171506857/0 10/2022

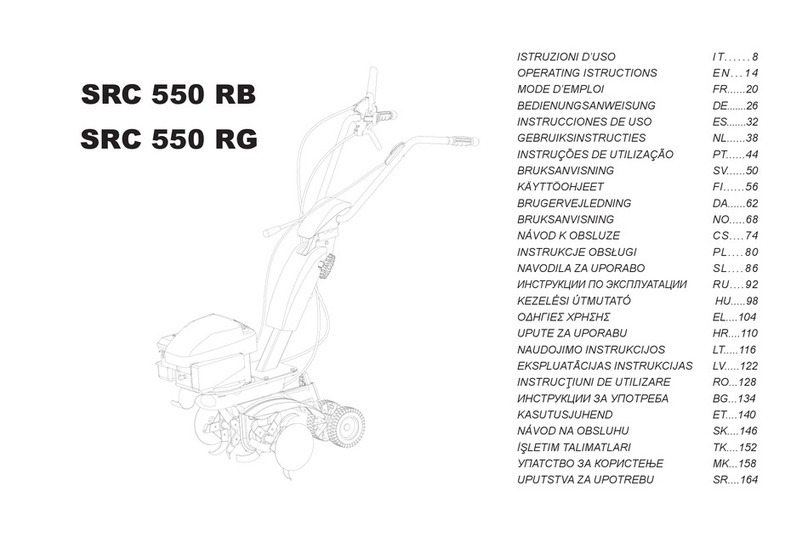

TYPE

RC 585

IT

Motozappatrice condotta a piedi -

MANUALE DI ISTRUZIONI

ATTENZIONE: prima di usare la macchina, leggere attentamente il presente libretto.

BG

УПЪТВАНЕ ЗА УПОТРЕБА -

Motokultivatoru kontrolisano pješacima

- UPUTSTVO ZA UPOTREBU

CS

- NÁVOD K POUŽITÍ

DA

Motorfræser betjent af gående personer

- BRUGSANVISNING

ADVARSEL: læs instruktionsbogen omhyggeligt igennem, før du tager denne maskine i brug.

DE

Handgeführte Motorhacke

- GEBRAUCHSANWEISUNG

ACHTUNG: vor inbetriebnahme des geräts die gebrauchsanleitung aufmerksam lesen.

EL

- ΟΔΗΓΙΕΣ ΧΡΗΣΠΣ

EN

Tiller

- OPERATOR’S MANUAL

WARNING: read thoroughly the instruction booklet before using the machine.

ES

Motoazada conducida de pie

- MANUAL DE INSTRUCCIONES

ET

Kõndiva juhiga mullafrees

- KASUTUSJUHEND

TÄHELEPANU: enne masina kasutamist lugeda tähelepanelikult antud kasutusjuhendit.

FI

Kävellen ohjattava puutarhajyrsin

- KÄYTTÖOHJEET

VAROITUS: lue käyttöopas huolellisesti ennen koneen käyttöä.

FR

Motobineuse à conducteur à pied

-

MANUEL D’UTILISATION

ATTENTION: lire attentivement le manuel avant d’utiliser cette machine.

HR

- PRIRUČNIK ZA UPORABU

HU

- HASZNÁLATI UTASÍTÁS

LT

NAUDOJIMO INSTRUKCIJOS -

.

LV

LIETOŠANAS INSTRUKCIJA

MK

- УПАТСТВА ЗА УПОТРЕБА

NL

Lopend bediende motorhakfrees

- GEBRUIKERSHANDLEIDING

LET OP: vooraleer de machine te gebruiken, dient men deze handleiding aandachtig te lezen.

NO

Motordrevet håndført jordfres

- INSTRUKSJONSBOK

ADVARSEL: les denne bruksanvisningen nøye før du bruker maskinen.

PL

Glebogryzarka prowadzona przez operatora pieszego

INSTRUKCJE OBSŁUGI

PT

Motoenxada para operador apeado

-

MANUAL DE INSTRUÇÕES

RO

MANUAL DE INSTRUCŢIUNI

RU

РУKОВОДСТВО ПО ЭKСПЛУАТАЦИИ

- NÁVOD NA POUŽITIE

SL

-

PRIROČNIK ZA UPORABO

SR

Motokultivator na guranje

- PRIRUČNIK SA UPUTSTVIMA

SV

Förarledd jordfräs

-BRUKSANVISNING

VARNING: läs igenom hela detta häfte innan du använder maskinen.

TR

- KULLANIM KILAVUZU

BS

SK