Sterlitech HP4750 Supplement

HP4750

ASSEMBLY & OPERATION

MANUAL

1. INTRODUCTION ........................................................................................ 1

2. BEFORE ASSEMBLY............................................................................... 2

3. STIRRED CELL ASSEMBLY .....................................................................3

4. OPERATION OF THE HP4750 STIRRED CELL .................................. 6

5. HP4750 EXAMPLE SYSTEM CONFIGURATION ............................... 8

6. ACCESSORY AND SPARE PART ORDERING INFORMATION ......... 9

7. O-RING CHEMICAL COMPATIBILITY...................................................10

8. RETURN MATERIAL ORDER PROCEDURE ......................................... 11

9. WARRANTY .............................................................................................. 11

10. TECHNICAL ASSISTANCE.................................................................... 11

APPENDIX 1: COMPRESSION CONNECTIONS ..................................... 12

APPENDIX 2: MEMBRANE CUTTING AND CONDITIONING .............. 13

APPENDIX 3: PRECONDITIONING MEMBRANE DISC FILTERS......... 14

APPENDIX 4: HP4750 BIBLIOGRAPHY .................................................. 15

APPENDIX 5: BENCH SCALE FILTRATION PRODUCTS...................... 16

CONTENTS

1. INTRODUCTION

The HP4750 Stirred Cell is a high-pressure, chemically resistant stirred cell that performs

a wide variety of membrane separations. With a maximum pressure rating of 1000 psig

(69 bar), the HP4750 Stirred Cell is ideally suited for reverse osmosis (RO) filtration,

nanofiltration (NF), ultrafiltration (UF), and microfiltration (MF) separations. Stainless steel

(316L) construction and chemically resistant components make the HP4750 Stirred Cell an

ideal choice to filter aqueous and non-aqueous solutions.

Table 1 outlines the operational parameters and technical specifications of the HP4750

Cell.

Prior to operating or servicing this device, this manual must be read and understood.

Table 1: HP4750 Features and Technical Specification

Parameter Description

Membrane Size 47-49 mm diameter (1.93 inches)

Active Membrane Area 14.6 cm2(2.26 in2)

Processing Volume 300 mL

Hold-Up Volume 1 mL

Maximum Pressure 69 bar (1000 psig)

Maximum Temperature 121 °C (250 °F) at 55 bars (800 psig)

Maximum Torque Setting for Nuts 20 ft-lbs

pH Range Membrane Dependant

Connections

Permeate Outlet ⁄ inch diameter 316L SS tubing

Pressure Inlet ¼ inch FNPT

Wetted Materials of Construction

Cell Body 316L Stainless Steel

O-Rings Buna-N, others available as options

Gasket Buna-N, others available as options

Stir Bar PTFE-coated magnet

Dimensions

Cell Diameter 5.1 cm (2.0 inches)

Cell Height 22.4 cm (10.0 inches)

Autoclavable Ye s

Sterlitech Corporation | HP4750 Cell Manual

1

2. BEFORE ASSEMBLY

HP4750 Cell Manual | Sterlitech Corporation 2

1. Stainless steel cell body

2. Cell Top

3. Cell Bottom

4. Cell Top Coupling

5. Cell Bottom Coupling

6. Porous Stainless Steel Membrane Support Disk

7. 2 O-rings

8. Top Gasket

9. Permeate Tube

10. Stir Bar Assembly

11. Stir Bar Retriever

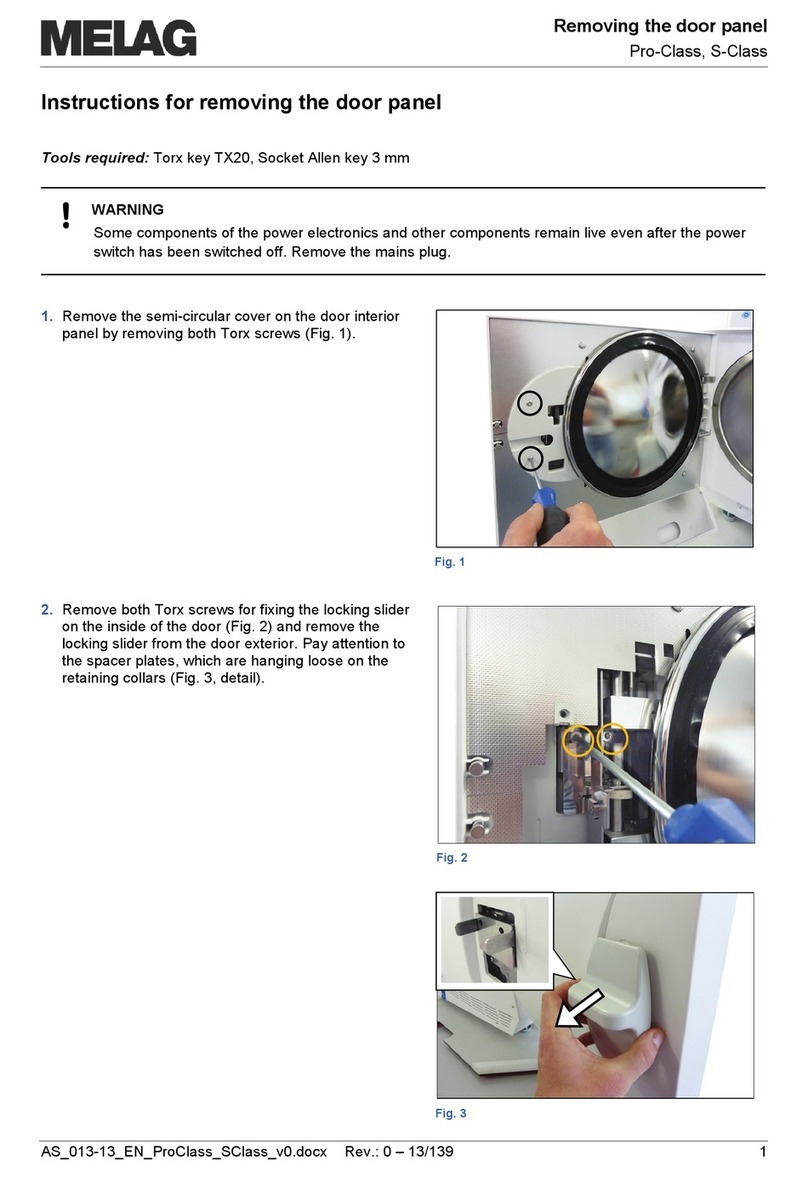

Verify that the stirred cell was shipped complete, intact, and undamaged. The complete

set of stirred cell parts is found in Figure 1 below.

Figure 1: HP4750 Components

Sterlitech Corporation | HP4750 Cell Manual

3

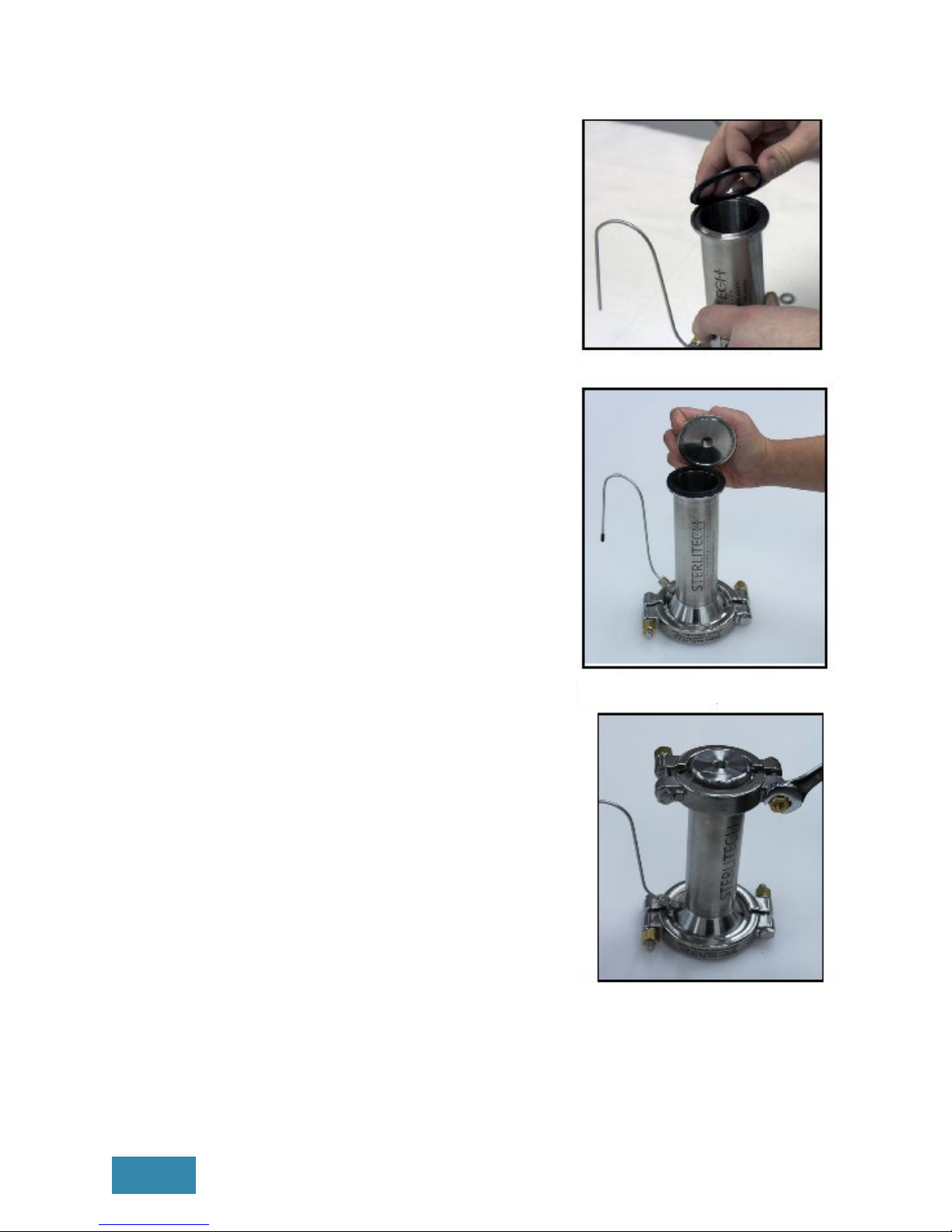

To assemble the HP4750 stirred cell:

1. Wet the O-rings with a small amount of

water or the fluid to be processed.

Note: HP4750 Stirred Cells are shipped

with Buna O-rings and gaskets by default;

other materials such as Viton and PTFE are

available as options. Table 3 outlines O-ring

and gasket material compatibility.

2. Insert the O-rings in the bottom of the cell

body (Photo 1 & 2). Check to be certain

that the O-rings it properly in the grooves.

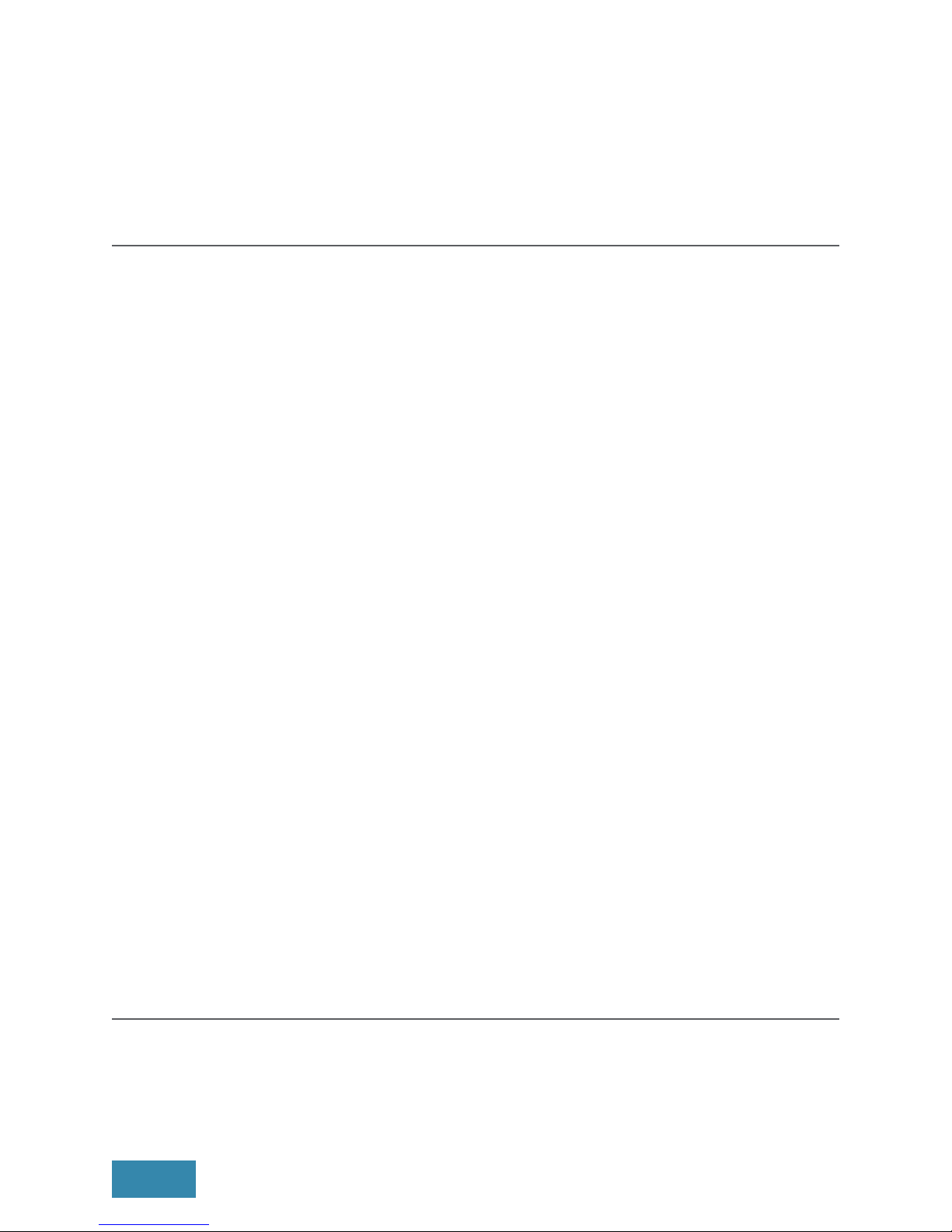

3. Place a piece of precut membrane over

the center O-ring. The membrane should

be installed with the active side toward

the cell reservoir. In general, membranes

coated on substrate have a shiny, active

side and a dull, substrate side (Photo 3).

4. Place the stainless steel porous membrane

support disk on top of the membrane to

hold the membrane in place (Photo 4).

Note: If you cut your own membranes, the

stainless steel porous disk can be used as a

template. See Appendix 3 for more details.

3. STIRRED CELL ASSEMBLY

After verifying that all of the necessary components were shipped and present, you can

begin the assembly of the stirred cell.

Photo 1: Outer Ring Insertion

Photo 2: Inner Ring Insertion

Photo 3: Membrane Filter Insertion

Photo 4: Membrane Support Disc Insertion

HP4750 Cell Manual | Sterlitech Corporation 4

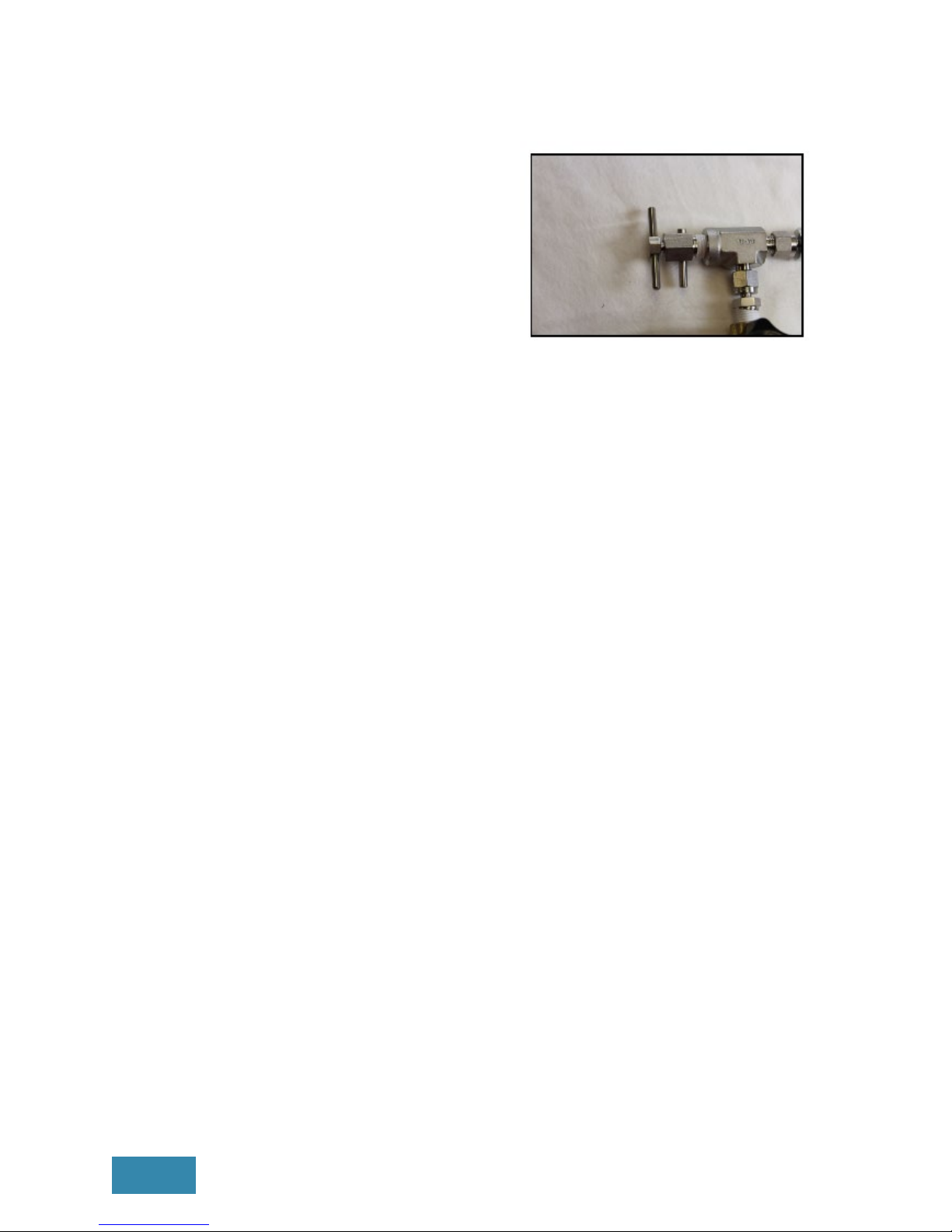

5. Fit the cell bottom onto the cell body,

aligning the circular groove with the

circular ridge on the bottom of the cell

body (Photo 5).

6. Use the 3-inch high pressure coupling to

clamp the cell bottom to the cell body.

Tighten the high pressure coupling with

16 foot pounds of torque for 1000 psig (69

bar) operation (Photo 6).

7. Insert Permeate Tube into side of cell

body, tighten using a wrench (Photo 7).

Note: The HP4750 uses Swagelok connection

fittings. More detailed instructions, information

and images of the fittings can be found in

Appendix 1.

8. Insert the Stir bar assembly by lowering

it into the cell with the stir bar retriever

(Photo 8). Figure 2 shows the correct

position of the Stir Bar Assembly. After the

assembly is in place, pour the solution to

be filtered into the Cell Body.

Figure 2: Proper Stir Bar Position

Photo 5: Cell Bottom Assembly

Photo 6: Bottom Clamp Assembly

Photo 7: Permeate Tube Installation

Photo 8: Stir Bar Insertion w/ Stir Bar Retriever

Sterlitech Corporation | HP4750 Cell Manual

5

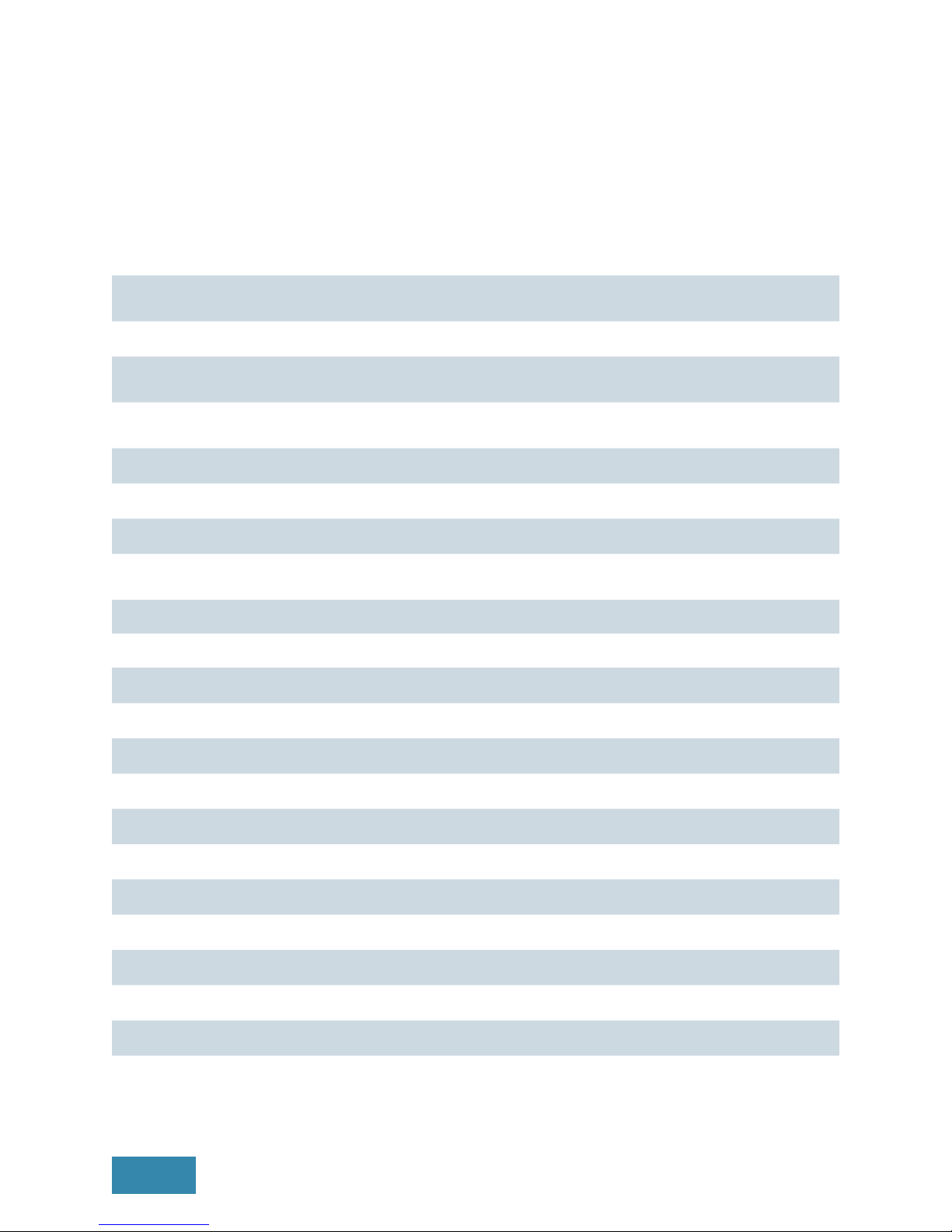

9. Insert the gasket on the top of the Cell

Body, making sure it fits properly in the

grooves (Photo 9).

10. Use the 2-inch high pressure coupling to

clamp the cell top to the cell body (Photo

10). Tighten the high pressure coupling

with 16 foot pounds of torque for 1000 psig

(69 bar) operation (Photo 11). After both

clamps are properly attached, the HP4750

Stirred Cell should be centered on top of a

magnetic stirrer.

Photo 9: Gasket Installation

Photo 10: Cell Top Attachment

Photo 11: Cell Top Clamp

HP4750 Cell Manual | Sterlitech Corporation 6

4. OPERATION OF THE HP4750 STIRRED CELL

1. Attach a high pressure hose (sold

separately, Sterlitech Part Number: 1151427)

to the fitting on the Cell Top (Photo 12).

2. Connect the other end of the hose to the

pressure regulator assembly on the inert

gas supply or the compressed air supply.

The compressed air or inert gas source

selected will determine pressure regulator

(sold separately, Sterlitech Part Number:

1144026 style and pressure requirements

(Photo 13).

3. Place a Permeate Collection Vessel (user

supplied) under the Permeate Tube (Photo

14).

4. Turn on the magnetic stirrer (sold

separately, Sterlitech Part Number 1144030

or 1144031) to start the motion of the Stir

Bar Assembly (Photo 15).

5. Begin filtration by gradually pressurizing

the HP4750 Stirred Cell, checking for

leaks. Foreign material on the surface of

the seals and insucient tightening of

the clamps are most common causes for

leakage.

Note: Preconditioning the membranes before

use will ensure consistent performance. See

Appendix 3 for more details.

Photo 12: High Pressure Hose Attachment

Photo 13: Pressure Regulator Connection

Photo 14: Permeate Collection Vessel

Photo 15: Magnetic Stirrer

Sterlitech Corporation | HP4750 Cell Manual

7

6. Upon completion of filtration, turn o

the pressure source and depressurize

the unit by the pressure relief valve

(sold separately, Sterlitech Part Number:

1155893) (Photo 16).

CAUTION: Do not depressurize the HP4750

Stirred Cell by loosening the couplings.

7. Once it is depressurized and empty, the

HP4750 Stirred Cell can be cleaned with

a variety of cleaners, including detergents,

solvents, caustic, acid, enzyme cleaners,

etc.

Note: Choice of the appropriate cleaning

regime should also consider the compatibility

of the gasket and O-ring material. A section of

O-ring chemical compatibilities is presented

on page 10.

Photo 16: Pressure Relief Valve

HP4750 Cell Manual | Sterlitech Corporation 8

5. HP4750 EXAMPLE SYSTEM CONFIGURATION

Figure 3 illustrates the typical configuration of a standard HP4750 Stirred Cell System. The

drawing shows the three major components of the system: the Cell Body with removable

top and bottom, Stir Bar Assembly, and Standard Coupling.

Figure 3: HP4750 Stirred Cell System Schematic

Sterlitech Corporation | HP750 Cell Manual

9

6. ACCESSORY AND SPARE PART ORDERING INFORMATION

Accessories and spare parts for the HP4750 can be ordered by calling Sterlitech

Corporation at 1-877-544-4420 or by visiting www.sterlitech.com.

Product Shipping Weight Ordering Number

HP4750 Stirred Cell, for operation to 69

bar (1000 psig) 3.8 kg (8 lbs) HP4750

Accessories

Pressure Regulator Assembly, 6.9-69 bar

(100-1000 psig) 2.3 kg (5 lbs) 1144026

Pressure Bleed Valve, 172 bar (2500

psig) 0.1 kg (0.25 lb) 1155893

High Pressure Hose, 183 cm (72 inch) 0.7 kg (1.5 lbs) 1151427

PTFE O-ring/Gasket Kit 0.5 kg (0.1 lb) 1144028

Viton O-ring/Gasket Kit 0.5 kg (0.1 lb) 1144029

PTFE Encapsulated Viton O-ring/Gasket

Kit 0.5 kg (0.1 lb) 1144027

Buna O-ring/Gasket Kit 0.5 kg (0.1 lb) 1144034

EPDM O-ring Gasket Kit 0.5 kg (0.1 lb) 1144036

Magnetic Stirring Plate

115 VAC 60 Hz 2.3 kg (5 lbs) 1144030

230 VAC 50 Hz 2.3 kg (5 lbs) 1144031

Spare Parts

Cell Top 0.1 kg (0.25 lb) 1143891

Cell Body 1.4 kg (3 lbs) 1149782

Cell Bottom 1.4 kg (3 lbs) 1143073

Porous Support Disk 0.1 kg (0.25 lb) 1114910

Stir Bar Assembly 0.1 kg (0.25 lb) 1143109

Membrane Packs

Visit www.sterlitech.com for membrane ordering information.

Table 2: Accessory and Spare Part Ordering Information

HP4750 Cell Manual | Sterlitech Corporation 10

7. O-RING CHEMICAL COMPATIBILITY

The following O-ring and gasket compatibility chart (Table 3) is provided as an aid in selecting

a specific synthetic rubber compound for a particular application situation. Operating

conditions and environment must also be considered in determining the media suitability.

For recommendations regarding fluids not listed, consult Sterlitech. The recommendations

represent compatibility of materials only and do not necessarily constitute a recommendation

for use in a specific application.

Table 3: O-Ring Chemical Compatibility Chart

Code Compound Temperature

BN Buna-N -40 to 120 °C (-40 to 250 °F)

EP Ethylene-Propylene -50 to 150 °C (-65 to 300 °F)

VViton -30 to 205 °C (-20 to 400 °F)

Media (Liquid or Gas) Code Media (Liquid or Gas) Code

Acetic Acid, Glacial EP Glycols EP

Acetone EP Grease and Oils BN

Aluminum Salts BN Glycols EP

Ammonium Hydroxide EP Hydrochloric Acid EP

Ammonium Salts BN Hydrofluoric Acid EP

Amyl Alcohol EP Hydrogen Peroxide V

Aniline Dyes EP Kerosene BN

Aromatic Fuel - 50% VLinseed Oil BN

Benzene VMethyl Ethyl Ketone EP

Bleach Liquor EP Mineral Oils BN

Butanol (Butyl Alcohol) BN Naphthas V

Butyl Cellosolve EP N-Hexane BN

Carbon Disulfide VOctyl Alcohol EP

Carbon Tetrachloride VOrganic Ester EP

Cellosolve EP Peanut Oil BN

Chlorinated Solvents VPhenol V

Crude Oil VPyridine Oil EP

Cutting Oil VSewage BN

Decane BN Sodium Acetate EP

Denatured Alcohol BN Sodium Chloride BN

Detergent, Water Solution BN Stoddard Solvent BN

Diesel Oil BN Sulfuric Acid V

Diethylene Glycol EP Tannic Acid BN

Dry Cleaning Fluids VTertiary Butyl Alcohol V

Ethyl Alcohol BN Titanium Tetrachloride V

Ethyl Hexanol BN Transmission Fluid BN

Ethylene Glycol EP Trioctyle Phosphate EP

Fatty Acids VVarnish V

Fatty Oil BN Water (Demineralized) BN

8. RETURN MATERIAL AUTHORIZATION

If materials are to be returned to Sterlitech for repair, evaluation, or warranty consideration,

a Return Material Authorization (RMA) number and form must be obtained from Sterlitech

prior to the return. Contact Sterlitech’s Customer Service Department for these forms.

The form must be completed and returned with the material. Be sure to include a

complete, detailed written reason for the return. Also, include serial numbers, installation

and removal dates, and any other pertinent information that is available. HP4750 Cells

have a serial number imprinted on the cell bottom.

Indicate the proposed disposition of the material, and reference the RMA number on all

packages or cartons. All material must be shipped to Sterlitech with freight prepared by

the customer.

9. WARRANTY

The following is made in lieu of all other warranties expressed or implied. Sterlitech

Corporation guarantees equipment to be free from defects in material and workmanship

when operated in accordance with written instructions for a period of one year from

receipt. Parts not manufactured by Sterlitech are covered by their manufacturer’s

warranties, which are normally for one year.

Manufacturers and Seller’s only obligation shall be to issue credit against the purchase

or replacement of equipment proved to be defective in material or workmanship. Neither

manufacturer nor seller shall be liable for any injury, loss or damage, direct or indirect,

special or consequential, arising out of the use of, misuse, or the inability to use such

product.

The information contained herein is based on technical data and tests, which we believe

to be reliable, and is intended for use by persons having technical skill at their discretion

and risk. Since conditions of use are outside Sterlitech’s control, we can assume no

liability whatsoever for results obtained or damages incurred through the application of the

data presented.

This information is not intended as a license to operate under, or a recommendation to

infringe upon, any patent of Sterlitech or others covering any material or use.

The foregoing may not be altered except by a written agreement signed by ocers of the

manufacturer.

10. TECHNICAL ASSISTANCE

Please contact us if you have any questions or technical inquiries about our products by

calling Sterlitech Corporation at 1-877-544-4420 or by visiting www.sterlitech.com.

Sterlitech Corporation | HP750 Cell Manual

11

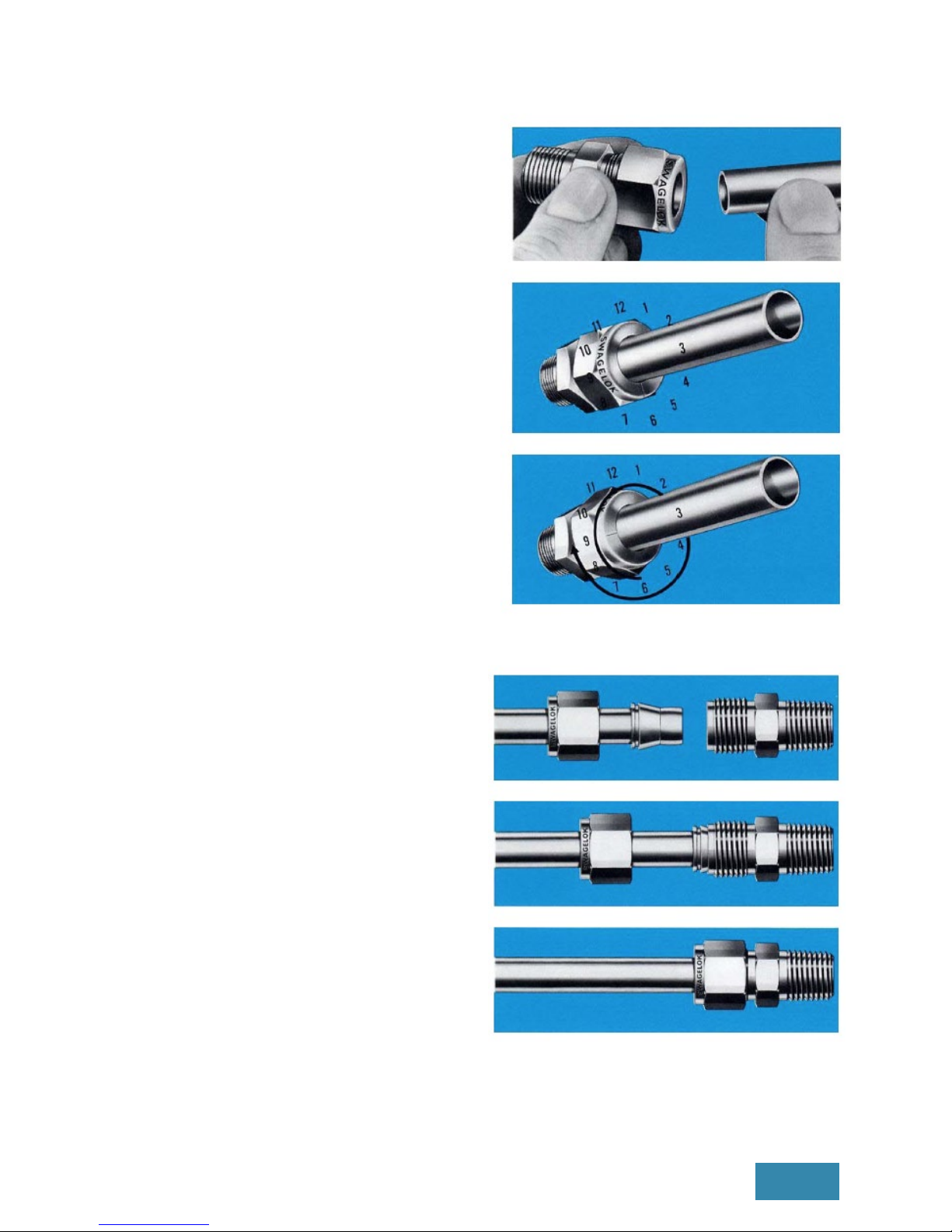

APPENDIX 1: COMPRESSION CONNECTIONS

To install Compression Tube Fittings:

1. Insert the tubing into the Compression

tube fitting. Make sure that the tubing rests

firmly on the shoulder of the fitting and that

the nut is finger-tight.

2. Scribe the nut at the 6 o’clock position. By

scribing the nut at the 6 o’clock position as

it appears to you, there will be no doubt as

to the starting position.

3. Hold the fitting body steady with a backup

wrench and tighten the nut 1¼ turns. Watch

the scribe mark, make one complete

revolution and continue to the 9 o’clock

position. When the nut is tightened to the

9 o’clock, you can easily see the fitting has

been tightened properly.

Compression connections can be

disconnected and retightened many times.

To retighten the Compression connection:

1. Start with the disconnected fitting.

2. Insert tubing with preswaged ferrules into

fitting body until front ferrule seats.

3. Tighten the nut by hand. Rotate nut to

the original position with a wrench. An

increase in resistance will be encountered

at the original position. Then tighten

slightly with the wrench.

HP4750 Cell Manual | Sterlitech Corporation 12

Sterlitech Corporation | HP750 Cell Manual

13

APPENDIX 2: MEMBRANE CUTTING AND CONDITIONING

Sterlitech oers a wide variety of membranes that have been pre-cut for use with the

HP4750. However, if you need cut your own membrane for use with the HP4750 Stirred

Cell, then you will need the following items:

• The porous stainless steel support disk, which will serve as the template

• The membrane sheet to be cut

• A pair of sharp scissors

• A pair of latex gloves

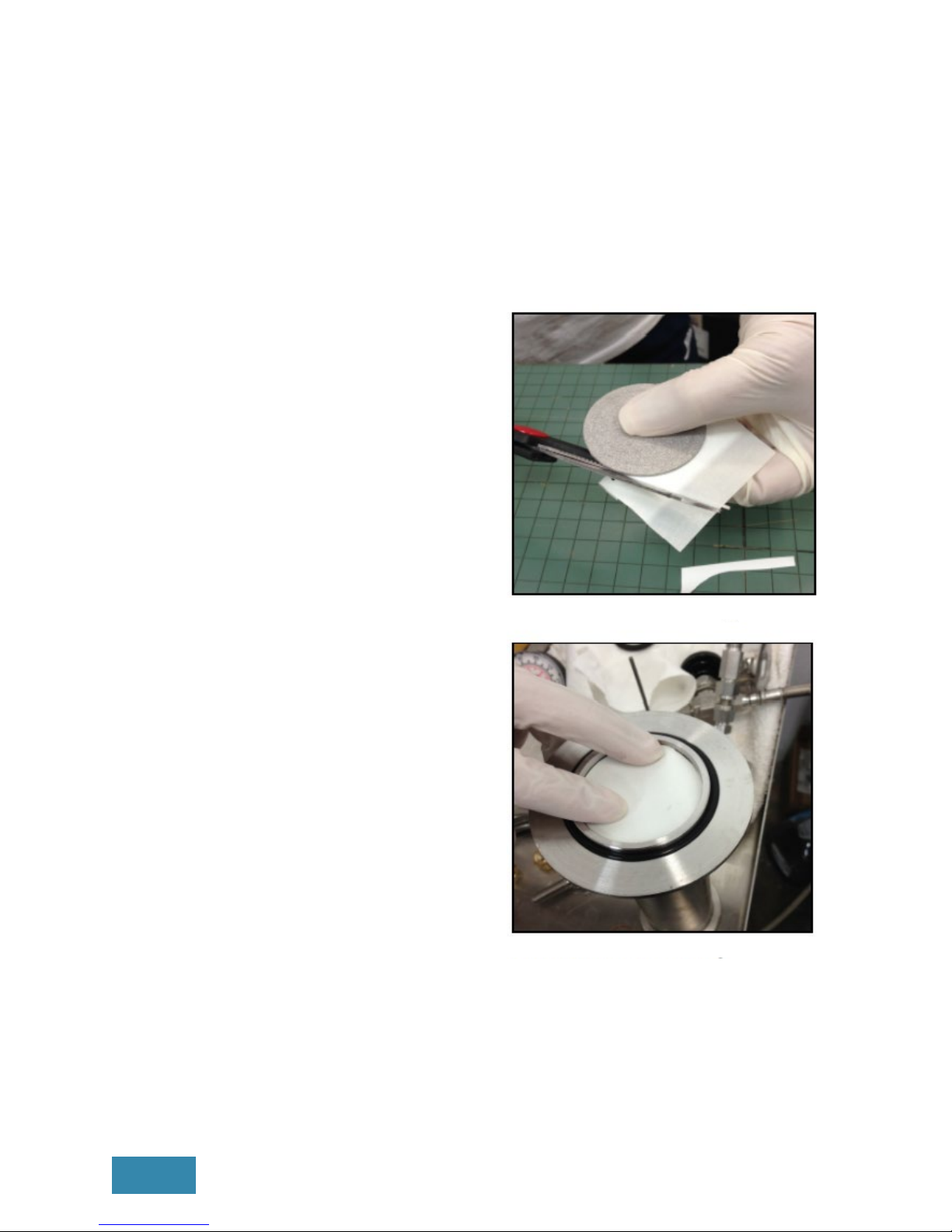

To cut a membrane disk filter for the HP4750:

1. Take the porous stainless support disk and

place the membrane sheet against it. Be

sure to have the latex gloves on to avoid

contaminating the membrane surface.

2. Cut along the edge of the template with

the scissors. Hold the scissors at an angle

towards the center of the template to

avoid undertrimming (Photo 17). Once

finished, the membrane should sit perfectly

flat on supports without any bending and

extend outside of the inner O-ring to avoid

leakage (Photo 18).

Photo 17: Membrane Cutting

Photo 18: Membrane Fitting

HP4750 Cell Manual | Sterlitech Corporation 14

APPENDIX 3: PRECONDITIONING MEMBRANE DISC FILTERS

To precondition the membrane:

1. Load the membrane into the HP4750 Stirred Cell.

2. Fill the stirred cell with deionized water and pressurize the cell. The temperature of the

water and the pressure used should be the same as the temperature and pressure that

will be used in the actual trials.

3. Run deionized water through the cell until flux is relatively constant. After a few

minutes, flux through the membrane will stabilize following a sharp change.

4. Release pressure, discard the deionized water and fill the tank with desired feed

sample.

APPENDIX 4: HP4750 BIBLIOGRAPHY

The following studies utilized the HP4750 Stirred Cell in their method and are listed here

to illustrate the potential applications for the HP4750. These studies are good references

for understanding the operation of the HP4750 Stirred Cell.

TITLE ABSTRACT FULL CITATION

Modeling of the retention

of atrazine and dimethoate

with nanofiltration

The HP4750 stirred cell

was used to test which

nanofiltration

membrane

(NF90, NF200, NF270,

and DK) worked best

at removing pesticides

from water.

A.L. Ahmad, L.S. Tan, S.R. Abd. Shukor.

Modeling of the retention of atrazine and

dimethoate with nanofiltration. Chemical

Engineering Journal, Volume 147, Issues

2–3, 15 April 2009, Pages 280–286.http://

dx.doi.org/10.1016/j.cej.2008.07.015

Eects of palm oilbased

fatty acids on fouling of

ultrafiltration membranes

during the clarification of

glycerin-rich solution

In this study, the

HP4750 cell was

used to examine the

membrane-binding

properties fatty acids

with polyethersulfone

(PES) and

polyvinylidenefluoride

(PVDF) ultrafiltration

membranes.

Indok Nurul Hasyimah Mohd Amin, Abdul

Wahab Mohammad, Mastura Markom,

Leo Choe Peng. Eects of palm oil-based

fatty acids on fouling of ultrafiltration

membranes during the clarification

of glycerin-rich solution. Journal of

Food Engineering, Volume 101, Issue 3,

December 2010, Pages 264–272. http://

dx.doi.org/10.1016/j.jfoodeng.2010.07.006

Preparation and

characterization of

a neutrally charged

antifouling nanofiltration

membrane by coating

a layer of sulfonated

poly(ether ether ketone)

on a positively charged

nanofiltration membrane

The HP4750 stirred

cell was used to test

the antifouling and

separation capability

of a specially

prepared, electrically

neutral nanofiltration

membrane.

Chaoyi Ba, James Economy. Preparation

and characterization of a neutrally

charged antifouling nanofiltration

membrane by coating a layer of

sulfonated poly (ether ether ketone)

on a positively charged nanofiltration

membrane. Journal of Membrane

Science, Volume 362, Issues 1–2, 15

October 2010, Pages 192–201. http://

dx.doi.org/10.1016/j.memsci.2010.06.032

Synthesis and

characterization of a

carbon nanotube/polymer

nanocomposite membrane

for water treatment

The HP4750 was used

to characterize the

separation properties

of carbon composite

membrane at 2.9, 3.9

and 4.9 MPa.

Hosam A. Shawky, So-Ryong Chae,

Shihong Lin, Mark R. Wiesner. Synthesis

and characterization of a carbon

nanotube/polymer nanocomposite

membrane for water treatment.

Desalination, Volume 272, Issues 1–3,

3 May 2011, Pages 46–50. http://dx.doi.

org/10.1016/j.desal.2010.12.051

Sterlitech Corporation | HP750 Cell Manual

15

APPENDIX 5: STERLITECH BENCH SCALE FILTRATION PRODUCTS

Discoverer Innovator Explorer Developer Investigator

Filter Holder

HP4750(X) CF016 CF042 Sepa 1812

Membrane Active

Area

14.6 cm2(2.26 in2) 20.6 cm2(3.2 in2) 42 cm2(6.5 in2)140 cm2(24 in2)0.27-0.46 m2(3-5 ft2)

Typical Permeate

Flux

30-300 LMH

(17.6-176 GFD)

30-300 LMH

(17.6-176 GFD)

30-300 LMH

(17.6-176 GFD)

30-300 LMH

(17.6-176 GFD)

30-300 LMH

(17.6-176 GFD)

Typical Permeate

Flow Rate

(per Cell)

1.5-15 mL /min 1-10 mL /min 2-20 mL/min 7-70 mL/min 350-2,300 mL/min

System Capacity

0.7-7 L /day

(0.2-2 GPD)

1.5-15 L/day

(0.4-4 GPD)

3-30 L/day

(0.5-5 GPD)

10-100 L/day

(2.6-26 GPD)

194-1,940 L/day

(51-510 GPD)

Min. Batch Volume

(per Cell)

300 mL 3.7 L (1 gal) 3.7 L (1 gal) 3.7 L (1 gal) 15 L (4 gal)

Max. Pump

Capacity

N/A 6.8 LPM (76 bar)

1.8 GPM (1,100 psi)

6.8 LPM (76 bar)

1.8 GPM (1,100 psi)

6.8 LPM (76 bar)

1.8 GPM (1,100 psi)

6.8-38 LPM (76 bar)

1.8-10 GPM (1,100 psi

)

Cell Material

SS316, HastelloyTM PTFE, Delrin, Acrylic,

SS316, HastelloyTM

PTFE, Delrin, Acrylic,

SS316, HastelloyTM

Acrylic, SS316, HastelloyTM

SS316

Max. Operating

Pressure

HP4750: 69 bar (1,000 psi)

HP4750X: 172 bar (2,500 psi)

PTFE/Acrylic: 27.6 bar (400 psi)

Delrin/SS316/HastelloyTM:

69 bar (1,000 psi)

PTFE/Acrylic: 27.6 bar (400 psi)

Delrin/SS316/HastelloyTM:

69 bar (1,000 psi)

Acrylic: 27.6 bar (400 psi)

SS316/HastelloyTM:69 bar

(1,000 psi)

41.4 bar (600 psi)

Filtration Mode(s)

Dead-End Stirred Cell Cross Flow, Forward Osmosis Cross Flow, Forward Osmosis Cross Flow, Forward Osmosis Cross Flow

HP4750 Cell Manual | Sterlitech Corporation 16

NOTES:

Table of contents

Other Sterlitech Laboratory Equipment manuals