STEP

iAStar Frequency Inverter For Elevator Door Machine manual Instructions

VII

Contents

Contents ........................................................................................................................................ VII

1 POINTS OF ATTENTION ............................................................................................................1

1.1 Application area and features of inverter ............................................................................1

1.2 Service ambient of the invert ..............................................................................................2

1.3 Points of attention on inverter discarding ...........................................................................2

1 Introduction of products.................................................................................................................3

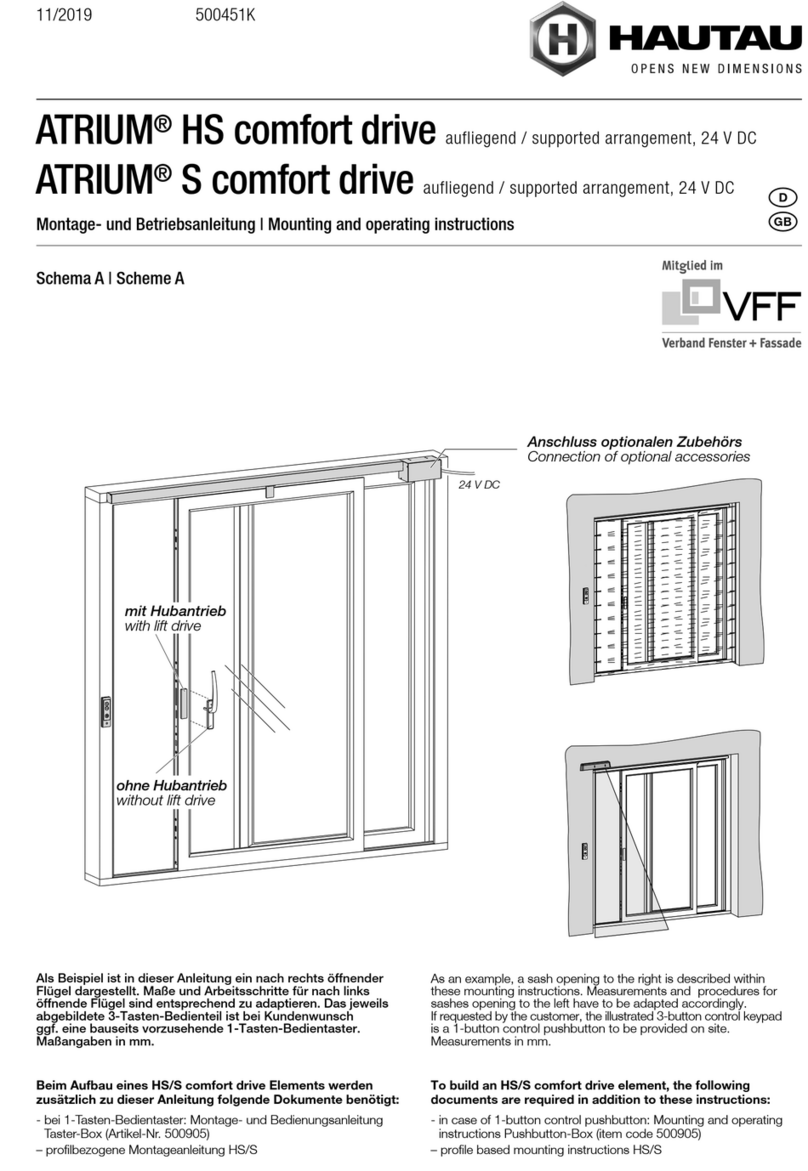

3 INSTALLATION & WIRING INSTRUCTION ...........................................................................6

3.1 Box-openning inspection ....................................................................................................6

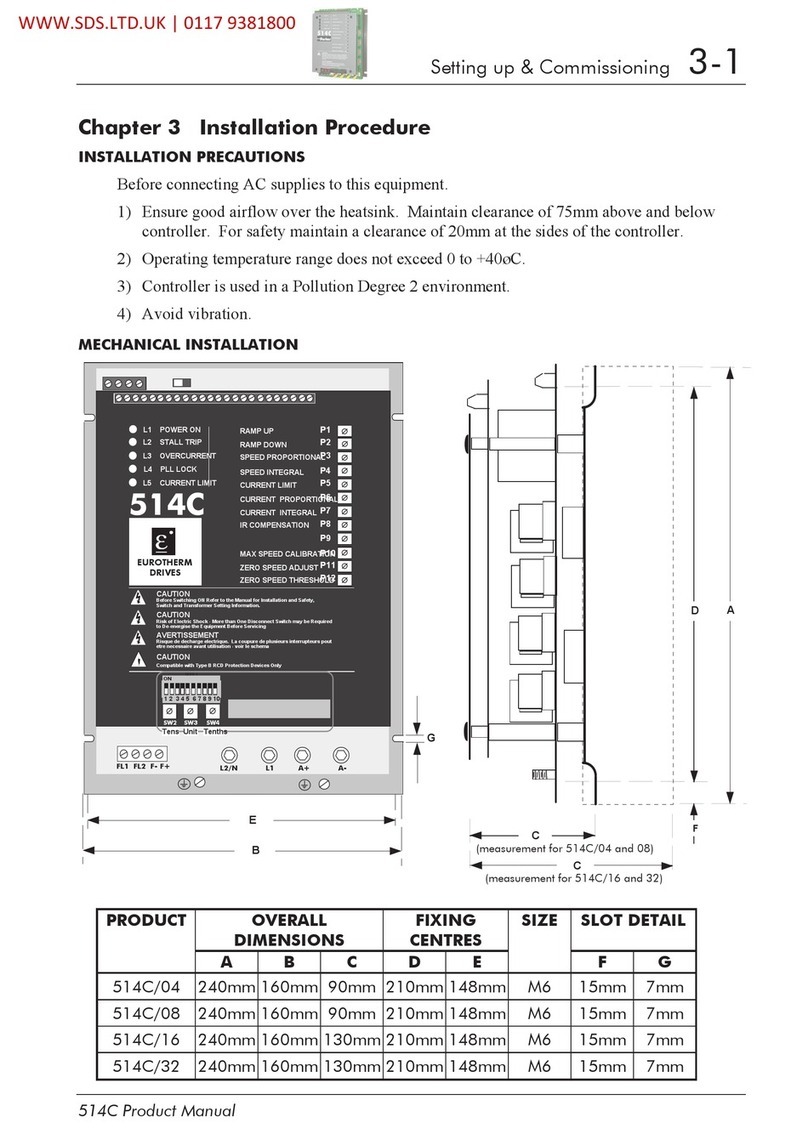

3.2 outline dimensions ...........................................................................................................6

3.3 Installation specification .....................................................................................................8

3.4 Definitions of the terminals.................................................................................................9

3.4.1 Definitions of the main loop terminals.....................................................................9

3.4.2 Definitions of control terminals .............................................................................10

3.5 Basic diagram of inverter wiring.......................................................................................14

3.5.1 Basic diagram of inverter wiring for Type A1 .......................................................14

3.5.2 Basic diagram of inverter wiring for Type 2..........................................................17

3.6 Wiring of jumpers .............................................................................................................20

4 Function parameter list.................................................................................................................22

4.1 Function parameter list......................................................................................................22

4.2 monitor parameter list .......................................................................................................26

5 specifications of function parameters...........................................................................................27

6 Hand-held operator ......................................................................................................................35

6.1 Introductions .............................................................................................................35

6.1.1 outline drawings of Hand-held operator.................................................................35

6.1.2 Operation................................................................................................................37

6.1.3 Fault Indication ......................................................................................................40

6.2 panel operator....................................................................................................................41

6.2.1 outline drawing of panel operator ..........................................................................41

6.2.2 keyboard of panel operator.....................................................................................41

6.2.3 list of parameter U of panel operator......................................................................46

6.3 Using of PC software ........................................................................................................49

7 System Adjustment ......................................................................................................................53

7.1 debugging Encoder control ...............................................................................................53

7.1.1 Encoder wiring .......................................................................................................53

7.1.2 debugging steps......................................................................................................53

7.2 debugging of control terminals .........................................................................................57

7.2.1 wiring of control terminals.....................................................................................57

7.2.2 debugging steps......................................................................................................57

7.3 Door- opening and closing course specification ...............................................................59

8 fault & solutions...........................................................................................................................61

8.1 instruction of fault code ....................................................................................................61