Eltek Smartpack S User manual

350030.013

User Guide

Monitoring and Control Units

Flatpack S DC Power Supply Systems

Smartpack S Controller

2 User Guide • Smartpack S Controller

350030.013, 1v0-2012-06

!

!

!

!

s

ss

DC Power Supply Systems

The product warranty becomes invalid if the following safety precautions are not followed during handling,

installation, commissioning and general use/operation of Eltek DC power supply system.

SAFETY and ENVIRONMENTAL PRECAUTIONS

General Precautions

Environmental Precautions

Precautions during Installation

CAUTION: Even though the product incorporates protection circuitry and other safeguards, it can be damaged, perform poorly or

have a reduced lifetime if it is exposed to incorrect treatment during transport, installation or service. Always handle the equip-

ment using proper lifting techniques, do not roll, climb or drill hole in the cabinets or enclosures.

CAUTION: Read the user documentation carefully before installing and using the equipment, as installation and operation is to

be performed as described in it. Always tighten screws and bolts with the torque values recommended in the documentation. For

safety reasons, the commissioning and configuration of the equipment is only to be performed by Eltek’s personnel or by author-

ized and qualified persons.

CAUTION: The installer is responsible for ensuring that the EMC properties of this product/ system do not deteriorate during in-

stallation, and that it is performed in accordance with applying regulations.

Installations in USA and Canada must comply with NEC/CEC requirements.

CAUTION: Before you start the electrical installation, you must always disconnect all external AC supply fuses, as well as internal

battery and load fuses/ breakers, if any.

CAUTION: To avoid damage the equipment, keep objects clear of system ventilation inlets, outlets and system fans, if any, ensur-

ing the airflow through the units is not obstructed, and that the fans rotate freely. Use caution with rectifiers, as they can reach

extreme temperatures under load and normal operation.

WARNING: The installer/user is responsible for ensuring that the DC power system is not damaged by current surges, over-

voltages, etc. caused by external transients, lightning, electrostatic discharge, etc. To avoid damage and obtain the expected

system reliability, it is mandatory to always install SPDs in Eltek’s power supply systems. Follow the instructions given in

“Guidelines for Lightning and Surge Protection”, doc. 2024623.

WARNING: The electronics in the power supply system are designed for indoor, clean environment. When installed in outdoor en-

closures, it is important to keep the door closed during operation, and replace the filters on a regular basis. Indoor installations

in dusty or humid areas require appropriate air filtering of the room, or filtering of the air entering the DC power system. Follow

the instructions given in “Generic Guidelines Environmental Protection.”, doc. 2038879

WARNING: Opening the equipment may cause terminal injury — even if the mains AC supply is disconnected. Hazardous voltages

may be present inside, as large capacitors may still be charged.

WARNING: For safety reasons (high leakage current / high touch current) you must always connect the AC earth wire (PE) to the

terminals, before you connect the AC input cable(s).

The batteries, if any, represent a major energy hazard. To avoid short-circuit of battery poles, you must always remove metallic

objects — uninsulated tools, rings, watches, etc. — from the vicinity of the batteries.

WARNING: 60V DC power systems are only to be installed in Restricted Access Locations (RAL). Access must be limited by use

of tool, i.e. lock and key.

Device

Hazard

Qualified

Personnel

EMC, NEC/CEC

Regard

Device

Hazard

Electric

Shock

Electric

Shock

Electric

Shock

Ventilated

Hot Surface

Current Surge

Protection

Humidity & Dust

Protection

G1

I1

I2

I3

E1

E2

E3

G2

I4

I5

356800.183, 3v1

User Guide • Smartpack S Controller 3

350030.013, 1v0-2012-06

Information in this document is subject to change without notice and does not represent a commit-

ment on the part of Eltek.

No part of this document may be reproduced or transmitted in any form or by any means — elec-

tronic or mechanical, including photocopying and recording — for any purpose without the explicit

written permission of Eltek.

Copyright ©: Eltek, 2012

Doc No: 350030.013 Issue 1.0, 2012 Jun Published 2012-07-05 mafeno

Eltek’s Part Number: 242100.410 SmartpackS Controller

4 User Guide • Smartpack S Controller

350030.013, 1v0-2012-06

Table of Contents

1.Introduction .................................................................................... 5

About this Guide...............................................................................................................5

System Diagram — Flatpack S Power System..........................................................5

2.The Smartpack S Controller ........................................................... 6

Key Features .....................................................................................................................6

Installing Smartpack S Controllers ........................................................................... 7

Removing Smartpack S Controllers......................................................................................7

Mounting Smartpack S Controllers.......................................................................................7

Mounting or Removing Blind Panels......................................................................................7

Accessing the Controller’s Ethernet Port ...........................................................................8

Location of Connector, Communication Ports ....................................................... 9

Connection Drawing ...................................................................................................10

CAN Bus Termination.....................................................................................................11

CAN Bus Cabling..................................................................................................................... 11

Configuration................................................................................................................12

CAN Bus Addressing......................................................................................................12

Front Panel Operation.................................................................................................13

Graphical Display............................................................................................................13

Front Keys ........................................................................................................................13

Software Menus.............................................................................................................14

Controller Access — Via Stand-alone PC...............................................................15

Technical Specifications............................................................................................16

Firmware Upgrade Controller ...................................................................................17

Overview LAN Devices and Firmware Files (PC - S19 Format) ............................... 18

3.About Power System Configuration ............................................. 19

Logical Groups or Menu Options.................................................................................19

1 - System Status options ................................................................................................... 20

2 - System Configuration options ...................................................................................... 20

3 - Alarm Configuration options..........................................................................................20

4 - Commands options.......................................................................................................... 21

5 - Logs and Reports options .............................................................................................. 22

6 - Statistics options............................................................................................................. 23

7 - Commissioning options................................................................................................... 23

8 - Up/Download options (Data Storage Device) ........................................................... 24

SD Card Storage - Overview Firmware Files (Binary Format).................................. 25

Flash Memory Storage .................................................................................................... 26

Alarm Monitors ...............................................................................................................27

Types of Alarm Monitors ...................................................................................................... 29

Typical Parameters for Alarm Monitors ............................................................................ 29

Alarm Output Groups....................................................................................................33

Output Test Commands ...............................................................................................35

Alarm Outputs Isolation (Output Blocked)...............................................................35

Introduction

User Guide • Smartpack S Controller 5

350030.013, 1v0-2012-06

1. Introduction

The advanced SmartpackS controllers are developed for Eltek’s FlatpackS sys-

tem platform, suitable for small and medium telecom and industrial DC power sys-

tems.

About this Guide

This booklet provides users of SmartpackS-based DC power systems with the re-

quired information for operating the system using the SmartpackS’s front panel.

The booklet also describes the SmartpackS controller’s building blocks, external

connections and technical specifications.

Read also the generic and site specific documentation for your DC power system.

For detailed functionality description, browse and search through the Functionality

Description Online Help file (or 350020.073) or WebPower Online Help file.

System Diagram — Flatpack S Power System

The generic SmartpackS (SP-S) distributed control system — used in FlatpackS PS

systems — monitors and controls the whole system.

The SmartpackS controller serves as the local user interface between you and the

system, monitors and controls the power system’s internal wiring and supplies the

CAN bus with power. Also, the controller provides the system with input monitor-

ing and output controlling signals. The WebPower application enables system con-

figuration via a standard web browser.

Figure 1. Typical Flatpack S DC power supply system for telecom and industrial equip-

ment, fed from external AC mains supply. It consists of rectifiers in power

shelves, Smartpack S controller, DC distribution, etc.

Load Fuses

& MCBs

DC Distribution

Battery Bank

Battery

Fuses

CAN bus

R1

R2

RX

AC Fuses,

external

(230VAC or 400VAC)

AC Supply

(Single- or 3-phase)

DC Supply

(24V, 48V or 60V)

AC Mains

supply

selector

To suitable

CAN nodes

(Load)

Telecom &

Industrial

Equipment

Smartpack S

Controller

Flatpack S

HE Rectifiers

Flatpack S

Power System

Internal System Monitoring

and external I/O signals

WebPower

(Web-based user interface)

Ethernet

cable (LAN)

Internet

LVLD

LVBD

6 User Guide • Smartpack S Controller

The Smartpack S Controller

350030.013, 1v0-2012-06

2. The Smartpack S Controller

The SmartpackS controllers are compact, rich-featured, hot swappable, all-in-one

powerful controllers, used in Smartpack S-based power supply systems. They

serve as the local user interface between you and the power system.

The SmartpackS controller covers all control and monitoring needs of small to

medium telecom and industrial DC power systems. System status and configura-

tion is fully available locally via the display, or via the Ethernet port both remote or

locally. Designed for the FlatpackS system platform, the SmartpackS controller

finds its way into many space restricted application. Used in the 1U high, 265mm

deep power racks, the SmartpackS controller oers comprehensive monitoring

and control of a 2- 3kW system occupying less than 6 liters.

Key Features

A wide range of features are implemented in the SmartpackS controller, as men-

tioned below:

◊ Graphical 2.2” TFT high contrast, high resolution color display for easy

navigation

◊ Ethernet for remote or local monitoring and control via Web browser

◊ LEDs for local visual alarming (Major, Minor, Power ON)

◊ SNMP v.3.0 protocol with TRAP, SET and GET on Ethernet. Email of TRAP

alarms

◊ 6 programmable relay outputs

◊ 6 programmable multi-purpose inputs (“digital inputs” or analog signals)

◊ Comprehensive logging

◊ Automatic battery monitoring and test

◊ Battery quality indication (based on test results)

◊ User defined alarm grouping (Boolean logic for grouped alarms)

◊ Uploading and downloading of firmware and configuration files via PC

◊ Buzzer for audio indication of alarm conditions and key pressure feedback

Read also chapter “Technical Specifications” on page 16, for more details.

The Smartpack S Controller

User Guide • Smartpack S Controller 7

350030.013, 1v0-2012-06

Installing Smartpack S Controllers

Removing Smartpack S Controllers

To remove the SmartpackS controllers, do following:

1. Unlock the controller by

using a screwdriver to turn the locking screw ¼

of a turn clockwise to the unlocked position 2

Notice: the display unit is locked, and cannot be

pulled out

2. Remove the controller by

using the rectifier’s handle to pull the module

loose. Support from underneath before the unit

is completely free

3. Mount blind panels in

unused controller or rectifier locations

Mounting Smartpack S Controllers

To mount the SmartpackS controllers, do following:

1. Unlock the controller by

using a screwdriver to turn the locking screw ¼

of a turn clockwise to the unlocked position 2

Notice: the controllers may be inserted in the

power shelf with the locking screw in both

locked and unlocked positions

2. Insert the controller by

sliding it fully into the power shelf, so that it

makes proper contact. Support from underneath

3. Lock the controller by

using a screwdriver to turn the locking screw ¼

of a turn counterclockwise to the locked posi-

tion 1. Then, the controller will be securely

locked in the shelf, or ready for transport

Notice: the display unit is unlocked, and can be

pulled out slightly to access the Ethernet port

Mounting or Removing Blind Panels

Always mount blind panels in unused controller or

rectifiers’ locations. Do following:

• To mount a blind panel

insert the panel in an unused location

until the panel engages and locks into

position

• To remove a blind panel

push the panel’s handle downwards and

pull out to release the panel

1

unlock; pos 2

display )

cw

2

Locking

Screw

Controller’s

handle

1(unlock; pos 2)

cw

2

Locking

Screw

Controller’s

handle

3(lock, pos 1)

(4)

(Display)

ccw

Insert

Removing:

Push down and

pull out to release

Blind

panel

Blind panel’s

handle

8 User Guide • Smartpack S Controller

The Smartpack S Controller

350030.013, 1v0-2012-06

Accessing the Controller’s Ethernet Port

To access the SmartpackS controller directly from a stand-alone computer — or

via a Local Area Network (LAN), if available —you have to connect an Ethernet ca-

ble from the computer to the controller’s Ethernet port. Refer to chapter “Location

of Connector, Communication Ports” on page 9.

Do the following to access the Ethernet port from the front:

1. Lock the controller

(locking screw in locked

position 1)

2. Slide the SmartpackS

controller’s display unit

slightly out

3. Connect the cable to the

controller’s Ethernet port

The controller’s Ethernet port can be accessed from the power system’s front, for

temporarily connections to a computer or LAN, e.g. to configure the system or up-

grade the firmware.

Do the following to access the Ethernet port from the rear:

1. Remove the SmartpackS

controller,

while locking screw is un-

locked position 2

2. Connect the cable to the

controller’s Ethernet port,

and fasten the cable

3. Insert the controller and lock

it (locking screw in position 1)

The Ethernet port can also be accessed from the power system’s rear, for more

permanent connections of the system to a LAN. A dedicated Ethernet cable may

be ordered from Eltek, when the rear cable entry to the controller becomes too

tight.

(side)

(front)

Flatpack S

Power System

Smartpack S

controller

Controller’s

display unit

(slid out)

Controller’s

connection terminals

Controller’s

Ethernet port

(lock, pos 1

display )

2

1

Locking Screw

Position

SmartpackS

Controller

Display

Unit

1 Locked Unlocked

2 Unlocked Locked

(side)

(front)

Flatpack S

Power System

Smartpack S

controller

Controller’s

RS232 & RS485 port

Controller’s

display unit

Controller’s

connection terminals

Controller’s

Ethernet port

The Smartpack S Controller

User Guide • Smartpack S Controller 9

350030.013, 1v0-2012-06

Location of Connector, Communication Ports

For a complete list of signals, pin-out, etc, refer to chapter “Connection Drawing” on

page 10.

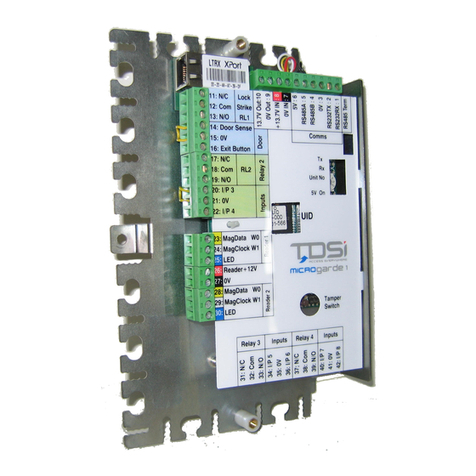

Figure 2. Location of pluggable terminal blocks, RS232/RS485 port and Ethernet

connector in the Smartpack S controller (the pluggable terminals may be black

or green)

All the controller’s system connections to the system’s backplane are implement-

ed via an edge connector, when inserting the controller in the power system.

Notice that when using the RS232 / RS485 port, you must configure RS232 to

COM1 and RS485 to COM2, e.g. via PowerSuite.

RJ-45 socket

(for Ethernet connection)

RJ-11 socket

(for RS232 or RS485 connection)

RJ-11 Pin-out

Function - Signal - Pinout

RS485 A 1

RS485 B 2

RS232 TxD 3

RS232 RxD 4

na -- 5

signal GND 6

RJ-45 Pin-out

Function Ethernet

Signal Pinout

Transmit + 1

Transmit – 2

Receive + 3

Ground 4

Receive – 5

Ground 6

Ground 7

Ground 8

Notice:

Relay contacts shown with

de-energized coil (Alarm)

DIP switches

(CAN ID address)

Customer I/O Terminals

(side view)

Smartpack S Controller

X:* Pin 1+

X:* Pin 2–

X:*** 1NO

X:*** 1NC

X:*** 1C

X:***** 6NC

X:** Pin 6–

Configurable Sense Inputs (6)

Alarm Relay Outputs (6)

10 User Guide • Smartpack S Controller

The Smartpack S Controller

350030.013, 1v0-2012-06

Connection Drawing

Use this drawing as a customer connection reference for all cabling. You find the

exact location of connection terminals, plugs, DIP switches, jumpers, etc. by refer-

ring to chapter “Location of Connector, Communication Ports” on page 9.

Figure 3. Connection Drawing for Smartpack S controller

The configurable inputs 1 through 4 operate in the range of max. – 10 to +10VDC,

and are intended for great accurate measurements, e.g. for temperature sensing

using an external temperature NTC probe. Also, these inputs are suitable for mon-

itoring other sensors (of pressure, humidity, etc.) that output 4mA to 20mA. An

external 470 ohms resistor is then to be connected to the input’s terminals on the

controller, in parallel with the sensor’s cables.

The configurable inputs 5 and 6 operate in the range of 0 to 75VDC, and are in-

tended for e.g. system voltage and battery symmetry measurements.

All the 6 inputs may be configured as Auxiliary Switch (open/close, pull-up or pull-

down), as temperature sense inputs with external NTC sensors, or as Clock inputs.

Read also chapter “Technical Specifications” on page 16.

Smartpack S

Controller

Connections

Smartpack S Controller

Customer Connections

FUNCTION

System Connections

(Via edge connector to the system’s backplane)

Customer Connections

Programmable Inputs

Alarm Relay Outputs

SIGNAL PIN-OUT

—

—

—

—

—

—

1Config. Input

Input Circuit 1

+

+

+

+

+

+

2Config. Input

Input Circuit 2

The figure shows the position of

the relay contacts when the PS system is in

alarm mode of operation; the relay coils are

then de-energized (fail-safe mode)

3

4

5

6

Config. Input

Input Circuit 3

Config. Input

Input Circuit 4

Config. Input

Input Circuit 5

Config. Input

Input Circuit 6

X:*

X:**

Max. 0.5mm

(20AWG) wire section

(spring loaded terminals)

Max. 0.5mm

(20AWG) wire section

(spring loaded terminals)

NO

C

NC

NO

C

NC

NO

C

NC

Relay 1

Relay 2

Relay 3

Alarm Circuit 1

Alarm Circuit 2

Alarm Circuit 3

NO

C

NC

Relay 4 Alarm Circuit 4

NO

C

NC

Relay 5 Alarm Circuit 5

NO

C

NC

Relay 6 Alarm Circuit 6

X:***

X:****

X:*****

Ethernet port

RJ45, 8 pins

DIP Switches

RS232 or RS485 port

RJ11, 6 pins

1

2

3

4

The Smartpack S Controller

User Guide • Smartpack S Controller 11

350030.013, 1v0-2012-06

CAN Bus Termination

To ensure a correct bus communication and avoid data reflection, you must always

terminate the CAN bus with two 120Ω resistors, one at each end of the line (60Ω

bus impedance).

SmartpackS-based DC power systems are shipped from factory with the CAN bus

already terminated with 120Ω resistors. The CAN bus termination is implemented

with a special RJ45 plug with built-in 120Ω end-of-line resistor.

Figure 4. Example of CAN bus addressing and termination in a Flatpack S power sys-

tem with Smartpack S-based control system and some CAN nodes connected

the CAN bus

When connecting more CAN nodes to the bus, you have to remove the CAN bus

termination plug from one of the CAN bus ends, and plug it in one of the CAN ports

on the last connected CAN node.

CAN Bus Cabling

In addition to the two dedicated wires for communication, the CAN bus multi-wire

cable must integrate wires for the CAN power supply and other signals. In standard

industrial environments, the CAN bus can use standard cabling without shielding

or twisted pair wiring. If very low interference (EMI) is required, a CAT-5 twisted-pair

cable is recommended.

Smartpack S

Controller

Flatpack S

HE Rectifiers

Load Monitor

120Ω

End-of-Line

Resistor

120Ω

End-of-Line

Resistor

Current

Monitoring

Sense Inputs

AC Voltage & Current

Sense Inputs

Temp, Fan Speed

Mon & Ctrl

Config Inputs

Battery string #1 Alarm Outputs

NC-C-NO

Config. Inputs

Shunts

Fuse

Monitoring

Config. Inputs

Fuses

01 02

49

I/O Monitor

81

Battery Monitor

33

AC Mains Monitor

97

n

1

WebPower

(Web-based user interface)

Internal System Monitoring

and external I/O signals

Ethernet

cable (LAN)

ID number

CAN Bus

cable

Flatpack S DC Power System (Telecom or Industrial App)

Internet

12 User Guide • Smartpack S Controller

The Smartpack S Controller

350030.013, 1v0-2012-06

Configuration

By the default, SmartpackS-based power systems are shipped from factory with

the controllers correctly installed and configured inside the power system.

CAN Bus Addressing

The power system’s master controller dynamically software-assigns ID numbers to

rectifiers. The master controller registers the rectifiers’ ID numbers — or CAN bus

address (01, 02…) — together with their Serial Numbers (software assignment).

Other control units make use of DIP switches for configuring their unique CAN bus

ID number (hardware assignment).

The SmartpackS controller’s ID numbers (1, 2…14) are assigned by DIP switches on

the controller’s top, refer to chapter "Location of Connector, Communication Ports"

on page 9.

A maximum of 14 SmartpackS controllers may be connected to the CAN bus.

Table 1. Smartpack S controller’s DIP switch addressing

Smartpack S

Controller**

ID # DIP Switch Position

1 — 2 — 3 — 4

1st Controller 1 OFF—OFF—OFF—OFF

2nd Controller 2 ON —OFF—OFF—OFF

3rd Controller 3 OFF— ON—OFF—OFF

4th Controller 4 ON — ON—OFF—OFF

5th Controller 5 OFF—OFF—ON —OFF

6th Controller 6 ON —OFF— ON—OFF

7th Controller 7 OFF—ON— ON —OFF

8th Controller 8 ON — ON— ON—OFF

9th Controller 9 OFF—OFF—OFF—ON

10th Controller 10 ON —OFF—OFF—ON

11th Controller 11 OFF—ON —OFF—ON

12th Controller 12 ON —ON —OFF—ON

13th Controller 13 OFF—OFF—ON —ON

14th Controller 14 ON —OFF— ON —ON

Note:

The controller’s ID# corresponds to the DIP switch’s binary value plus 1

** The DIP switch positions above applies to all controllers, except for

Smartpack2Master and Compack controllers, which have unchangeable ID#

11 and 1 respectively

Smartpack S controller's

DIP switch configuration

ID <1>

(All Switches OFF)

The Smartpack S Controller

User Guide • Smartpack S Controller 13

350030.013, 1v0-2012-06

Front Panel Operation

This chapter describes the SmartpackS controller’s keys and indicators, and how

to operate the SmartpackS-based DC power system from the controller’s front

panel.

Figure 5. Smartpack S controller’s front keys and indicators

Graphical Display

The Graphical Color Display — 2.2” TFT — is either in Status Mode (displays the sys-

tem’s status) or in Menu Mode (displays the menu structure).

The SmartpackS controller has the following LED indications:

Table 2. Description of the Smartpack S controller’s LED illumination status

Front Keys

You can operate the power system navigating intuitively through the graphical

menu structure via the following 4 front keys. We recommend using a pen or similar

tool to press the keys, as they are small.

• The Enter or Left arrow key

When entering numbers, a short press of this key navigates to the left.

A long press of this key to enter and save data

• The Cancel or Right arrow key

When entering numbers, a short press of this key navigates to the right.

A long press of this key to cancel or abort data

• The Up and Down arrow keys

to navigate up- or downwards the menu icons, point at options and

increase and decrease values

“Alarm”

LED lamp (red)

Arrow keys

“Enter” key

“Cancel” key

“Power”

LED lamp (green)

Smartpack S controller

“Warning”

LED lamp (yellow)

LED Indicator Illumination Status Description

Power OFF

ON green

The controller has NO supply

The supply is healthy

Warning OFF

ON amber

No Warning

Warning (Minor alarm, Non-critical alarm)

Alarm OFF

ON red

No Alarm

Alarm (Major alarm, Critical Alarm)

14 User Guide • Smartpack S Controller

The Smartpack S Controller

350030.013, 1v0-2012-06

Software Menus

The SmartpackS-based system’s functionality is accessed via a network of soft-

ware menus and submenus, enabling you to configure and control the whole power

system from the controller’s front panel. When browsing the menus, the Menu Lev-

el Indicator shows the menu level you are in. Editing parameters is password pro-

tected, (default pin code <0003> should be changed). The display can be in Status

Mode or in Menu Mode.

From a PC’s web browser, via WebPower, or running the PowerSuite program, you

can also access the complete system functionality, described in the programs’ On-

line Help.

To change from

Status Mode to Menu Mode

press on the Enter key

Chosen option (yellow text)

Press “Enter” to display the

Mains submenu

System Parameters

Display more navigating Left or Right

(Display area P)

System Status

Normal mode, Alarm mode, etc.

(Display area S)

Status Battery Bank

Displayed in % or in Ah

(Display area B)

Chosen option

Menu Icons

Scrollbar

Warning (minor alarm)

Alarm (major alarm)

Menu Names

Menu Level Indicator

hierarchical menus (Level 1)

Menu Level Indicator

hierarchical menus (Level 2)

Menu Level Indicator

hierarchical menus (Level 3)

Pin Code required for changing configured parameters

(use the arrow keys to enter code).

Default pin code <0003> (should be changed)

System Messages

Animated icons, keys to press, alarms,

system time, etc

(Multi-Info field, Display area M)

Status ModeMenu Mode

Icon Enabled Function

none Float Batt. Charging

Battery Charging

Battery Discharging

Current Limitation

Eciency Management

Generator running

Batt. Boost Charging

Battery Test

Temp. Compensated Ch.

Outputs Blocked

When no battery bank installed, the

icons are shown in Display area B

Animated System Messages (M)

in Normal Mode

System in Normal Mode

Main Menu Options (Level 1)

Submenu “System Status” (Level 2) Submenu “System Configuration” (Level 2)

Example Submenu “Monitors Statistics” (Level 3)

System in Alarm Mode

The Smartpack S Controller

User Guide • Smartpack S Controller 15

350030.013, 1v0-2012-06

Controller Access — Via Stand-alone PC

You can access the SmartpackS controller directly from a stand-alone computer,

or via a Local Area Network (LAN) if available.

Each controller is shipped with a unique Eltek MAC address stored inside the con-

troller and marked on the controller’s label, and with the fixed IP address

<192.168.10.20>.

Do following to access the controller:

1. Start the “Eltek Network Utility” (EVNU) program

(EVIPSetup.exe)

2. Connect the computer to the controller; (see page

page 8)

check its MAC address is displayed

3. Find the computer NIC’s IP address and subnet mask

(network card)

Tip:

using DOS command IPCONFIG, in a Command Prompt

window

e.g. computer’s IP address <169.254.52.132> Subnet

mask <255.255.0.0>

4. Change the controller’s IP address and Network Mask

to be in the same range as the computer’s

Tip:

Using the EVNU program,

1. Select the controller,

2. Click in the “Configuration” button

3. Change e.g.

from default <192.168.10.20> <0.0.0.0>

to IP address <169.254.52.133> <255.255.0.0>,

4. Click on the “Enable Static IP” button

Notice: Check that the IP address <169.254.52.133> is

not used, e.g. issuing the DOS command: “Ping

169.254.52.133“

5. Access the controller’s configuration pages

in your Web browser, e.g. clicking the “Web Interface”

button in the EVNU program

6. Log in with the <admin> account,

7. Change the controller’s Device Name

After accessing the controller, you can configure and monitor the power system

using a standard web browser (via WebPower) or via the PowerSuite program. Pow-

erSuite’s newest version is always available on our FTP server. Contact your clos-

est Eltek representative.

For detailed functionality description, browse and search through the Functionality

Description Help file (or 350020.073) or WebPower Online Help file.

Smartpack S

Controller

WebPower

(Web-based user interface)

Ethernet

cable (LAN)

16 User Guide • Smartpack S Controller

The Smartpack S Controller

350030.013, 1v0-2012-06

Technical Specifications

Model Smartpack S

Part number 242100.410

INPUT DATA

Voltage (nominal) 10 - 75 VDC

Power Consumption, max - no relays energized

max - all relays energized

TBD W

TBD W

SYSTEM CONNECTIONS - SYSTEM MONITORS

Voltage sense, system voltage support 12 VDC, 24VDC, 48VDC & 60VDC

Current sense, shunt support 0 - 20mV and 0 - 60mV

Battery fuse monitoring Auxiliary switch NO/NC, Pull up/down

Load fuse monitoring Auxiliary switch NO/NC, Diode Matrix Pull up/down

Ground fault detection Simple bridge circuit detection

SYSTEM CONNECTIONS - LVD CONTROL

Battery disconnect 1 (latched or non-latched supported)

Load disconnect 1 (latched or non-latched supported)

INPUTS AND OUTPUTS

Digital configurations, Inputs #1-6 Auxiliary switch: NO/NC, Pull up/down

Analog configurations, Inputs #1-4 Analog Voltage[±0 - 10V]

±4-20mA current measurement (through external 470kΩ resistor)

Temperature (for NTC probe)

Analog configurations, Inputs #5-6 Analog Voltage[0-75V]

Symmetry measurement

Output configurations, Outputs #1-6

(alarms)

6x Relay–Dry/Form C

Configurable Normally Open/Closed

[Max capacity 75V/2A/60W]

USER INTERFACE

Local 2.2” TFT 65k Colour display

QVGA resolution

4 keys

Ethernet port 10/100 BASE-T

HP Auto MDI/MDI-X

IP protocols: HTTP / SSL, SNMP v3, MODBUS TCP and pComm UDP

(PowerSuite)

Serial port RS-232 or RS-485 on RJ11 connector

Serial protocols (pending): MODBUS RTU, Modem Call-Back/SMS

reporting (PSTN or GSM) and CSCP

GENERAL SPECIFICATIONS

Dimensions (WxHxD) 72.2 x 43.0 x 220.7mm (2.8 x 1.7 x 8.7”)

Temperature Range Operating -20 to +60˚C (-40 to 140˚F)

DESIGN STANDARDS

Electrical safety UL 60950-1-3rd edition, EN 60950-1-3rd edition

EMC ETSI EN 300 386 V.1.4.1

EN 61000-6-1 / -2 / -3 / -4

FCC Part 15 Subpart 109

Marine*) DNV- OS-D202, Ch.2 Sev.4 (DNV 2.4), Temperature Cl. B, Humidity Cl.

B, Vibration Cl. A and EMC Class B

Environment ETSI EN 300 019: 2-1 (Class 1.2), 2-2 (Class 2.3) & 2-3 (Class 3.2)

ROHS compliant

*) As part of CA0603.000 Flatpack S 3U Marine system

Specifications are subject to change without notice

Doc 242100.410.DS3 – v1

The Smartpack S Controller

User Guide • Smartpack S Controller 17

350030.013, 1v0-2012-06

Firmware Upgrade Controller

Upgrade of the SmartpackS controller’s firmware, while the system is live, is per-

formed via the controller’s Ethernet port, using the “Eltek Network Utility” program

(EVIPSetup.exe) to transfer the firmware file to the controller.

Upgrading the firmware does not delete or change any of the configuration and

calibration values stored in the controllers.

You can upgrade the SmartpackS controller’s firmware using the following meth-

od.

Figure 6. Example of Smartpack S controller’s firmware upgrade via PC

Do following:

• Slide out the controller’s display module

Refer to chapter "Accessing the Controller’s Ethernet Port" on page 8

• Connect a PC to the Smartpack S controller

plugging one end of a standard Ethernet cable to the PC and the other

end to the controller’s Ethernet port

• Start “EVIPSetup.exe”,

the “Eltek Network Utility” program in the PC

• Select the Smartpack S controller;

using the EVNU program, check correct MAC and IP address and the

correct firmware file <SmartpackS_(part #)_(version #)_APP.s19>

Refer to topic "Controller Access — Via Stand-alone PC" on page 15

• Click on the “Update Software” button

in the EVNU program

For more detailed description, browse and search through the Functionality De-

scription Help file (or 350020.073) or WebPower Online Help file.

Smartpack S

Controller

WebPower

(Web-based user interface)

Ethernet

cable (LAN)

18 User Guide • Smartpack S Controller

The Smartpack S Controller

350030.013, 1v0-2012-06

Overview LAN Devices and Firmware Files (PC - S19 Format)

The “Eltek Network Utility” program <EVIPSetup.exe> will transfer the specific

firmware file (s19-format) from a LAN connected computer to the device (or hard-

ware platform).

LAN Device File Name (examples) File Type

SmartpackS SmartpackS_(part #)_(version #)_APP.s19 Firmware upgrade Controller & embedded

Web Adapter

Smartpack2Master SmartPack2_Master_405006.009_1.3_APP.s19 Firmware upgrade Controller & embedded

Web Adapter

Compack ComPack_xx.xx_APP.s19 Firmware upgrade Controller & embedded

Web Adapter

Smartpack

(Part 242100.113)

Rev4.2_SB70WebPower_APP.s19 Firmware upgrade embedded Web Adapter

Smartpack

(Part 242100.118, HW v2)

WebPower_MCF5208_43_APP.s19 Firmware upgrade embedded Web Adapter

Smartpack

(Part 242100.118, HW v3)

WebPower_MCF5235_43_APP.s19 Firmware upgrade embedded Web Adapter

WebPower Adapter SB72 Rev4.2_SB72WebPower_APP.s19 Firmware upgrade Web Adapter (stand-alone

with Smartpack)

WebPower Adapter SB72 Rev2.0_SB72WebPower_APP.s19 Firmware upgrade Web Adapter (stand-alone

with Aeon Gold)

WebPower Adapter SB72-512 WebPower_SB72-512_20_APP.s19 Firmware upgrade Web Adapter (stand-alone

with Aeon Gold)

WebPower Adapter SB72 Rev2.0_SB72WebPower_APP.s19 Firmware upgrade Web Adapter (stand-alone

with MCU)

WebPower Adapter SB72-512 WebPower_SB72-512_20_APP.s19 Firmware upgrade Web Adapter (stand-alone

with MCU)

The “xx.xx” refers to the firmware file’s version number.

About Power System Configuration

User Guide • Smartpack S Controller 19

350030.013, 1v0-2012-06

3. About Power System Configuration

The Eltek DC power supply system’s functionality represents a vast set of func-

tions, characteristics or capabilities implemented in the hardware and software

of the controllers, control units and nodes connected to the system’s CAN bus.

You can use following types of user interfaces to access the functions and param-

eters:

• The controllers’ front panel keypad

using software menus and submenu options

• A standard web browser

to access the WebPower firmware, a platform-independent graphical

user interface (GUI) built-in the controllers

• The PowerSuite program

A PC application run on computers using MS Windows operating sys-

tems

Logical Groups or Menu Options

All the mentioned functions, characteristics and parameters are fully configura-

ble, and are organized in following system-oriented logical groups:

• Power System

• Mains

• Generator

• Rectifiers

• Battery

• Load

• Control System

Also, these functions, characteristics and parameters are presented in following

task-oriented logical groups:

1. System Status

2. System Configuration

3. Alarm Configuration

4. Commands

5. Logs and Reports

6. Statistics

7. Commissioning

8. Up/Download

For detailed functionality description, browse and search through the Functionality

Description Help file (or 350020.073) or WebPower Online Help file.

20 User Guide • Smartpack S Controller

About Power System Configuration

350030.013, 1v0-2012-06

1 - System Status options

Configuration changes are not allowed at System Status level. To make changes

you have to access the System Configuration options, the Alarm Configuration op-

tions or similar.

This logical group presents the important system parameters, which indicate the

status of the power system, such as number of battery banks, voltage, current,

temperatures, fuse status, inputs and outputs status, and many similar parame-

ters.

The presented parameters are organized in system-oriented groups: Power Sys-

tem, Mains, Generator, Rectifier, etc.

Refer to these topics (Mains, Rectifiers, etc.) for more information about the Sys-

tem Status parameters.

2 - System Configuration options

The options in this logical group let you change all the relevant system parameters,

values and characteristics, such as temperature scales, system polarity, language,

system voltages, rectifiers and battery related values, and many similar parame-

ters.

Configuration changes are allowed at this level, using a Pin-Code.

Notice:

The default Service Access Level password or Pin-Code is <0003>. We strongly recommend

changing the passwords as soon as the power system is installed.

The parameters are organized in system-oriented groups: Power System, Mains,

Generator, Rectifier, etc.

Refer to these topics (Power System, Mains, Rectifiers, etc.) for more information

about the System Configuration parameters.

3 - Alarm Configuration options

All the power system’s alarms are fully configurable, and are implemented using

Alarm Monitors (software modules). These software modules monitor input signals

and logical states, and raise alarms when the signals reach certain limits or values.

Read more about "Alarm Monitors" on page 27.

The options in this logical group (the Alarm Configuration options) let you config-

ure all the limits, values, etc. for the system’s Alarm Monitors.

Configuration changes are allowed at this level, using a Pin-Code.

Notice:

The default Service Access Level password or Pin-Code is <0003>. We strongly recommend

changing the passwords as soon as the power system is installed.

The available Alarm Monitors are organized in system-oriented groups: Mains, Gen-

erator, Rectifier, Load, etc.

This manual suits for next models

1

Table of contents

Other Eltek Controllers manuals

Popular Controllers manuals by other brands

LOGICDATA

LOGICDATA SMARTneo Series user manual

HydroPoint

HydroPoint WeatherTRAK ET Pro3 Bidding Specifications

Azbil

Azbil Infilex WY5317C Specifications & instructions

Woodward

Woodward 723PLUS Original instructions

LOVATO ELECTRIC

LOVATO ELECTRIC INSTALLATION MANUAL installation manual

Nibe

Nibe EME 20 Installer manual