steinert KM 3100 SE User manual

OPERATING INSTRUCTIONS KM 3100 SE

STANDARD ACCESSORIES

PAGE 2

TECHNICAL DATA

PAGE 2

Liability

SETTING UP THE MACHINE

PAGE 2

Lifting and Moving

Standard version and extended version

ELECTRIC CONNECTION

Power requirement: 20 Ampere/2,25 kW, fuse protection with circuit breaker B16A

PAGE 3

WORKING WITH THE MACHINE

PAGE 3

Speed Regulation

Spindle Speed and workpiece diameter

Changing the direction of spindle rotation

Emergency off button

PAGE 4

Movable Control Box

Swivelling of headstock

Fine- Adjusting of headstock to “0” Position

Indexing

WORKING WITH CHUCKS

PAGE 5

Operating chucks, prong mandrel, live centre

Clamping the workpiece

Tool Rest

PAGE 6

Outrigger for turning with swivelled headstock

PAGE 6

SAFETY ADVICES AND REGULATIONS

PAGE 6

MAINTENCANCE

PAGE 6

ACCESSORIES AND OPTIONS

Copying Units, Laterial Turning Device, Ball Bearing Device

CE CONFORMITE

PAGE 8

STANDARD FITTINGS

4-prong-mandrel MT2 D=25 mm

for spindle/headstock

4-prong mandrel MT 2 D=35 mm

For spindle/headstock

Live centre MT2/60 °

For tailstock quill

Live centre MT2/with pressring D=20x26 mm

For tailstock quill

Indexing Pin

Mounted fix at spindle nose

never use the indexing pin for locking the spindle!

Tool Rest bottom part

Tool Rest 350 mm

Toolbox with rubber mat

Center knock-out-rod

For prong mandrel

Pin

To loosen chucks

TECHNICAL SPECIFICATIONS

Centre height 280 mm

Distance between centres 850 mm standard

optional 1500 mm with 2nd short bed/3rd foot

optional 2300 mm with 2nd long bed/4 feet

Swing over bed 560 mm

Swing with outrigger 900 mm appor.

Spindle thread M 33 with centering collar, inner cone MK 2

Spindle bearing 2 angular ball bearings front , 1 ball-bearing rear

Indexing System integrated indexing system with scale

Spindle speed rpm 3steps: 40-850 80-1645 125-3025 rpm/min.

Max. permissible workpiece D 500 220 130 mm

Tailstock MK 2 quill taper, stroke 135 mm with scale

Spindle motor 400 V/3 ph/2,2 kW/50 Hz/ connected value B16A

inverter electric mains 230 V/1 ph/50 Hz

Vee-belt poly-vee-belt 10PJ 711

Electrical system with undervoltage and overload protection

Security/Interruption switch inside of vee-belt cover

CEE-Plug 17A, connected 1x230 V electric mains

.

Dimensions L/W/H 185 x 60 x 125 cm max.

Weight 440 –510 –590 kg (depending on centre distance)

Paint grey-white RAL 9002/anthrazit RAL 7016

Warranty 1 year

Subject to change without notice

The machine meets the safety requirements and is CE-conform

LIABILITY

It is not permitted to make alterations or additions to the construction of the machinery supplied, to parts of the machinery supplied

or to accessories. Any warranty and liability claims become void in such case.

SETTING UP THE MACHINE

The anti-rust protection must be removed from the bright machine parts before first use.

The machine is completely installed an mounted.

Place machine at final destination, use a water level to level the machine , adjust with the M12 screws which

are fixed at the feet.

Do not srew/tighten the machine resp. legs to the floor !

LIFTING AND MOVING

Due to the heavy weight of the machine it can be lifted and moved by a forklift or with a pallet truck

Never lift the machine below of the tool box !

If it is necessary to disassemble the machine to move it at the final place: there is a special instruction on request

ELECTRIC CONNECTION

The lathe is supplied complete with a 16A CEE- plug, connected 1 x 230 V

Blue = neutral wire

Brown = L1/Phase

Green/yellow = ground wire

Power requirement 20 Ampere, fuse protection with circuit breaker

Attention

If any other plug than the CEE-plug supplied is used , the connection must be done from a professional electrician

The inverter is mounted at the lefthandside foot

If any work is done at the lefthandside foot pull off the plug from electric mains.

The Inverter parameters are set up for the right rpm in relation to the vee-belt-pulley steps

Any alterations made at the inverter warranty is expired as a result.

SPEED REGULATION

Inside the vee-belt-cover is an additional safety switch to meet the CE-conformity

the machine automatically will stop If the vee-belt-cover is opened or not properly closed

Infinitely variable speed with 3 pulley-steps

changing vee-belt to requested pulley:

loosen the motor clamping by handle, hold motor at grip and move it forwards (loosening of tension)

change vee-belt onto the requested pulley step by “moving” the pulley by hand forward/reverse

fasten clamping lever but do not use too much tension: high tension can cause

vibration, wear of bearings and veebelt, could also cause damage on the motor-schaft

close vee-belt pulley correctly otherwise the motor will not run (safety switch inside)

If working with the lowest speed i.e. 300 rpm/min use the pulley-step with 40-850 rpm/min to ensure

a sufficient power in the lowest speed

Regulation of spindle speed only while the spindle is running!

the spindle speed is controlled by an inverter

start the spindle running

turn speed regulation knob to change speed

clockwise = increasing of speed

anticlockwise = decreasing of speed

speed is shown on the speed digital diagram

Before the machine is switched it is recommended first to check if the Potentionmeter is adjusted to “Zero”

SPINDLE SPEED AND WORKPIECE DIAMETER

The maximum permissible peripheral speed = 3.000 U for a maximum workpiece diameter of 130 mm

Watch the stickers on headstock for the adjusted speed and the max. workpiece diameter

CHANGING TURNING DIRECTION = ROTATION OF SPINDLE

to righthanded rotation, clockwise

correct turning direction is anticlockwise, lefthanded rotation

the flip switch/or selector for forward/reverse switch is integrated at the movable box.

For adjusted turning direction watch the sticker on the headstock

when changing the turning direction the inverter will automatically slow down the speed:

spindle starts slow in opposite direction, speed increases again as adjusted before

Caution to meet safety regulations

adjust the slowest spindle speed before changing the spindle direction.

Chucks may only be used if supplied with optional security locking!

Advise

If the machine is supplied for a school, training or education centre the function of turning direction

can be blocked /disabled by a screw or splint.

Emergency-Off-Button/Mainswitch

The main switch on the headstock is also used as emergency-off-button

If the emergency-off-button was pressed down the button must be turned to activate electric power.

MOVABLE OPERATING BOX

The box is equipped with a “magnet” and can be placed at any position onto the lathe bed

Switches with following functions

Green button = “on”

Red button = “off”

Speed regulator or potentiometer = rotable knob :

Clockwise = increasing the rpm

Anti-clockwise = decreasing the rpm

Turning direction of spindle fwd/rev

Attention: the correct working direction for turning is lefthand i.e. anticlockwise !

SWIVELLING OF HEADSTOCK

the headstock can be swivelled in 6 different positions: 0/60/90/120/180/270°

switch machine off, never turn headstock if motor is switched on

loosen the headstock fixing lever on lefthand side of headstock

loosen headstock fixing pin on front , pull it out

rotate the headstock to one of the 6 possible positions:

take care of your fingers, do not squeeze them between lathe bed

push in the pin until it engages automatically into the given position

at least tighten the fixing pin and the headstock fixing lever again

STOP ADJUSTMENT FOR HEADSTOCK

It prevents the headstock moving lengthways if the tailstock is used as counter pressure for

big and heavy parts

Caution:

If headstock shall be moved or swivelled the clamping plate with hexagon screw must be removed !

FINE ADJUSTMENT OF HEADSTOCK FOR “ZERO-POSITION” TIP TO TIP

Step One: release the headstock clamping lever sideways

unscrew the adjustment bolt until it

gets loose

Pull down the sliding stop

between the lathe cheeks

Push the sliding stop in direction to the lefthand side

(lefthand = seen from frontside of spindle)

at least tighten the headstock clamping lever and screw in the adjustment bolt again

The tips are now correctly in alignment a requirement for exact boring work or turning of writing utensils

CAUTION: before you move or swivel the headstock

The sliding stop must be pushed upwards until its end stop

We also recommend to loosen lever of spindle headstock before

If the Fine Adjustment has been misplaced by force (wrong handling)

it is possible to re-adjust the fine adjustment as follows:

insert in 4-prong mandrel into the spindle of headstock

insert live centre into the tailstock quill

move tailstock in direction to the headstock and clamp it

move quill with live centre by turning the handwheel of tailstock until it touches the tip of prong mandrel

move gently the headstock (loose the clamping lever!) until both tips are in alignment

clamp headstock lever

unscrew slightly ! the both hexagon socket screw M6 x 12 from sliding stop

push it in lefthand direction against the inner cheek of lathe bed

tighten both screws M6 x 12

INDEXING SYSTEM AT SPINDLE

The indexing pin is fixed on headstock, never use the indexing pin to lock the spindle

or for loosen chucks

In the pulley of the spindle are made 36 borings with numbers 1-36

Indexing is done be the fixed mounted black locking pin on top of headstsock which is adjusted

In the requested boring.

f.e. workpiece with 9 tiwsts or flutings: 36:9= 4 , lock the pin after each 4th boring (4,8,12,….)

Safety Advice

Do not switch on spindle motor while the indexing pin is locked!

The indexing pin may not be used as locking of spindle to loosen chucks!

OPERATING CHUCKS, PRONG MANDREL AND LIVE CENTRE

The chucks are mounted on the external thread M 33 of the spindle, which is having a centering collar

Switch off spindle motor

lock spindle with fixing pin (below of spindle nose)

screw on the chuck, surface of thread must be close and plan ! to the centering collar, fasten it properly

handtight by using the pin

Caution: remove the pin before switching on spindle

Do not use spindle motor power to fasten your chuck: you might get problems unscrewing the

chuck from spindle

If direction of spindle is changed to righthanded rotation secure the chuck against

running off from spindle with the security ring

security nut for chuck seat: option

The prong mandrel on spindle/headstock is knocked out with the long supplied bar

The live centre on tailstock comes out automatically :

Loosen the clamping lever on top of quill

turn handwheel until centre is released from quill, hold centre by hand to avoid falling out

CLAMPING THE WORKPIECE

Turning between centres with the 4-prong-mandrel and live centre:

Roughly centre the workpiece at both ends outside the lathe (make bearings last longer)

that markings are visible.

Press the driver prongs firmly into the workpiece by turning the hand wheel.

Tighten the set screws for the tail stock and the quill.

Overhung turning with chucks

Changing of spindle direction may not be used, otherwise the security system

to fix the chuck against running off from the spindle must be ordered (option)

Cone-shaped chuck: Taper turn the workpiece to suit the chuck diameter and drive it in with heavy blows.

Heureka-chuck: Drive the face of the unmachined workpiece into the chuck so that the sharp edge penetrates

approx. 10-15 mm . Maximum work length 200 mm. Most suitable for soft wood.

Face plate: Secure the wooden discs with wooden screws through the bores provided.

Disc-chuck: Screw the workpiece into the wooden screw (if necessary, drill core hole. Wooden discs can be

used to limit the depth of penetratin of the screw).

Jaw-chucks: Increased risk to operator with jaws which project beyond the chuck body. Remove the tightening

key before starting the machine.

div.chucks i.e. Nova Chuck, Super Nova etc. see separate operating manual

TOOL REST

move toolrest close to the workpiece , correct position from time to time if workpiece is turned+

to smaller dimension

we recommend you to turn the spindle with clamped workpiece before by hand to watch if the

Workpiece does not touch the tool rest

after checking true running, switch on spindle motor

move and correct tool rest position only if the spindle motor is switched off

OUTRIGGER=EXTERNAL TURNING ATTACHMENT (Option)

instruction and photo is supplied with the outrigger

.

SAFETY REGULATIONS

The belt guard must be reclosed after each change of V-belt position, motor does not run if vee-belt cover

is not properly closed

Before the machine is switched on:Turn Potentiometer always to “0”

Spindle speed must be checked against the maximum permissible workpiece diameter.

Large, out-of-balance workpieces must be machined at minimum speed,

cut them by a bandsaw octagonal to decrease out-of-balance

All clamping levers i.e. spindle-/tailstock, tool rests etc must be tightened before beginning to work,

any operating pins /keys must be removed from chucks or spindle!

MAINTENANCE

The machine requires no special maintenance.

The bearings are sealed at both sides and are life-time protected with high performance grease.

The Angular Ball bearing retainer ring strengthened from fiber glass Polyamid is applicable for continious

temperatures up to +120°C.

A temperature of 70° is uncritical as per manufacturers information.

Bright parts should be oiled occasionally to prevent corrosion, f.e. Balistol or similar product can also be used.

Expecially if constantly green and wet wood is turned and to safe the life time of your machine

clean the machine immediately after turning, wipe dry bright parts and oil them i.e. lathe bed, spindle etc.

Indexing pin, excenter shaft of tool rest, quill and spindle should be oiled between 4-6 month

to ensure true running and prevend seizing up.

ACCESSORIES, ATTACHMENTS, OPTIONS, COPYING UNITS

We refer to our Accessory Catalogue and our web-page www.drechslershop.de

Drechselzentrum Erzgebirge - steinert®

Heuweg 4

09526 Olbernhau

Tel./Phone: +49 (0)37360-6693-0

Fax/Fax: +49 (0)37360-6693-29

mail [email protected]

shop www.drechslershop.de

webseite www.drechslershop.de/drechselbaenke/killinger

ORIGINAL DECLARATION OF CONFORMITY

KILLINGER declares that the following listened machines have been designed in compliance with:

89/392 EEC/DIN EN292-1/DIN EN 292-2/DIN EN 294/DIN EN 349/DIN EN 418 and 72/23 EEC/89/336 EEC/86/188

EEC.

Wood Turning Lathe KM 1000 Nova

Wood Turning Lathe KM 1400 SE

Wood Turning Lathe KM 1500 SE

Wood Turning Lathe KM 2000 S/SE

Wood Turning Lathe KM 2500 S/SE

Wood Turning Lathe KM 3000 S/SE

Wood Turning Lathe KM 3100 S/SE

Wood Turning Lathe KM 6000 S

Copying-Lathe KM 5000 S

Copying-Lathe KM 5000 SM

Copying-Lathe KM 5000 S-Hydro

Copying-Lathe KM 6000 SM

Copying-Lathe KM 6000 S-Hydro+Hydro Plus

Copying-Lathe KM 7000 S-Hydro

Copying Lathe KM 8000 CNC

Milling Lathe KM 9000 S-Hydromill

Copying Unit KM 100

Copying Unit KM 300

Copying Unit KM 500

Barley Twist Machine KM 150

Level of sound pressure according to 86/188/EED & 89/392 EEC, measured according to EN 50144:

Lpa sound pressure 66 dB (A)

Lwa acoustic power 81 dB (A)

The maximum peripheral speed of the Lathe may not exceed 30 m/s.

Drechselzentrum Erzgebirge - steinert®

Heuweg 4

09526 Olbernhau

Deutschland

Roland Steinert/ Inhaber

CE-Konformitätserklärung / CE - Declaration of Conformity

für / for

Handdrechselbank / Woodturning lathe:

killinger® KM3100 Nr.: / No.: _________________

Wir / We: DRECHSELZENTRUM ERZGEBIRGE –steinert®

Heuweg 4, 09526 Olbernhau, Deutschland/Germany

Tel./Phone: +49 (0)37360-6693-0

Fax/Fax: +49 (0)37360-6693-29

E-Mail/Email: [email protected]

Internet/Internet: www.drechslershop.de

erklären, dass die zuvor benannte Maschine den Anforderungen der Maschinen-Richtlinie 2006/42/EG entspricht.

declare that this machine named above meets the essential health and safety requirements of machinery directive

2060/42/EC.

Elektrische und elektronische Komponenten entsprechen den Anforderungen der Niederspannungsrichtlinie

2006/95/EC und der EMV-Richtlinie 2004/108/EG.

Electrical control and its Components are in accordance with the Low Voltage (2006/95/EC) and EMC (2004/108/EC)

Directives

Angewandte harmonisierte Normen / Harmonized standards applied:

EN ISO 12100 EN ISO 3746

EN ISO 13857 EN ISO 11202

EN ISO 13850 EN ISO 11204

EN 13849-1 EN 60 204 T 1

EN 1088

Diese Erklärung wird verantwortlich für DRECHSELZENTRUM ERZGEBIRGE - steinert® abgegeben durch:

This declaration is made for and on behalf of DRECHSELZENTRUM ERZGEBIRGE - steinert® by:

Roland Steinert (Inhaber / Owner)

Unterschrift:_______________________________________

Table of contents

Other steinert Lathe manuals

Popular Lathe manuals by other brands

Jet

Jet BD-920N Operator's manual

Sealey

Sealey SM1100.V2 instructions

Hardinge

Hardinge T-51 Installation and Extended Storage Instructions

Brevetti Motta

Brevetti Motta SMART Instruction manual and maintenance

GULLCO

GULLCO KBM-28U PARTS LIST & OPERATING INSTRUCTIONS

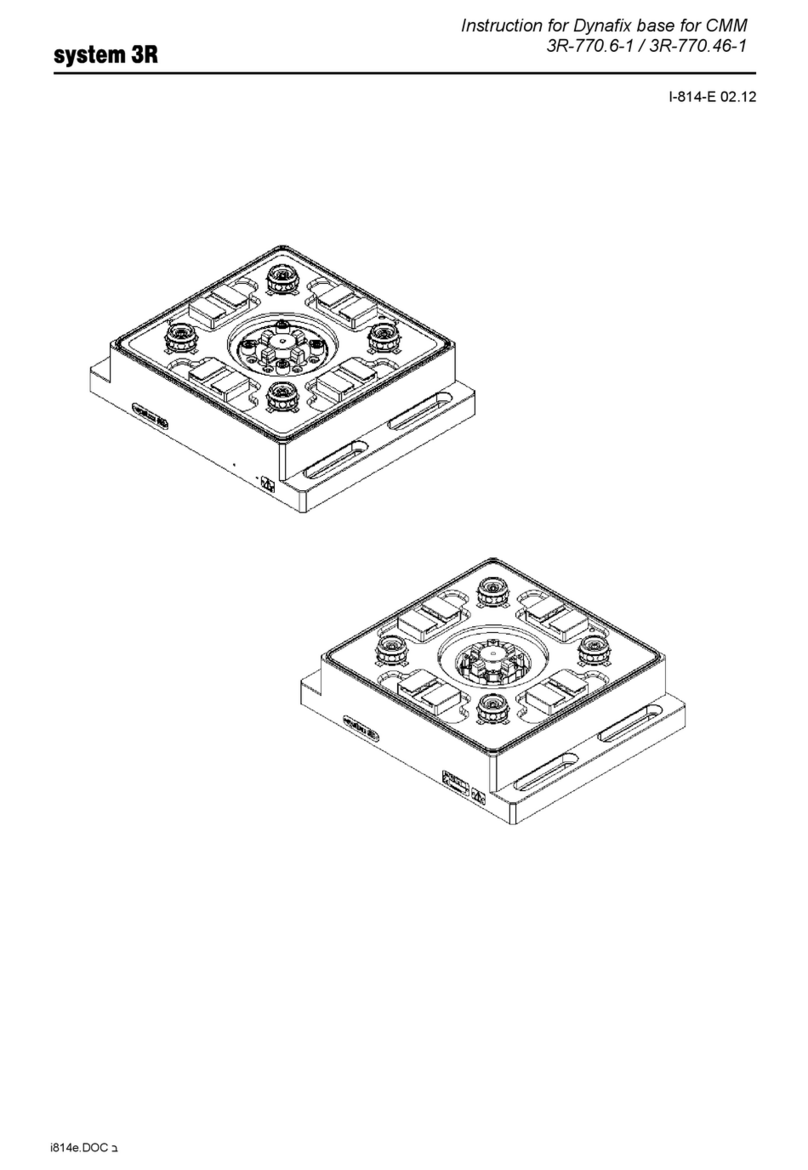

System 3R

System 3R 3R-770.6-1 instructions