stefani Reverse Osmosis User manual

Congratulations on purchasing the Stefani 5 Stage Reverse

Osmosis Filtration System. Please read carefully the installation

and operation manual before installing the unit.

1

IMPORTANT:Installation must comply with existing State and Local Plumbing codes. Plumbing

The Pressure limiting valve must be installed to ensure the correct operation of the unit and

compliance to the warranty. For your convenience, a Pressure Limiting Valve is included in the

box.

Please note our warranty requires proof of installation by a Licenced Plumber including water

pressure testings and results.

CAUTION:

is microbiologically safe- that is, water that has been adequately chlorinated or disinfected.

Additional sterilising equipment will be required for unsafe water.

pressure of 862kPa (125psi); minimum pressure of 69kPa (10psi) and at a maximum temperature

-

cartridges which are consumable items).

AS/ NZS3497. This valve must be installed as a standard equipment and as detailed in the

Installation Drawings and Instructions, to provide:

RECOMMENDATION:

water.

HELPFUL HINT:

water.

We recommend you continue to check for leaks for a day after installation.

INCLUDED ACCESSORY: For your convenience the following accessory is included:

Pressure Limiting Valve with dual check valve - limits the pressure to 345kPa (50psi).

For further information please contact Stefani +61 8 93506178

To maintain optimum water quality you will need to replace the cartridge at least every 6 months.

Installation Note: A water lter system/tap, like any product, has a limited life and may eventually fail.

Also sometimes failure happens early due to unforeseen circumstances. To avoid possible property

damage, this product should be regularly examined for leakage and/or deterioration and replace when

necessary. A drain pan, plumbed to an appropriate drain or outtted with a leak detector, should be used

in those applications where any leakage could cause property damage, and /or the water supply should

be turned o if no one is home/present.

TABLE OF CONTENTS

REVERSE OSMOSIS SYSTEM DIAGRAM

LIST OF PARTS ............................................................................................ 4

INSTALLATION INSTRUCTIONS

REVERSE OSMOSIS SYSTEM CONTENTS DIAGRAM ............................. 5

STEP 1 – MAINS WATER CONNECTION ................................................... 6

STEP 2 – FAUCET INSTALLATION ............................................................. 9

STEP 3 – DRAIN SADDLE INSTALLATION ............................................... 9

STEP 4 - 5 FILTER COMPONENTS & MANIFOLD INSTALLATION ... 10

STEP 5 – STORAGE TANK PRE FILL & LOCATION ............................... 10

STEP 6 – FINAL TUBING CONNECTION ............................................... 11

STEP 7 - SYSTEM START UP .................................................................... 11

THE QUICK CONNECTION PUSH SYSTEM ........................................... 12

REPLACING THE REVERSE OSMOSIS MEMBRANE ............................. 12

REPLACING FILTER CARTRIDGE ............................................................. 12

WARRANTY ................................................................................................. 14

STEFANI WATER FILTER CARTRIDGE GUIDE ........................................ 15

2

OPTION 1...................................................................................................................6

CONNECTING TO ½” COPPER PIPE WHERE EXISTING PLUMBING FITTINGS ARE AVAILABLE

OPTION 2...................................................................................................................7

CONNECTING TO ½” COPPER PIPE

OPTION 3...................................................................................................................8

INSTALLING WITH AN EXISTING MIXER TAP/DISHWASHER TAP

............................................... 3

01

04

03

04

04

08

09

18

11

12

13

21

20

17

22

02 05

09

1516 14

06

06

25

3

Reverse

Syetem

Osmosis

EXPLODED DIAGRAM

LIST OF PARTS

Stefani 5 Stage Reverse Osmosis Water Filtration System

component identication & content check list:

4

Re QtvDescription Product No.

HOUSING

PLV

BRACKET

MFV

BV-101

Filter Housing

Bracket

Multi-Function valve (MFV)

Stopper Plug for Multi-Function valve

Ball Valve ¼” NPT

01

02

03

04

05

1

1

1

1

1

WDF-103Lead Free Chrome Drinking Faucet with Locking Nut06 1

PE-14WHITE

BRASS-T

HKEY

Faucet Fittings ( Chrome Cover Plate, O-ring, Plastic Washer,

Lockwasher, Brass Insert, Chrome Nut , Metal Olive)

¼” OD PE White Tube 3 Metres

Brass Tee DR ½” (M)

Hex Key 8mm

08

09

1

1

1

1

Automatic shut-oValve11 1

WRENCH

PP-0510

110

102

RO3

RO2

Single Clip

Wrench

Sediment PP Filter 5 micron

Granular Carbon Filter 5 micron

12

14

15

2

1

1

Double Clip13 2

1

1

Carbon Block lter16 1

SCREW-6

In line Final Carbon Filter

Black Washers

Reverse Osmosis membrane housing & membrane

Pressure storage tank

Tank Valve

17

20

1

2

1

1

¼”QC Pressure limiting valve with dual check valves

21 1

Reject waste water connection22 1

1

07

10

18

19

24

CON1044¼”Union Connector

25

Drain Clamp

23

06 07 25

10

04

19 18

23

24

21

05

02

08 09

20

14

15

16

17

5

Reverse

Syetem

Osmosis

CONTENTS DIAGRAM

Filter Housing and Accessories Assembled

or

INSTALLATION INSTRUCTIONS

6

STEP 1 – MAINS WATER CONNECTION

The 5 Stage Reverse Osmosis Filtration System can be xed in 3 dierent ways

below are the options:

1. Connecting to ½” copper pipe where existing plumbing ttings are available

2. Connecting to ½” copper pipe

3. Installation with an existing mixer tap/dishwasher tap

OPTION 1

Connecting to ½” copper pipe where existing plumbing ttings are available

1. Turn the main water supply o.

2. Disconnect the compression nut from the copper pipe, install the brass tee to the water supply

valve and reconnect the copper pipe.

3. Take Multi-Function valve and with Hex Key, unscrew the inlet nut by placing the Hex Key into

the key provision inlet spinning nut adaptor and unscrew by turning anticlockwise. Insert the 2

Black Washers into the Multi-Function valve.

4. Using thread tape, thread tape the brass tee. Screw the Multi-Function valve into the brass tee

piece. Ensure Particle Screen is tted to entry point of Multi-Function valve.

5. Using thread tape, thread tape the ball valve. Select the port you want to use and screw the ball

valve into the port. Thread tape stopper plug for Multi-Function valve and screw into unused port.

CAUTION! Do not use tools or over tighten, hand tighten Multi-Function valve and stopper plug

only.

BRASS TEE

MULTI

FUNCTION

VALVE BALL VALVE

STOPPER PLUG

½” COPPER PIPE

CUT HERE

BRASS TEE

7

6. Upon completing the above steps, proceed to STEP 2 (page 9)

OPTION 2

Connecting to ½” copper pipe

1. Turn the main water supply o.

2. Caution: Make sure the ½” copper pipe is a cold water line.

3. Find a suitable, straight section of pipe where the brass tee provided can be inserted, use pipe

cutter or a hacksaw and remove a sucient length of copper pipe.

4. Go back to Option 1 and start from number 3, page 6 to complete the connection.

8

BRASS

TEE

MIXER

TAP

DISHWASHER

COLD WATER SUPPLY DISHWASHER TAP

MULTI

FUNCTION

VALVE

BALL VALVE

TUBE IN

STOPPER

PLUG

or

or

OPTION 3

Installing with an existing mixer tap/dishwasher tap

1. Turn the main water supply o.

2. Locate the cold water supply or dishwasher tap and then disconnect the exible hose from the

mixer or dishwasher tap (the use of a exible hose which complies with Australian Standards is

recommended).

3. Remove the two compression nuts and olives from the brass tee and then wrap both ends with

thread tape.

4. Connect one end of the brass tee to the cold water supply or dishwasher tap and then other

end to the exible hose.

5. Go back to option 1 and start from number 3, page 6 to complete connection.

9

STEP 3 – DRAIN SADDLE INSTALLATION

1. Position the drain saddle valve at the

selected location and mark the

opening on the drain pipe.

2. Drill a ¼’hole through one side ONLY

of the pipe.

3. Remove the backing from the gasket

and place the adhesive side to the

tube connection side of the saddle

clamp.

4. Position both halves onto the drain

pipe being careful to align the hole –

use a small drill bit or Phillips head

screwdriver to ensure the holes are

aligned.

5. Secure the drain saddle with the

xings provided.

Drain Pipe

Foam Gasket

¼” Drain Line

¼” Nut

Drain Clamp

Back Plate

Drain Clamp

Front Plate

¼” Screw

STEP 2 – FAUCET INSTALLATION

1. Find the suitable location to install the faucet,

and stabilise the faucet by using the faucet

ttings provided.

2. Remove the locking nut from the faucet.

Place Chrome Cover Plate and O-ring on the

shaft of faucet. Insert faucet shaft into the hole

on the counter/sink top.

3. Place Plastic Washer and Lockwasher on under

counter/sink side of the faucet shaft. Tighten

with Locking Nut and ensure faucet handle is

pointing in desired direction.

4. Place the 1/4” union connector onto the

bottom of the faucet pushing rmly until it will

not go any further. Pull back to ensure it is

secured rmly.

5. Insert the 1/4” tube into the bottom of the

union connector, pushing rmly until it will not

go any further. Pull the tubing back to ensure it

is secured rmly.

counter

Locking Nut

Small Rubber

Chrome Cover

Large Rubber

Round Plate

Locking Washer

Faucet and 1/4” Tube

Connector

1/4” Tube

Washer

Plate

Washer

10

1. Remove lters from packaging and insert into lter housings

2. Connect the 3 lter housing head sections to each other using the connec

tors provided

3. Connect the joined lter housing head units to the manifold bracket using

the screws provided

4. Connect the Membrane housing with membrane already inserted to the top

of the manifold bracket

5. Connect the in line carbon lter to the membrane using the clips provided

6. Screw on each of the lter housings to the lter head units using the

wrench

provided, be careful to ensure they are placed in the correct position as

marked on the manifold bracket

STEP 5 – STORAGE TANK PRE FILL & LOCATION

1. Wrap the Teon tape around the thread on the top of the storage tank

2. Connect the ball valve to the top of the tank, tighten rmly without over

tightening

3. Connect desired length of tubing to the ball valve and directly to the ball

valve at the main water connection

4. Open both ball valves and pre ll the storage tank.

5. Once lled, turn oboth ball valves and remove tubing from the main water

connection ball valve

6. Position storage tank in the desired position sitting it on the plastic stand

provided as close to 5 lter components and manifold

1

2

3

4

5

6

STEP 4 – 5 FILTER COMPONENTS &

MANIFOLD INSTALLATION

Select the location for the Reverse Osmosis components under your sink. Allow

space for the storage tank and at least 50mm to the underside of the housing

to cater for lter cartridge changeover.

Tube insert

o

on

11

STEP 6 – FINAL TUBING CONNECTIONS

1. Connect desired length of tubing from Main water connection to water feed

IN on the Filter housing manifold using the nylon threaded and quick t

connection

2. Connect the desired length of tubing from the water OUT on the main lter

housing manifold using the threaded and quick t connection and connect to

the water IN on the Reverse Osmosis Membrane lter

3. Connect the desired length of tubing to the OUTLET of the Reverse Osmosis

Membrane to the T connection on the Carbon Post lter

4. Connect the desired length of tubing from waste reject water outlet to the

Drain Clamp saddle

5. Connect the desired length of tubing from the post Carbon Filter to the

Storage tank

6. Connect the desired length of tubing from the OUTLET of the Post Carbon

Filter to the Faucet

STEP 7 – SYSTEM START UP

1. Check all ttings are connected and tight

2. Open ball valve from main water connection

3. Open ball valve on storage tank

4. Open faucet until water ows evenly

5. Check carefully for any drips or leaks

6. Allow system to run a full tank of RO water, approximately 3 hours

If possible, collect water and water the garden

The Quick Connection Push System

To connect, cut end of tube square, insert and push in rmly until it can not go

any further

To Disconnect: Press and hold collar against tting, pull tube out of tting.

CHANGING THE REVERSE OSMOSIS MEMBRANE

1. Remove the supply tube from the end of the membrane housing

2. Unthread the cap from the housing

3. Remove the membrane using a pair of needle nose pliers

4. Clean the inside of the housing with a stinylon brush, ush with water

5. Install new membrane, be sure to push the membrane into the housing as

far as it will go

12

REPLACING FILTER CARTRIDGES

It is recommended to only use Stefani water lter cartridges with this ltration

system.

This will ensure optimum performance, protection from contaminates and

compliance with the warranty.

13

1. Turn owater supply to lter system this can be achieved by turning the ball valve on

the main water supply and the storage tank (as shown in the installation drawings)

clockwise until it will not turn any further. Test water supply is oby operating faucet

on sink. If water does not ow from faucet when lever is operated, water is turned o.

2. Unscrew lter housing from system by turning to the left (looking at front view of

system).

3. Remove and discard lters.

4. Clean lter housing with soap and hot water. Do not use any abrasive cleaner, rinse

thoroughly.

5. Remove lter from packaging, place new lter cartridge into lter housing, ensuring

post in bottom of lter housing is located in the centre of lter cartridge.

6. Screw lter housing and tighten.

Helpful hint: After carrying out a lter replacement or any maintenance on lter

systems, we recommend you observe system for possible water leaks for a day after

lter replacement, seals and plumbing to the system may have been disturbed.

Do not over tighten housing as rubber O-ring can be dislodged.

7. Open faucet by pulling lever up. It should toggle into place and stay open.

8. Turn water on. Allow water to run through system for several minutes to expel air

bubbles trapped in the system during the lter cartridge change. Water may appear

milky. These are only tiny air bubbles being expelled from the new lter cartridge.

Flush water until it runs clear.

Note: The ball valve in the system can be turned oin the case of malfunction

of the cut ovalve in the Manifold when replacing the lter cartridge.

LOW /NO MAINTENANCE REQUIRED: The only requirement is changing the lter

cartridges. The life and performance of lter cartridges may vary depending on

volume and quality of the incoming water supply being ltered. Your lter

cartridges may need replacing earlier than 6-8months if you notice a reduced

volume or ow from the lter faucet, or the return of an unpleasant

taste/odour to the ltered water. Please contact Stefani Australasia Pty Ltd on

(08) 9350 6178 or email to stefani@stefani.com.au if you require any assis-

tance.

14

WARRANTY

This warranty is expressly limited to repair or replacement at our premises of

any parts proving defective providing purier has been installed in accordance

with our installation instructions, and pressure and temperature do not exceed

limits stated herein. This warranty does not extend to mechanical damage. Save

insofar as they may be excluded by law, this warranty is given in lieu of all other

expressed or implied warranties or conditions and STEFANI shall in no event be

held liable for damages or delays caused by defects and assume no responsibili-

ty for unauthorised repairs.

This warranty becomes void if the system has not been installed by a licensed

plumber according to plumbing codes in your state, and if it has not been

installed in accordance with installation instructions.

STEFANI WATER FILTER CARTRIDGES GUIDE

Depending on your usage and requirement you may consider using the water

lter cartridges listed below in your Stefani water ltration system. Stefani

water lter cartridges can also enhance or improve performance and protection

when used in other brands of water ltration systems. Suitable for use in all

systems using standard length 248-250mm lter cartridges.

Product code Barcode Description

PP-0510 9319652006720 5 micron (nominal)

PPG-0510 9319652006775 5 micron (nominal)

9319652006737 10 micron (nominal)

9319652006744 25 micron (nominal)

PPG-5010 9319652006751 50 micron (nominal)

107 9319652003798 0.2 micron (nominal)

STEFANI SEDIMENT REDUCTION CARTRIDGE

For removal of sediment, dirt, rust, turbidity, algae and all other particulate contaminants

STEFANI ACTIVATED CARBON TASTE AND ODOUR REDUCTION CARTRIDGS

Filter Service Life:

▪1st stage Sediment lter : Recommend Changing every 3~6 months.

▪2nd stage Carbon block lter : Recommend Changing every 3~6 months.

▪3rd stage Carbon block lter : Recommend Changing every 3~6 months.

▪4th stage TFC/TFM membrane : Recommend Changing every 6~12 months.

▪5th stage Inline carbon lter : Recommend Changing every 3~6 months.

Stefani Australasia PTY LTD

55 Banksia Road, Welshpool

Western Australia 6106

Tel: (08) 9350 6178

Email: [email protected]

www.stefani.com.au/

Product code Barcode Description

106 9319652003781 0.5 micron (nominal)

105 9319652003774 0.5 micron (nominal)

103 9319652003750 0.6 micron (nominal)

104 9319652003767 2 micron (nominal)

102 9300764037955 5 micron (nominal)

9319652006829 1 micron

9319652006836 10 micron

Replacement lter code:

Code Barcode

PP-0510 9319652006720

102 9300764037955

110 9319652008632

RO2 9319652008649

RO3 9319652008656

Please check the Water Filter Cartridge Guide on page 14 for other suitable lters for this system.

Register online at www.stefani.com.au for a lter change reminder by email. A lter change reminder

fridge magnet has been supplied for your convenience.

FILTER CHANGE REMINDER

STEFANI GREEN CARBON FILTER

RO1 / 2021 REV C

Table of contents

Other stefani Water Filtration System manuals

Popular Water Filtration System manuals by other brands

THERMEx

THERMEx Water filter Installation and user instructions

Schako

Schako FKU Instructions for installing

Oneida Air Systems

Oneida Air Systems Dust Deputy Plus AXD050004 instructions

WAGO

WAGO 750-626/020-002 manual

Klimawent

Klimawent STRONG-2000-N Use and maintenance manual

SpectraPure

SpectraPure The Producer System Installation and operating manual

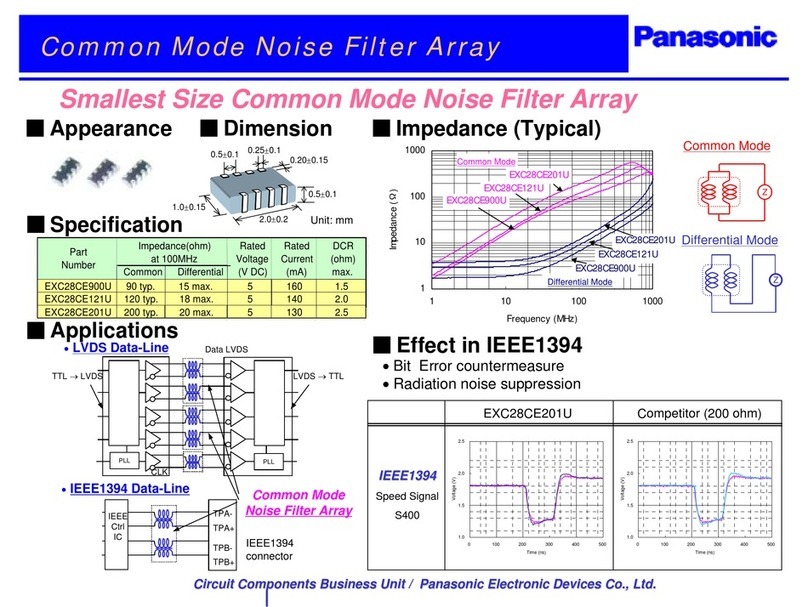

Panasonic

Panasonic Noise Filter Array specification

Bosch

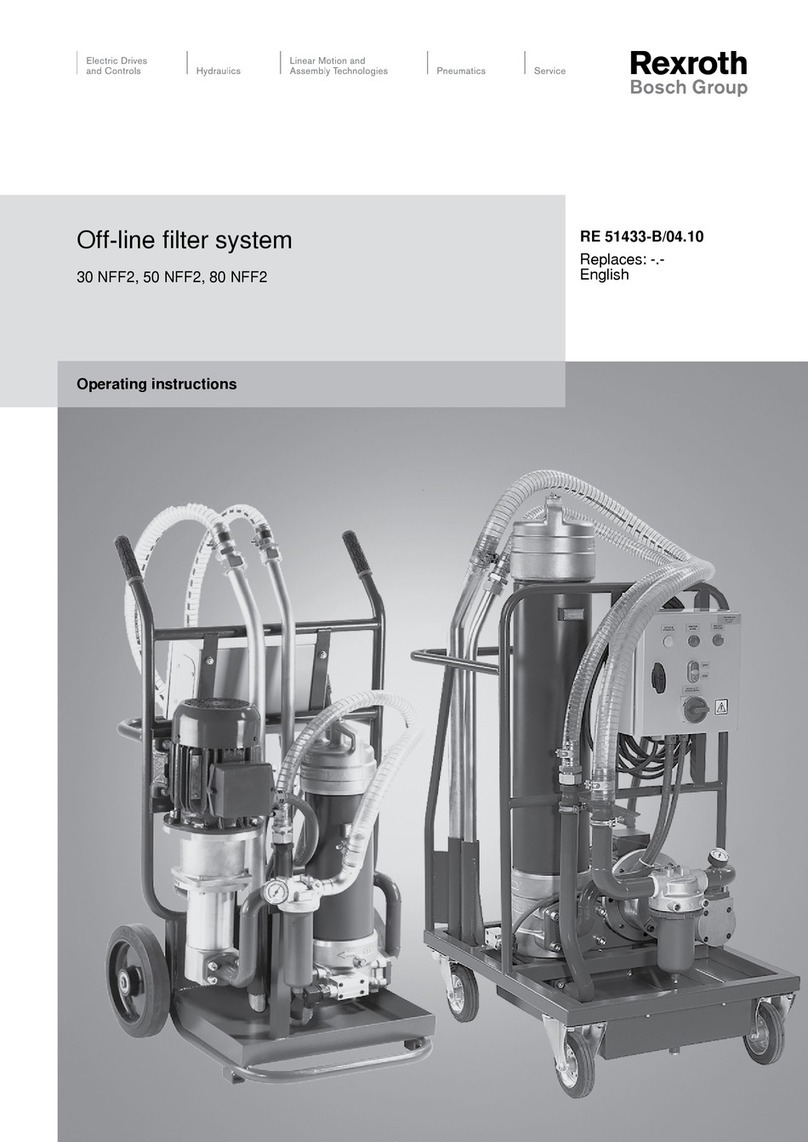

Bosch Rexroth 50 NFF2 operating instructions

waterlovers

waterlovers DW 2800 Operation manuals

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS OF5 S Series Installation and maintenance instructions

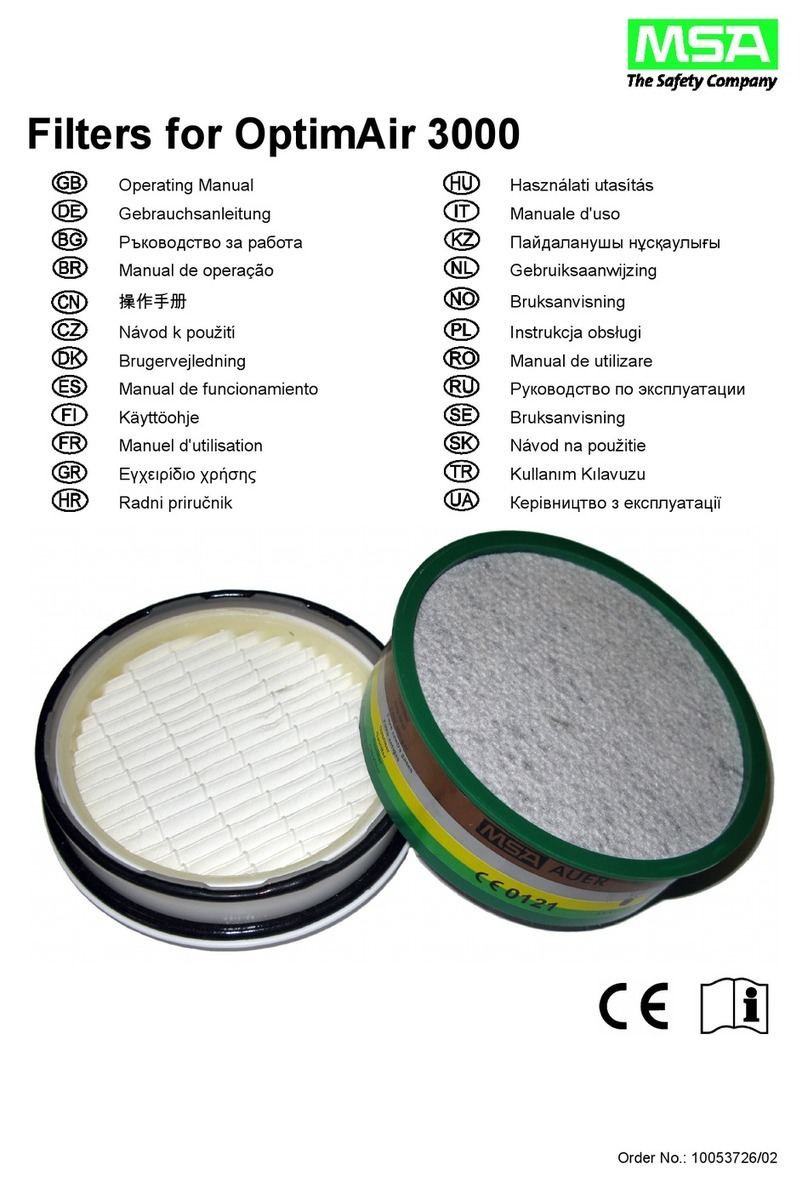

MSA

MSA OptimAir 3000 operating manual

3M

3M AP902 Series Installation and operating instructions