– When dispatching used products: Comply with all legal requirements for the

handling of hazardous substances and the transport of dangerous goods. For

return to Festo è 2.1 General safety instructions.

– Store the product in a cool, dry, UV-protected and corrosion-protected envir-

onment. Ensure that storage times are kept to a minimum.

– In case of long-term storage: regularly check the function of the semi-rotary

drive.

– Observe environmental and storage conditions è 14 Technical data.

– To prevent contamination, close any pneumatic connections.

– Protect the coupling parts with grease or protective oil.

– To prevent damage to the coupling flange, store the semi-rotary drive on a

level wooden pallet.

7 Assembly and installation

NOTICE!

Semi-rotary drives of the series DFPD-HD are intended for installation parallel to

the line axis.

• If another installation position is necessary, consult your regional Festo con-

tact èwww.festo.com.

NOTICE!

Semi-rotary drives with a hydraulic manual override are designed for a horizontal

installation position only. In this position, the pump and reservoir are mounted

towards the top of the hydraulic cylinder.

7.1 Assembly

1. Clean the coupling flange.

2. Adjust the valve position according to the semi-rotary drive settings.

3. Lubricate the valve stem.

4. Place the semi-rotary drive on the control shaft of the process valve.

5. Mount the semi-rotary drive on the connecting flange of the process valve

using 8 threaded pins.

6. Tighten the nuts of the threaded pin crosswise.

Tightening torque è Tab. 2

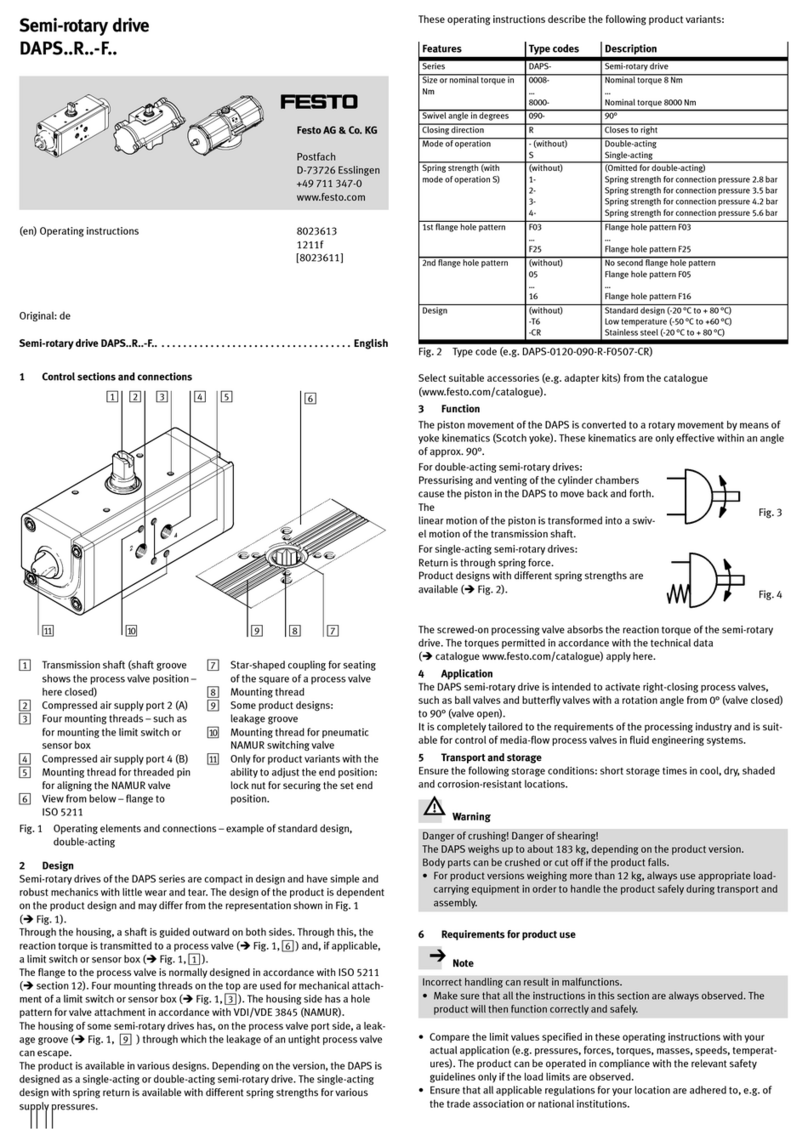

Flange type F25 F30 F35

Tightening torque [Nm] 160 320 1100

Tab. 2

7.2 Pneumatic installation

• Observe the operating instructions of the process valve.

• Test the correct function of the pneumatic control.

Connection Effect

2 Air supply; always connected

4 Return stroke

Tab. 3

8 Commissioning

8.1 Requirements

– The drive is fully mounted and connected.

8.2 Commissioning the semi-rotary drive

1. Check operating conditions and limit values è 14 Technical data.

2. Switch on the compressed air supply.

3. Check the semi-rotary drive for leakage.

4. First check the direction of rotation of the semi-rotary drive and reaction of

the process valve at a low travel speed.

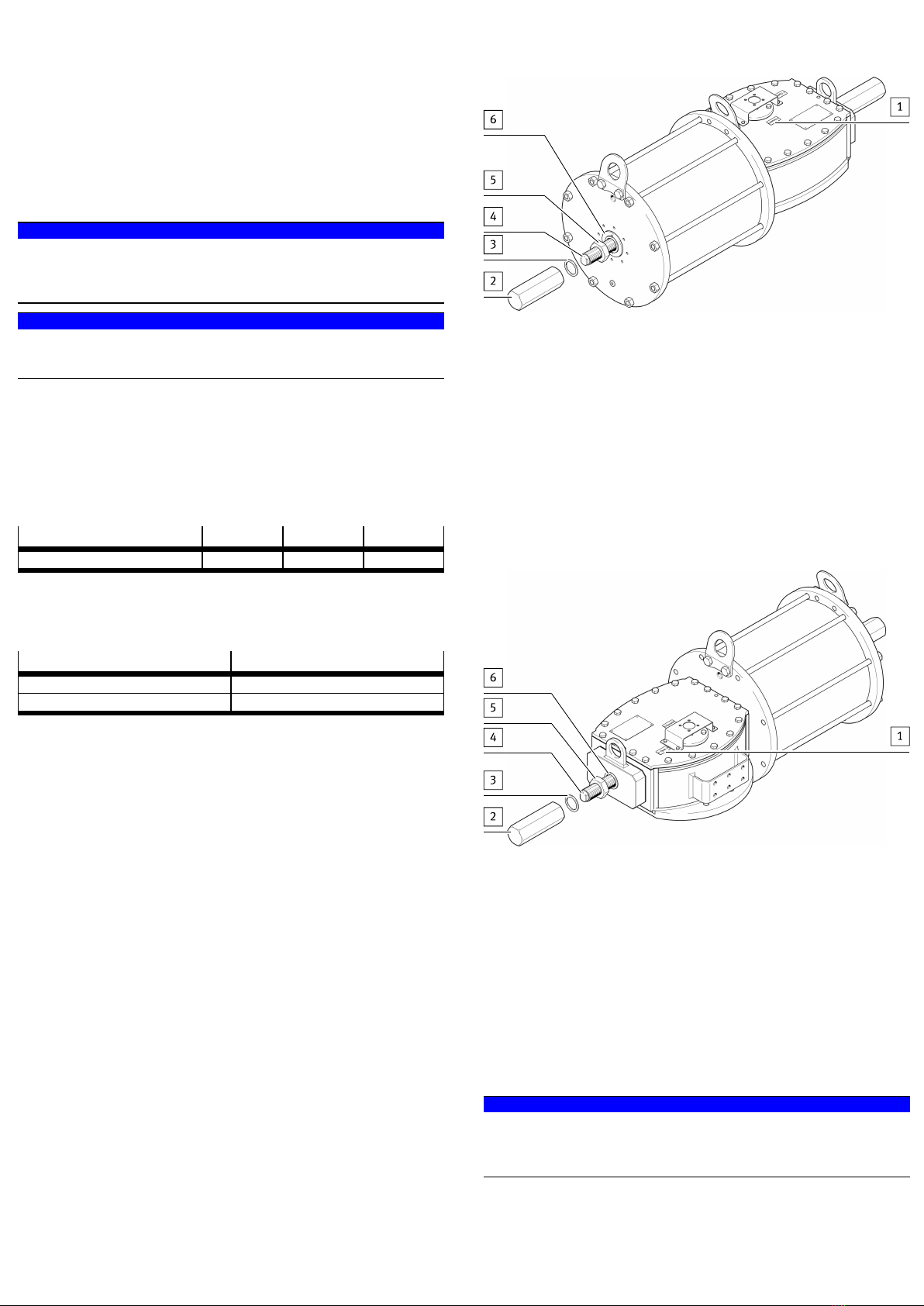

8.3 Adjusting the end position – “Valve closed” position

The “Valve closed” position is set using the adjusting screw on the end flange of

the pneumatic cylinder.

Fig. 4

1. Set the semi-rotary drive to the “Valve closed” position1.

2. Switch off the compressed air supply.

3. Remove the cover of the stop bolt 2and sealing disc3.

4. Loosen the stop nut 5together with the sealing disc6.

5. To reduce the rotation angle, screw in the stop adjusting screw4.

To increase the rotation angle, unscrew the stop adjusting screw4.

6. Tighten the stop nut5. Make sure that the sealing disc6 is centred on the

stop nut and lies in the recess of the flange.

7. Switch on the compressed air supply.

8. To check the adjustment, run through a complete cycle.

9. Put the cover of the stop bolt2 and sealing disc3 into place again.

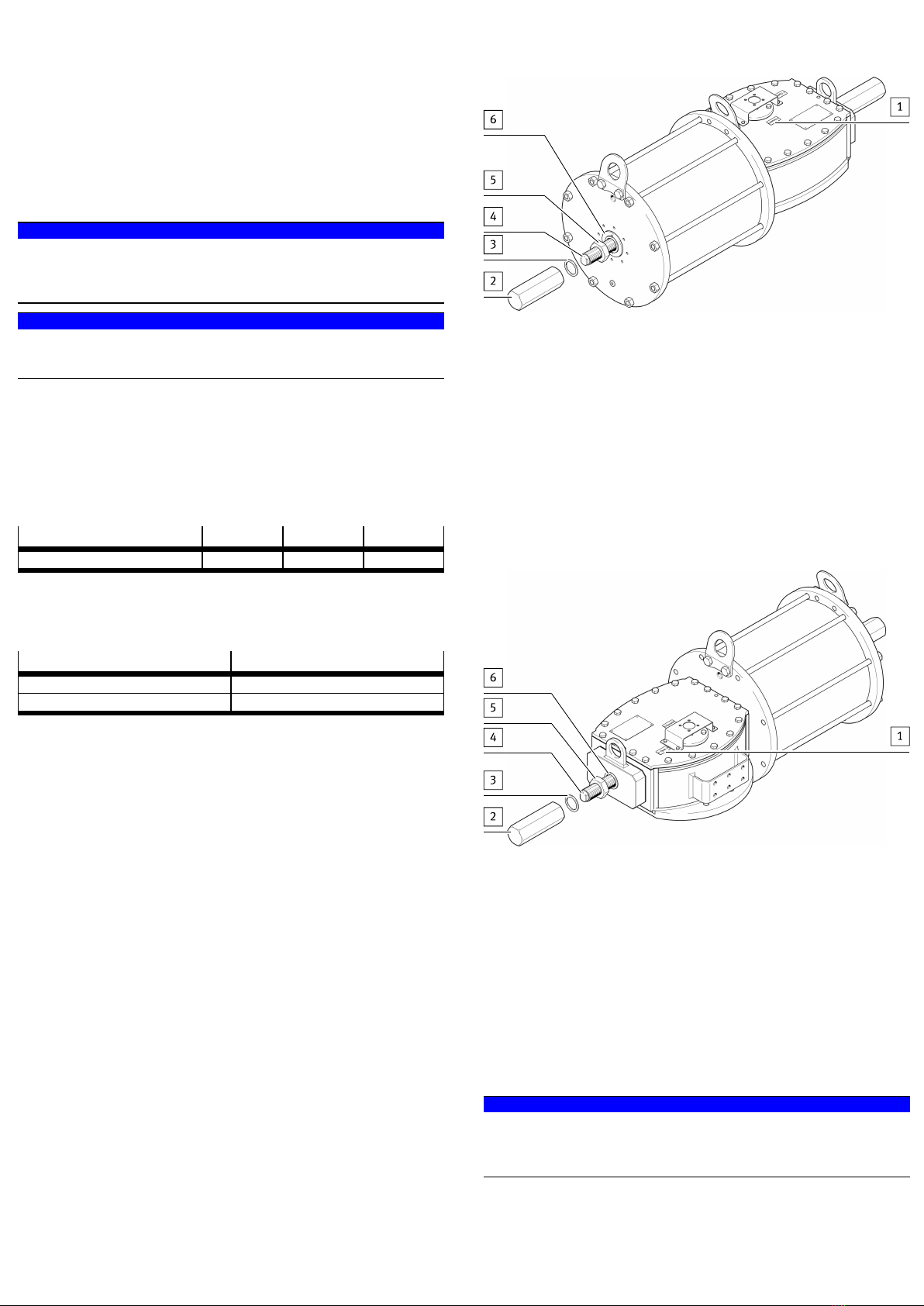

8.4 Adjusting the end position – “Valve open” position

The “Valve open” position is set using the adjusting screw on the end flange of

the gear unit.

Fig. 5

1. Set the semi-rotary drive to the “Valve open” position1.

2. Switch off the compressed air supply.

3. Remove the cover of the stop bolt 2and sealing disc3.

4. Loosen the stop nut 5together with the sealing disc6.

5. To reduce the rotation angle, screw in the stop adjusting screw4.

To increase the rotation angle, unscrew the stop adjusting screw4.

6. Tighten the stop nut5. Make sure that the sealing disc6 is centred on the

stop nut and lies in the recess of the flange.

7. Switch on the compressed air supply.

8. To check the adjustment, run through a complete cycle.

9. Put the cover of the stop bolt2 and sealing disc3 into place again.

9 Operation

• Comply with operating conditions.

• Observe the permitted limit values.

NOTICE!

For continuous operation under extreme conditions: Use lubricated compressed

air. The oil must be chemically inert and must not carbonise. Once the product has

been used with lubricated compressed air, it must continue to be operated with

lubricated compressed air only.