Translation of the original instructions

© 2021 all rights reserved to Festo SE & Co. KG

1 Identification EX

Identification mark Certificate

IECEx Ex ib IIC T4 Gb

Ex ib IIIC T100°C Db

IECEx IBE 13.0046X

ATEX II 2G Ex ib IIC T4 Gb

II 2D Ex ib IIIC T100 ° C Db

IBExU 12ATEX 1110X

China Ex ib IIC T4 Gb

Ex ex ibD 21 T100

GYJ20.1646X

Tab. 1 Identification EX

2 Applicable documents

NOTICE!

Technical data for the product can have different values in other documents. For

operation in an explosive atmosphere, the technical data in this document always

have priority.

All available documents for the product èwww.festo.com/sp.

3 Safety

3.1 General safety instructions

– The device can be used under the stated operating conditions in zones 1 and

2, explosive gas atmospheres, and in zones 21 and 22, explosive dust atmo

spheres.

– Use the device in its original status without any unauthorised modifications.

– The device may only be used in the delivered configuration in a potentially

explosive atmosphere.

– Operate the device only with compressed air of at least quality class [7:4:4] in

accordance with ISO 85731:2010.

– Always generate compressed air outside the potentially explosive area.

– Use only plug sockets KMYZ4 ... BEX for the electrical connection.

– Connect valve plates to a certified intrinsically safe circuit Ex ia IIC or ib IIC in

accordance with the operating conditions.

3.2 Intended use

The valve terminal controls pneumatic actuators as intended. The intrinsically safe

solenoid coils control the individual valve plates of the valve terminal.

3.3 Identification X: special conditions

– Ui= 32VDC; Ii= 0.2A; Pi= 0.76W

–Ambient temperature 5°C £ Ta £ +50°C.

– At ambient temperatures up to max. +40°C the valve terminal can be oper

ated with higher performance characteristics (è 8 Technical data).

– Conversion and replacement of valve plates is permissible.

– Use only approved accessories èwww.festo.com/catalogue.

– Install electrical plug connectors protected against electric shock.

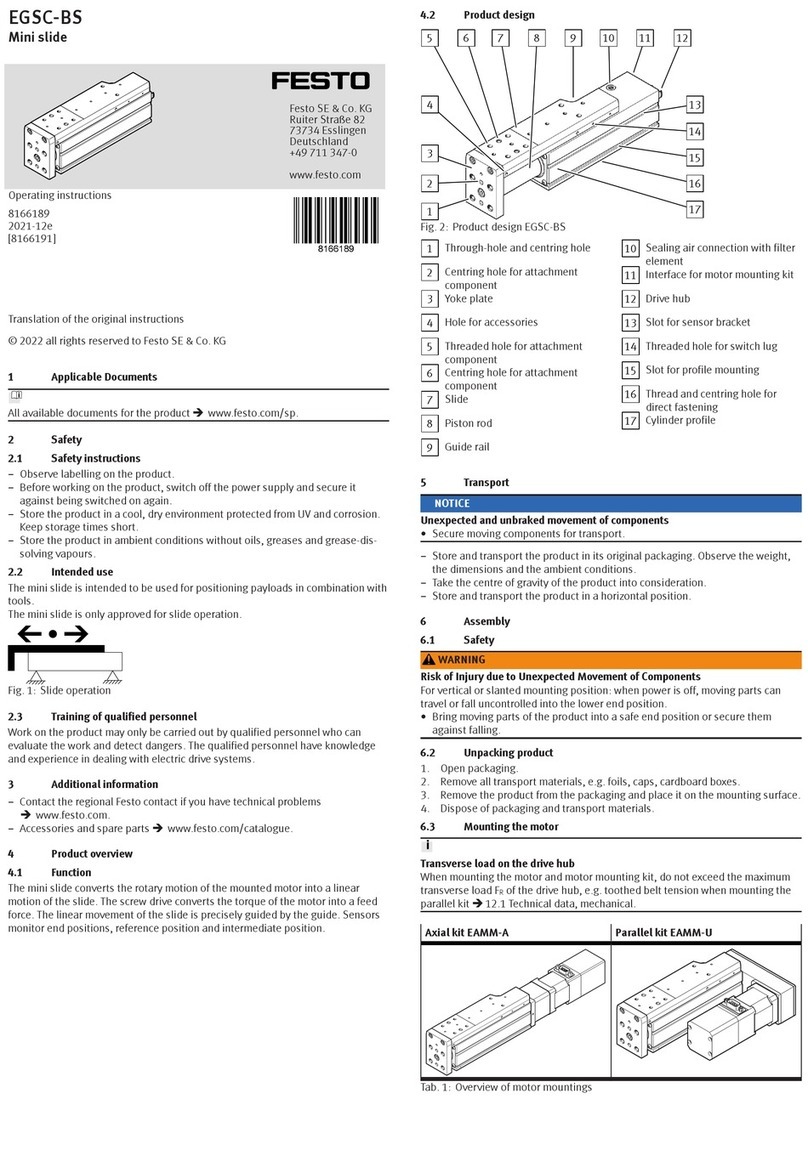

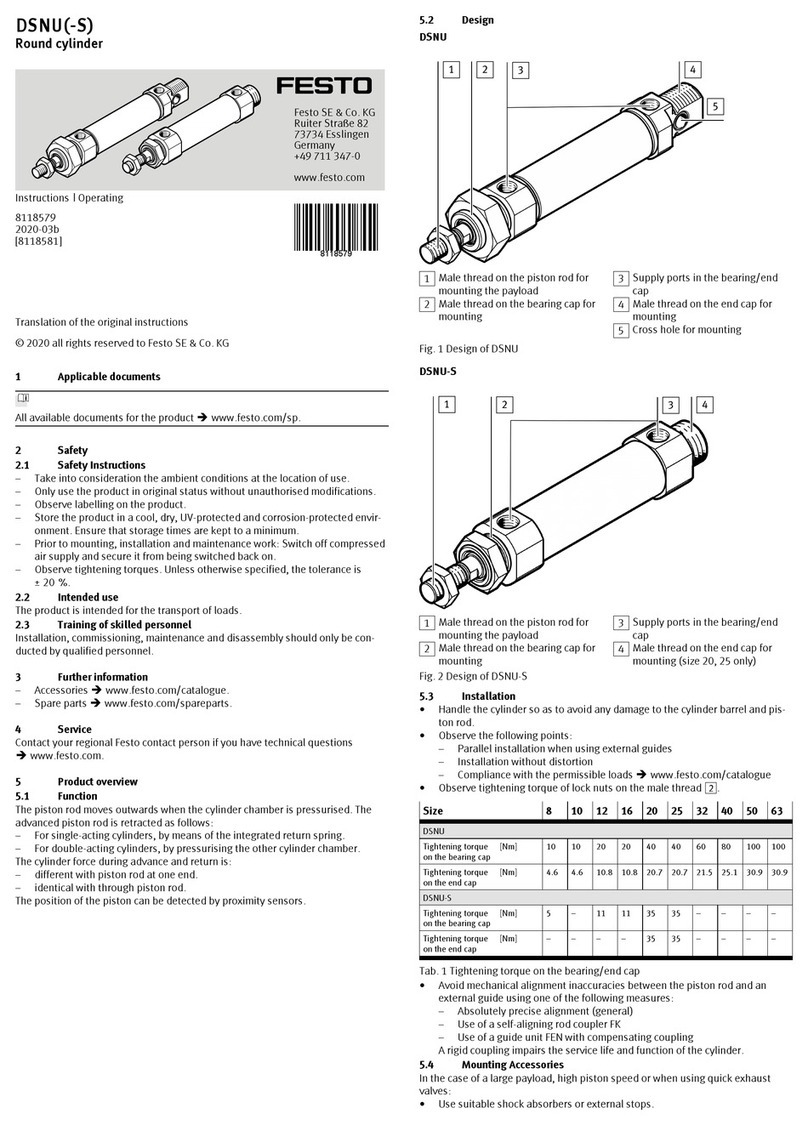

4 Function

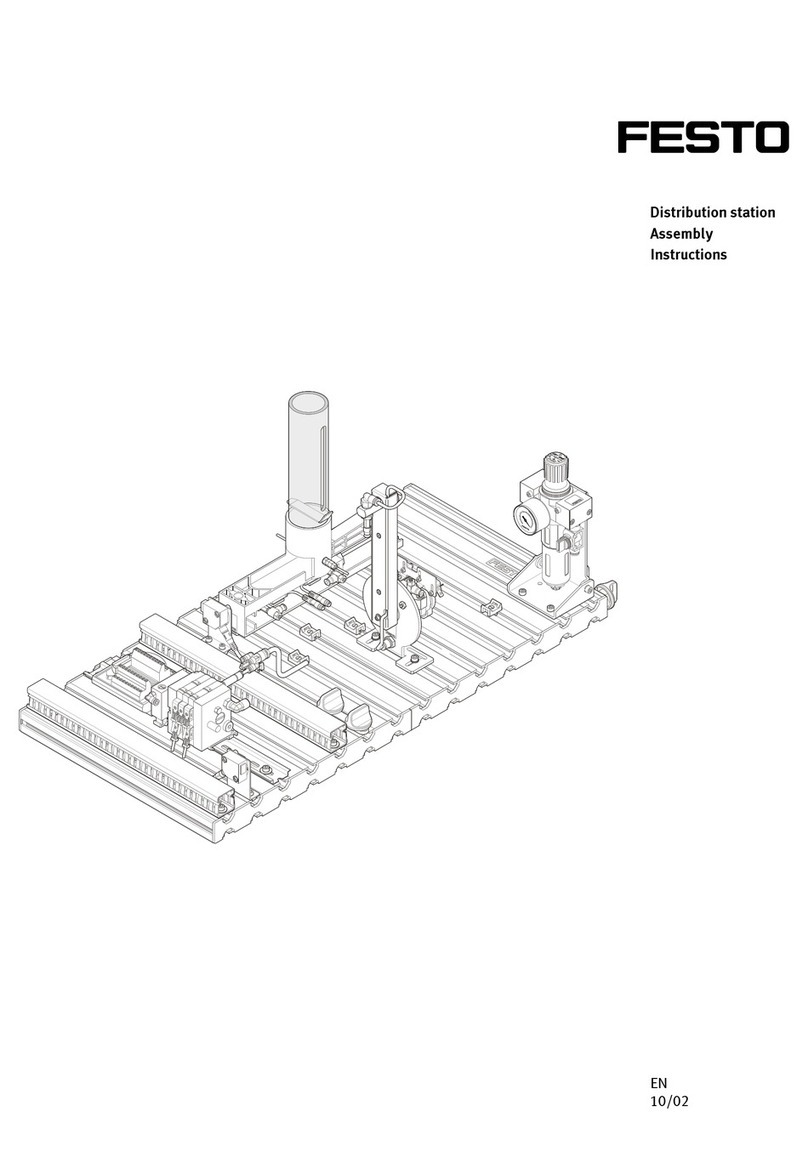

The valve terminal is a configurable functional unit for controlling pneumatic drive

systems. The valve terminal includesa. valve plates with 5/2, 3/2or

2/2way valves. Switching on the voltage energises the solenoid coil and the

valve is actuated.

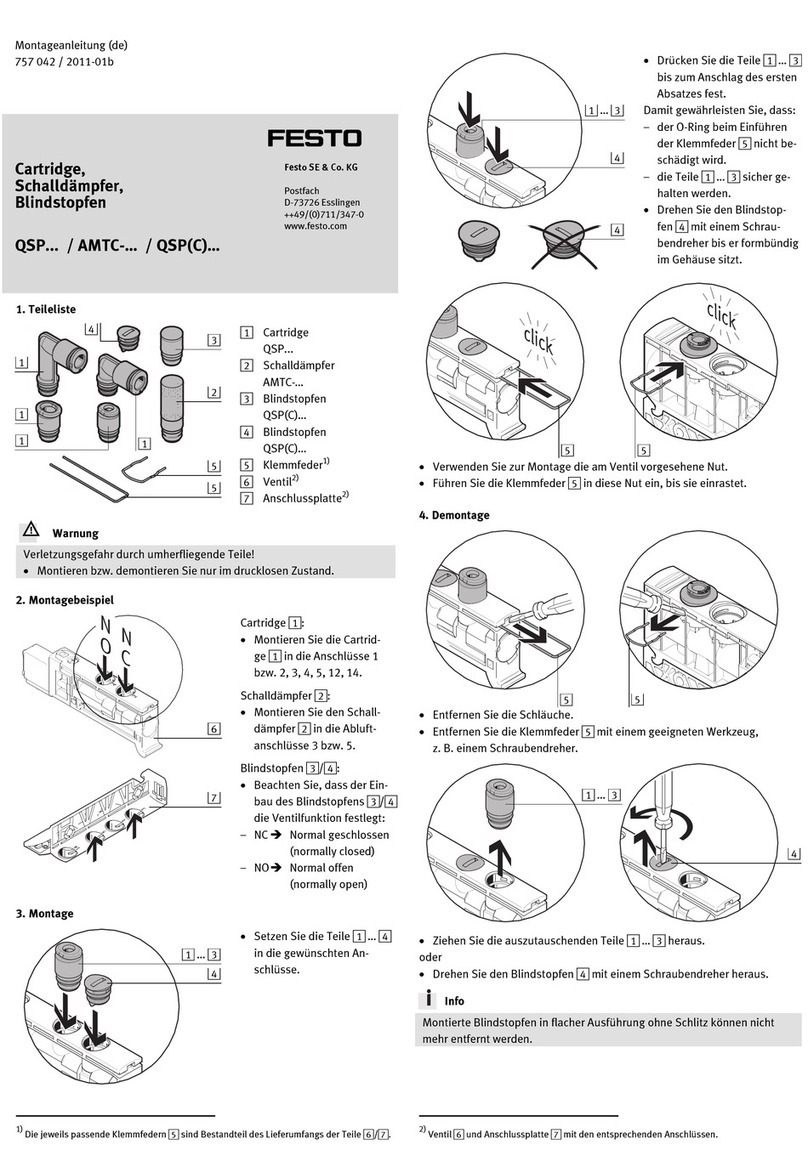

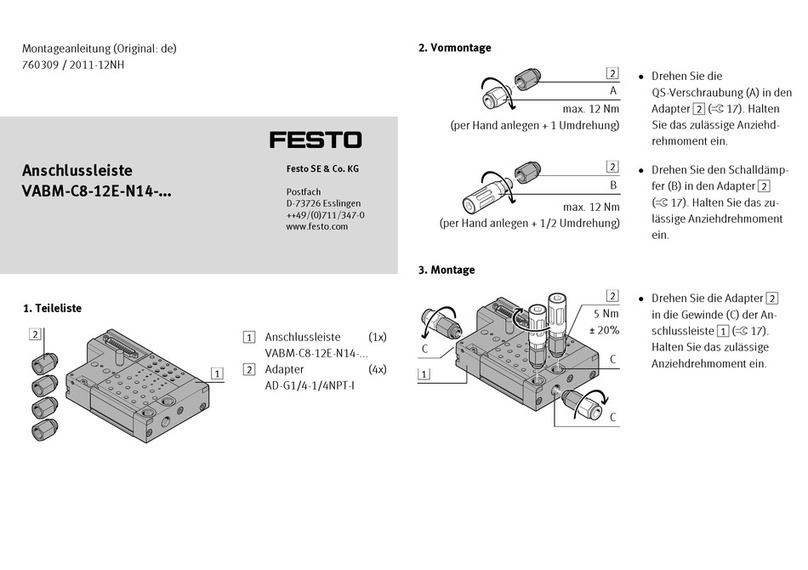

5 Assembly

5.1 Mechanical

NOTICE!

Installation and commissioning may only be performed in accordance with the

operating instructions and by qualified personnel.

– Allow dissipation of selfheating. The device surface of the solenoid coil must

not be covered.

– Ensure that surfaces to be cleaned can be easily accessed.

5.2 Pneumatic

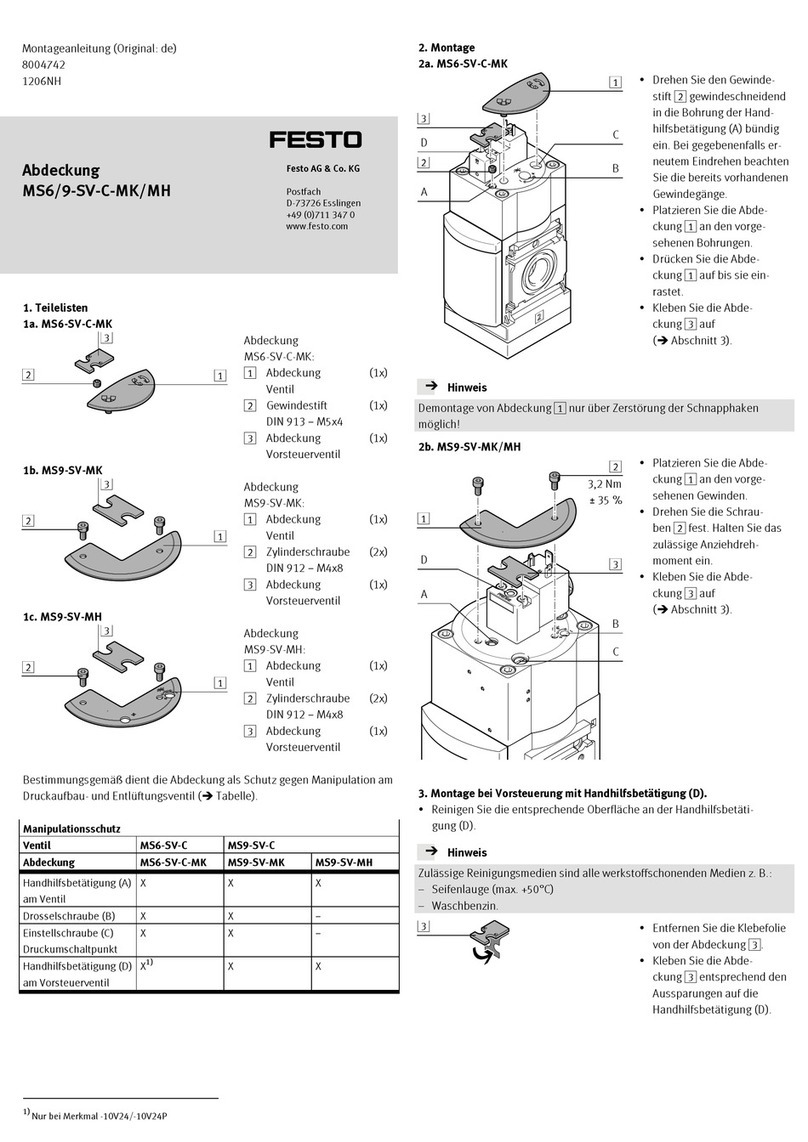

– Seal unused openings in outlets 12 and 14 (pilot air) as well as 82 and 84

(exhaust air) with blanking plugs.

5.3 Electrical

WARNING!

Switching the connections will result in loss of intrinsic safety.

• Pay attention to the correct polarity of the plug socket

The electrical connection is established via 2pin pushin connectors on each indi

vidual solenoid coil. A plug socket KMYZ4 ... BEX is required for this.

Pin Function Colour code1)

– 0V DC BU

+£ 32VDC or £36VDC BUWH

1) Colour code in accordance with IEC 60575:198301

Tab. 2 Pin allocation for solenoid coils

Fig. 1

6 Commissioning

WARNING!

The discharge of electrostatically charged parts can lead to ignitable sparks.

• Prevent electrostatic charging by taking appropriate installation and cleaning

measures.

• Include the device in the system’s potential equalisation. The surface coating

of the solenoid valves is electrically nonconductive.

• Prevent processes that are chargegenerating.

– Observe the specifications on the product labelling.

– Observe operating conditions

7 Maintenance and care

– The product is maintenancefree if used as intended.

– Check function of the product regularly.

– If there is audible leakage: check the fitting of the connections or replace the

affected valve circuits.

The replacement of wearing and spare parts is possible in individual cases.

Repairs of this type must only be carried out by trained and authorised special

ists.

– Please contact your Festo technical consultant.

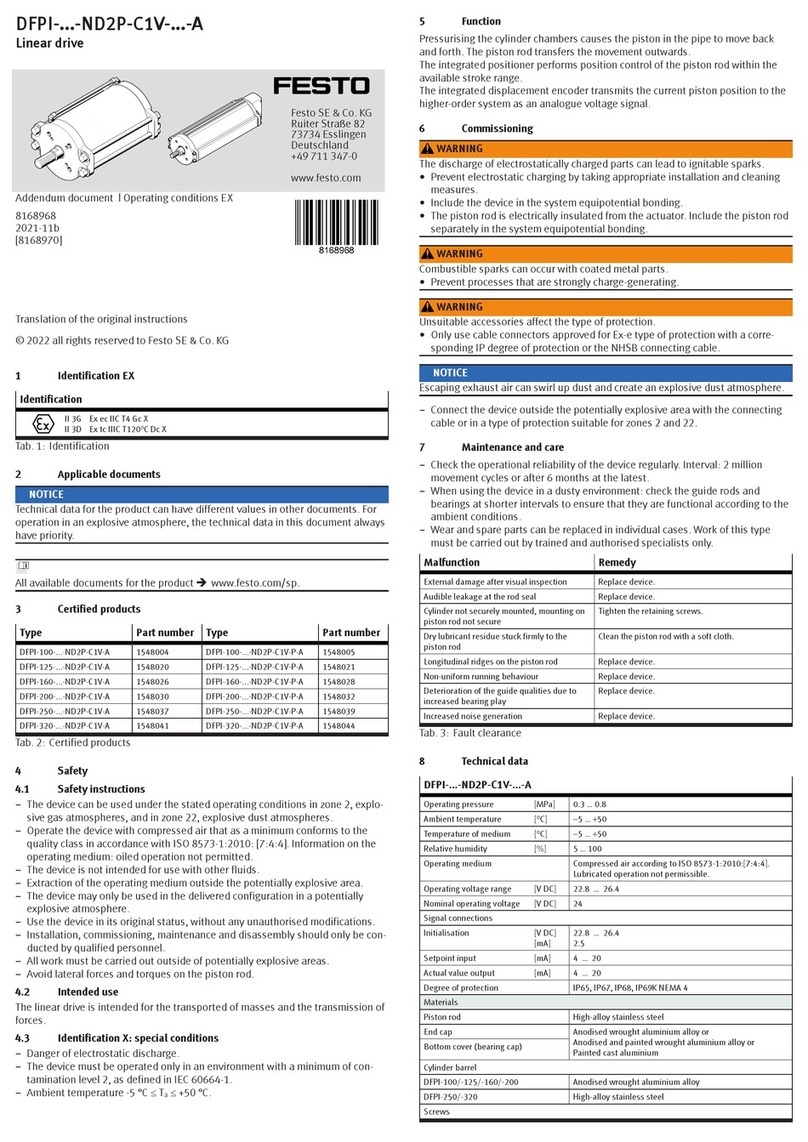

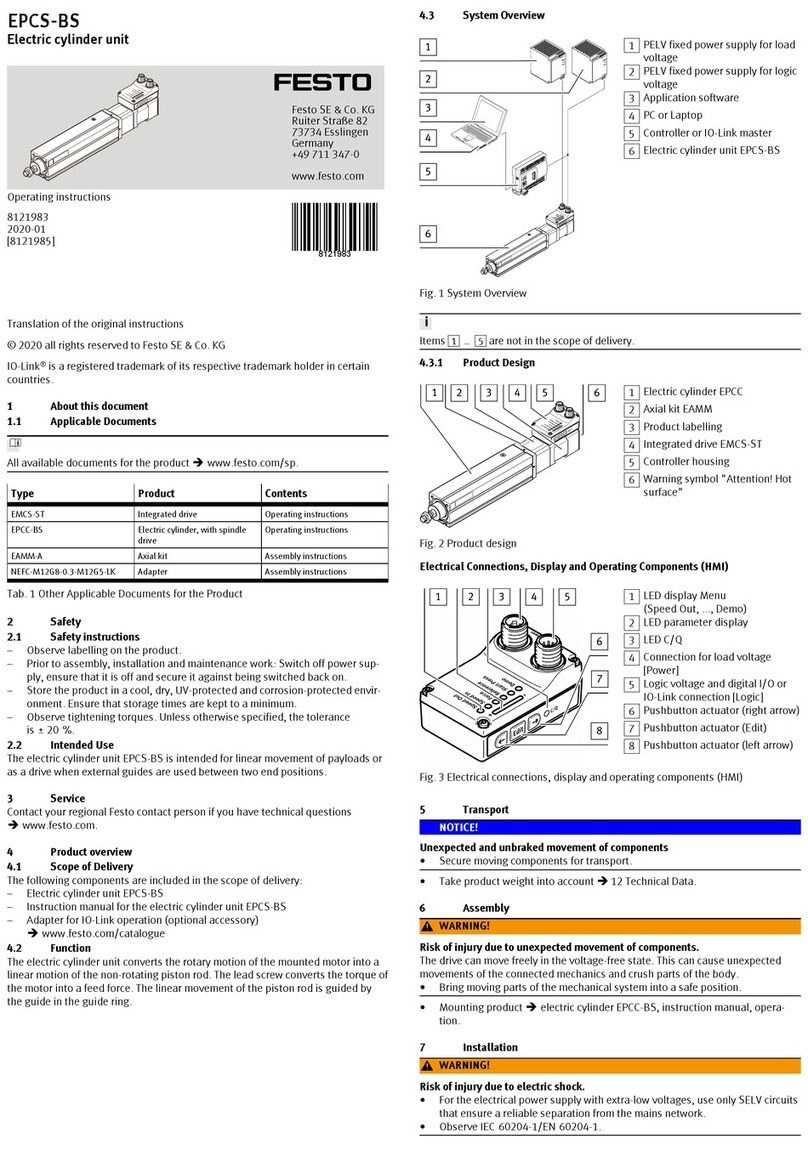

8 Technical data

General operating conditions

Operating pressure with

external pilot pressure

[bar] 0…10

Operating pressure with

internal pilot pressure

[bar] 3…8

Ambient temperature [°C] –5…+50

Temperature of medium [°C] –5…+50

Operating medium Compressed air in accordance with

ISO 85731:2010:[7:4:4]

Mounting position any

8141984

CPV10-EX-VI

Valve terminal

8141984

202102e

[8141986]

Addendum document|Operating conditions EX

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 3470

www.festo.com