Stinson TC12-3060 User manual

1 April 30, 2019

STINSON OWL-LITE

ARROW BOARD

MODEL NO. TC12-3060

USER MANUAL

2 April 30, 2019

Contents

GENERAL DESCRIPTION ……………………………………………………………………………………………………………………..3

MODEL TABLE ………………………………………………………………………………………………………………………………….4

INSTALLATION ………………………………………………………………………………………………………………………………….5

CAB CONTROLLER ……………………………………………………………………………………………………………………………..8

ARROW BOARD CONTROLLER…………………………………………………………………………………………………………….9

OPERATING INSTRUCTIONS ………………………………………………………………………………………………………..9

TROUBLE SHOOTING................………………………………………………………………………………………………………… 9

SPECIFICATION………………………………………………………………………………………………………………………………… 12

SPARE PARTS …………………………………………………………………………………………………………………………………12

WARRENTY …………………………………………………………………………………………………………………………………15

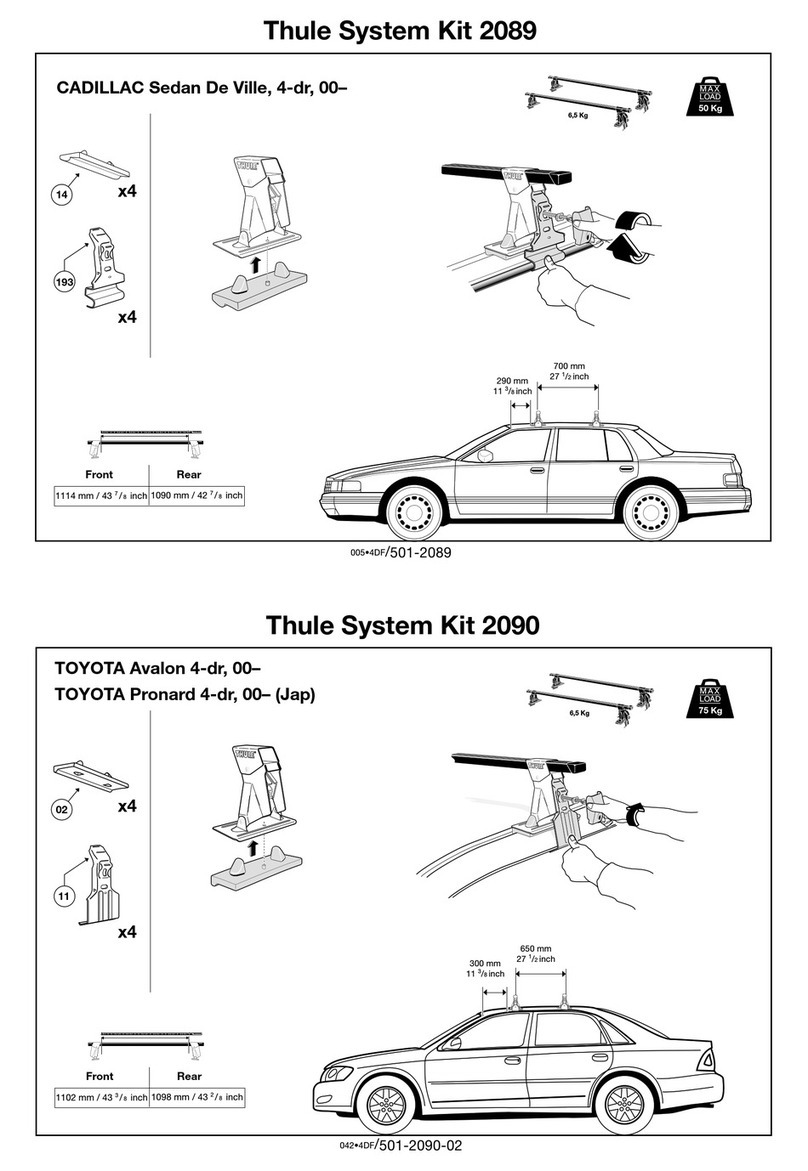

Figure 1 Installation Electrical....................................................................................................................... 6

Figure 2 Terminal Block Wiring ..................................................................................................................... 7

Figure 4 Cab Controller ................................................................................................................................. 8

Figure 6 Fuse Legend .................................................................................................................................. 11

Figure 7 Outline DWG .................................................................................................................................12

Figure 8 BOM ..............................................................................................................................................14

Table 1 MODELS............................................................................................................................................ 4

Table 2 CAB CONTROLLERS........................................................................................................................... 5

Table 3 TROUBLE SHOOTING GUIDE...........................................................................................................11

3 April 30, 2019

GENERAL DESCRIPTION

Stinson Arrow Board model no. TC12-3060 conforms to MOT specification for TC12 Arrow Boards

The standard configuration is a roof rack system allowing the Arrow Board to stand up (vertically)

while deployed or lay flat (horizontally) via a motor driven actuator. The actuator is driven via an

up/down switch on the Cab Controller.

Switches on the cab controller will activate the bar lights, left arrow lights, right arrow lights, the

up/down motor and wing actuators. A beacon switch is also provided as an option.

To activate the Arrow Board, turn the Bar switch to the UP position. The Bar LEDs will now be

ON. Left and right Arrows can now be deployed.

To de activate the Arrow Board, turn the bar switch to the OFF position. The wings will return to

the extended position and all LEDs on the Arrow Board will turn off.

See section CAB CONTROLLER for more detail.

4 April 30, 2019

MODEL TABLE

The AUTO1 version is typically installed on a stainless-steel rack system allowing the Arrow Board too

move into upright position. A Cable, Cab Controller and Up/Down Actuator are typically supplied.

Standard cable lengths are 30 ft. For custom cable lengths please contact Customer Service

Stinson Equipment will factory install the rack. For rack dimensions and drawings, please see Stinson

Customer Service. 1-800-561-6639

AUTO2 and MAN versions are typically vertically installed in a fixed position. A cable and Cab Controller

are typically supplied.

Pivot or gravity mount units are available.

For wireless communication between Cab Controller and the Arrow Board a wireless option is available.

For more information on these and other options Contact Stinson Customer Service for more

information.

MODEL NO.

TYPE

DESCRIPTION

TC12-3060-X

AUTO1

WINGS ARE DRIVEN AUTOMATICALLY

VIA INTERNAL ACTUATORS.

PROVISION FOR UP DOWN ACTUATOR

(FOR RACK MOUNT ARROW BOARDS)

AUTO2

WINGS ARE DRIVEN AUOMATIIALLY VIA

INTERNAL ACTUATORS

NO PROVISION FOR UP DOWN

ACTUATORS

MAN MANUAL WINGS ONLY

P PIVOT OR GRAVITY MOUNT

Table 1 OPTIONS

5 April 30, 2019

MODEL NO.

DESCRIPTION

TC12-3060

CAB CONTROLLER FOR AUTO1

BEACON SWITCH AVAILABLE

TC12-4848

CAB CONTROLLER FOR AUTO2

CAB CONTROLLER FOR MAN

Table 2 CAB CONTROLLERS

INSTALLATION

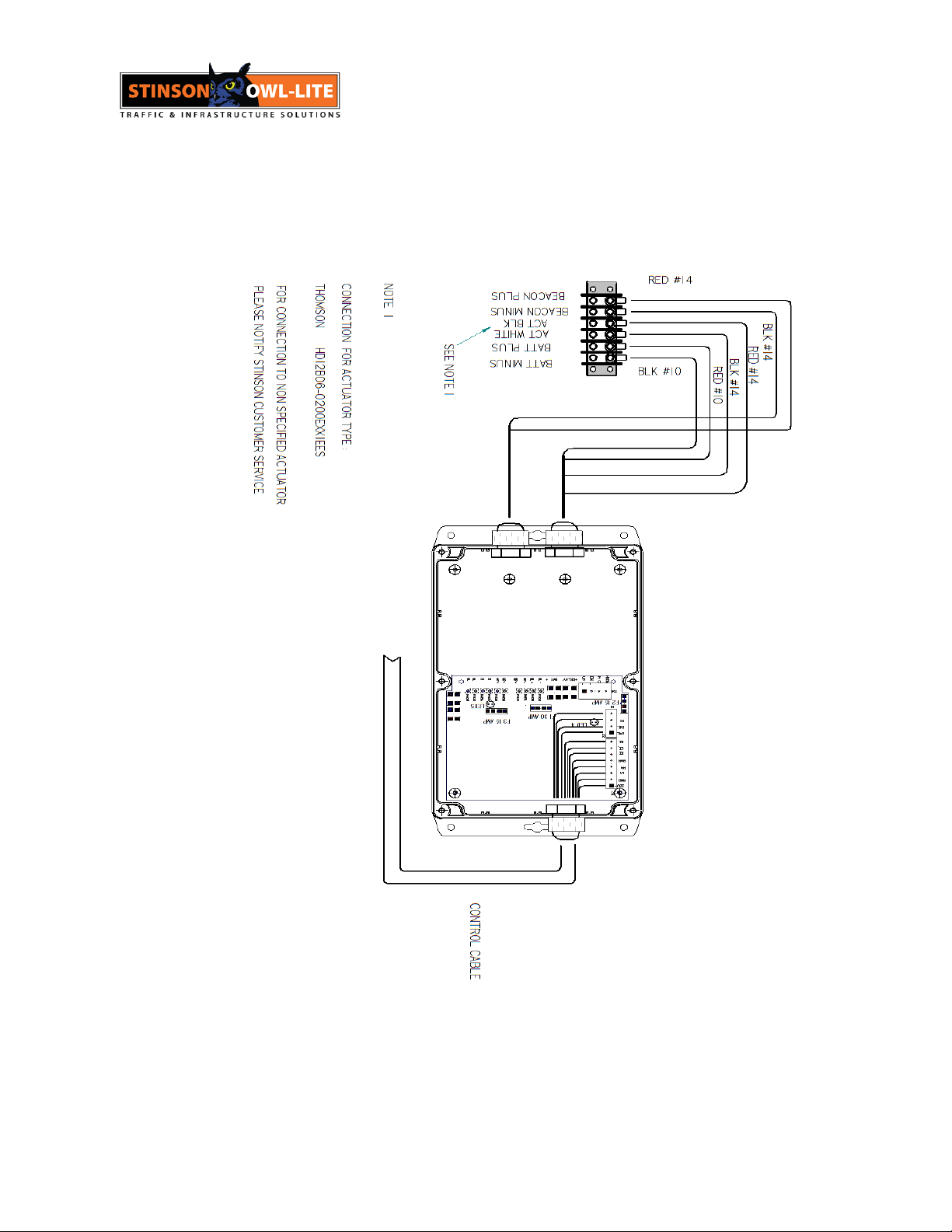

The electrical installation is shown in figure 1. For field installations, the user shall provide necessary

AWG cable. The fuse shall be physically located at the Battery terminal and rated at 30 AMP. A 10 AWG

cable is required to power the Arrow Board.

6 April 30, 2019

Figure 1 Installation Electrical

7 April 30, 2019

Figure 2 Terminal Block Wiring

8 April 30, 2019

CAB CONTROLLER

The top row of toggle switches control Arrow Board LEDs and actuators. To activate the LEDs

the BAR switch is moved to the ON or to the UP position. The bar row is now activated. The

center LED will flash approximately 40-50 times per second.

The left and right LEDs and actuators can now be deployed by moving the left and right toggle

switches to the UP or ON position.

To de activate the Arrow Board, turn the bar switch to the OFF position. The wings will return to

the extended position and all LEDs on the Arrow Board will turn off.

The switch at the lower left controls raising and lowering the Arrow Board. When the switch is in

the UP position, the arrow board will be in the UP or operating position. The two LEDs beside the

switch indicate the position of the Arrow Board. The top LED (red) is ON when the Arrow Board

is in the UP position. The lower LED is ON (green) when the Arrow Board is in the down position.

There is an option for a beacon switch.

Figure 3 Cab Controller

9 April 30, 2019

ARROW BOARD CONTROLLER

The Arrow Board Controller is located inside the Arrow Board. Signals from the Cab Controller activate

actuator relays and Arrow Board LEDs. The on and off timing of the LEDs is controlled by electronic

circuitry.

A photo sensor is located on the printed circuit board. A clear window located on the rear panel of the

Arrow Board allows light to illuminate the photo cell. During night time operation, the LED intensity is

reduced.

For proper operation of the photo cell, this window should be clear.

The removal and installation of the Arrow Board Controller is straight forward.

OPERATING INSTRUCTIONS

NOTE: When in the vertical position, The Arrow Board is designed for use in moving operations at or

below 40 km/hr.

Prior to operation make sure both the Arrow Board and Cab Controller are connected as shown

in Figure 1

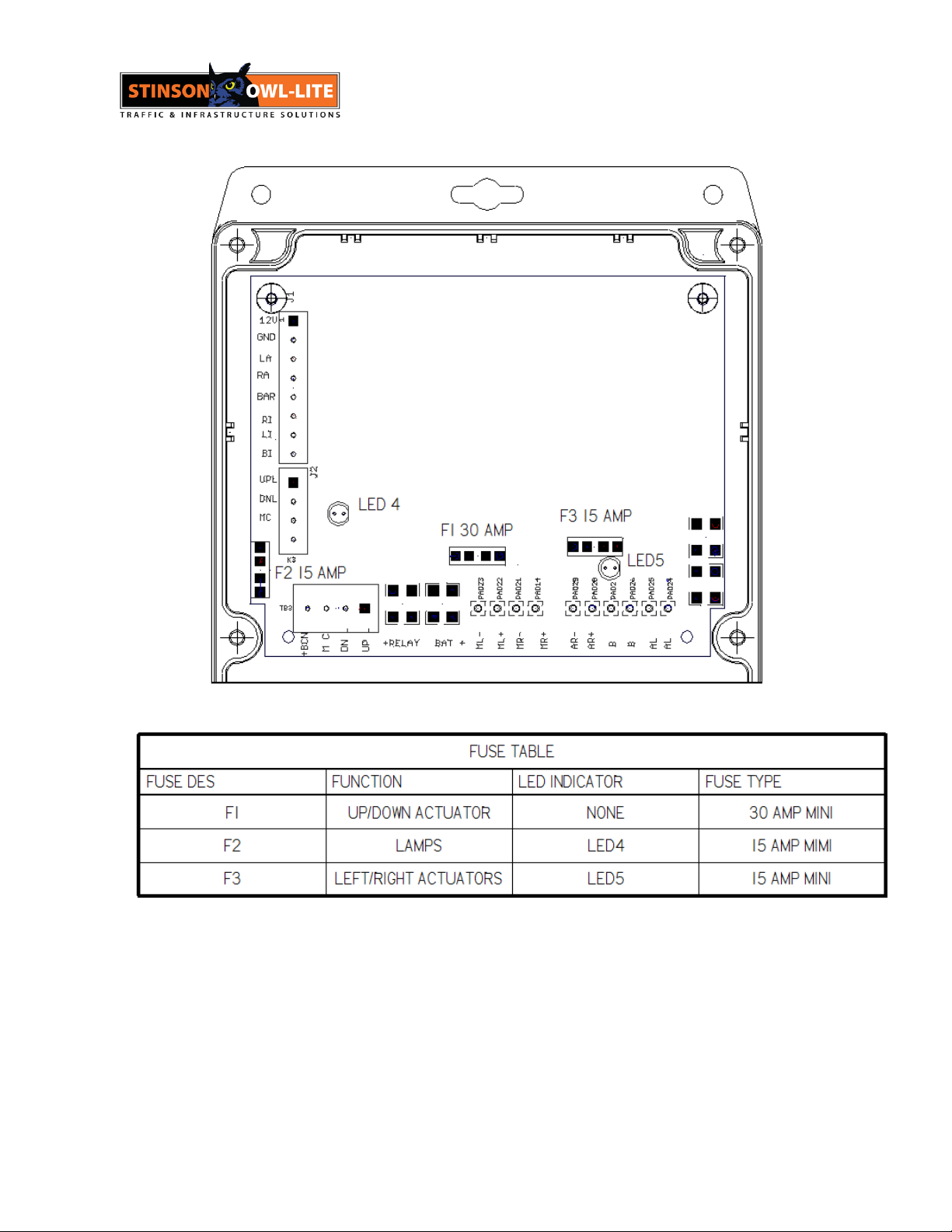

TROUBLE SHOOTING

In the event of failure, please review Table 6 below

The controller is fused to protect against short circuits in the Arrow Board

There are LED indicators that will illuminate under the following Conditions

1. An Lamp (Led) short circuit will open F2. Under these conditions LED 4 will illuminate

indicating fuse F2 has failed or is open.

2. A wing Actuator failure or short circuit will open F3. Under these conditions LED 5 will

illuminate indicating fuse F3 has failed or is open.

3. A short circuit in the up/down actuator circuit will open F1.

In the case of fuse failure, attempt to find short location prior to applying power to controller.

Replace fuses with sizes indicated in figure 6.

10 April 30, 2019

For replacement parts, please see parts list. You can contact our customer service for

assistance in securing a damaged component.

SYMPTON

CAUSE

The Cab Controller does not operate LEDs or

actuators. There is no LED indication on the

Cab Controller

The Arrow Board is not connected to the

Battery or the Battery polarity is reversed.

The Cab Controller does not operate LEDs or

actuators. The UP or DOWN LED correctly

indicates mechanical configuration of the

Arrow Board

Battery Voltage is under 11.5 volts.

Wing Actuators do not function

Check Voltage at Wing Actuator. If the

voltage is present, the Wing Actuator has

failed.

If there is no Actuator voltage, check for open

Actuator fuse (F3 15 AMP). See Fuse

Legend figure 6.

UP/DOWN Actuator Motor does not activate.

Check voltage at UP/DOWN Actuator. If

present UP/DOWN Actuator has failed.

If there is no Actuator voltage, check for open

UP/DOWN fuse (F1 30 Amp) in the Arrow

Board Controller. See fuse legend figure 6.

Bar, Left, Right LEDs are not ON

Check for open fuse (F2 15 Amps). See fuse

legend figure 6.

The Arrow Board LED intensity is low

Probably the solar window at the rear of the

Arrow Board is dirty not allowing the photo

sensor to operate at full intensity.

11 April 30, 2019

Table 3 TROUBLE SHOOTING GUIDE

Figure 4Fuse Legend

12 April 30, 2019

SPECIFICATION

See Stinson Customer Service for specification details 1-800-561-6639

nvironmen

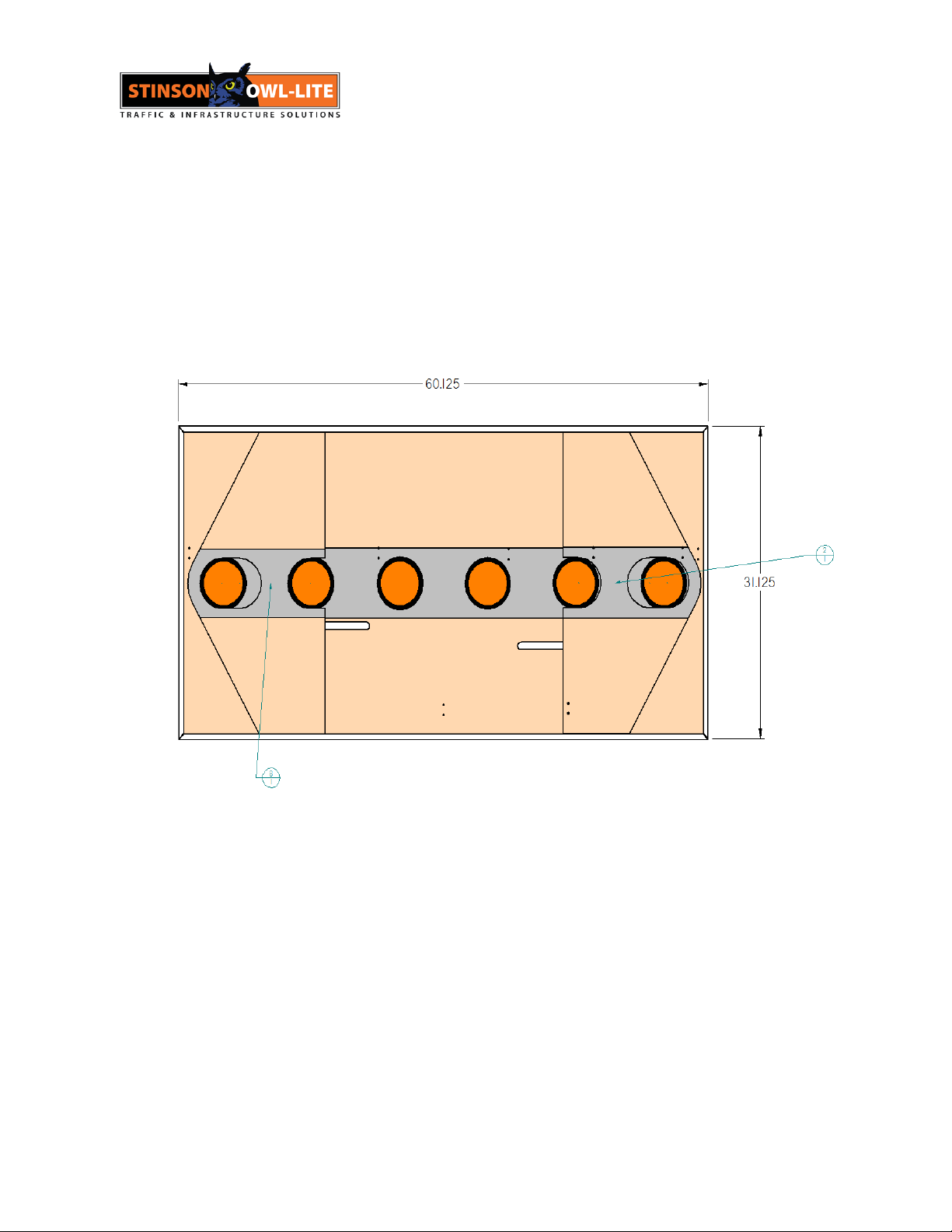

Figure 5 Outline DWG

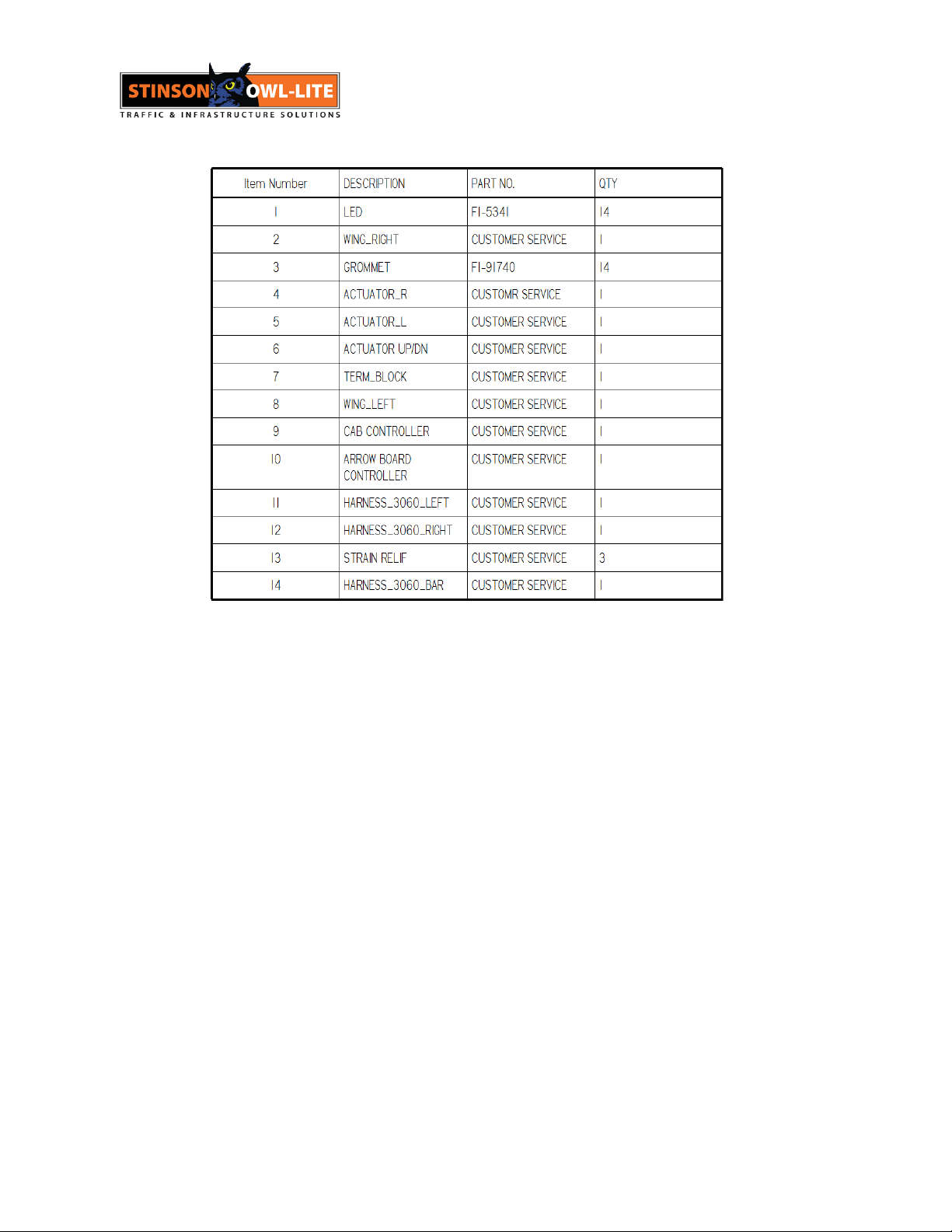

SPARE PARTS

See Stinson Customer Service for spare part service 1-800-561-6639

13 April 30, 2019

14 April 30, 2019

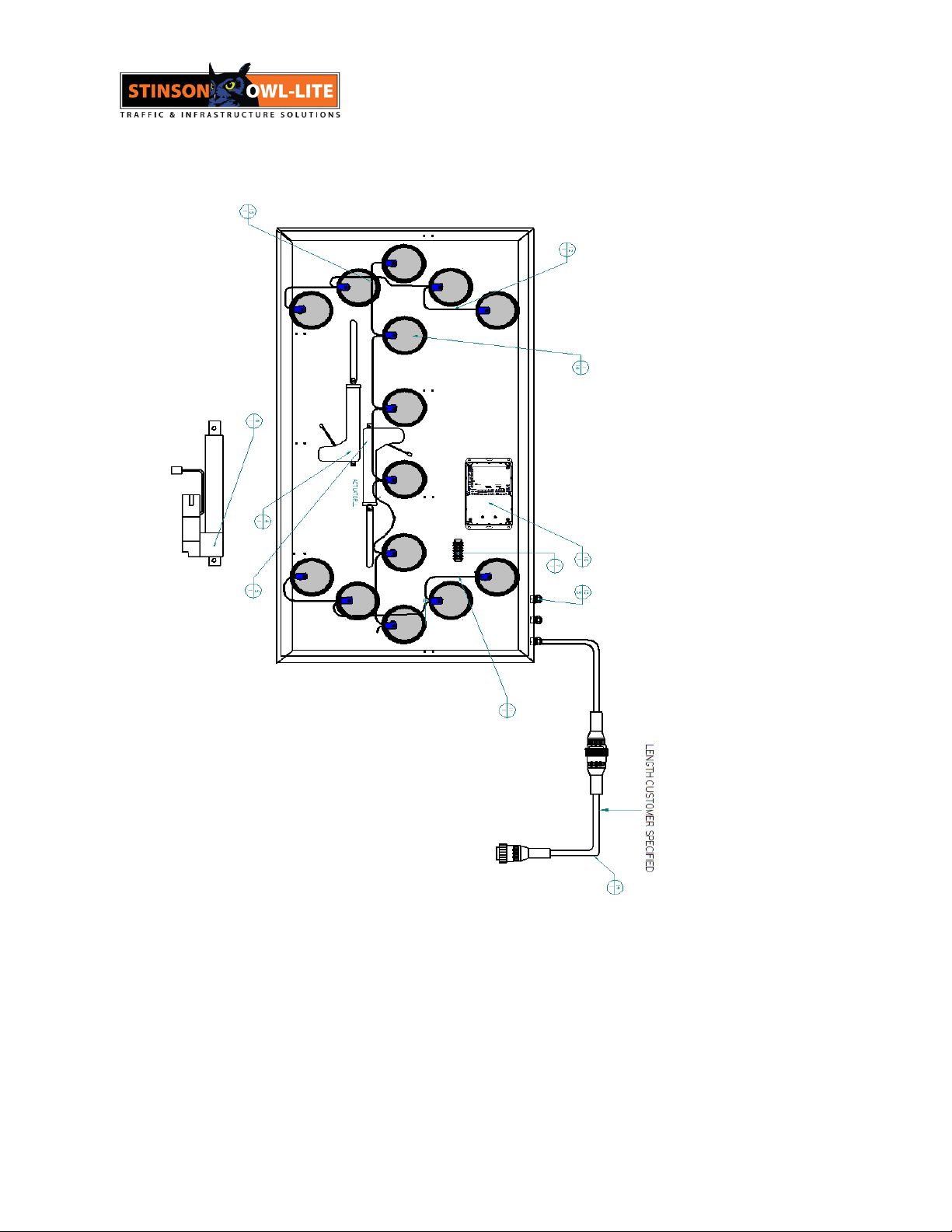

Figure 6 BOM

15 April 30, 2019

WARRENTY

WARRANTY POLICY

Thank you for purchasing this quality STINSON EQUIPMENT LIMITED (STINSON) product. We are proud to stand

behind every new STINSON product and this warranty policy is our commitment to you. Please read it carefully.

STINSON warrants that this product will conform to the manufacturer’s standard specifications without defects in

materials and workmanship as outlined below:

Product/ Component

Warranty Period

Mechanical Assembly; (trailers, metal sign

frames, mounting hardware, arrow boards)

-1 year

-Standard coatings excepted

Molded Products; (barrels, cones, markers)

-1 year on plastic integrity

Electrical and Electronic

-1 year

Signs and Sheeted Products

-Sheeting defects, 30 days

Components, sub-assemblies and devices produced by other manufacturers are covered separately and individually

under warranties provided by the specified manufacturer.

There are no warranties expressed or implied which extend these warranty periods. The loss of the product, loss of

time, inconvenience, commercial loss or consequential damages, including cost of any labour, is not covered.

STINSON reserves the right to change the design of the product without assuming any obligation to modify any

product manufactured. This warranty is granted to the original purchaser of the product and is not assignable to any

subsequent purchaser or user. Any leasing or borrowing of these goods or other use beyond normal demonstration of

the same shall be deemed to be use by the original purchaser. The period of this warranty shall commence on the

date of delivery to the first original purchasers. Proof purchase and delivery date may be required when warranty

service is requested.

The sole remedy under this warranty shall be the repair or replacement of parts which have been determined to be

defective after inspection by an approved representative of STINSON. STINSON reserves the right to request the

return of parts replaced under this warranty or in disputable fitness and must be consulted for authorization before

any such return. All defective parts replaced under this warranty shall become property of STINSON. If as claimed

defect cannot be identified or reproduced in service, the purchaser will be held responsible for the costs of

replacement or remanufactured parts. STINSON shall not be responsible for the transportation or mileage costs

associated with repair or replacement of warranted products or parts. The costs of labour associated with corrections

under this warranty shall be reimbursed at a rate deemed reasonable by STINSON if such labour is not performed by

STINSON factory approved personnel. Tampering with the serial number or posted safety and operating instructions

may constitute a breech of this warranty. This warranty shall not extend to any goods or parts which have been

altered, repaired, operated, or maintained outside of approved STINSON procedures or directives. This warranty

does not cover damage resulting from causes beyond the control of STINSON, including without limitation; misuse,

abuse, neglect, or accident; external electrical faults, power surges, or power failure; damage occurring in shipment

or from improper transportation, installation, operation or application; or damage resulting from improper usage or use

of the product with components, accessories or other items not supplied by STINSON. The end-user is responsible

for the selection, use and results obtained from the product.

This warranty applies only to products that have been paid for according to terms under which the product has been

invoiced. Further, the buyer agrees that STINSON will not be required to honour any warranty claim from a customer

whose account at STINSON is not current according to STINSON’s payment terms. This warranty is exclusive and in

lieu of all other warranty, expressed or implied including warranties of merchantability or of fitness for purpose, and

no other warranties which extend beyond the descriptions on the face hereof. The remedies set forth herein and

manufacturer shall not be liable for special, indirect or consequential damages. The obligations of STINSON

hereunder shall not exceed the cost of the equipment or part upon which such liability is based.

Stinson Equipment Ltd. 130 Creditstone Rd. Concord Ontario L4K 1P2

16 April 30, 2019

130 Creditstone Road

Concord Ontario Canada L4K 1P2

Ph ( 905 ) 669-2360 Fax ( 905 ) 669-3537

Company

Address

Phone

Fax

Product

Serial #

Date Purchased

130 Creditstone Road

Concord Ontario Canada L4K 1P2

Ph ( 905 ) 669-2360 Fax ( 905 ) 669-3537

Company

Address

Phone

Fax

Product

Serial #

Date Purchased

Environmental

-40 C – 50 C Opera�onal

-40

Table of contents

Other Stinson Automobile Accessories manuals