3

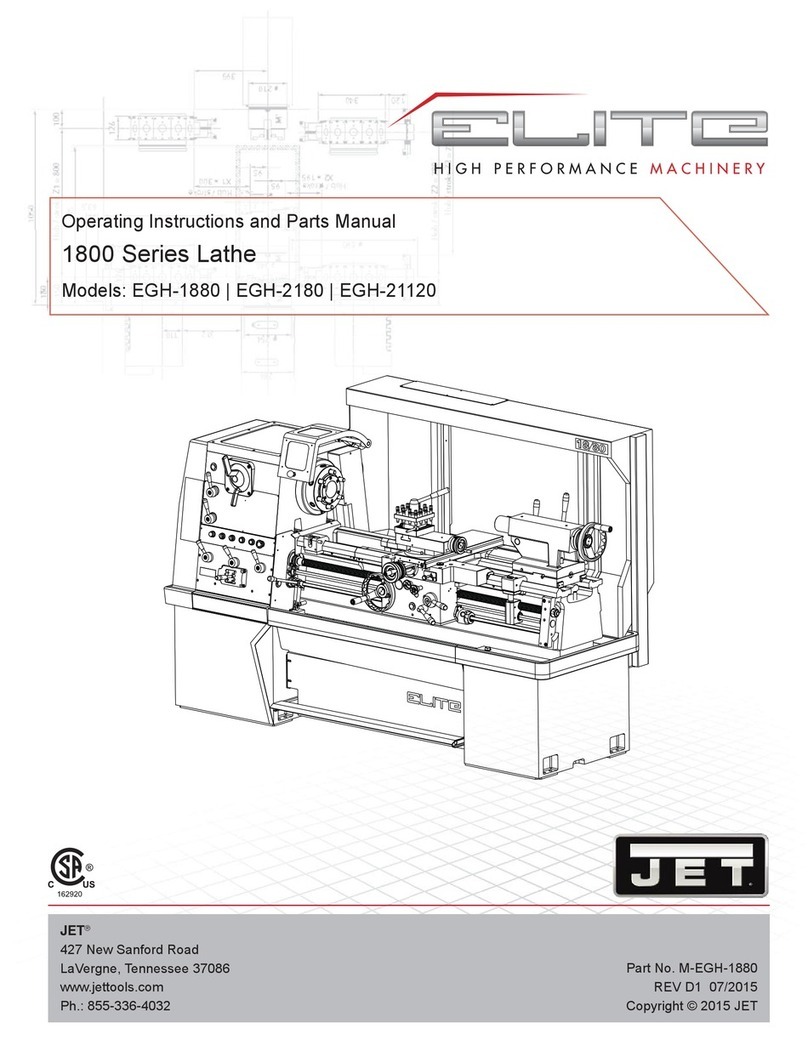

Table of Contents

Warranty and Service............................................................................................................................................2

Table of Contents..................................................................................................................................................3

Introduction ...........................................................................................................................................................7

Specifications........................................................................................................................................................7

Unpacking .............................................................................................................................................................8

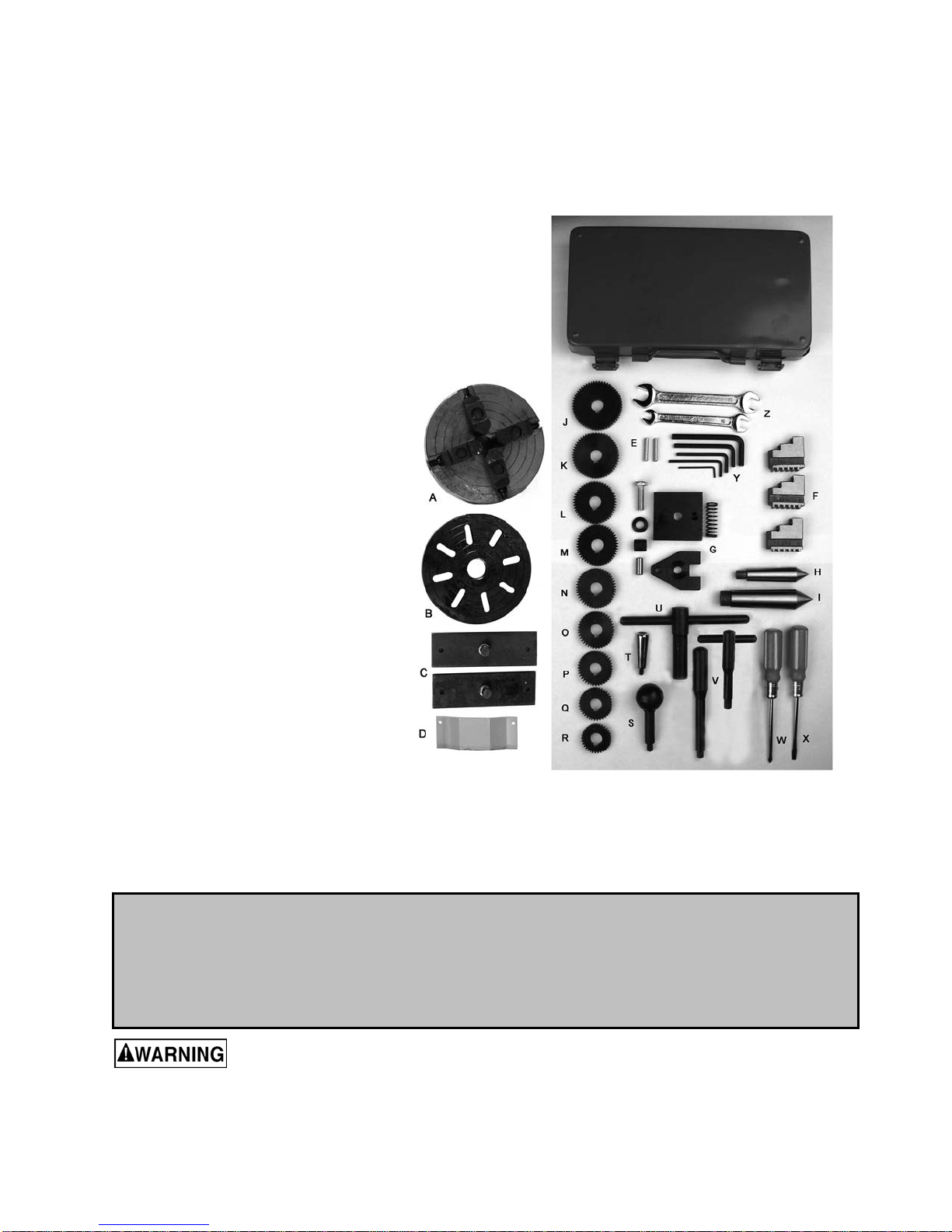

Contents of the Shipping Container......................................................................................................8

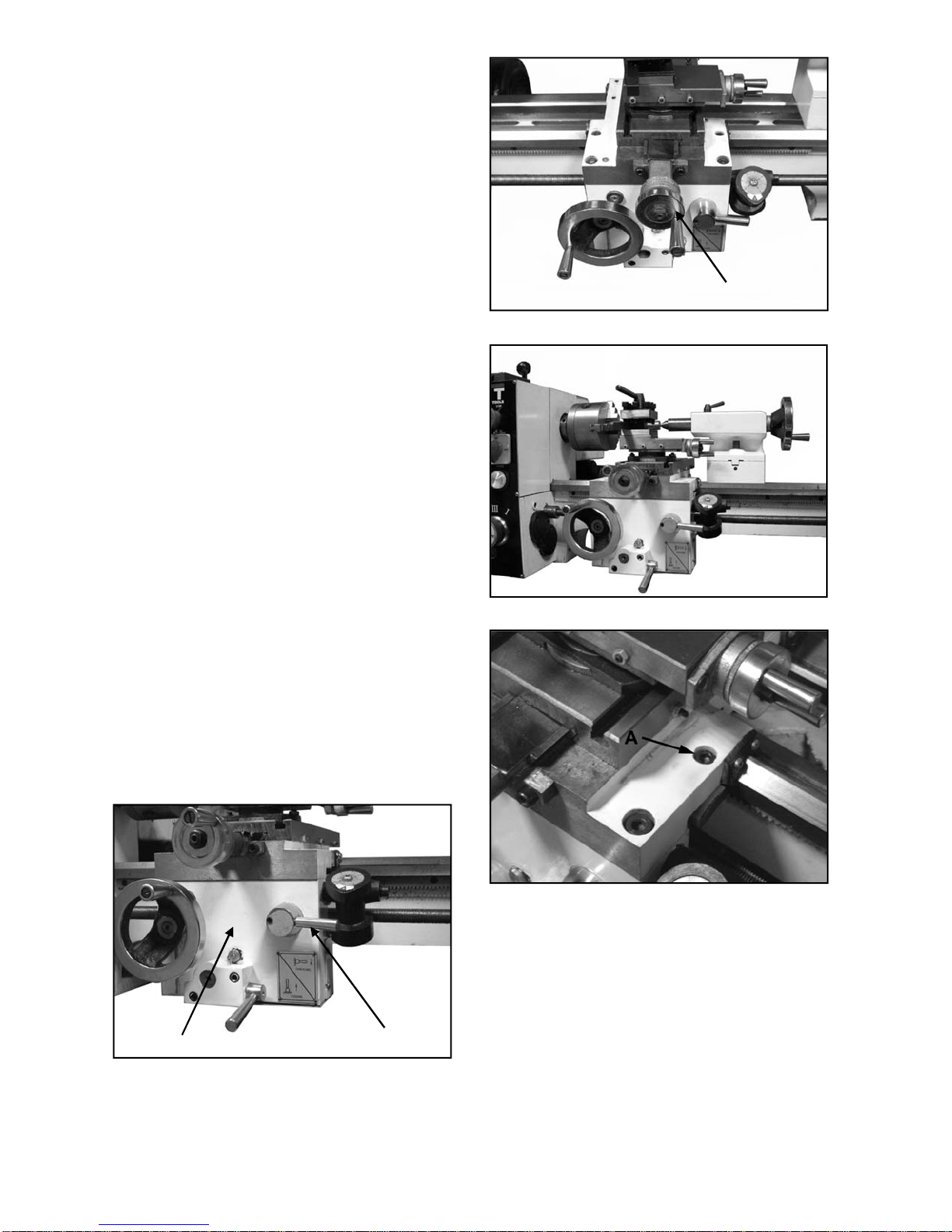

Set Up and Preparation for Operation...................................................................................................................9

General Description ..............................................................................................................................................9

Controls...............................................................................................................................................................12

Operation ............................................................................................................................................................13

Tool Set-Up........................................................................................................................................13

Manual Turning..................................................................................................................................13

Longitudinal Turning with Auto-Feed..................................................................................................13

Taper Turning Using Tailstock Off-Set................................................................................................14

Taper Turning by Setting the Top Slide ..............................................................................................14

Turning Between Centers...................................................................................................................14

Thread Cutting...................................................................................................................................15

Metric Thread Cutting.........................................................................................................................15

Lathe Accessories...............................................................................................................................................16

Adjustment and Replacement

...............................................................................................................................18

Adjustment of Main Spindle Bearings.................................................................................................18

Adjustment of Cross and Top Slide ....................................................................................................18

Adjustment of Compound Feed Screw and Float................................................................................19

Cross Slide Screw..............................................................................................................................19

Compound Slide Spindle Backlash Adjustment ..................................................................................19

Adjustment of Half-Nut guide..............................................................................................................20

Replacing the Shear Pin in the Leadscrew .........................................................................................20

Replacing the V-Belt ..........................................................................................................................20

Lubrication Schedule...........................................................................................................................................21

Replacement Parts..............................................................................................................................................22

Headstock Assembly – Exploded View...............................................................................................22

Headstock Assembly – Parts List.......................................................................................................23

Drive Assembly – Exploded View.......................................................................................................24

Drive Assembly – Parts List................................................................................................................25

Tension Roller Assembly – Exploded View & Parts List......................................................................26

Quadrant Assembly – Exploded View & Parts List..............................................................................27

Electrical Assembly – Exploded View.................................................................................................28

Electrical Assembly – Parts List..........................................................................................................29

Gear Box Assembly – Exploded View.................................................................................................30

Gear Box Assembly – Parts List.........................................................................................................31

Apron Assembly – Exploded View......................................................................................................32

Apron Assembly – Parts List ..............................................................................................................33

Apron Assembly (continued) – Exploded View...................................................................................34

Apron Assembly (continued) – Parts List............................................................................................35

Saddle and Cross Slide – Exploded View...........................................................................................36

Saddle and Cross Slide Assembly – Parts List ...................................................................................37

Top Slide Assembly – Exploded View................................................................................................38

Top Slide Assembly – Parts List.........................................................................................................39

Tailstock Assembly – Exploded View.................................................................................................40

Tailstock Assembly – Parts List..........................................................................................................41

Steady Rest Assembly – Exploded View & Parts List..........................................................................42

Travel Rest Assembly – Exploded View & Parts List...........................................................................43

Lathe Bed Assembly – Exploded View ..............................................................................................44

Lathe Bed Assembly – Parts List........................................................................................................45

Wiring Diagram ...................................................................................................................................................46