steinert KM 1450 User manual

OPERATING INSTRUCTION KM 1450

03-2020

Standard Accessories

2

Technical Data

3

Liability

Setting up: Benchmodel or Standmodel

Electric Connection

4

Operating the Lathe

Speed Regulation with Potentiometer

Changing the spindle direction

Mainswitch, ASS-Safety System at Spindle

Magnet Box with buttons and switches

5

“0” Point adjustment for Tip-to-Tip alignment

6

Swivelling of Headstock

7

Operating the chucks

Safety instructions, clamping of workpieces

8-9

Tool Rest Base/Support and upper part

10

Outrigger and Bed Extension (options)

10

Maintenance

11

Declaration of conformity

Headstock

Hinge for Vee-belt-cover

Lock pin for 36-indexing system

Digital Display for read out

The adjusted spindle speed

RED main Button “on/off”

If button is pushed:

Lathe is disconnected from electric mains

all buttons of Mobile Box without function

Black Lock Pin for Headstock swivelling

Vee-Belt-POulley with integrated

indexing system

Handle to lift motor for changing

vee-belt

Black lock-pin for 36-division

indexing with automatically lock

if in unlocked postion

STANDARD ACCESSORIES

4-prong mandrel MT2 D=25 mm

for spindle inner cone

Pictures shows also the ASS-safety-ringnut

at the spindle and scale of indexing system

Live centre with ball-bearing MT2/60°

for cone of tailstock quill

quill with engraved scale

1 Tool Rest support

1 Tool Rest 350 mm, stem D=30 mm

1 Double cone MT2/MT2 for re-adjusting

“0” Zero-Point Adjustment

Pin to lock spindle

to loose the chucks from spindle thread

never insert the pin into the boring of

the handwheel sleeve !!

1 long bar D=8 mm to push out the prong mandrel

from spindle cone

1 Pin D=8 mm for chucks with a Bo=8,1 mm

to loose the chuck from spindle thread

TECHNICAL SPECIFICATIONS

Centre height

200 mm

Centre Distance

710 mm

Swing over bed

400 mm

Turning Diameter with outrigger

660 mm max.

Hollow Spindle

D=10 mm with inner cone MT2

Spindle thread outside M33x3,5 with centering collar

and ASS safety-ring-nut

Spindle speed

3 step pulley:

40-850 80-1.645 150-3.025 rpm/min

Max. permissible workpiece D

400 mm 220 mm 130 mm

Tailstock

Cone MT2

Tailstock Quill

100 mm stroke with engraved scale

Motor Power

Motor 400 V/3 ph/2 HP/1,5 kW/50-60 Hz

Electric mains of inverter: 230 V/1 ph

Vee-Belt

Poly-V-Belt J210, 10 ribs

Electric Box

Inverter FU 230 V/1 ph /EMV conform

with undervoltage and overload protection

In case of mains failure: prevents self-staring

of the lathe

2 sockets at side of lefthandside of foot

(if foot is mounted)

for additional equipment or light

Dimension of Lathe bed

1.150 mm

Dimension over all

1.450 mm/width 600 mm

Weight Benchmodel

approx. 110 kg

Weight with Stand

approx. 185 kg

Paint

RAL 9002 and RAL 9007

Warranty

1 year Electric

3 years mechanical parts

WEEE-Reg.Nr.

DE 79137012

Subject to change without notice

The lathe meets the safety regulations

LIABILITY

It is not permitted to make alterations or additions to the construction of the machinery supplied, to parts of the

machinery supplied or to accessories. Any warranty and liability claims become void in such case.

SETTING UP THE MACHINE

The anti-rust protection must be removed from the bright machine parts before first use.

Remove grease from inner cones of spindle and quill.

BENCHMODEL

We recommend an adequate long and stable base which should not vibrate, f.e. workbench or

Joiners bench with a minimum length of 150 mm to fasten/screw the lathe.

The inverter is mounted in a separate box, place or hang the box below the workbench or at the wall

do not place it near the lathe, protect it from chips/dust . Ensure that the inverter has enough

ventilation and is prevented against overheating

STANDMODEL (legs option)

If your lathe comes with dismounted legs:

Place the lathe onto a stable workbench or table, screw on the legs from the lower side.

Adjust and level the lathe with spirit level by the M12 screws

picture left shows parts supplied standard and righthand side how to use it

the adjusting screws are just to level the lathe if the floor is uneven

if the optional feet are dismounted for transport:

the lathe is screwed with plates onto the palet

first remove the small plates and screws, use then the supplied screws M12 for the legs and also

for the inverter to fix it inside at the LEFTHAND SIDE of foot: helpful with 2 Manpower

ELECTRIC CONNECTION

The lathe is supplied complete with a plug 230 V/1 ph for electric mains

OPERATING THE LATHE

SPEED REGULATION

the spindle speed is automatically stopped if the vee-belt cover is opened!

Push red main Button “OFF” before you open the vee-belt cover!

Infinitely speed regulation is performed by the 3 step pulleys:

Changing vee-belt to requested pulley:

loosen the motor clamping by handle, move it forwards

change vee-belt onto the requested pulley step by “moving” the pulley by hand forward/reverse

(easier handling)

Vee-belt Tension

fasten clamping leve, do not use too much tension because high tension can cause

vibration, wear of bearings and veebelt, could also cause damage on the motor-schaft

if working with low speed up to 300 rpm use vee-belt-pulley step 0-850 rpm to avoid power loss

and to ensure a sufficient power at the lowest speed

close vee-belt pulley correctly otherwise the motor will not run (safety switch inside)

regulation of spindle speed only while spindle is turning

SPINDLE SPEED AND WORKPIECE DIAMETER

The maximum permissible peripheral speed = 3.000 U for a maximum workpiece diameter of 130 mm

Watch the stickers at headstock for the adjusted speed and the max. workpiece diameter

The adjusted speed can be read out at the digital display

CHANGING TURNING DIRECTION/ROTATION OF SPINDLE

With the potentiometer at mobile box = righthanded rotation clockwise

Up from series 08-2017 the spindle is fitted with the ASS safety system resp. ring-nut at spindle nose

in any case of righthand rotation:

use only chucks with the optional security ringnut in chuck seat

The safety system works only with the security ring (standard) which is locked into the ring-nut

of the spindle and the ring-nut of the chuck

If the turning direction is changed by the selector switch, the inverter will automatically slow down the speed:

spindle starts in the opposite direction with speed adjusted before.

For your safety: slow down the potentiometer to “0” before changing the spindle direction

and use only chucks with security Lock system as described before

MAINSWITCH and EMERGENCY-OFF-BUTTON

The lathe is switched on by the RED Main Button at the headstock: release button

Not until then are all switches/buttons at the Mobile box activated.

During working with the lathe use only the buttons and functions at Mobile Box

After working time: push in the red main switch button at headstock to disconnect the lathe

from electric mains.

The main switch is at same time used as Emergency-Off-Button:

by turning the switch you activate or deactivate electric power

MOVABLE OPERATING BOX

The box is equipped with a “magnet” and can be placed at any position onto the lathe bed

The functions of switches see sticker:

Green Button = Start

Red Button = Stop

Selector Switch black for left/right

The correct adjusted direction for turning

= anticlockwise

Potentiometer for speed regulation

+ = increasing of speed

_ = decreasing of speed

“0” POINT ADJUSTMENT OF HEADSTOCK

This adjustment is fixed at the front of headstock

Fixing the “0” point system

Loosen clamping lever at headstock

Push down the slide with yellow knob

between the bed guiding

Swivel headstock slightly to the front guiding

and touch it

Clamp lever of headstock

The headstock is now exactly aligned to the

middle

Axis of the lathe (Tip-to-Tip)

If the headstock is moved or swivelled take care: the slide must be pushed upwards until it is “locked”

Turning cross timbers:

f.e. bowls, cups high accuracy is not required

Turning longitudinal:

before you start with any work requiring high accuracy as for peppermills, level your lathe again with

a spirit level and if necessary adjust also the “0-Point-Adjustment” (see also page 12)

SWIVELLING OF HEADSTOCK

the headstock can be swivelled in 6 different positions: 0/60/90/120/180/270°

Do not swivel the headstock during turning reps. If the spindle motor is running

switch off the motor/spindle

loosen the headstock fixing lever on lefthand side of headstock

push down the slide of “0” point fixing upwards until it is locked

pull out the black lock pin in front of the lathe and swivel headstock in the requested position

(take care of your fingers!)

the pin locks automatically in any of the 6 position

finally tighten lever of headstock again

36-INDEXING SYSTEM

The indexing system allows to make various borings or flutings in equal distances into any workpiece

The indexing plate with 36 borings is fixed with the vee-belt-pulley

The Lock pin, at the headstock front locks into any of these borings

The spindle nose has similar borings 0-36

In the pulled off position the lock pin has an adjustmend “by force” and cannot engage itself in case

of contact or vibration

Safety instruction : do not switch on spindle motor if the index pin is engaged

Any division which can be devided by 36 can be used: f.e. 36 : 9 = 4 divisions

OPERATING CHUCKS

The chucks are mounted at the external thread M 33x3,5 of the spindle

Spindle Lock Pin to loosen chucks:

Switch off spindle motor by the red button

of the mobile box

use always this button during your work, do

not stop by the main switch at headstock

only in case of danger

Lock the spindle by using the pin (see picture)

Screw on the chuck and tighten chuck with

The pin 8 mm supplied standard

Caution: Remove the 8 mm pin before machine is

switched on

True running of chuck only possible if the chuck lies flat with the face onto the spindle seat.

Do not use spindle motor power to fasten your chuck: you might get problems unscrewing the

chuck from spindle

Caution: if direction of spindle is changed to righthanded rotation secure the chuck against

running off the spindle (optional ring-nut in chuck seat)

prong mandrel on spindle/headstock: push out with the supplied long bar

live centre on tailstock: turn handwheel until centre is released from quill

Caution: loosen the clamping lever of quill before turning the handwheel

Hold live centre with hand to pretend from falling out

SAFETY INSTRUCTIONS

additional safety instruction see EG-conformity declaration

The vee-belt cover must be closed after each change of V-belt position by the hinge

otherwise motor does not run

Before the machine is switched on: turn potentiometer down to “0”

the selected speed must be checked against the maximum permissible workpiece diameter.

For large, out-of-balance workpieces adjust lowest speed, cut the workpiece before if possible

octagonal with a bandsaw

All clamping levers of spindle-/tailstock, tool rests etc must be tightened before beginning to work

any operating pins /keys must be removed from chucks, indexing pin from spindle

CLAMPING THE WORKPIECE

Turning between centres with the 4-prong-mandrel and live centre

centre the workpiece at both ends outside the lathe (make bearings last longer)

that markings are visible (f.e. use centering device 05.0336.00 or 05.0337.00)

press the driver prongs firmly into the workpiece by turning the hand wheel.

for hardwood and exotics we recommend to make a boring with a drill D=4 mm

tighten the set screws for the tailstock and the quill

Overhung turning with chucks

Cone-shaped chuck: Taper turn the workpiece to suit the chuck diameter and knock workpiece

outside of lathe into the chuck

Face plate: Secure the wooden discs with wooden screws (long enough) through the borings of plate

Disc-chuck: Screw the workpiece into the wooden screw: if necessary, drill core hole before

Wooden discs can be used to limit the depth of the woodworm-screw

Jaw-chucks: Increased risk to operator with jaws which project beyond the chuck body.

Remove the tightening key before starting the lathe

div.chucks i.e. SUPER NOVA2, NOVA G3, NOVA TITAN II, Sorby Patriot

see separate operating manual supplied with the chuck

HANDWHEEL TAILSTOCK

Please notice that the handwheel is no a precision part, , the run-out accuracy of the handwheel

has NO influence to the run-out-accuracy of the spindle

TOOL REST

Move the tool rest as close as possible to the workpiece, re-adjust it during the work.

Take care of the square dimension of your workpiece.

Move tool rest just if workpiece is not turning. Clamp fastening screws.

OUTRIGGER (Option)

The outrigger can be placed at any position at the lathe bed

Mounting

Move tailstock and toolrest complete out to the righthandside of lathe bed

Put the outrigger arm onto any position at the lathe bed and fix it

Advise: use headstock 180° degree swivelled and move it to the middle of lathe bed

The outrigger is placed at lefthand side of headstock

Insert tool rest bottm part into the arm of the outrigger and clamp it

Insert the supplied extension piece into the boring of the tool rest support, clamp it

Insert the tool rest upper part into the extension piece

.

BED EXTENSION (Option)

Screw the extension first just hand-tight with both lower screws at the face of lathe bed

Align the bed extension to the top and side of standard lathe bed (use only rubber hammer)

Check if there is no step, if the tailstock runs smooth over the both bed parts

Finally set in the upper screws and tighten all 4 screws

MAINTENANCE

The machine requires no maintenance.

The ball bearings are closed-off dust-proof and must not be lubricated.

Bright parts should be oiled occasionally to prevent corrosion. We recommend Ballistol Universal Oil

Item Nr. 85.0200.20

If turning whet wood, clean immediately the blank parts and oil them

Movable parts i-r- excenter shaft of tool rest base, quill with inner thread and spindle should

be oiled between 2-3 month, to ensure true running and prevend seizing up.

RE-ADJUSTMENT OF “0-Point-Locking”

Level the lathe with a spirit level (righthandside

and lefthandside cross to lathe bed)

+ use the supplied adjusting screws

+ metal and rubber plates

Double cone MT2/MT2

Insert Double cone into tailstock quill

Loosen tailstock clamping

Move tailstock close to the headstock until the

cone is inserted into the spindle cone

Clamp tailstock

bevore the „0-Point-Locking“ is re-adjusted:

the yellow bolt/slide must be pulled upwards until it is engaged/locked

Loosen clamping lever of headstock

move out the quilll of tailstock in direction to the

headstock by turning the handwheel

headstock moves lightly to the lefthandside:

clamp now the lever of headstock

headstock and tailstock stands to each other

Loosen tailstock clamping

insert the long bar from lefthandside through the

handwheel into the hollow spindle and push out

the double cone with tailstock to the righthand

side

Fasten Tailstock and Quill lever

insert long bar through the boring of tailstock

handwheel and push out the couble cone to

the lefthandside

Hold cone to avoid fall down

Headstock Clamping must be fixed

loosen the 2 x black hexagon socket screws

SW5 (left and right) from the 0-point-locking

use any pocket lamp to help adjusting the

0-point-locking by a “light-gap-method”

push down the yellow bolt/slide

it must touch now parallel the inner front of

lathe cheek without any light-gap-sight

press on the bolt and fasten evenly the both

black screws again

check lift of stroke up/down from the yellow

bolt/slide

ACCESSORIES, ATTACHMENTS and COPYING UNITS

All recommended and available accessories see special accessory leaflet.

Drechselzentrum Erzgebirge

Heuweg 4

09526 Olbernhau

Deutschland

Tel./Phone: +49 (0)37360-6693-0

Fax/Fax: +49 (0)37360-6693-29

Shop www.drechslershop.de

Mail: Inf[email protected]

CE-Konformitätserklärung / CE - Declaration of Conformity

für / for

Handdrechselbank / Woodturning lathe:

killinger® KM1450

Wir / We: DRECHSELZENTRUM ERZGEBIRGE –steinert®

Heuweg 4, 09526 Olbernhau, Deutschland/Germany

Tel./Phone: +49 (0)37360-6693-0

Fax/Fax: +49 (0)37360-6693-29

E-Mail/Email: [email protected]

Internet/Internet: www.drechslershop.de

erklären, dass die zuvor benannte Maschine den Anforderungen der Maschinen-Richtlinie 2006/42/EG entspricht.

declare that this machine named above meets the essential health and safety requirements of machinery directive

2060/42/EC.

Elektrische und elektronische Komponenten entsprechen den Anforderungen der Niederspannungsrichtlinie

2006/95/EC und der EMV-Richtlinie 2004/108/EG.

Electrical control and its Components are in accordance with the Low Voltage (2006/95/EC) and EMC (2004/108/EC)

Directives

Angewandte harmonisierte Normen / Harmonized standards applied:

EN ISO 12100 EN ISO 3746

EN ISO 13857 EN ISO 11202

EN ISO 13850 EN ISO 11204

EN 13849-1 EN 60 204 T 1

EN 1088

Diese Erklärung wird verantwortlich für DRECHSELZENTRUM ERZGEBIRGE - steinert® abgegeben durch:

This declaration is made for and on behalf of DRECHSELZENTRUM ERZGEBIRGE - steinert® by:

Roland Steinert (Inhaber / Owner)

Unterschrift:_______________________________________

Table of contents

Other steinert Lathe manuals

Popular Lathe manuals by other brands

Jet

Jet BD-920W Operating instructions and parts manual

Hafco Metalmaster

Hafco Metalmaster AL-1000C instruction manual

Doosan

Doosan MX 2000 Troubleshooting

Anhui Pan-sino

Anhui Pan-sino BL330E operating instructions

TRI tool

TRI tool BEVELMASTER 214B Operation manual

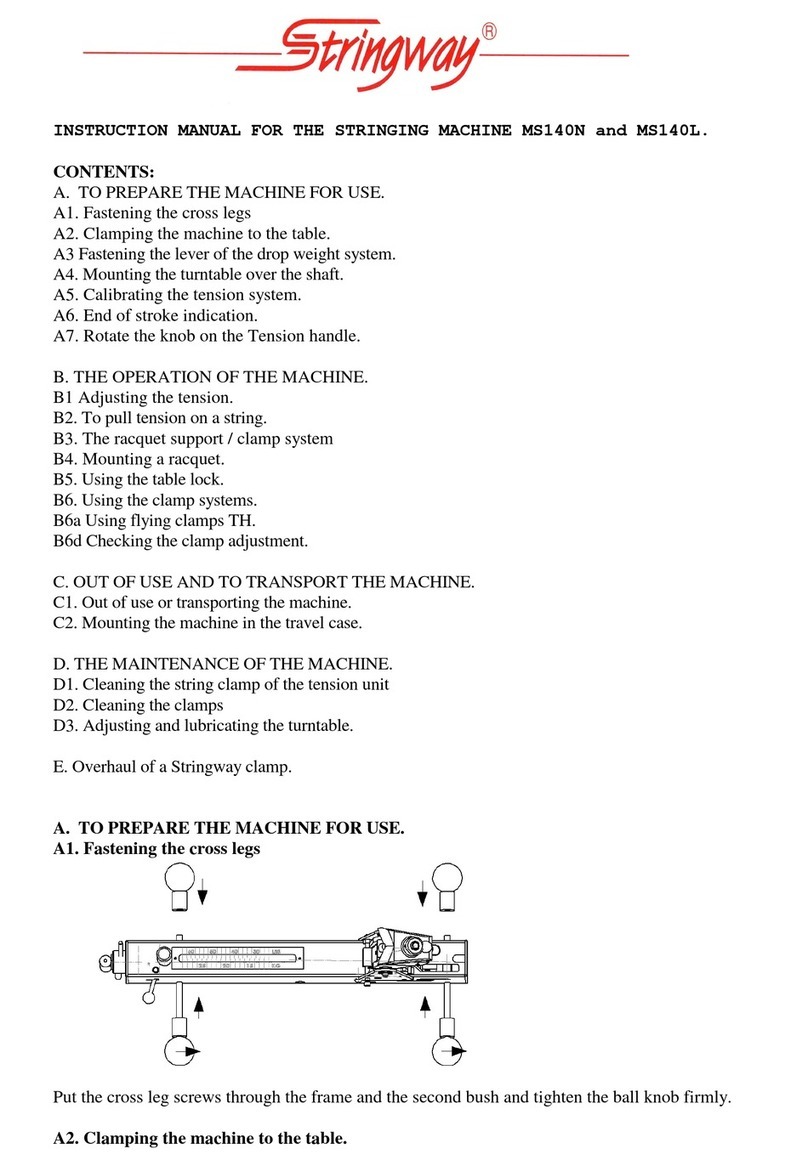

Stringway

Stringway MS140L instruction manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN VD 1100N user manual

MicroLux

MicroLux True-Inch 84631 instruction manual

Axminster Craft

Axminster Craft AC305WL Original instructions

Axminster Trade

Axminster Trade AT350WL Original instructions

Steel City

Steel City 60170 user manual

Grizzly

Grizzly G4003 owner's manual