Stewart MacDonald Erlewine Neck Jig User manual

21 N. Shafer St. Athens, OH 4570121 N. Shafer St. Athens, OH 45701

800-848-2273 800-848-2273

Fax: Fax:

740-593-7922740-593-7922

stewmac.comstewmac.com

page 1 of 9page 1 of 9

MM

aa

ii

n n

bb

ee

aa

mm

CC

rr

oo

ss

ss

bb

aa

rr

s s

((

3)3)

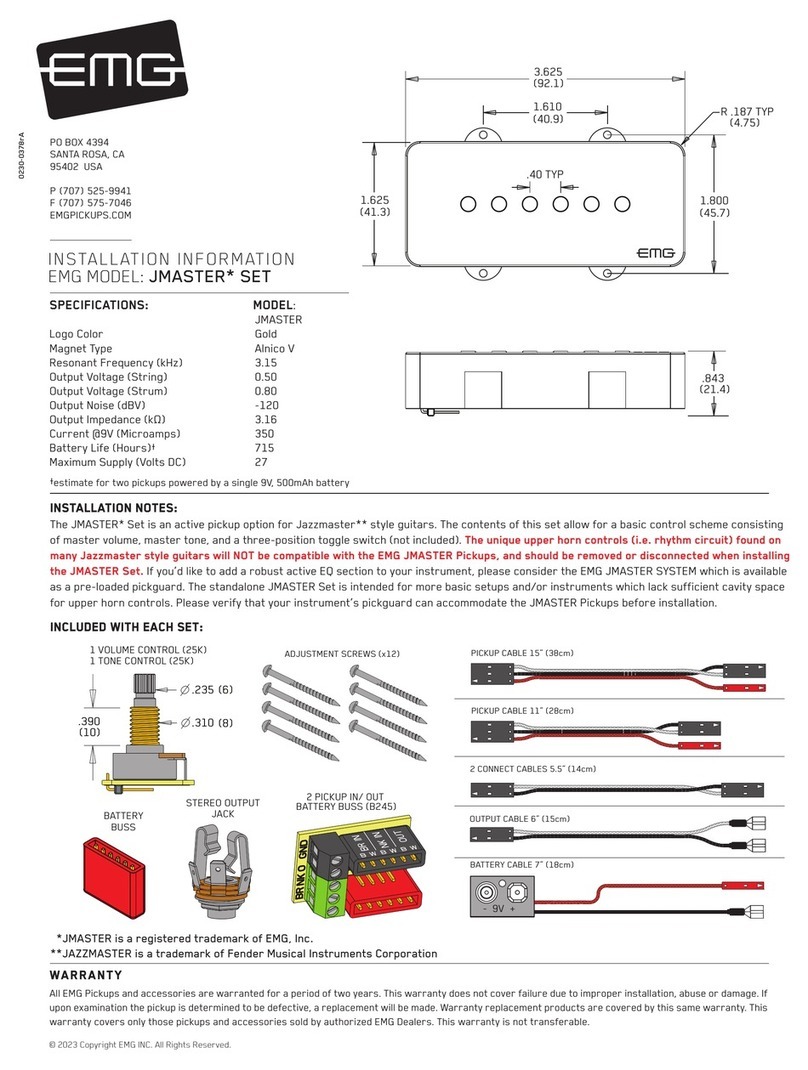

Angle supports (3)Angle supports (3)

Urethane pads for levelers and peghead jack (7)Urethane pads for levelers and peghead jack (7)

Allen wrenches (4)Allen wrenches (4)

Wood support slats with cork pads (4)Wood support slats with cork pads (4)

Body straps (2)Body straps (2)

Body levelers (6)Body levelers (6)

Dial indicators (2)Dial indicators (2)

Neck supports (3)Neck supports (3)

Peghead pullerPeghead puller

with strapwith strap

Peghead jackPeghead jack

Eyebolt hangerEyebolt hanger

How to assemble the Neck JigHow to assemble the Neck Jig

1.1.

Install an aInstall an a

ngle support in each ngle support in each

of the three of the three

crossbars.crossbars.

The T-shaped sliders fit The T-shaped sliders fit

the crossbars, and the the crossbars, and the

square nutssquare nuts

are for mounting to tare for mounting to t

he main beam. he main beam.

TwTw

o of the crossbarso of the crossbars

have etched centering scales, which should have etched centering scales, which should

face upward.face upward.

Sheet Sheet

#i-5399 #i-5399

04/201404/2014

Erlewine Neck JigErlewine Neck Jig

2.2.

Attach the crossbars to the main beam using the squaAttach the crossbars to the main beam using the squa

rere

nuts. The shortest bar provides support near the nenuts. The shortest bar provides support near the ne

ck jointck joint

and should be instaland should be instal

led first. led first.

The longest bar supports theThe longest bar supports the

tail end of the instrument and should be installed last.tail end of the instrument and should be installed last.

Square nut for main beamSquare nut for main beam

T-shaped slT-shaped sl

iderider

InstructionsInstructions

stewmac.com

page 2 of 9

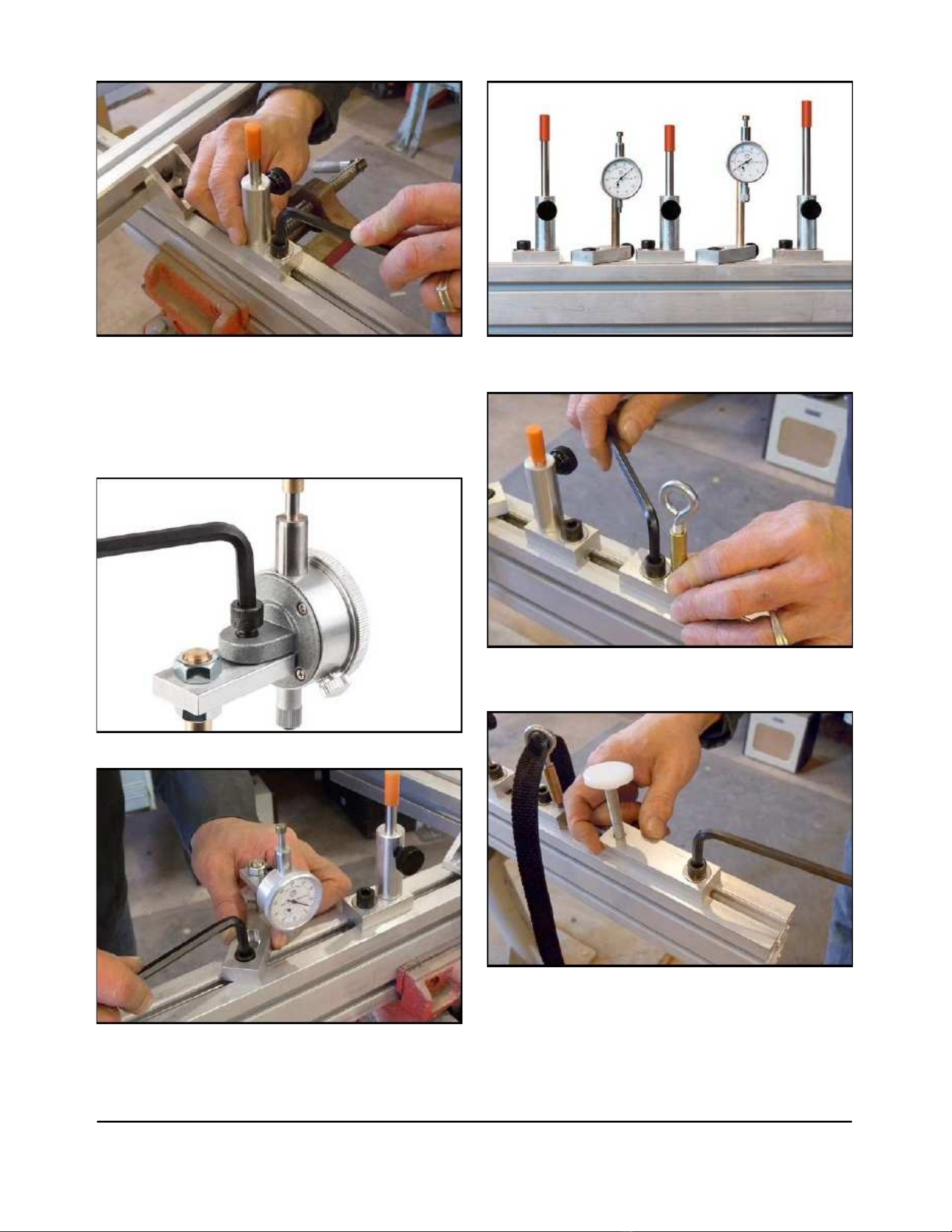

3.

Install a

neck support rod on

the main beam

. These

three rods adjust vertically to support the instrument neck.

The bottom end of the rods drop down into the slot in the

main beam.

TIP:

Sand the top of the plastic cap to create a smooth, flat

surface for contacting the instrument neck.

4.

Attach the two dial

indicators to their

supports.

5.

Attach the first dial indicator t

o the main beam. The dial’s

mounting bracket is offset,

allowing the height-adju

stable

rod to move in relation to the main beam.

6.

Install the two rem

aining neck support rods and the dia

l

indicator.

7.

Attach the peghead puller and thread the strap throug

h

the eyebolt.

8.

Install the peghead jack. The threaded level

er can swing

to either side to support asymmetrical p

egheads.

stewmac.com

page 3 of 9

9.

Attach two le

velers to ea

ch beam.

We have included urethane pads to cushion the levelers.

Attach them to the swivel head levelers using super glue.

We have also included wooden slats which span the levelers,

giving gentle support to any instrument strapped into the

Jig. Self-adhesive cork pads are included, and

may be cut to

any size that suits your needs. Wrap these slats in clean paper

before using them; this provides a smooth surface to protect

instrument finishes under clamping pressure.

10.

Install the eyebolt hanger in

either end of the main beam

for storing the Neck Jig.

You

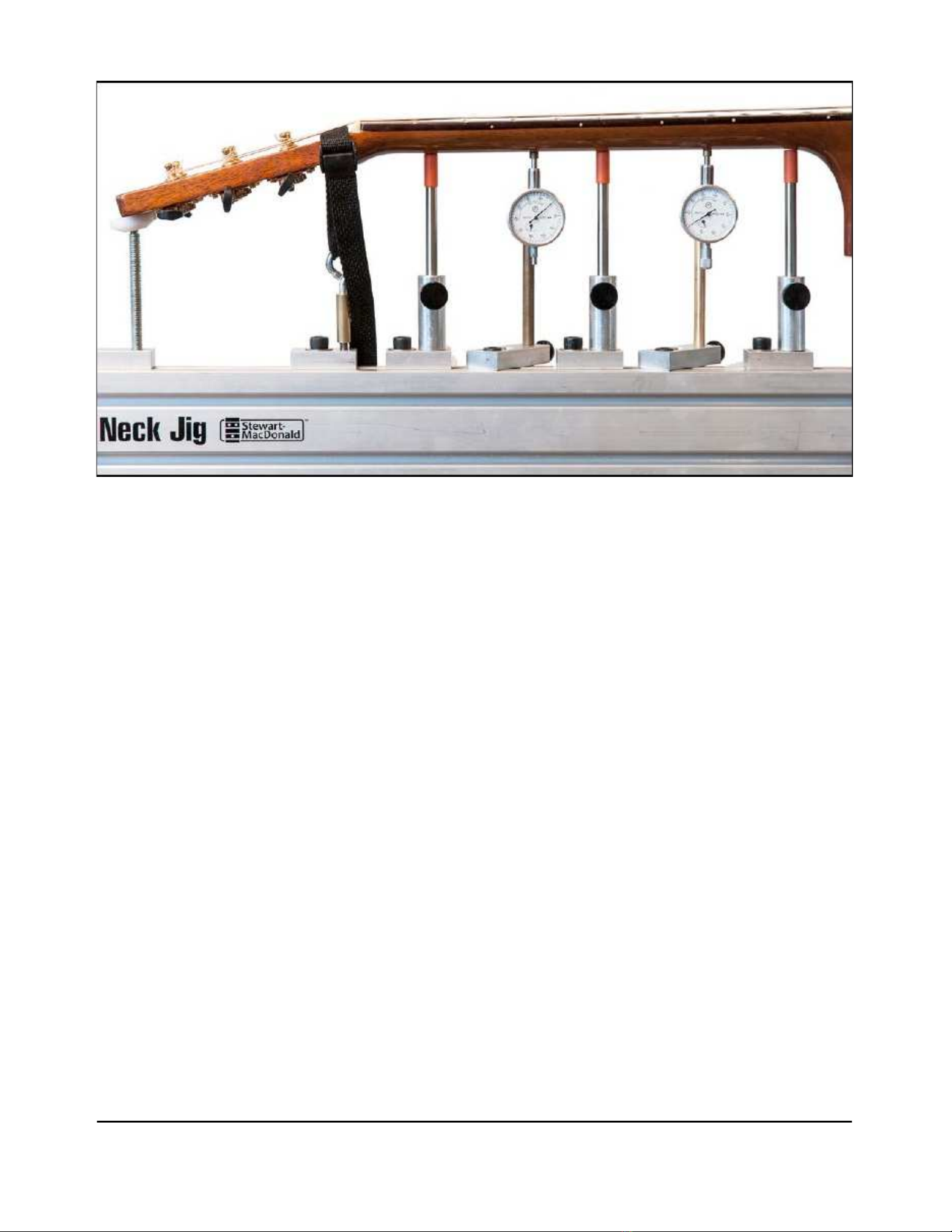

r assembled Neck Jig is

ready for use!

stewmac.com

page 4 of 9

Using the Neck Jig

The E

rlewine

Neck

Jig

is a

string

tension

simulat

or.

When

the

strings are removed, the Neck Jig holds the neck in

the same

curvature that existed under string tension.

This eliminates the problem of w

orking on frets, then find-

ing that everything has changed when you s

tring the guitar

back up to pitch. The result: fret

work without guesswork!

Quick overview

Jig

the

body

Begin with strings on the guitar, tu

ned to pitch.

It’s not necessary to loosen the truss rod

or adjust the neck

at this point. Rest the guitar body

on the adjustable-height

levelers, and hold it firmly with the body straps while the

neck remains free and untouched.

Tilt to playing position

With the g

uitar strapped in, tu

rn

the Neck Jig 90 degrees into the same position as when it's

being played.

Adjust the neck

In the pla

ying position wit

h the strings

tuned to pitch, adjust the neck for

the work you plan to do.

This usually mean

s straightening the neck.

Zero out the dials

Bring the dial

indicators into

contact

with the straightened neck, and set the dials to zero. Now,

any change in the neck will be evident in these dials, causing

them to deviate from zero.

Return to horizontal and

remove the strings

Tilt the

Jig

back into the horizontal working position and remove the

strings. The neck will backbow from the release of string

tension and the pull of the truss rod.

Simulate string tension

Use the peghea

d jack

and the

peghead puller, lifting and pulling to recreate string tension.

This forces

the neck

back into position

as you

see the

dial

indicators read zero again.

Support the neck

Now raise the neck s

upport rods, bring-

ing them into firm contact with the back of the neck. These

supports keep the ne

ck from flexing during leveling.

Consider replacing the nut:

Most refret jobs require a

new

nut. It’s easier to level the frets, or the fretboard, when the

guitar’s nut is out of the way. If you’re planning to replace

the nut, remove when you take the strings off.

stewmac.com

page 5 of 9

Jigging a guitar

, step-by-step

1.

Hold the guitar over t

he jig to determine where to position

the neck supports

and body levelers (photo, left). Move the

support rods, crossbars and

levelers roughly into position.

2.

Using the wooden support slats is optional

(see below).

Position them now so that they span

the levelers.

Warning about acoustic guitars:

Before

jigging

an acoustic, think about the guitar body’s internal

construction. The body must be suppor

ted under the strong

kerfed joint where the back meets the sides, not at the un-

supported areas of the back.

Some acoustic guitars, such as Martin

dreadnoughts, will jig

safely with the just body levelers supporting them directly

under the edge joint, but most won’t. We recommend

spanning the levelers with wooden slats for all acoustics.

The

adhesive-backed

cork

supplied

for

the

slats

is

useful

padding, but wrap the slats in clean paper

to have

a smooth,

non-reactive surface for contacting finishes under pressure.

Center the body strap over the guitar’s waist and tighten

it just enough to hold the body firmly.

!

stewmac.com

page 6 of 9

3.

Gently set the g

uitar on the

body levelers (and

paper-

wrapped slats, if you’re using them). A sandbag or padded

weight placed on the guitar body is a helpful temporary

weight to keep the guitar from moving as you position the

body on levelers and center the neck over the support rods.

Adjust the height of the levelers so that the fingerboard is

approximately parallel with the main beam. The

lower you

can set the le

velers the better—

for solid, stable s

upport.

4.

Arrange the neck support rods and dials a

long the neck,

centering the neck over the support rods. Position one

support rod near the cur

ve of the heel and another approxi-

mately under the first fret. Once they’re in

position, tighten

the cross bars, levelers, and neck supports.

5.

Now you’re ready to strap down the guitar body. This will

pull the guitar downward, so first lower the neck support

rods out of the way so they won’t mar the neck.

Place the body strap across the guitar’s waist, pass it under

the beam, and thread it through the slotted hub of the

ratchet. The ratchet opens toward you, with the strap con-

nection at the top. The ratchet can be p

ositioned above or

below the jig. Close the ratchet and snug the strap loosely.

Protect the guitar’s finish with

pieces of felt or paper where

the strap contacts the corners

of the instrument.

Add the second strap over the

body’s lower bout if needed.

stewmac.com

page 7 of 9

7.

Set each dial to zero by turning the indicat

or’s outer ring.

Tu

rn the dial to zero, then turn it past zero by two ful

l rota-

tions before arriving at zero again. These ex

tra rotations give

the dial room to move and adjust on either side of zero as

you adjust the neck. The thumbscrew locks

the outer ring.

8.

Return the Neck Jig t

o the horizontal

working position

and remove the guitar’s strings. Adjust the peghead jack

until it fits loosely between the beam and the end of the

peghead. Install the peghead pull-down strap allowing a

small amount of slack.

Caution:

Before tightening the body straps, lower

the neck support rods. Tighten the hold-down

strap gradually until the guitar body is snug

on the levelers.

Sometimes a guitar will require two straps in order to se

cure

it on the levelers.

6.

With the guitar tuned t

o pitch, move t

he Neck Jig onto

its side

(the playing position)

. Adjust the neck

for fret level-

ing or dressing; the truss rod should create backbow when

tightened and create relief when loosened. You want the

neck to be straight for fret work.

!

stewmac.com

page 8 of 9

11.

When the neck is re-

zeroed to your

satisfaction, slide

the neck supports up against the back of the neck. These

rods keep the neck from flexing while you level the frets

or

the fretboard.

12.

Here a fret leveler is used t

o level the t

ops of the frets.

Whether you're doing a complete refret, or a

fret-dress job,

once the frets have been

leveled you can remove it from the

Neck Jig to finish the details at your workbench.

The guitar can remain

in the Neck Jig throug

hout an entire

fret job if you’re pressing in frets, but

don’t hammer on the

frets over t

he support rods and

dial indicators

—

the hammer

blows can cause support rods to dent the

back of the neck.

Even when you hammer over the body extension, put cush-

ioning material between the neck and the support rods to

prevent damage.

9.

The neck will backbow with the string

s removed, and the

dial settings will no longer read zero. In our case, the dial

nearest the nut has compressed .031" (left photo) and the

dial nearest the body has compressed .008" (right photo).

These are typical readings.

10.

Slowly raise the peghead jack u

ntil the dials read zero

again. If the rear dial is

off, tighten down the peghead strap

until zeroed. Go back and

forth between these

adjustmen

ts,

until both dials remain as close to zero as possible.

Depending on the neck, you may not always get perfect

zeros. If the peghead jack and pull-down strap don’t zero the

dials to your satisfaction, use your straightedge as a guide

while forcing the neck

into the same configuration you saw

when in the playing position.

stewmac.com

page 9 of 9

Using the Neck Jig wit

hout a ShopStand

Our Shop Stand/Angle Vise combination rotates the Neck

Jig quickly between the playing and working positions. We

recommend it as the best support for the Neck J

ig. But the

Neck Jig can also be used

on any benchtop: for supporting

the Jig in the working position, turn two of the levelers

downward to become stabilizing

feet (above).

To

rot

ate

the

Ne

ck

Jig

int

o

the

pla

yin

g

pos

iti

on

on

a

benchtop, place two wooden blocks under

the main beam.

Use two bar clamps to hold the Jig and block

s to the bench.

The guitar body is suspended off t

he end of the bench.

Table of contents

Popular Accessories For Musical Instruments manuals by other brands

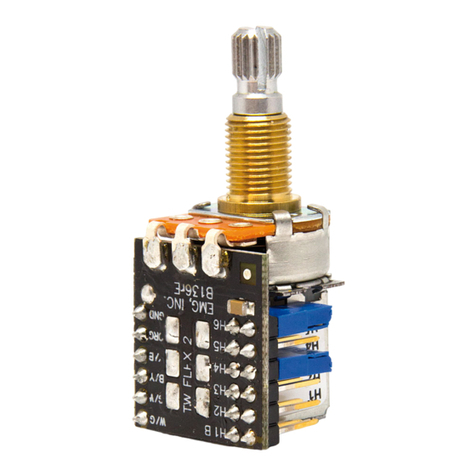

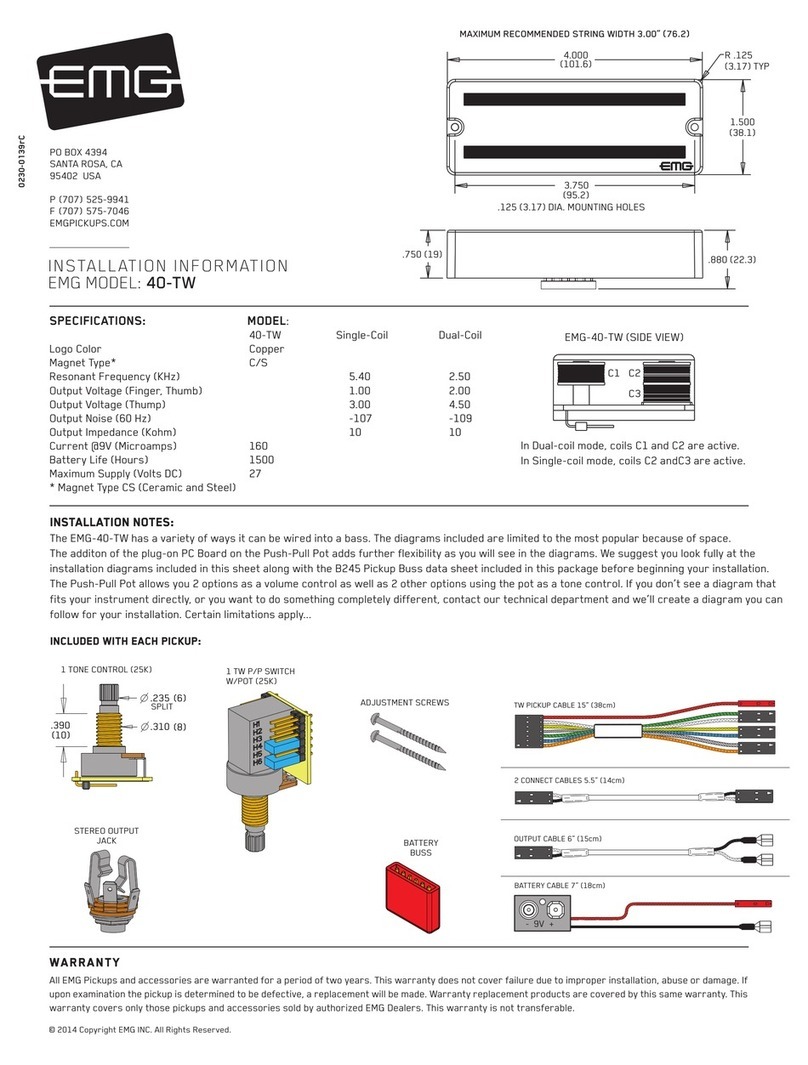

EMG

EMG 40-TW Installation information

Vigilant

Vigilant Guardian 10 operating instructions

Awesome Guitars

Awesome Guitars Pickup Switch Upgrade installation instructions

Trance Audio

Trance Audio THE AMULET M owner's manual

FuzzDog

FuzzDog MUFF GUN quick start guide

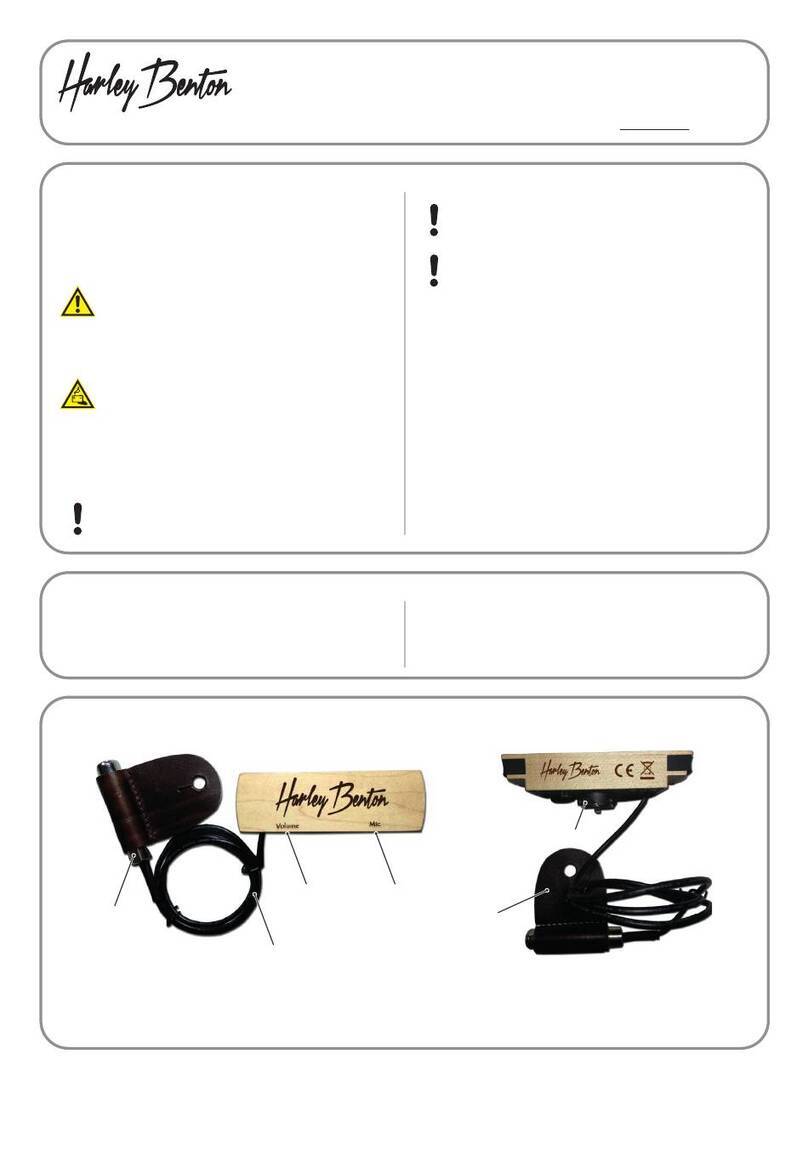

Harley Benton

Harley Benton TrueTone SH-30 Pro Active quick start guide