VDO, replacement of battery, setting, programming•

• Cleaning

Maintenance and service•

Base setting of resistance•

Retighten the rim•

• Problems during use

• Accessories

• Technical data

CE declaration of conformity•

Product guaranty•

Log for product maintenance•

Form for claims•

U S E R M A N U A L

R

Steens Industrier congratulate you for choosing our improved MANUPED

with digital counter. We hope both you and your patient will have a great

and a meaningful training moment with use of this apparatus. Steens In-

dustrier AS have their own fabric with modern machinery at Ski. The firm

have developed and produced treatment apparatus and benches since

1974. The products are sold all over the world under the trade mark;

The firm is all the time focused on delivering product of high quality, ac-

cording to the users needs and wishes. The firm is certified according to

ISO 9001 and develop an produce all products to fulfill the claims of the

day. MANUPEDEN is CE marked and confirming with the relevant active

standards and directives.

This user manual for the MANUPED 373 100, is made based on the qual-

ity philosophy of Steens Industrier and the goal is to give the user an

advantage, all the way, with the new apparatus. Please, read this manual

carefully and give the advice and guidance your attention. Then the ap-

paratus will serve you in many years and you will have our complete

guaranty.

FOREWORD

IMPORTENT SYMBOLS

INFORMATION!

This symbol in the text gives information, making it easier to use the

product and an orientation about special functions.

i

WARNING!

This symbol give a general warning for danger. Please, follow the guidance

to avoid injury on persons and damage to equipment and environment.

SQUEEZING!

This symbol warns for squeezing possibility. Please, pay attention and

follow guidance to avoid injury on persons.

R

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

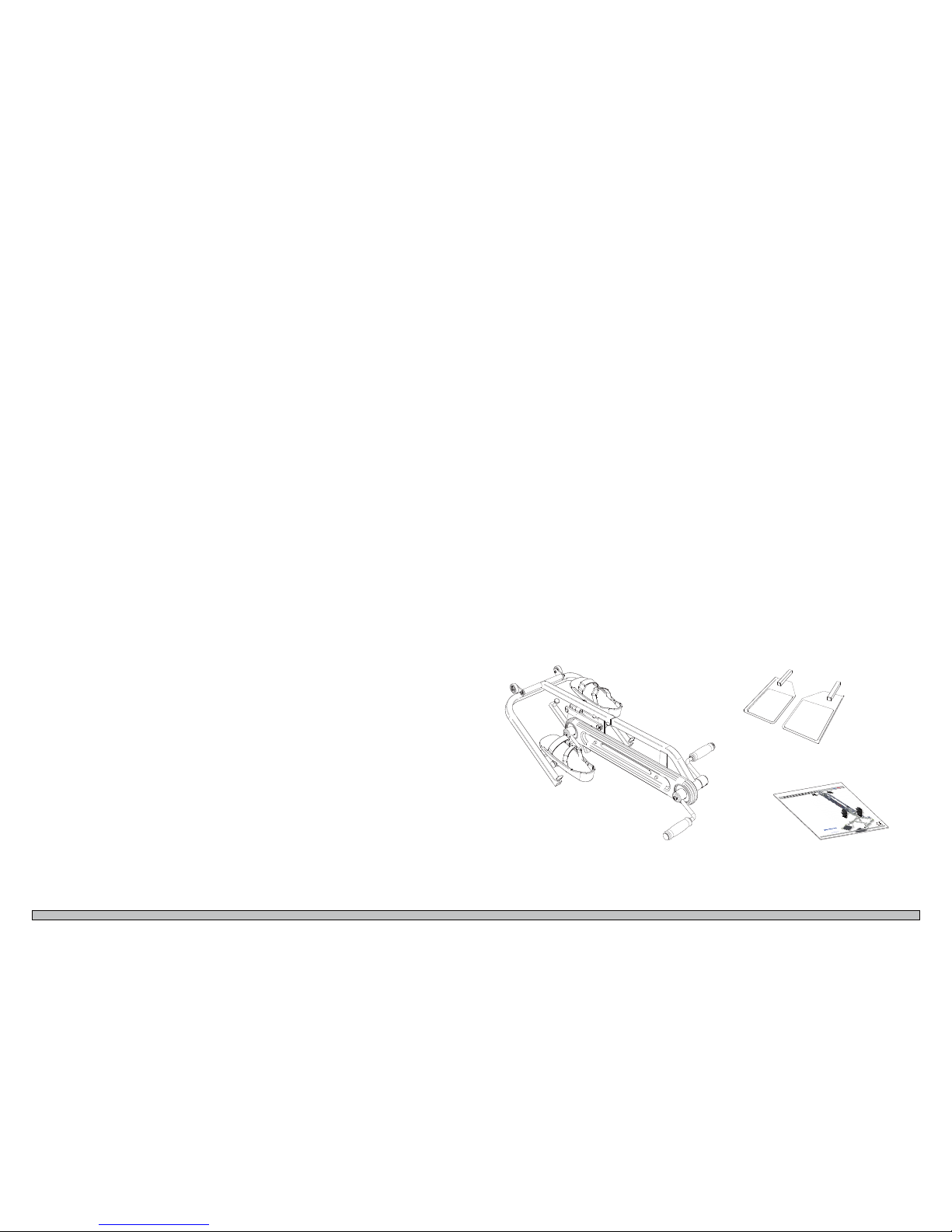

1 MANUPED

1 set of chair/wheel plate.

Battery 12V LR23 (mounted in the transmitter).

Battery 3V CR2032 (mounted in the display).

1 User manual (this one)

RECEIVING and CHECK OUT

CONTENT in the BOX

When receiving the goods, check out order no. model no. recipient in1.

relation to your order.

Check the wrapping for any transport damages. Make a notice on the2.

transport paper and on the form at the end of this booklet. Replace-

ment/repair would not be carried out less proper notice is made and

mailed to us within 10 days.

Rev.:05.02.2008rg

Dato:04.02.2008rg

Fil:373100BM manuped 05.--- -

MANUPED

Art.nr.: 373 100

Modell2008 mk III

I-nr.:100 794

EllingsrudIndustrifelt, Verkstedsveien 25

Postboks254, N-1401 SKI

Telefon:+4764 91 47 00- Faks: +47 64 87 13 74

e-post:post@steens-industrier.com

Hjemmeside:www.steens-industrier.com

Regulerbarmotstand

Regulerbarhøyde (vinkel)

Digitalteller

hastighet

•

distanse

•

klokke

•

Stol-/hjulplatermedfølger

U S E R M A N U A L

R

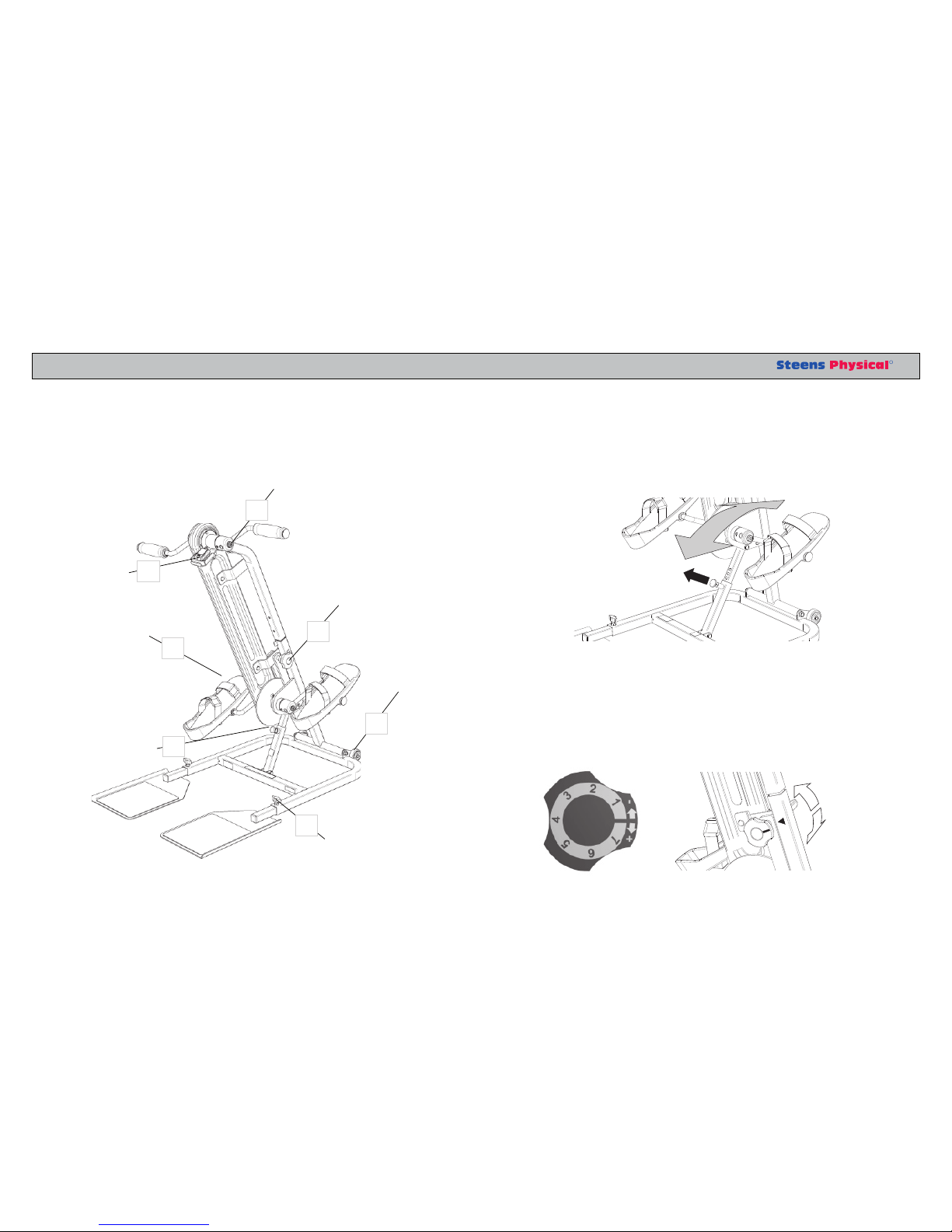

ASSEMBLING, PREPARATION and TEST of FUNCTIONS Make some space on the floor and put down the1. MANUPED.

Raise up the pedal unit2. A.

Put the support tube with the gas spring (3. 1)on the pedal part into the

outer tube (2)on the base frame B

Pull out the snap locker (4. 3) so that it can enter one of the locking

holes. Angle the pedal unit to the desired position, and make sure it

locks properly C.

Put the chair/wheel plates in back end of the base frame (5. 4,5) tighten

the wing screws (6) D.

Unlock the resistant wheel (6. 7), it is tighten throughout transport.

Check now that the digital counter is working. Turn the handle (7. 8)

for some second, a small indicator will appear at the upper left cor-

ner of the display (9).

The apparatus is now ready to be used.8.

Please, make a note in the LOG - at the end of this booklet - date and9.

signature

A

6

12

6

7

5

4

8

9

3

C

B

D

There in no need of tools during assembling.

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

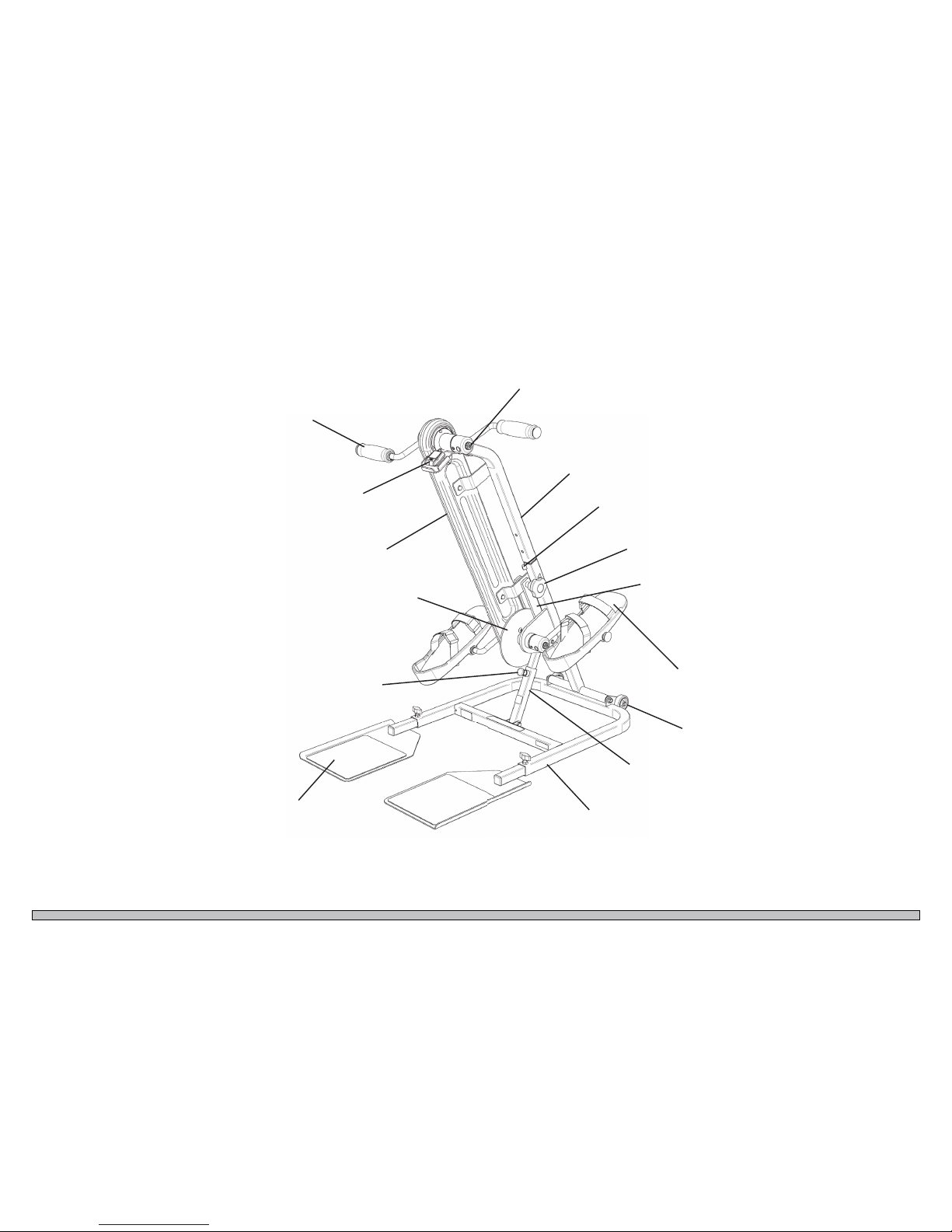

PARTS and DEFINITIONS

RIGHT SIDE

LEFT SIDE

Fix screw with contra nut for

adjustment of arm length.

Handle, gear rim connection to

foot pedals

VDO A4+ digital km counter

with transmitter and receiver

Rim gear cover

Fix screw for tightening

of the rim

Wheel for adjustment

of resistance

Pedals with adjustable foot

straps

Small wheels for moving

the apparatus

Chair/wheel plates with

none slippery cower

Snap lock for height/

angle adjustment

BASE FRAME

Friction disk

Support arm

PEDAL UNIT

ANGLE SUPPORT

U S E R M A N U A L

R

FIELDS of USE

PRODUCT DESCRIPTION

The MANUPED is an apparatus for training of arms and legs. You use it

together with a chair or a wheelchair. The MANUPED is mainly used in

institutions, however it also have a great potential in private homes. It is

developed in order to give elderly a good physical training with softening

of links, stronger muscles, increased condition and blood circulation with

better fitness and increased quality of life.

The MANUPED also has an application where there is a need for coordi-

nation and / or movement between the extremities of various disability or

rehabilitation after injury.

The MANUPED should always be used under the expert guidance of

a therapist.

The MANUPED have foot pedals and hand crank that is connected to

each other and adapted so that the rotational speed is the same. Gear rim

with tightening adjustment, is encapsulated.

Rotation resistance can be adjusted easily with a number marked wheel.

The MANUPED is equipped with a digital counter and the display shows

speed, trip and total “distance” and the clock. VDO Bike Computer A4 +

is used and provides the user with a good quality feeling.

Angle/height to the floor, can easily be adjusted in 5 positions and snap

lock provides a safe setting. The feature is weight balanced with the help

of the compression gas spring and prevents the pedal unit falling and

cause damage.

The MANUPED have floor plates for the chair or wheelchair to set up on.

This ensures that The MANUPED will be at rest during your workout.

Pedal and crank periphery path has two sizes and can be easily adapted

to user needs.

The foot pedal have stops with Velcro and is easy to regulate.

The MANUPED is equipped with 2 casters which facilitates the transfer.

When the device is tilted, it is easy to roll.

i

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

RULES FOR USE

SAFETY

The MANUPED is a device that has a low risk of injury when used ac-

cording to intention. Nevertheless, it is necessary to emphasize that it is

your duty to use the MANUPED only for what it is intended.

Always make sure that the MANUPED is in order - none defective part

or features that work improperly.

The person who trains should always sit confidently. Make sure that the

chair / wheelchair stays properly on the plates.

Always make sure that the MANUPED is preset properly to the person

who will exercise:

Set the correct height

Set the appropriate resistance

Set the right pedal and crank length

If desired, 0-set km counter

See the boards are firmly screwed

Place the chair / wheelchair correct relative to the MANUPED

The therapist should always ensure that exerciser/patient are train-

ing correctly. When the workout is optimal the opportunities for er-

ror and injury during training reduced. Always check:

Proper sitting position

Correct height

Proper resistance

Correct intensity

Correct duration.

i

Before use, read the User Manual for full filling the claims of Guar

anties.

Be aware of your

responsibility for safety when using the Apparatus and accessories, to prevent damage and/or

avoid injury. Always get a program and follow the therapists instructions during training.

Før bruk, les brukermanualen for å oppfylle garantikrav.

Vær oppmerksom på ditt ansvar for

sikkerhet når du bruker apparatet og utstyr, for å unngå ødeleggelse og forebygge skader. Få alltid

veiledning og følg instruksjonen til terapauten under treningen.

U S E R M A N U A L

R

POSITIONS and ADJUSTMENTS

ADJUSTMENT OF THE

RESISTANSE

SAFETY SCREWS

FOR PLATES

CHANGING THE LENGTH

OF THE HANDLE

WHEEL FOR EASY

MOVING

CHANGE THE

LENGTH OF THE RIM

ADJUSTMENT OF

THE ANGLE/HEIGHT

0-SET

KM COUNTER

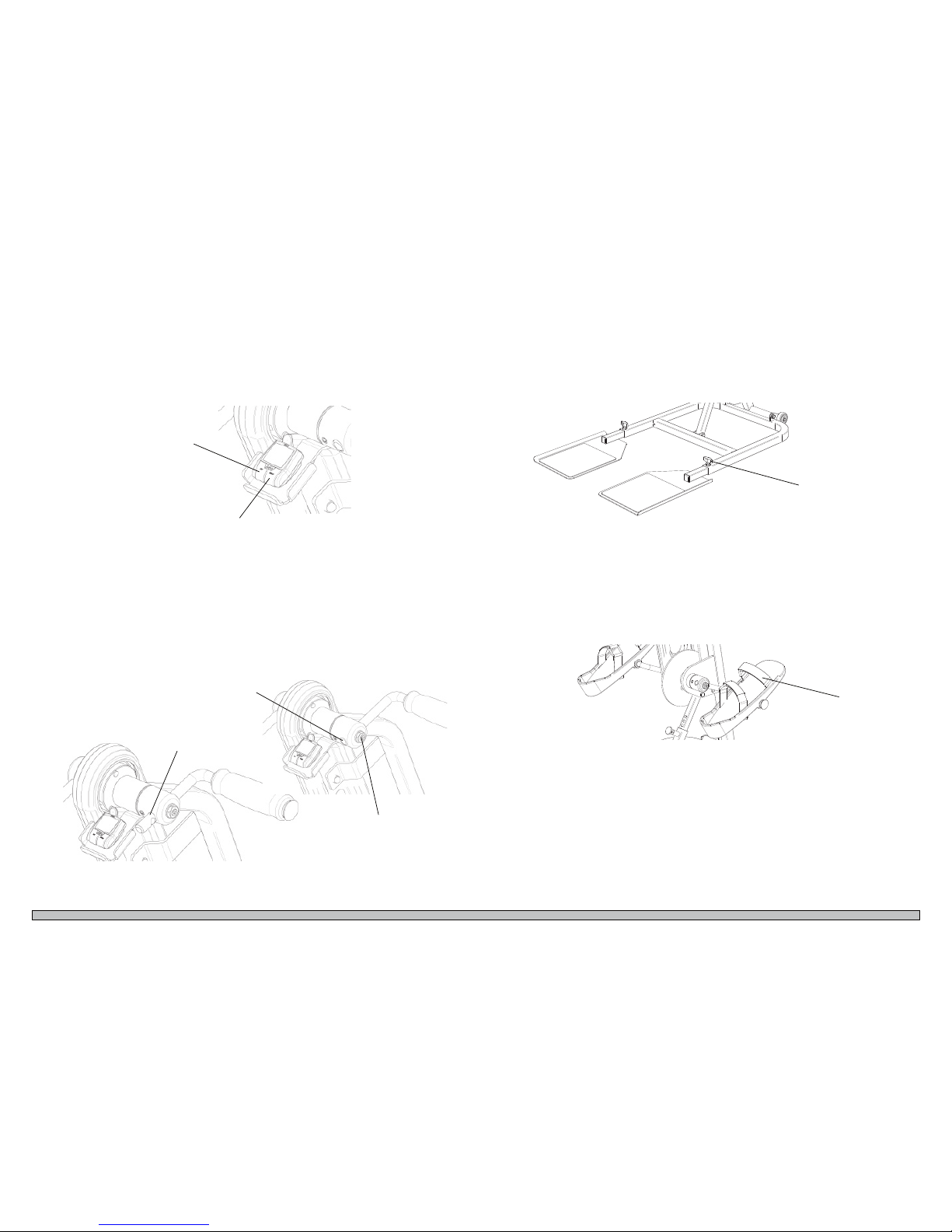

1. SETTING THE HEIGHT / ANGLE

Pull out the snap lock head (A), tilt the balanced handle-support up or down

until correct height. Drop the snap lock and ensure that it locks properly.

2. REGULATION OF RESISTANCE

When the wheel (A) is completely turned on, the resistance is greatest, read

against the small triangle mark on the support tube. When the wheel is turned

turn clockwise the resistance is reduced. Settings in between are indicated

with numbers from 1 to 7.

+

-

B

A

1

2

5

6

4

8

3

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

5. WHEEL PLATES AND LOCKING SCREWS.

Always make sure that boards are fully in and lock the lock screw (D) tight.

6. PEDALS AND STRAPS

The straps (E) on the pedals have Velcro lock and are easy to regulate. Make

sure they are correct and appropriate tightened.

4. CHANGE OF ARM LENGTH OF HANDLE AND CRANK

To change the length of the handle and the crank, you needed a 17mm wrench

and a 5mm 6-sided key. Lock nut (C) must be loosened before the set screw

can be turned out slightly. Make sure the set screw hits the dent in the arm

when it is turned on again. Remember to tighten the lock nut at last.

7. MOVING OF THE MANUPED

When the MANUPED is being moved / pushed, turn handle as an arm point-

ing up and move to the resistance wheel completely. Then it’s easier to tilt the

MANUPED on its wheels. It also gives more control when it is rolled.

3. 0-POSITION OF KM COUNTER

Press the SET and MODE buttons simultaneously for 3 seconds. Then the trip

counter is TRP reset to 0 km.

C

D

E

SET button

MODE button

Long arm

(standard)

Short arm

U S E R M A N U A L

R

DIGITAL km COUNTER

Magnet

Speed

Mode

Watch

Distance

Indicator

SET button MODE button

DISPLAY

Transmitter

Battery

Battery

1. Taste function

RIGHT BUTTON (MODE button)

In bike mode: Use this button to progress through the ODO, TRP and

CLK screens.

In setting mode: (Set-Mode) Use this key to adjust the values in the

Set-up screen.

LEFT BUTTON (SET button)

Use this button to access the Set-up screens for the wheel size, clock

and odometer.

In SET-Mode: You change the figures.

2. Data Features

CURRENT SPEED (KMH / MPH)

Current speed is displayed permanently on display up to 120 KMT

(75 MPH) with an accuracy of 0.1 KMT

TRAVEL DISTANCE (TRP = TRIP)

Displays the distance to travel for the current trip, up to 999.99 KM

or M. When excess of 999.99, the counting restarts at 000.00

CLOCK (CLK)

Displays the current time in 24-hour format

TOTAL DISTANCE ODOMETER (000)

Showing the total distance, sum of all data of all the individual tours.

Counts up to 99999. The values are KM or M

SLEEP MODE

To extend battery lifetime, the A4 + automatically go into ”sleep”

mode after 3 minutes of use. Only the time will be shown. The wire-

less receiver A4 + will remain active for 3 hours, to allow Auto start

/ stop. In case of non-use, the receiver will be turned off. This is

indicated by a flashing ”CLK” symbol. To reset the computer, press

any key. If the computer is not used, it will turned it self off, no later

than 24:00 midnight. The computer will restart by pushing one of the

keys.

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

3. Reset the computer

3.1 RESET APPLICABLE TOUR DATA

To reset the current trip data TRP press SET and MODE buttons

simultaneously for 3 seconds.

3.2 RESET COMPUTER

To reset the computer to factory settings, use a pen and press the

”AC” knob on the back side of the computer.

NOTE: This action will erase all data and all of your setup for

wheel size. Clock and odometer will also be deleted.

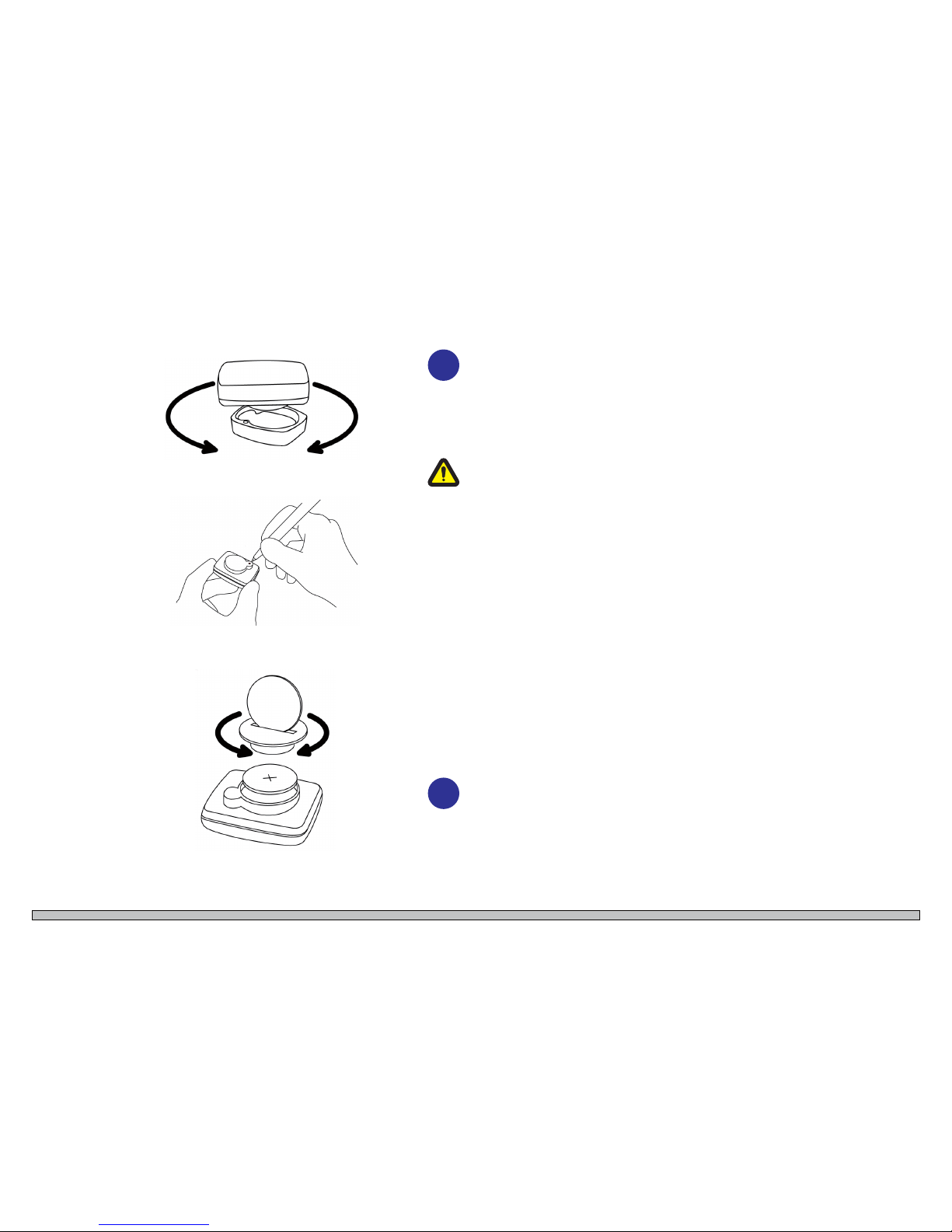

4. Replacing of battery and setting

4.1 INSTALLATION OF BATTERY I COMPUTER

VDO A4 + need a battery 3V type CR 2032. Batteries are available

at your dealer (VDO Part No. # 1013). Battery lifetime is around 12

months under normal use. Notice! In case of error display, check the

battery first, before it is taken into claim.

In order to change battery, the computer has to be taken off. Turn it1.

firmly to the left and lift it up.

Remove the battery door with a suitable coin.2.

Place the battery in the battery compartment, + - pole visible. Be3.

careful when installing the battery not to damage the battery connec-

tion.

Replace the battery cover, make sure the rubber O-ring will not be4.

squeezed out of the door. Notice! If the O-ring is damaged it can get

moisture into the battery and the computer can be damaged.

Screw the battery door firmly back in place with a suitable coin.5.

IMPORTANT: During battery replacement, all data and all settings will be

stored in about 20 seconds. In order to save your data, replace the battery

within 20 seconds, otherwise all the settings for the wheel size, clock and

odometer has to be configured again.

Tip: Buy a new battery in time. In order to preserve all data and settings,

change the battery in time. Before you replace the battery, we recommend to

take a note of your wheel size setting and odometer data.

i

i

U S E R M A N U A L

R

4.2 REPLACING THE BATTERY I TRANSMITTER

The VDO A4 + transmitter uses a 12V battery, type LR 23 Batteries are avail-

able at your dealer (VDO Part No. # 1014). Battery life is around 12 months

under normal use.

Remove the battery cover on the transmitter with a suitable coin. This1.

is the side that points down and forwards.

Place the battery in the slot + - pole visible. Be careful when you2.

insert the battery so you do not destroy the battery connection.

Replace the cover. Make sure the O-ring will not be crushed or dis-3.

torted. Then the transmitter will not be waterproof anymore and can

be damaged.

Screw the battery cover firmly back in place with a suitable coin.4.

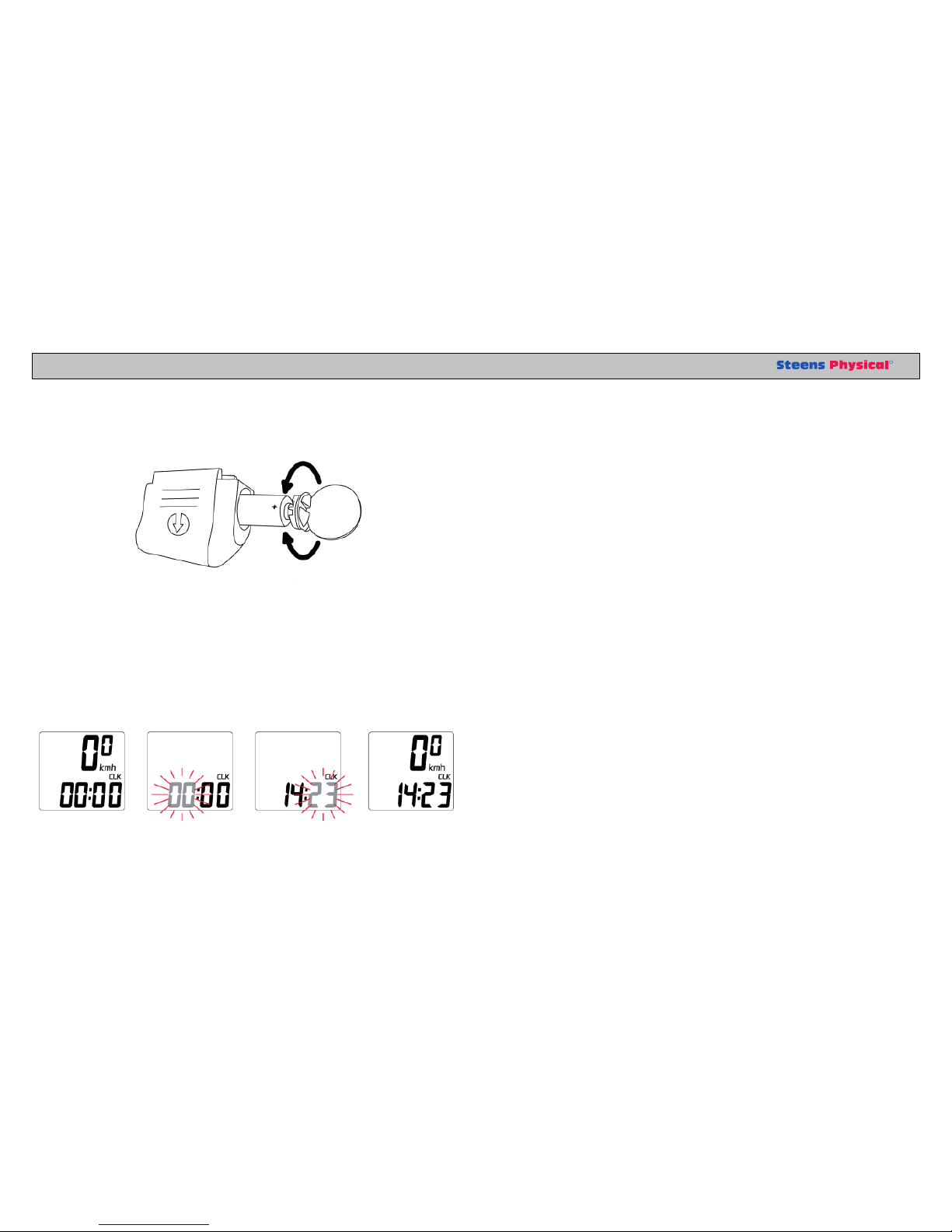

5. Programming of the km counter

To view an approximate speed and figure out “travelled” distance and other

data, the VDO A4 + km counter set by default, is programmed with a wheel of

a diameter like 700 mm (28 ”) corresponding to a circumference = 2155 mm.

This can be changed if desired (see separate information). The counter is set to

km as the measurement unit.

5.1 SETTING THE CLOCK

The VDO A4 + shows the current time in 24:00 hour format.

Take the CLK screen. Press and hold SET button for 3 seconds.1.

Clock SET-Mode will appear on the screen.

Use the MODE button to change the flashing hour figure. Hold the2.

MODE button pushed down for speed setting. Confirm the setting by

pressing the SET button and then move over to the setting of minutes.

Use the MODE button to change the flashing minutes figures. Hold3.

the MODE button pushed down to speed setting.

Press the SET key for 3 sec. Clock setting is completed and CLK4.

screen displays.

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

5.2 PROGRAMMING OF ODOMETER

The total distance ODO can be programmed at any time - after battery

change or from previous notes. ODO is a function that shows the total

”trip” distance and always add the last ”trip”.

Take the ODO screen, press and hold SET button for 3 seconds.1.

ODO Set Mode will appear on the screen.

Press the MODE button to change flashing digit to the desired2.

value. Confirm this by pressing the SET button and at the same

time move to the next number that is blinking.

Repeat STEP 1 and STEP 2 until all numbers are programmed3.

as desired.

Press the SET key for 3 sec. to save the ODO programming and4.

return to the ODO screen.

6. Errors and Testing

- If the screen is black, it will be necessary to replace the battery.

- If the screen for some reason is blank or it shows an irregular display

after a battery change, press the AC button on the back side of the com-

puter. This action will erase all data and all settings, and requires new

settings of the clock and odometer.

- If the indicator does not go around it will be necessary to replace the

battery in the transmitter.

7. Recirculation of the battery

This product is consistent with EU Directive 2002/96/EC. The symbol

on the product or on its packaging indicates that this product should not

be treated as ordinary housekeeping waste. Instead it shall be submit-

ted to the collection station for recycling of electronic equipment. When

insure proper waste handling, you will help preventing negative conse-

quences for the environment and human health. In other case, procedure

can cause improper waste handling of this product. For more informa-

tion about recycling of this product, please contact your nearest waste

depot, waste handling service or your dealer of the product.

U S E R M A N U A L

R

CLEANING

MAINTENANCE AND SERVICE

The MANUPED should be cleaned with light soapy water and nearly

dry cloth when needed or at least 1once a year.

The MANUPED is not designed to withstand machine washing or any

use of high pressure cleaners.

Max, washing temperature 80°C, pH between 5 and 7

The MANUPED does not require any special presides of service or

maintenance. But, it is important to check that all functions are working

properly.

The device has no lubrication points. It is designed and manufactured so

lubrication of any kind not is required.

Make it a habit to log all the checks at the back of the user manual.

Complete control at least once annually. Check the following points:

Check and tighten loose screws.1.

Check and replace defective or missing parts.2.

Check straps for pedals3.

Check gear rim. Adjust tightening if required and always when4.

the crank and pedals can be turned asynchronous.

Check batteries. To ensure safe operation of the digital km5.

counter, you will need to replace the battery in the transmitter

and receiver at least 1 time per year.

i

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

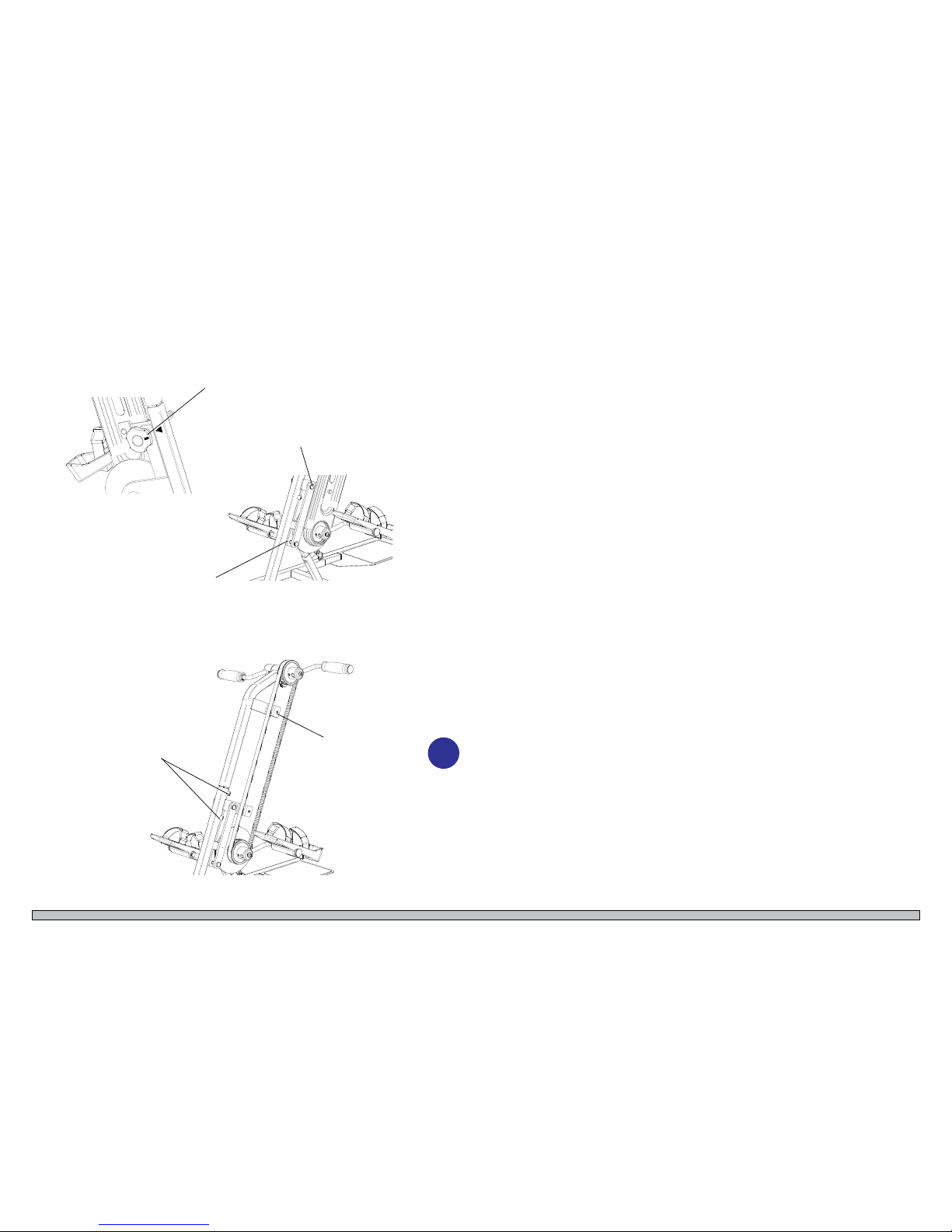

BASE SETTING OF RESISTANCE

RETIGHTEN THE RIM

STARTING POINT: Resistance unit is correctly and loosely mounted.

The brake pads resting on their respective pins. Follow the procedure

below to adjust the resistance knob and nut:

Tighten the steering wheel. Note the 0 point in relation to the1.

triangle mark (1) on manuped tube.

Now turning the wheel so far that the head of the screw can be2.

turned to correct position in its recess (2).

Turn the wheel quite tight and check that the 0 point is in line3.

with triangle mark. If needed, repeat step 2.

Turn the wheel 1 revolution up and now adjust the nut (3) so4.

that the brake pads just allow the disc to run freely. Nut is fitted

with locking means, so that it does not come out of position

during use.

Tighten the wheel completely and check that the friction is5.

working. If the handle still is easy to turn, the nut has to be

tighten some more, repeat step 4.

Follow the steps below when the gear rim aught to be tightened:

Disassemble the cover, remove the nut caps and unscrew nuts.1.

Loosen the upper, inner nut (1) as the permanent cover gets a2.

leeway.

Loosen the set screws (2).3.

If required adjust the pedals and handle so they run synchro-4.

nously.

Take a suitable screwdriver, insert it in the slot between the up-5.

per and lower tubes and turn them from each other until the rim

is tighten properly. NOTE! Do not tighten the rim to hard,

then the MANUPED will run slowly.

Tighten set screws (2)6.

Tighten the inner, upper nut (1)7.

Mount the cover back in place. Ensure that the long slot facing8.

upwards. Turn on the nut and replace the nut cups.

1

2

3

2

1

Here shown without cover.

i

U S E R M A N U A L

R

DISTURBANCE OF FUNCTIONS The MANUPED has few sources that can cause operational disturbanc-

es. Here are mentioned some situations that may arise:

It is difficult to regulate the angle / height ...

Gas Pressure Spring (11) as weight balancing the pedal/handle

support is defect and needs replacement.

The pedals are too heavy to pull around ....

Friction steering wheel (36) is pulled all the way to.

Adjustment nut (32) is too tight.

The pedals are too easy ...

Friction steering wheel (36) is not set correctly

Adjustment nut (32) is the slack

The km counter has black screen ...

Replace the battery (68)

The km counter does not record the activity ...

Replace the battery in the transmitter (69)

Any of the 3 magnet (65) may have fallen off

Foot pedals and handle jumps or runs asynchronously

Adjust and tighten gear rim (24)

Screeching noises ...

Check the reason - repair the error source as soon as possible

Check with a qualified personal when the service should be per-

formed.

- the sooner a fault is repaired, the less risk of danger when used. It also

reduces the risk of more serious consequential damage and more errors.

Wear is reduced and the product gets a longer lifetime.

i

Rev.: 09.02.2010 rgDate: 09.02.2010 rgFil: 373 100 BM manuped 06 EN net.--- -

ACCESSORIES To the MANUPED the following equipment are available:

Long chair/wheel plates - art.no.: 373 100-10

Standard chair/wheel plates - art.no.: 373 100-09

Chair/wheel plate with straps - art.no.: 373 100-02

One piece chair/wheel plate - art.no.: 373 100-06

U S E R M A N U A L

R

TECHNICAL DATA The MANUPED are manufactured in steel and powder coated. Parts that

can be worn out, are chrome plated.

It is not used materials or processes that pollute the environment.

The product and the batteries should be recycled in accordance with ap-

plicable regulations.

(C) Steens Industrier AS reserves all rights to this drawing

in accordance with Norwegian law.

Use, abuse, duplication, communication to third person,

completely or in part, must be cleared with us in advance.

Steens Industrier AS disclaims any liability with regard to abuse of

this drawing, its idea or its content.

Drawing information may change without notice.

Date stamp, signature and ordeing verifies the drawing.

Tittel:

Konstruert Kontrollert: Godkjent:

Toleranser:

NS-ISO 2768-1

Beregning:

Henvisning:

Dato:

Dato: Dato:

Middels Ekstra

grov

Fin Grov Fil:

Erstattet av:

1400 SKI Tlf: 64 91 47 00 post@steens-industrier.com

Steens Industrier AS

Erstatter:

Målestokk:

/

Side/sider

Utgave:

Tegning nr.:Tempus:

Manuped digital

RG

09.02.2010

2 3

Art.nr.: 373 100 MK IV

109200.iam

x

A - 09.02.2010 - rg

109200

-

075

612

970-1075

935

66°-81

a

ADJUSTABLE 5 positions:

1 - 66

a

2 - 69

a

3 - 73

a

4 - 76

a

5 - 81

a

Weight: ca 26.2 kg

This manual suits for next models

1

Table of contents

Other Steens Industrier AS Fitness Equipment manuals

Popular Fitness Equipment manuals by other brands

G-FITNESS

G-FITNESS AIR ROWER user manual

CAPITAL SPORTS

CAPITAL SPORTS Dominate Edition 10028796 manual

Martin System

Martin System TT4FK user guide

CIRCLE FITNESS

CIRCLE FITNESS E7 owner's manual

G-FITNESS

G-FITNESS TZ-6017 user manual

Accelerated Care Plus

Accelerated Care Plus OMNISTIM FX2 CYCLE/WALK user manual