70357100T10Z002K000

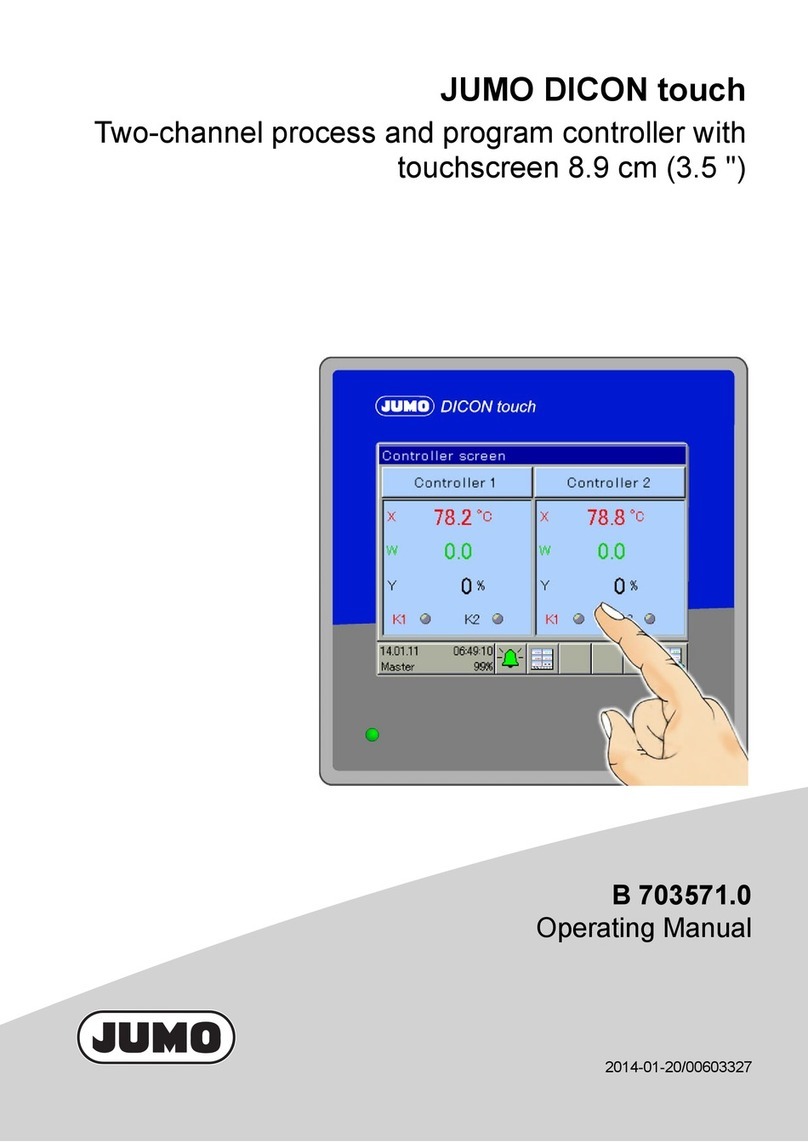

Description

Controller types

The controller can be configured as a two-

state controller, three-state controller, modu-

lating controller, continuous controller, or con-

tinuous controller with integrated position

controller. The cycle time is 150 ms.

Parameter blocks

Four parameter blocks can be assigned to

each controller. Each parameter block has 15

parameters. The controller structures P, I, PD,

PI, and PID can be adjusted.

Self-optimization

Self-optimization also makes it possible for the

controller to be matched to the control path by

a user who is not a control technology expert.

The way the control path reacts to changes in

the actuating variable is evaluated in the pro-

cess. Two different optimization processes are

available. The oscillation method is preset as

the standard method in the controller.

User level

Up to 25 parameters of any type from the con-

figuration or parameter level can be included

in this level. These parameters, for example,

often need to be changed or made available to

operating personnel (see "User administra-

tion").

User administration

Password-protected user administration guar-

antees safe process operation. This function

allows the individual assignment of rights, en-

abling four users to access different levels and

control commands.

Setpoint values

Up to four setpoint values can be entered for

each controller channel. Toggling these set-

point values is controlled by two binary-coded

digital signals. However, the setpoint values

for both controllers can also be specified as an

external setpoint specification via an addition-

al analog input or an interface.

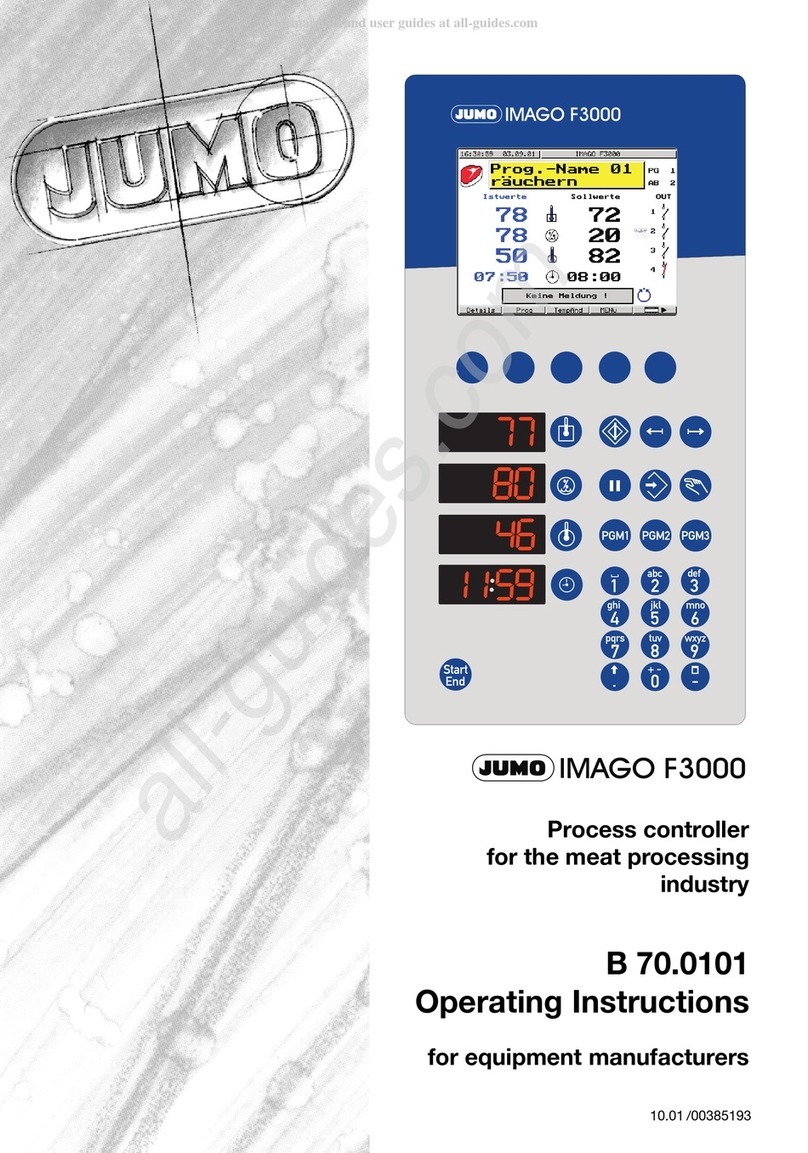

Program controller (extra code)

Ten programs with 50 sections can be pro-

grammed in the program controller. Each pro-

gram can be assigned a program name and

an icon.

Two setpoint values, section run times, operat-

ing contacts, tolerance bands, cycles, and pa-

rameter blocks can be assigned in each

program section.

The tolerance band monitoring function moni-

tors the actual value in an adjustable band

around the setpoint value. The output signal of

the tolerance band monitoring function can, for

example, also be used to stop the program.

Ramp function

The ramp function allows a continuous change

of the setpoint value to the ramp end value

(setpoint specification) for each controller

channel. After power ON, the ramp starts at

the current actual value. The slope of the ramp

is determined via different gradients for a ris-

ing and falling ramp. The ramp starts at the

time the setpoint value is changed or at the

same time as a digital signal. The ramp func-

tion can be controlled by digital signals or via

the functional level.

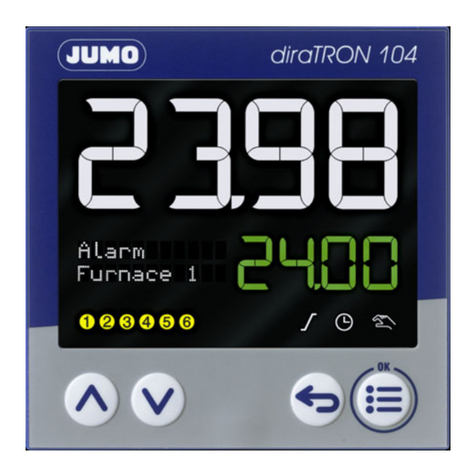

Limit value monitoring

There are 16 limit value monitorings each with

8 selectable alarm functions AF1 to AF8 avail-

able. The limit value can be fixed or be depen-

dant on another value (setpoint value).

Using additional parameters such as location

and value of the switching differential, switch

on/off delay, pulse function, type of acknowl-

edgement and start-up alarm suppression ex-

tensive functions may be realized. Processes

can be hindered through the start-up alarm

suppression, for example the activation of the

limit value monitoring during the start-up

phase.

Math and logic function (extra

code)

The math and logic module allows analog and/

or digital signals to be operated. The following

math formulas are available to the operators:

+, -, *, /, SQRT(), MIN(), MAX(), SIN(), COS(),

TAN(), **, EXP(), ABS(), INT(), FRC(), LOG(),

LN(), humidity and floating average, as well as

!, &, |, ^, and ( and ).

Difference, ratio, and humidity can also be

configured on the device without extra code.

Analog inputs

The analog inputs (maximum of four) are uni-

versally configurable for RTD temperature

probes, thermocouples, resistors (resistance

transmitters, potentiometers), and standard

signals (current, voltage). Linearizations for

over 20 common measuring probes are

saved. A measured value offset or a fine ad-

justment can be carried out to compensate for

machine-specific deviations.

Due to the measuring circuit monitoring, out of

range measurements (too high or too low),

probe/cable break, and probe/cable short cir-

cuit are detected depending on the type of

measuring probe. Due to the measuring circuit

monitoring function, out of range (too high or

too low), probe/cable break, and probe/cable

short circuit are detected depending on the

type of measuring probe so that the system is

switched to a safe operating status (configu-

rable) in the event of a fault.

Customer-specific

linearization

A customer-specific linearization is additional-

ly possible. Programming is carried out with

the aid of the setup program, using a value ta-

ble with 40 pairs of values or a fourth-order

polynomial as a formula.

Analog outputs

Up to five analog outputs can be realized in the

device. They can be used, for example, as

controller outputs, setpoint value outputs, to

output results of the math formulas, or as ac-

tual value outputs. The signals are freely scal-

able.

Digital inputs

The signals of the seven standard digital in-

puts (potential-free contacts) can be used to

initiate different internal functions, for example

switching the parameter block, starting self-

optimization, or acknowledging limit value

monitoring.

Digital outputs

Up to 12 digital outputs can be realized in the

device (see block diagram). They can be used

as, for example, controller outputs, limit value

monitoring signals, results of logic operations,

or for programmer signals, etc.

External inputs

Eight external analog inputs and eight external

digital inputs can each by read via an inter-

face. The unit, range limits, and alarms can be

adjusted for the external analog inputs.

Timers

Two timer functions are provided as standard.

They can be used as relative timers or as

weekly time switches (linked to the real-time

clock).

Digital controller signals

There are eight digital control signals with dif-

ferent functions (OR operation, BCD opera-

tion, delay, inversion). The results are also

available to control internal functions or they

can be output to digital outputs.

Web server (online visualization)

This function is available with the insertion of

the Ethernet interface on expansion slot

COM2. All appearances in the device operat-

ing loop are automatically attainable without

configuration.

Alarm transmission by email

An email alarm can be sent to up to three ad-

dresses simultaneously via a mail server.

Up to five alarm messages can be configured;

the sending process is controlled by digital sig-

nals. There are five different alarm messages

for this. These are linked to specific digital sig-

nals from the device.