Sterlitech 1812 Supplement

1812 Spiral Wound Membrane

High Pressure Housing

Assembly & Operation Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

www.sterlitech.com 1-877-544-4420info@sterlitech.com

Table of Contents

2

3

5

10

12

14

15

15

15

16

19

12

Page

1. Introduction

3. 1812 Housing Assembly

7. Accessory and Spare Part Ordering Information

2. 1812 Housing Components

5. Operation of the 1812 Housing Assembly

4. 1812 Housing Assembly Connections and Parts

6. Supplementary Operating Information

8. Return Material Authorization

9. Warranty

10. Technical Assistance

Appendix 1: Compression Connections

Appendix 2: Bench Scale Filtration Products

2

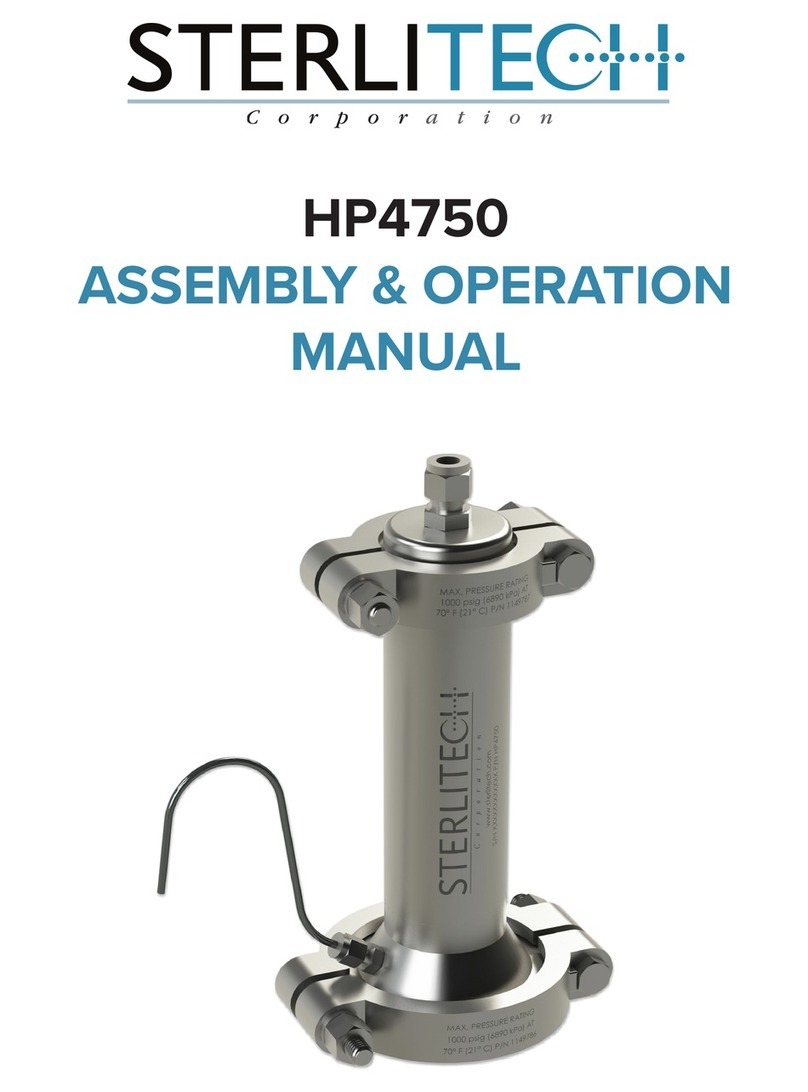

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

The 1812 Spiral Wound Membrane Housing is a bench-scale crossflow filtration system that is designed

to evaluate 1812 spiral wound membrane elements in a variety of applications. It simulates the flow

dynamics of commercially available spiral wound membrane elements. Users can vary the operating

conditions and fluid dynamics over broad ranges.

Table 1 below outlines the features and technical specifications of the 1812 Spiral Wound Membrane

Housing (hereafter referred to as 1812 Housing).

Prior to operating or servicing this device, this manual must be read and understood.

1. Introduction

Parameter Description

Membrane Active Area

Maximum Pressure

Cross Flow Velocity

Inlet/Outlet/Permeate connection

Variable (1 to 5 ft2)

SS316

60 bar (870 v psig)

Variable

Gasket

Tube Length

Viton (Other materials available)

374.6 mm (14.75 inches)

9.3 mm (0.365 inches)

48 mm (1.88 inches)

1812 Housing

Maximum Temperature

Dimensions

200°C (400 °F)

pH Range

Tube ID

Membrane Dependent

Table 1: 1812 Housing Features and Technical Specification

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

3

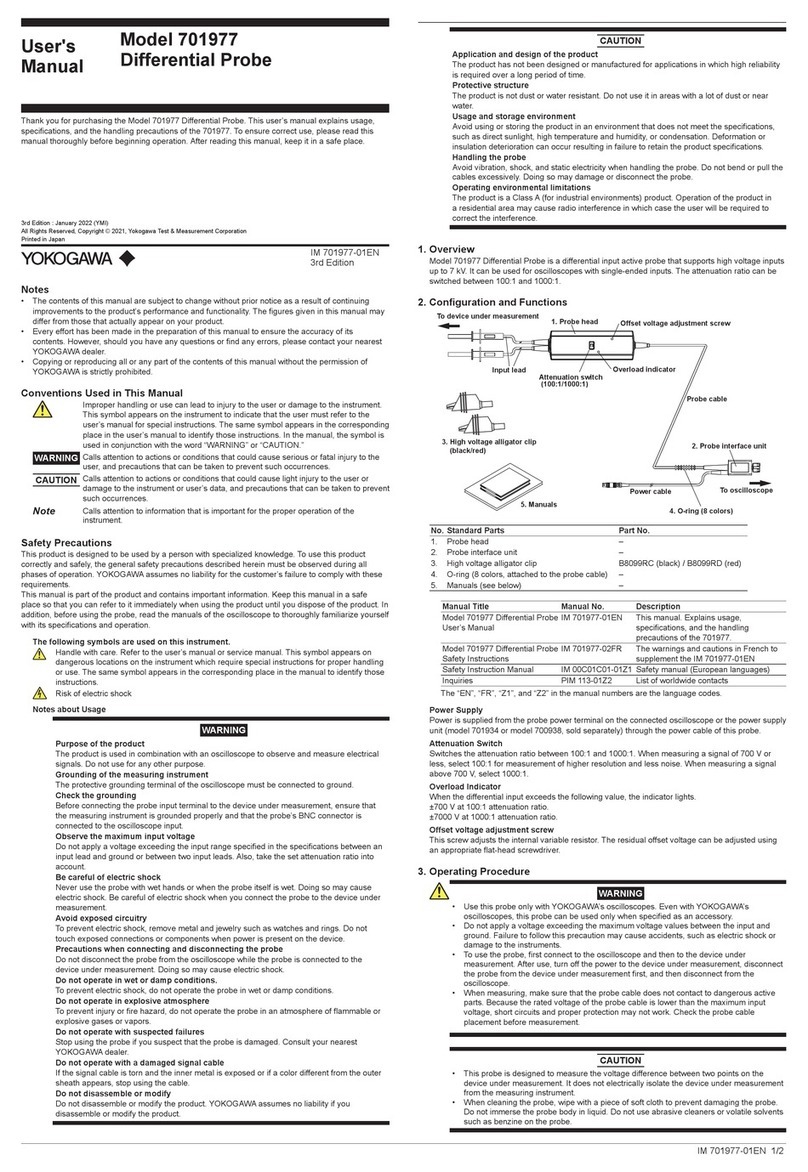

The 1812 housing consists of the following components. Figure 1 illustrates a typical

assembly of the 1812 Housing.

Figure 1: 1812 Housing Assembly

Legend:

1. Stainless Steel 316 housing

2. 3/8 inchgaskets for top and bottom end caps

3. 2.5 inch gasket for permeate tube

4. Top end cap

5. Bottom end cap

6. 2.5 inch Tri clamp fittings

7. 1/2 inch Tri clamp fitting

8. 3/8 inch ferrule, connection

3

5

7

7

7

4

86

6

1

2

3

2. 1812 Housing Components

4

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

Operation of the 1812 housing cell requires additional equipment that are sold

separately as listed below. To inquire about a complete system, contact

sales@sterlitech.com.

• Feed Pump

• Feed Tank

• 1812 Spiralwound Membrane Elements

• Concentrate Control Valve

2.1. Additional Equipment

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

5

After verifying that all of the necessary components were shipped and present, you can begin

the assembly of the system.

To assemble the 1812 Element into the housing:

To remove the 1812 Element from the housing:

1. Close the longer end of the permeate tube of the membrane module (the end without

the PTFE seal) using the compression connection (Figure 2, #1). Appendix 1 shows how to

install Swagelok Tube Fittings

2. Connect the hollow compression connection to the shorter end of the tube (the end with

the PTFE seal) (Figure 2, #2).

3. Connect the hollow end cap to the hollow compression connection (Figure 3#1)

4. Insert the membrane module in the housing starting from the close end of the permeate

tube (Figure 4, #1,2)

Note: make sure the gasket (Figure 1, #3) is in place before connecting the top end cap to

the tube

5. Use the tri clamp fitting to secure the hollow end cap (Figure 4, #3)

6. Place the solid end cap on to the other side of the element and secure it using the tri

clamp fitting. (Figure 5, #1,2)

7. Connect the feed inlet, retentate outlet and permeate outlet houses using the clamps

NOTE: Feed inlet should be connected to the side of the housing where top end

cap is connected and the retentate outlet tubing should be connected to the side

where the end cap is connected

The 1812 Housing is now assembled and ready to be connected to a feed pump for

operation.

WARNING: Do not exceed 870 psi (60 bar) in the 1812 Housing.

1. Remove the clamp and open up hollow end cap.

2. Remove the element by pulling the element through the hollow end cap.

3. Separate the element from the hollow end cap.

3. 1812 Housing Assembly

6

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

Figure 2: Connecting compression fittings (Swagelok tube fittings) to the

module permeate tubes

Legend:

1. Permeate line compression fitting, solid

2. Permeate line compression fitting, solid

3. 1812 element

1

3

2

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

7

Figure 3: Connecting the top end cap

Legend:

1. Top End Cap

2. Compression Fitting

1

2

8

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

Figure 4: 1812 Element insertion into the housing

Legend:

1. 1812 male element

2. Top End Cap

3. Tri clamp fitting

1

23

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

9

Figure 5: Bottom End Cap

Legend:

1. Bottom End Cap

2. Sanitary Fitting on Bottom End Cap

3. 3/8-inch gaskets for bottom end cap

1

3

2

10

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

1

2

3

5

6

4

7

11

A

A

B

C

D

9

10

8

1812 FLOW DIAGRAM

ITEM NO.

PART DESCRIPTION

1

FEED TANK

2

PRESSURE RELIEF VALVE

3

FEED PUMP

4

FEED BY-PASS VALVE

5

FEED BY-PASS FLOW METER

6

FEED PRESSURE GAUGE

7

1812 HOUSING

8

CONCENTRATE CONTROL VALVE ASSEMBLY, (0-1000PSI)

9

CONCENTRATE FLOW METER

10

PERMEATE FLOW METER

11

PERMEATE TANK

A

3/8" HIGH PRESSURE TUBING, FEED LINE

B

3/8" LOW PRESSURE TUBING, BY-PASS

C

3/8" LOW PRESSURE TUBING, RETURN LINE

D

3/8" LOW PRESSURE TUBING, PERMEATE OUTPUT LINE

Figure 6: 1812-HP Housing Assembly Connections and Parts

1812 Flow Diagram

Item No.

4

8

Part Description

Feed By-Pass Valve

Concentrate Control Valve Assembly, (0-1000 PSI)

2

6

10

B

Pressure Relieve Valve

Feed Pressure Gauge

Permeate Flow Meter

3/8” Low Pressure Tubing, By-Pass

1

5

9

A

Feed Tank

Feed By-Pass Flow Meter

Concentrate Flow Meter

3

7

11

C

D

Feed Pump

1812 Housing

Permeate Tank

3/8” Low Pressure Tubing, Return Line

3/8” High Pressure Tubing, Feed Line

3/8” Low Pressure Tubing, Permeate Output Line

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

11

Figure 6 shows the typical plumbing connections that are needed for the operation of the

1812 Housing; the configuration can change slightly depending on the objectives ofthe user.

In general, the connections needed are as follows:

1. Feed vessel to the pump inlet

2. Pump outlet to the feed inlet of the 1812 housing

3. Concentrate outlet of the 1812 housing to the feed vessel

4. Permeate collection tube to the permeate collectionvessel

Figure 6 also lists the additional components that are necessary to operate the 1812

Housing. These components are sold separately and can be found in the Membrane/ Process

Development section of the Sterlitech website (http://www.sterlitech.com/membrane-

process-development.html). The final assembly of the system will vary with the feed vessels,

pumps, and tubing used.

12

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

4. Operation of the 1812 Housing Assembly

5. Supplementary Operating Information

5.1. Membrane Performance Results

5.2 Membrane Performance

Once the 1812 Housing has been assembled and connected to a feed pump, it can be used

in reverse osmosis, ultrafiltration, nanofiltration, and microfiltration separation processes

for applications in a variety of industries, including food and beverage, pharmaceutical, or

industrial.

To operate the 1812 Housing Assembly:

1. Open all of the valves in the system to relieve any pressure build-up before turning on

the feedpump.

2. Turn the feed pump on.

3. Set the feed pressure to be less than 600 psig by gradually closing the concentrate

control valve (Figure 6,8) (sold separately).

4. Verify the feed pressure reading on the concentrate pressure gauge (sold separately)

(Figure 6, 8).

5. Adjust the bypass valve (Figure 6, 4) and concentrate control valve (Figure 6, 8) to

obtain the desired pressure and ow. Experimentation enables you to determine the

optimum settings for pressure, and flow rate to use on the chosen membrane and the fluid

being processed.

6. Once the experiment is complete, shut down the system by turning the feed pump o and

opening all of the valves to relieve any pressure buildup.

Spiral wound membranes containing mesh spacers are usually operated with a fluid velocity

across the membrane surface of 0.1–0.5 m/sec (0.3–1.6 ft/sec). Higher velocities in membranes

may lead to excessive pressure dierential across the membrane and possible damage.

Other parameters such as viscosity, pressure, and suspended solids may also aect

performance/operation. Experimentation with the 1812 Housing can help predict the best

operating parameters. If your pump is delivering too much flow, a portion of the flow can

be diverted back to the feed container before entering the feed inlet of the cell body. This

requires installation of an optional bypass valve and fitting on the pump outlet (Figure 6, 4),

which is not supplied with the housing.

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

13

5.3. Temperature Limits

5.4. Membrane Cleaning

The membranes, feed spacer, permeate, O-rings, and cell body materials construction dictates

maximum operating temperatures.

The 1812 housing can be cleaned easily after the membrane is removed. However, you may

wish to simulate the actual cleaning conditions of Cleaning-In-Place (CIP) in larger systems

with spiral-wound or tubular membranes. CIP chemically cleans without removing the

membrane to mechanically scrub the unit.

During CIP, cleaning solutions are re-circulated and, in some cases, allowed to sit for a period

of time within the cell body. In some cases, the feed pump can be used to re- circulate the

cleaning solutions.

Components Maximum Temperature

1812 Housing 177 °C (350 °F)

Variable

Viton 200 °C (400 °F)

150 °C (300 °F)

Membrane Elements

O-rings

EPDM

Table 2: Upper Temperature Limits

14

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

6. Accessory and Spare Part Ordering Information

Accessories and spare parts for the 1812 housing can be ordered by calling Sterlitech Corporation at

1-877-544-4420 or by visiting www.sterlitech.com.

Table 3: Accessory and Spare Part Ordering Information

Product

Spare Parts

Shipping Weight Ordering Number

1812 Housing, for operation to 60bar (870 psig)

2.5” Viton Gasket

Concentrate Control Valve

1812 Membrane Elements

4.67 kg (10.3 lbs)

Contact Sterlitech Contact Sterlitech

1200373

1230133

1149419

Contact Sterlitech

1200371

1230131

1180150

0.05 lb (0.028 kg)

2 lbs (0.9 kg)

Contact Sterlitech

2.5”EPDM Gasket 0.05 lb (0.028 kg)

Feed Flow Pump

1/2“ VitonGasket for Permeate Line 0.5 lbs (0.22 kg)

3/8“EPDMGasket for Permeate Line 0.5lbs (0.22 kg)

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

15

7. Return Material Authorization

8. Warranty

9. Technical Assistance

If materials are to be returned to Sterlitech for repair, evaluation, or warranty consideration, a Return

Material Authorization (RMA) number and form must be obtained from Sterlitech prior to the return.

Contact Sterlitech’s Customer Service Department for these forms.

The form must be completed and returned with the material. Be sure to include a complete, detailed

written reason for the return. Also, include serial numbers, installation and removal dates, and any other

pertinent information that is available. 1812 Housings have a serial number imprinted on the cell bottom.

Indicate the proposed disposition of the material, and reference the RMA number on all packages or

cartons. All material must be shipped to Sterlitech with freight prepared by the customer.

The following is made in lieu of all other warranties expressed or implied. Sterlitech Corporation

guarantees equipment to be free from defects in material and workmanship when operated in

accordance with written instructions for a period of one year from receipt. Parts not manufactured by

Sterlitech are covered by their manufacturer’s warranties, which are normally for one year.

Manufacturers and Seller’s only obligation shall be to issue credit against the purchase or replacement of

equipment proved to be defective in material or workmanship. Neither manufacturer nor seller shall be

liable for any injury, loss or damage, direct or indirect, special or consequential, arising out of the use of,

misuse, or the inability to use such product.

The information contained herein is based on technical data and tests, which we believe to be reliable,

and is intended for use by persons having technical skill at their discretion and risk. Since conditions

of use are outside Sterlitech’s control, we can assume noliability whatsoever for results obtained or

damages incurred through the application of the data presented.

This information is not intended as a license to operate under, or a recommendation to infringe upon,

any patent of Sterlitech or others covering any material or use.

The foregoing may not be altered except by a written agreement signed by ocers of the manufacturer.

Please contact us if you have any questions or technical inquiries about our products by calling

Sterlitech Corporation at 1-877-544-4420 or by visiting www.sterlitech.com.

16

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

Appendix 1: Compression Connections

To install Swagelok Tube Fittings:

1. Insert the tubing into the Swagelok tube fitting. Make sure that the tubing rests firmly on

the shoulder of the fitting and that the nut is finger-tight.

2. Scribe the nut at the 6 o’clock position. By scribing the nut at the 6 o’clock position as it

appears to you, there will be no doubt as to the starting position.

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

17

3. Hold the fitting body steady with a backup wrench and tighten the nut 1¼ turns. Watch

the scribe mark, make one complete revolution and continue to the 9 o’clock position.

When the nut is tightened to the 9 o’clock, you can easily see the fitting has been

tightened properly.

Swagelok connections can be disconnected and retightened many times.

To retighten the Swagelok connection:

1. Start with the disconnected fitting.

18

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

2. Insert tubing with pre-swaged ferrules into fitting body until front ferrule seats.

3. Tighten the nut by hand. Rotate nut to the original position with a wrench. An increase

in resistance will be encountered at the original position. Then tighten slightly with the

wrench.

1812 Spiral Wound Membrane High Pressure Housing Manual

www.sterlitech.com 1-877-544-4420info@sterlitech.com

19

Appendix 2: Sterlitech Bench Scale Filtration Products

Filter Holder

Membrane

Active Area

Typical

Permeate Flux

Typical

Permeate Flow

Rate (per Cell)

System

Capacity

Max. Pump

Capacity

Min. Batch

Volume (per

Cell)

Filtration

Mode(s)

Cell Material

Max Operating

Pressure

HP4750(X)

14.6 cm2(2.26in2)

30-300 LMH

(17.6-176 GFD)

1.5-15 mL/min

0.7-7L/day

(0.2-2 GPD)

N/A

300mL

Dead-End Stirred

Cell

SS316,HastelloyTM

HP4750: 69bar

(1,000 psi)

HP4750X: 172bar

(2,500 psi)

20.6 cm2(3.2in2)

30-300 LMH

(17.6-176 GFD)

1-10mL/min

1.5-15L/day

(0.4-4 GPD)

6.8 LPM (76 bar)

1.8 GPM (1,100 psi)

3.7 L(1gal)

Cross Flow, Forward

Osmosis

PTFE, Delrin,Acrylic,

SS316, HastelloyTM

PTFE, Delrin,Acrylic,

SS316, HastelloyTM

PTFE/Acrylic: 27.6

bar (400psi)

Delrin/SS316/

HastelloyTM:

69 bar (1,000 psi)

PTFE/Acrylic: 27.6

bar (400psi)

Delrin/SS316/

HastelloyTM:

69 bar (1,000 psi)

Acrylic: 15.2bar

(220 psi) SS316/

HastelloyTM: 69bar

(1,000 psi)

Acrylic, SS316,

HastelloyTM

SS316

Standard:41.4 bar

(600 psi)

High pressure:60 bar

(870 psi)

42 cm2(6.5in2)

30-300 LMH

(17.6-176 GFD)

2-20 mL/min

3-30L/day

(0.5-5GPD)

6.8 LPM (76 bar)

1.8 GPM (1,100 psi)

3.7L(1gal)

Cross Flow, Forward

Osmosis

140 cm2(6.5in2)

30-300 LMH

(17.6-176 GFD)

7-70mL/min

10-100L/day

(0.5-5GPD)

6.8 LPM (76 bar)

1.8 GPM (1,100 psi)

3.7L(1gal)

Cross Flow, Forward

Osmosis

0.27-0.46 m

(3-5ft2)

30-300 LMH

(17.6-176 GFD)

350-2,300mL/min

194-1,940 L/gal

(51-510 GPD)

6.8-38 LPM (76bar)

1.8-10GPM(1,100psi)

15L(4gal)

Cross Flow

Discoverer

CF016

Innovator

CF042

Explorer

Sepa

Developer

1812

Investigator

Other manuals for 1812

1

Table of contents

Other Sterlitech Laboratory Equipment manuals