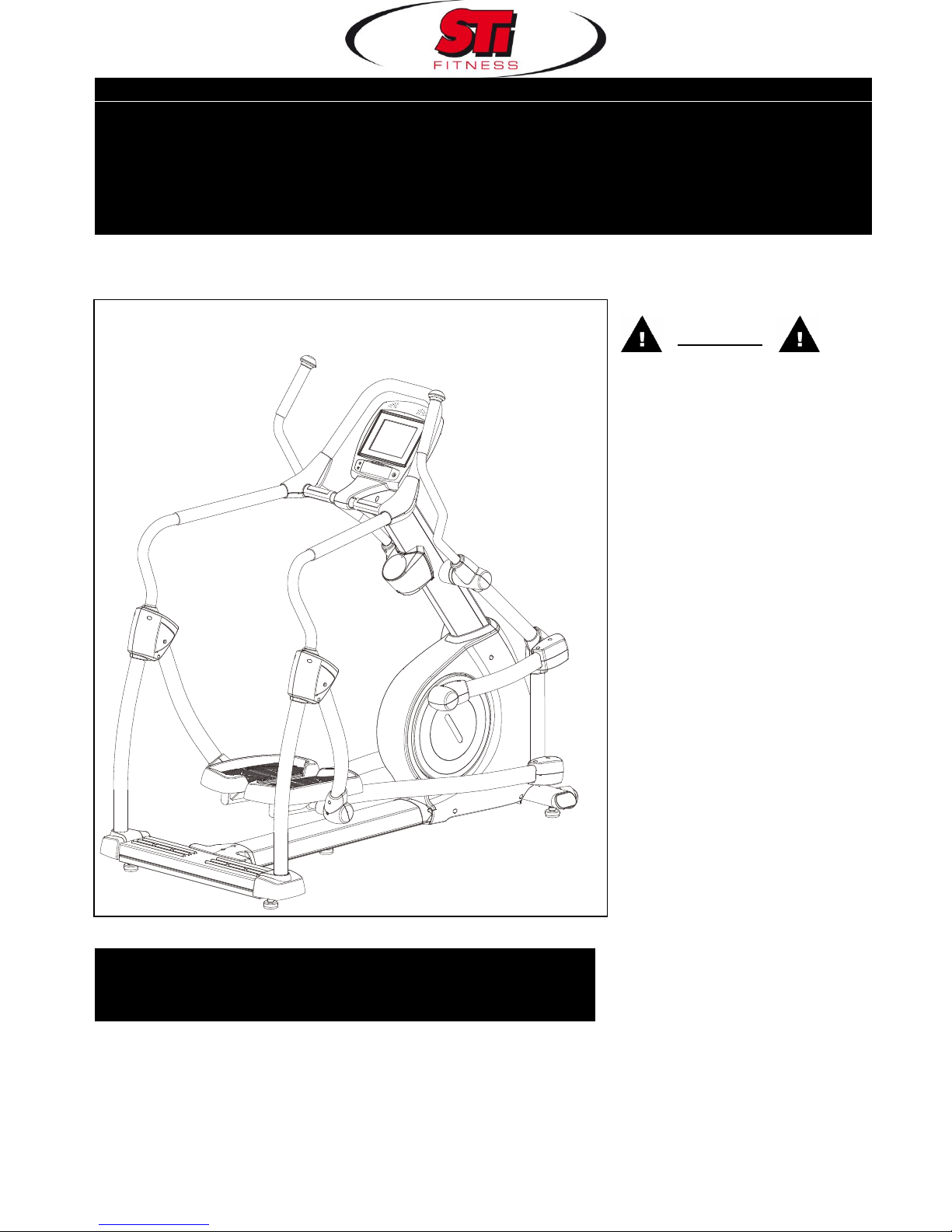

SAFETY INSTRUCTIONS

WARNING:Toreducetheriskofserious injury,readthefollowingSafetyInstructionsbefore usingthe

Climber.

1.ReadallwarningspostedontheClimber.

2.ReadthisOwner'sManualandfollowitcarefullybeforeusingtheClimber. Makesurethatitisproperlyassembledand

tightenedbeforeuse.

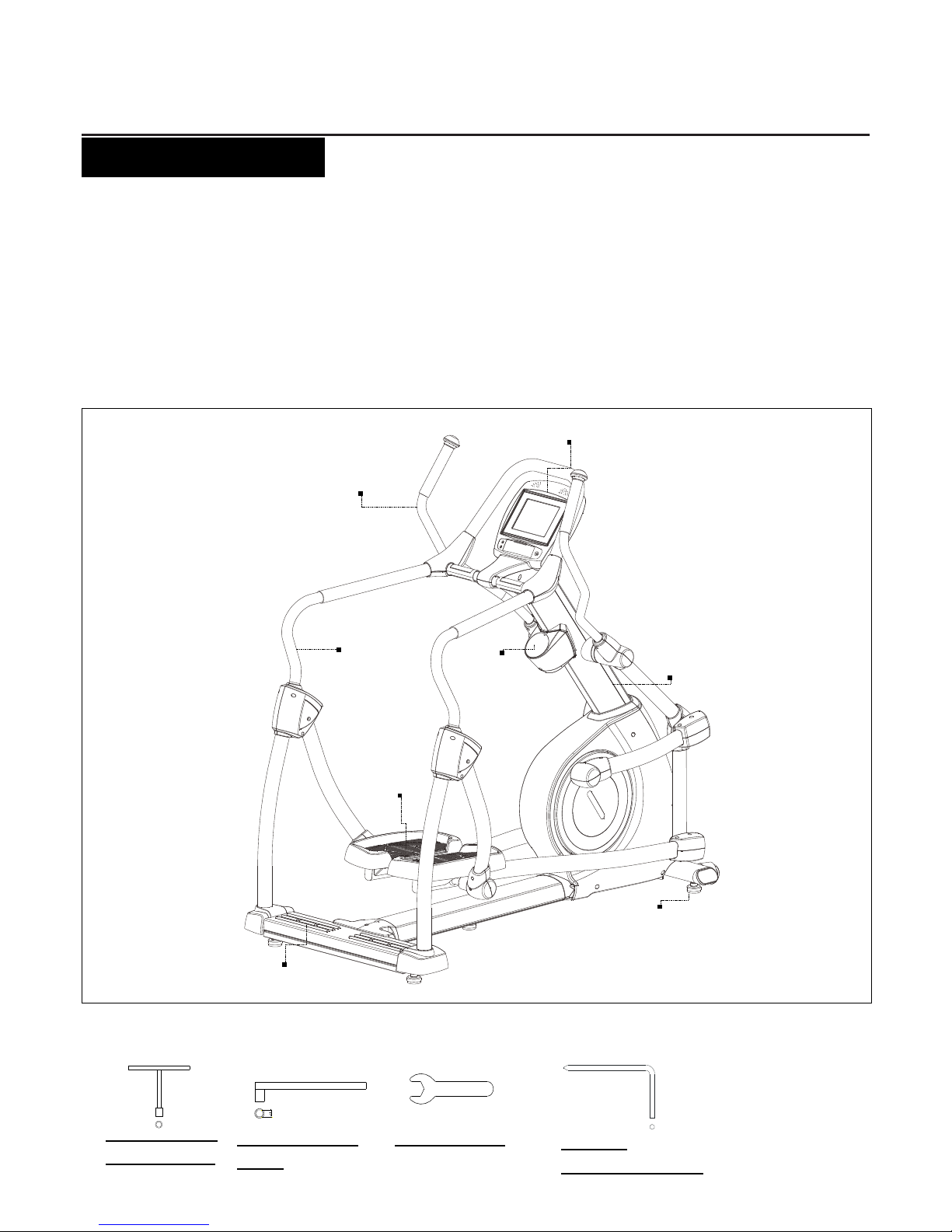

3.Werecommendthattwopeoplebeavailableforassemblyofthisproduct.

4.KeepchildrenawayfromtheClimber. DonotallowchildrentouseorplayontheClimber. Keepchildrenandpets away

fromtheClimberwhenitisinuse.

5.Itisrecommendedthatyouplacethisexerciseequipmentonanequipmentmat.

6.SetupandoperatetheClimberonasolidlevelsurface.DonotpositiontheClimberonlooserugsorunevensurfaces.

7.InspecttheClimberforwornorloosecomponentspriortouse.

8.Tighten/replaceanylooseorworncomponentspriortousingtheClimber.

9. Consultaphysicianpriortocommencinganexerciseprogram.If,atanytimeduringexercise,youfeelfaint,dizzy,or

experiencepain,stopandconsultyourphysician.

10. Followyourphysician'srecommendationsindevelopingyourownpersonalfitnessprogram.

11. Alwayschoosetheworkoutwhichbestfitsyour physicalstrengthandflexibilitylevel.Knowyourlimitsandtrainwithinthem.

Alwaysusecommonsensewhenexercising.

12.Beforeusingthisproduct,pleaseconsultyourpersonalphysicianforacompletephysicalexamination.

13. DonotwearlooseordanglingclothingwhileusingtheClimber.

14. Neverexerciseinbarefeetorsocks;alwayswearcorrectfootwear,suchasrunning,walking,orcross-trainingshoes.

15. Becarefultomaintainyourbalancewhileusing,mounting,dismounting,orassemblingtheClimber, lossofbalance may

resultinafallandseriousbodilyinjury.

16. KeepbothfeetfirmlyandsecurelyontheFootPedalswhileexercising.

17. TheClimbershouldnotbeusedbypersonsweighingover400 pounds/181kgs.

18. TheClimbershouldbeusedbyonlyonepersonatatime.

19.UsetwopeopletoassembleandmovetheClimber.

20.Maintenance:Replacethedefectivecomponentsimmediatelyand/orkeeptheequipmentoutofuseuntilrepairthe

equipmentcompletely.

21.MakesurethatadequatespaceisavailableforaccesstoandpassagearoundtheClimber;keepatleastadistanceof1

meterfromanyobstructionobjectwhileusing themachine.

22.TheClimberiswell-suitedtocommercialusage.

WARNING:Beforestartinganyexerciseorconditioningprogramyoushouldconsultwithyourpersonalphysiciantoseeif

yourequireacompletephysicalexam.Thisisespeciallyimportantif you are overtheageof35,haveneverexercisedbefore,

arepregnant,orsufferfromanyillness.

READ ANDFOLLOWTHESAFETYPRECAUTIONS.FAILURETOFOLLOWTHESE

INSTRUCTIONSCAN RESULTINSERIOUSBODILYINJURY.