Stober ComTrac User manual

STOBER Drives Inc. • ComTrac2012 • www.stober.com 1

Table of Contents

ComTrac Adjustable Speed Drives

Advantages and Features...................................................2

Performance........................................................................3

Washdown Duty ..................................................................4

Operating Characteristics....................................................5

Ratings and Dimension

.50 HP .......................................................................6

.75 HP .......................................................................7

1.0 HP .......................................................................8

1.5 HP .......................................................................9

2.0 HP .....................................................................10

3.0 HP .....................................................................11

5.0 HP .....................................................................12

Electric Remote Control (ERC) .........................................13

Selection and Performance Characteristics......................14

Installation Instructions......................................................16

Maintenance and Lubrication............................................18

"C" Series MGS Adjustable Speed Drives

Performance Specifications...............................................19

Ratings..............................................................................20

Dimensions........................................................................34

Mounting Positions............................................................70

"F" Series MGS Adjustable Speed Drives

Performance Specifications...............................................37

Ratings..............................................................................38

Dimension .........................................................................44

Mounting Positions............................................................70

"K" Series MGS Adjustable Speed Drives

Performance Specifications...............................................47

Ratings..............................................................................48

Dimensions........................................................................64

Mounting Positions............................................................71

Mounting Hollow Output Units...........................................68

Mounting Positions............................................................69

Terms and Conditions........................................................72

Company Profile

STÖBER was first established in Germany in 1934, and has been

a pioneer in the gearing industry ever since. Through constant

innovation, STÖBER today is known for high precision, high ef-

ficiency and low noise in their various gearing technologies. STO-

BER®Drives Inc., located in Maysville, KY, manufactures products

to serve the North American market.

Beginning with the ComTrac®Mechanical Variable Speed Reduc-

ers, STÖBER established itself as a technology leader, later

adding the innovative MGS®Modular Gear System to the product

offering. MGS®Food and Beverage Reducers excel in the harsh-

est of washdown environments.

STÖBER next introduced ServoFit®Precision Planetary Gear-

heads, establishing the standard for low noise and low back-

lash in the servo industry. The recent introduction of the SMS®

ServoFit Modular System gearheads adds a high precision, cost

effective alternative to the servo market.

STÖBER has the broadest offering of speed reducers available,

providing one stop shopping for both the industrial market and the

rapidly growing motion control market.

On behalf of the worldwide family of STÖBER employees, we

thank you for trying our products and pledge to continue to meet

your product and service needs with the newest solutions.

Sincerely,

Bernd Stöber, Chairman

Stöber Antriebstechnik GmbH

Peter Feil, VP/General Manager

STOBER Drives, Inc.

ComTrac®Adjustable Speed Drives

2STOBER Drives Inc. • ComTrac2012 • www.stober.com

Advantages:

You're probably already aware of the many common-sense

advantages offered by traction-type adjustable speed drives like

the ComTrac drive. When compared to mechanical belt-type, or

electrical adjustable speed drives, traction type drives offer:

• Often, a lower initial cost.

• Few worries about motor overheating during low speed

operation.

• No motor brushes to replace.

• Very compact and lightweight when compared to other me-

chanical drives.

• Simple design with few rotating components to wear or re-

place.

• Easily serviced by semiskilled personnel

• Low maintenance – doesn't need to be cycled through its

speed range to prevent component damage.

• 2 year warranty–your assurance of satisfactory product perfor-

mance.

Features:

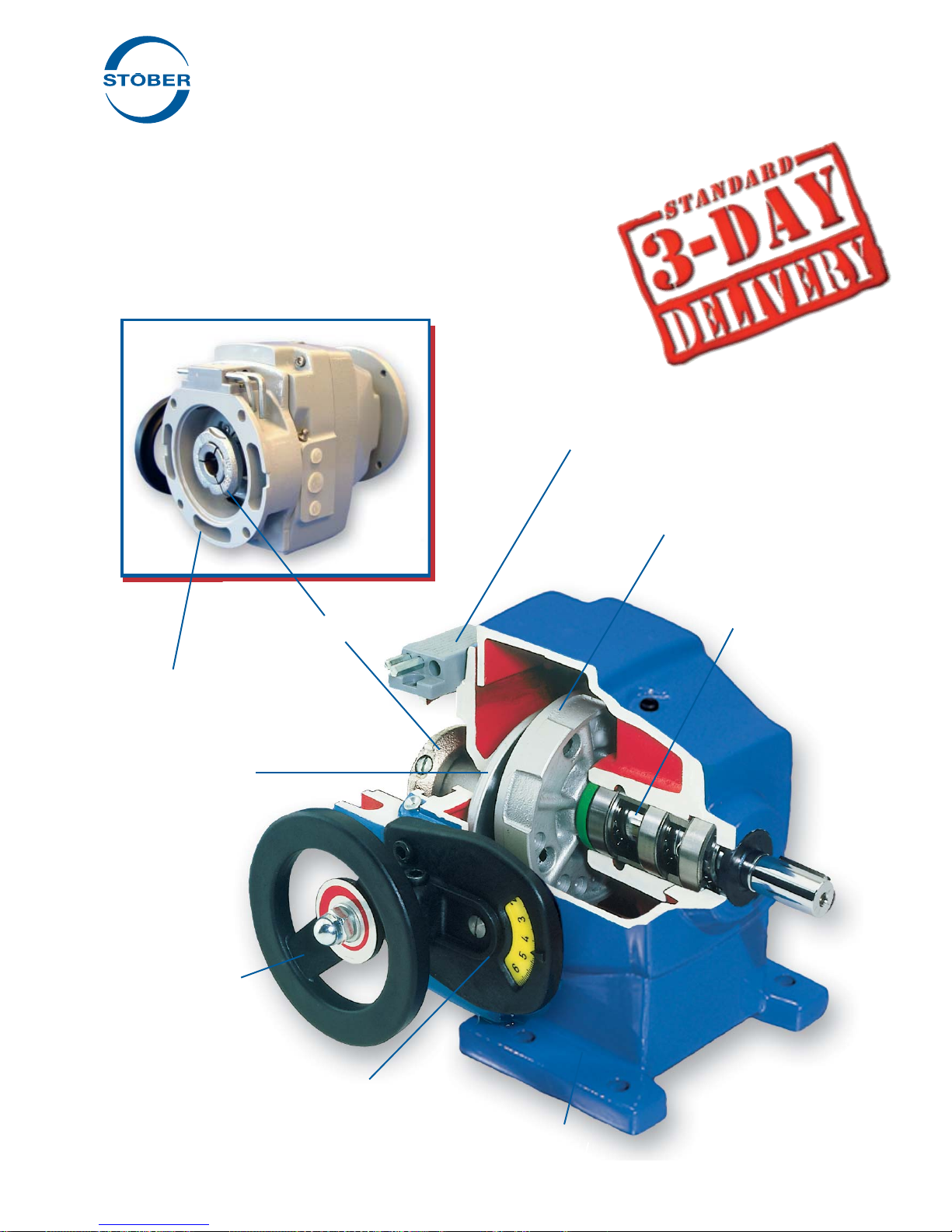

Drive cone – The drive cone is made from ductile iron and is

precision ground for long service life. It contains inner air cham-

bers for efficient heat dissipation. It is independently supported by

a shielded bearing mounted into the motor adapter/slide – not just

by the motor bearing.

Traction ring – ComTrac's self-lubrication traction ring is made

from a proprietary material that provides exceptional resistance

to wear and high temperatures. When replacement is necessary,

only the ring and not the entire friction ring mounting flange is

replaced.

Speed adjustment – ComTrac's rack and pinion speed adjust-

ment system features stainless steel components to resist cor-

rosion and is dust resistant by design. The stainless steel pinion

shaft and ductile iron rack are designed to provide assured speed

adjustments in the wettest, dirtiest environments.

Handwheel control – Handwheel control with a position indicator

is standard on every ComTrac drive. Remote speed controls and

overspeed protection is also available.

All ComTrac drives are shipped with the handwheel positioned

on the left as viewed from the output shaft end of the drive. The

handwheel can be quickly and easily moved to the right side by

using the tools and instructions included with the drive.

Mounting position – ComTrac drives can be mounted in virtually

any position.

NEMA C-face input – All ComTrac drives feature a NEMA C-

face input – that means standard off-the-shelf motors, available

locally. ComTrac's patented corrosion resistant collet clamp ring

makes motor shaft attachment fast and simple. The proper hex

wrenches are included with each unit in the motor access cover.

When the motor must be replaced, it can be done easily and

quickly without disassembly of the entire drive.

In addition, the 0F unit is standard with a NEMA C-face output

flange. It enables you to add adjustable speed capability to new or

existing applications.

Torque compensator – The torque compensator assembly fea-

tures high-capacity cylindrical roller bearings – not needle bear-

ings – for long life and quiet operation. The design allows speed

changes during operation or while the drive is at rest. The load

compensating cams precisely match the pressure between the

drive cone and the traction ring in proportion to the load torque.

Cast iron housing – High tensile strength cast iron housing for

long service life in demanding applications.

Stainless steel nameplate.

Two year warranty – Every ComTrac unit is backed by a two-

year warranty.

Delivery – ComTrac units are shipped in 3 days or less.

Selection:

In general, proper selection of a ComTrac drive is as easy as the

drive is to operate.

1. Establish the maximum horsepower required by the driven

machine at maximum speed.

2. Select the drive which meets or exceeds the maximum HP

rating of the driven machine at maximum speed.

Part No. Example:

TD47 0 F K182 W

Traction Drive Model/Size

0– Non-geared

F– Flange Mount

Input for NEMA Frame Size (182TC)

Washdown/Severe Duty (Option)

Speed Control Made Simple!

ComTrac®Adjustable Speed Drives

STOBER Drives Inc. • ComTrac2012 • www.stober.com 3

Performance Specifications:

• Horsepower ratings – from 1/2to 10

• Output speeds – available from 2180 to 311 RPM

• Speed range – 5:1 to 7:1

• Output torques – up to 496 in.lbs.

• NEMA frames – from 56C to 215TC

Torque Compensator

NEMA C-face Input

Drive Cone

Handwheel

Speed Adjustment Dial

Cast Iron Housing

Access Cover with wrenches

Collet Clamp Ring

Friction (Traction)

Ring Flange

Assembly

ComTrac®Adjustable Speed Drives

Footed unit shown for illustration only.

This style is no longer available.

4STOBER Drives Inc. • ComTrac2012 • www.stober.com

ComTrac®Adjustable Speed Drives

Washdown/Outdoor Service/ Severe Duty

Advantages:

STÖBER has developed a severe duty protection package for

ComTrac drives which significantly improves the drives' ability

to withstand the effects of outdoor use, exposure to excessively

humid or acidic environments, or spray washed with water or

caustic fluids.

The ComTrac severe duty package includes corrosion protection

for all functional components and housings including:

• Drive cone

• Motor clamping ring

• Motor slide and rack

• Bearing housing

• Main housing cover

To prevent corrosion, these components are protected by a spe-

cial heat treatment process similar to chrome plating.

Features:

Drive cone – Corrosion protected drive cone extends cone and

ring life.

Speed adjustment – The protected motor slide, stainless steel

control shaft with pinion, and greased rack and slideway assure

the proper speed adjustment.

NEMA C-face input – ComTrac's patented corrosion resistant

collet clamp ring assures ease of motor replacement.

External surface – All external surfaces are protected with a spe-

cial acid-resistant epoxy paint to prevent corrosion and lubricant

contamination.

Internal surface – All internal surfaces and bearing housing are

protected with a special anticorrosion paint.

Double seals – Double output seals can be provided for maxi-

mum protection in very harsh environments.

Mounting position – ComTrac drives in a vertical mounting posi-

tion (output shaft down) must be adapted to allow water to drain.

Stainless steel nameplate – Other features of the severe duty

unit are: stainless steel nameplate, rivets, and chrome plated

bolts.

Two year warranty – Like the standard drive, this ComTrac unit

is also backed by a two-year warranty.

Delivery – ComTrac units are shipped in 3 days or less.

Footed unit shown for illustration only.

This style is no longer available.

STOBER Drives Inc. • ComTrac2012 • www.stober.com 5

ComTrac®Adjustable Speed Drives

Operating Characteristics

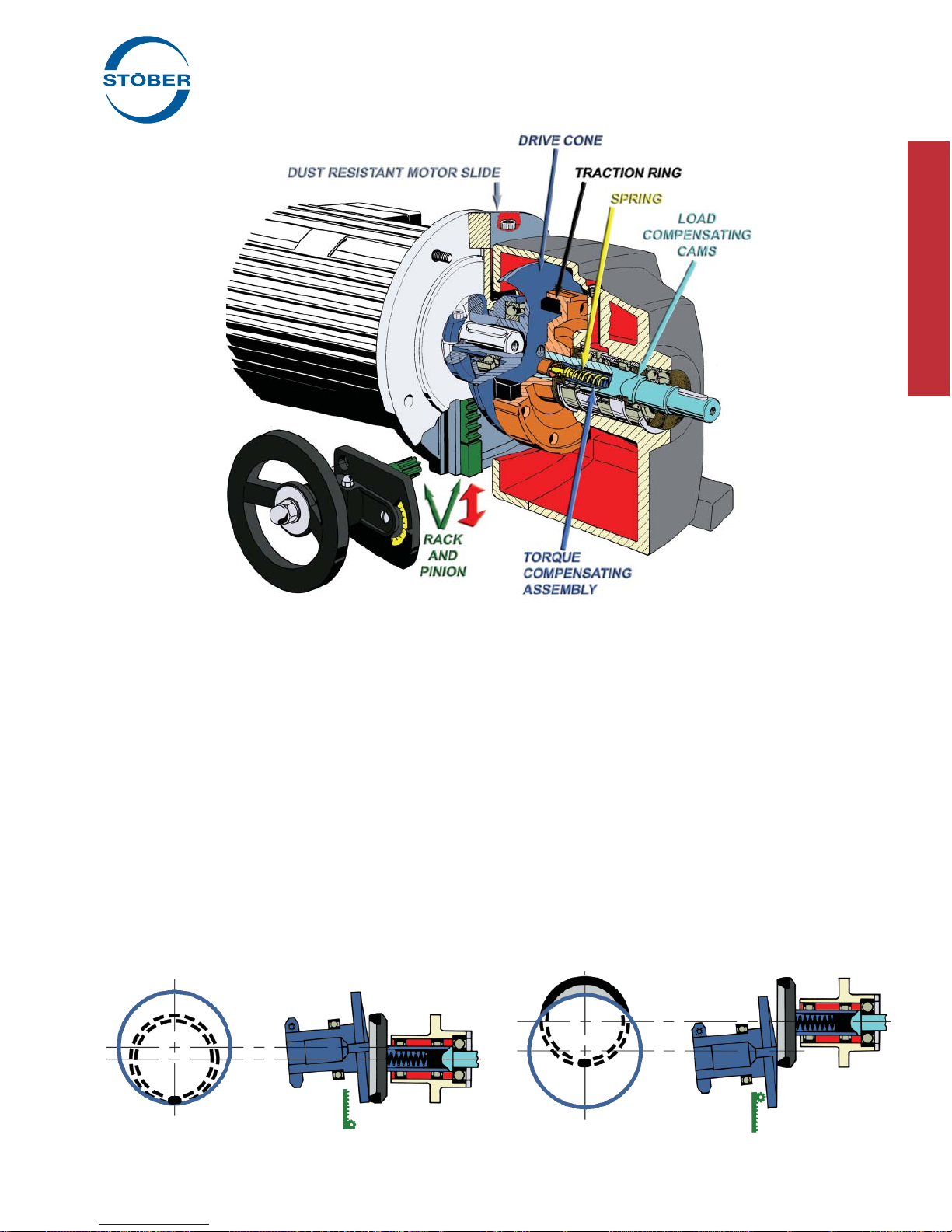

Speed changes are made by changing the relative running

diameters of the drive cone and the traction ring. As the motor

and drive cone are moved upward, the contact point between the

cone and ring moves to the faster running outer diameter of the

drive cone and output speed increases. As the motor and drive

cone are lowered, the contact point between the cone and ring

moves to the slower running center of the drive cone and output

speed decreases.

Movement of the motor and drive cone are accomplished

through the use of a handwheel attached to a rack and pinion.

By turning the handwheel, the motor is easily raised or lowered

on the dust resistant motor slide. Speed changes can also be

made through the use of an optional electric remote control which

replaces the handwheel.

Speed Control Made Simple!

• Turn the handwheel – pinion moves the rack on the motor slide – up or down.

Maximum speed – motor slide up. Minimum speed – motor slide down.

Contact Point

Contact Point

Operation:

The ComTrac drive is an adjustable speed traction drive. Its

operation is based upon the transfer of power between the motor

mounted drive cone and the traction ring. The drive cone and

the traction ring are forced together to transmit torque through

the use of a spring loaded torque compensator assembly.

At rest, the spring inside the torque compensator produces only

a small contact pressure between the drive cone and traction

ring. Unlike other mechanical drives, the minimal spring pressure

allows speed changes to be made while the drive is at rest.

As the drive is started, the load compensating cams move

against each other to increase pressure between the drive cone

and traction ring. During operation, the load compensating

cams maintain the proper amount of pressure between the drive

cone and traction ring in proportion to the output load torque

required.

Footed unit shown for illustration only.

This style is no longer available.

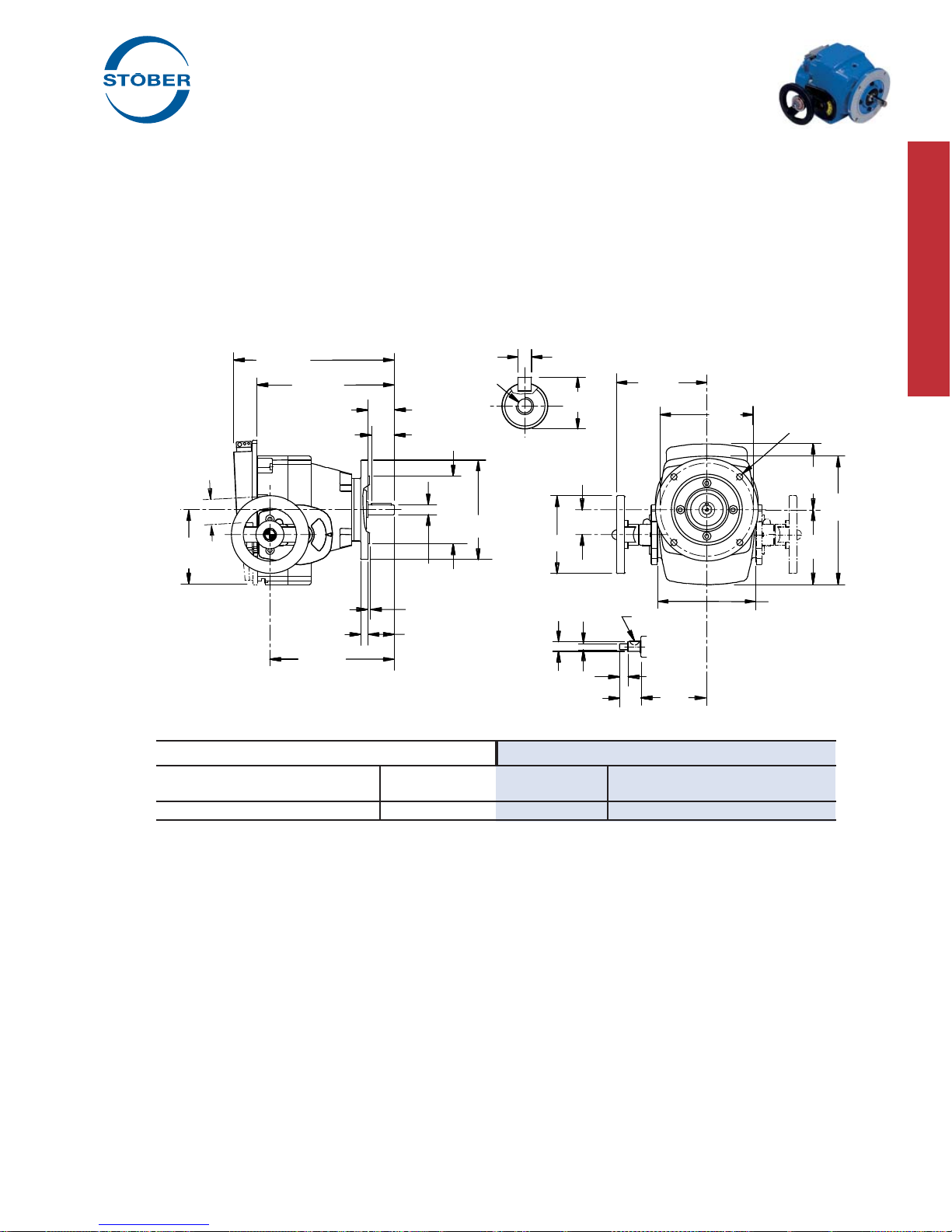

6STOBER Drives Inc. • ComTrac2012 • www.stober.com

Motor Slide

Adjustment

All ratings shown are based on 1750 RPM motor speed and are rated to provide constant torque through the entire speed range. Contact STOBER for

constant horsepower applications. MOTOR MUST BE ORDERED SEPARATELY.

1) Speed tolerance at rated load is ±3%. At less than rated load, minimum speed may increase 5%.

2) The ComTrac drive operates at constant horsepower above transition values and at constant torque below transition values. Note shaded area.

Engineering advances may cause slight changes to the information shown.

Constant Horsepower Range Constant Torque Range

MAXIMUM TRANSITION

(2) MINIMUM

RPM (1) in.lbs. HP RPM (1) in.lbs. HP RPM (1) in.lbs. HP

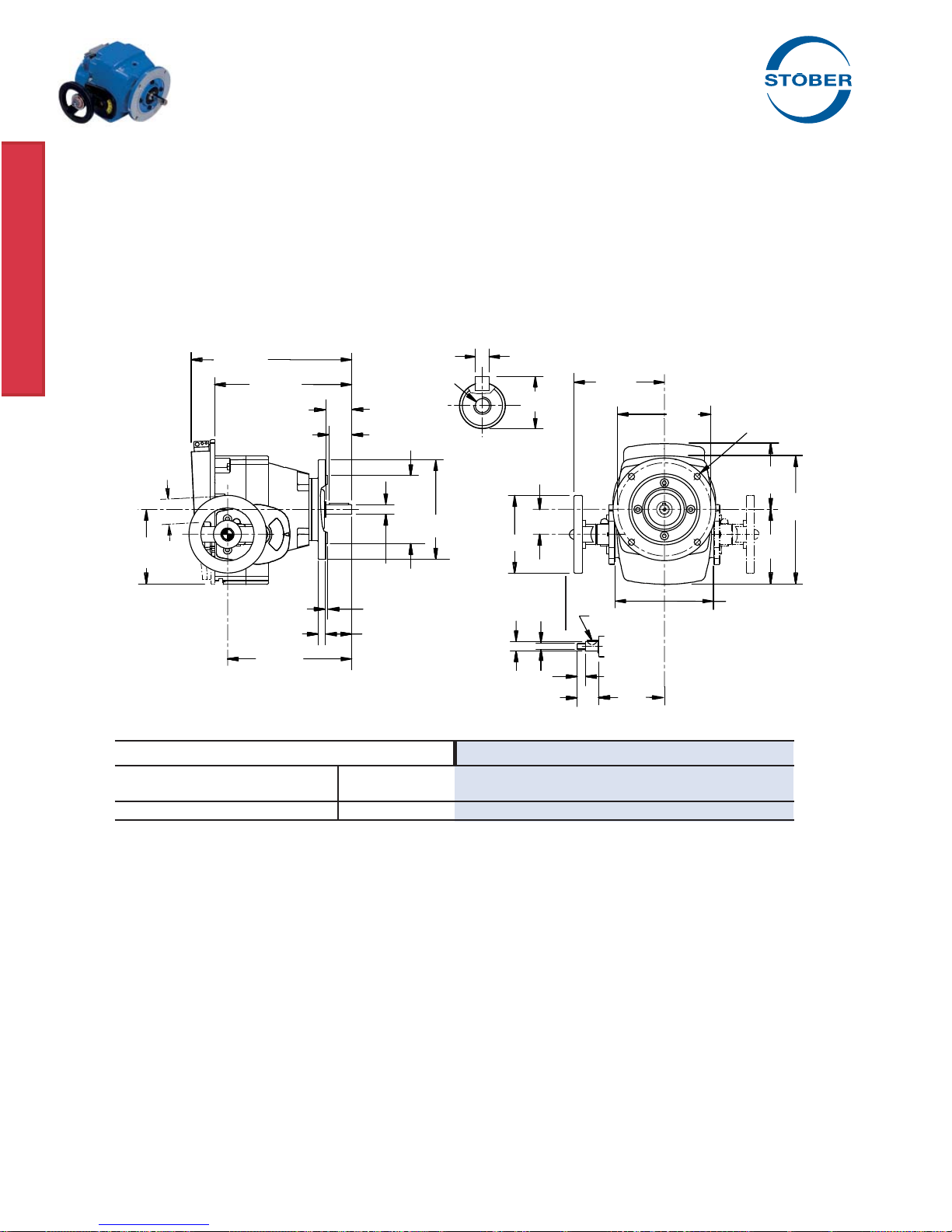

Part No. – 33 lbs.

TD270FK56

Flange Style

56C Input and Output

ComTrac®Adjustable Speed Drives

.50 HP @ 1750 RPM

All TD27 units are available with 56C and 143TC input.

10.67

8.86

1.87

4.41

4.72

8.07

.47

.625

+.0000

-.0005

4.500

+.000

-.001 6.50

2.06

.12

.1875 +.0000 / -.0005

x 1.38 Lg.

.71

#12-24 NC

1.57

4.92

M10

.5903

+.0000

-.0005 4.29

1.30

.51

5.875 3/8-16 NC

5.67

.20 x .26

1.65

6.22

8.11

Handwheel Shaft Dimensions

2.09

5.55

2,180 12.2 0.42 334 66 0.35 311 66 0.33

STOBER Drives Inc. • ComTrac2012 • www.stober.com 7

Motor Slide

Adjustment

All ratings shown are based on 1750 RPM motor speed and are rated to provide constant torque through the entire speed range. Contact STOBER for

constant horsepower applications. MOTOR MUST BE ORDERED SEPARATELY.

1) Speed tolerance at rated load is ±3%. At less than rated load, minimum speed may increase 5%.

2) The ComTrac drive operates at constant horsepower above transition values and at constant torque below transition values. Note shaded area.

Engineering advances may cause slight changes to the information shown.

Constant Horsepower Range Constant Torque Range

MAXIMUM TRANSITION

(2) MINIMUM

RPM (1) in.lbs. HP RPM (1) in.lbs. HP RPM (1) in.lbs. HP

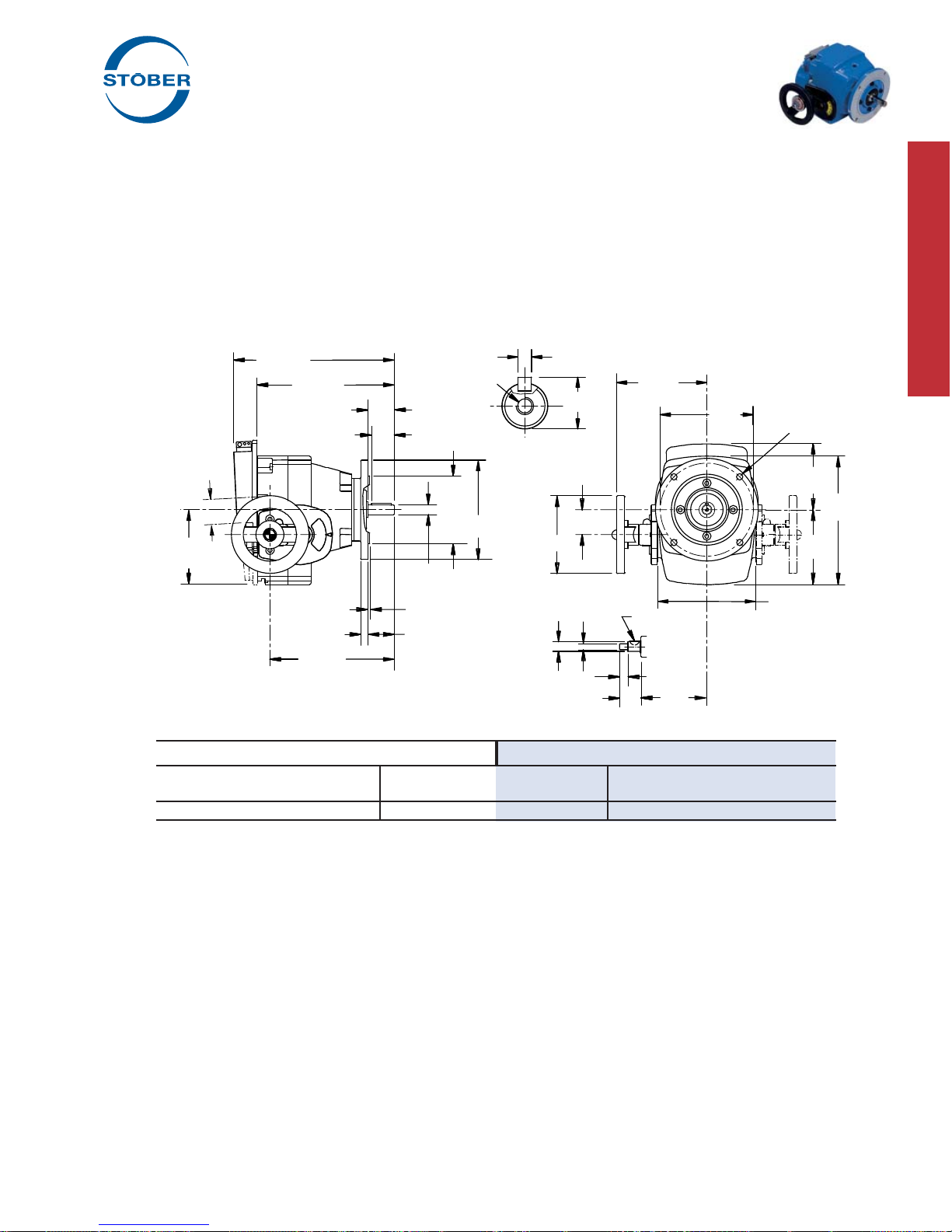

ComTrac®Adjustable Speed Drives

.75 HP @ 1750 RPM

All TD27 units are available with 56C and 143TC input.

2,180 18.3 0.63 582 66 0.61 311 66 0.33

Part No. – 33 lbs.

TD270FK56

Flange Style

56C Input and Output

10.67

8.86

1.87

4.41

4.72

8.07

.47

.625

+.0000

-.0005

4.500

+.000

-.001 6.50

2.06

.12

.1875 +.0000 / -.0005

x 1.38 Lg.

.71

#12-24 NC

1.57

4.92

M10

.5903

+.0000

-.0005 4.29

1.30

.51

5.875

3/8-16 NC

5.67

.20 x .26

1.65

6.22

8.11

Handwheel Shaft Dimensions

2.09

5.55

8STOBER Drives Inc. • ComTrac2012 • www.stober.com

Motor Slide

Adjustment

All ratings shown are based on 1750 RPM motor speed and are rated to provide constant torque through the entire speed range. Contact STOBER for

constant horsepower applications. MOTOR MUST BE ORDERED SEPARATELY.

1) Speed tolerance at rated load is ±3%. At less than rated load, minimum speed may increase 5%.

2) The ComTrac drive operates at constant horsepower above transition values and at constant torque below transition values. Note shaded area.

Engineering advances may cause slight changes to the information shown.

Constant Horsepower Range Constant Torque Range

MAXIMUM TRANSITION

(2) MINIMUM

RPM (1) in.lbs. HP RPM (1) in.lbs. HP RPM (1) in.lbs. HP

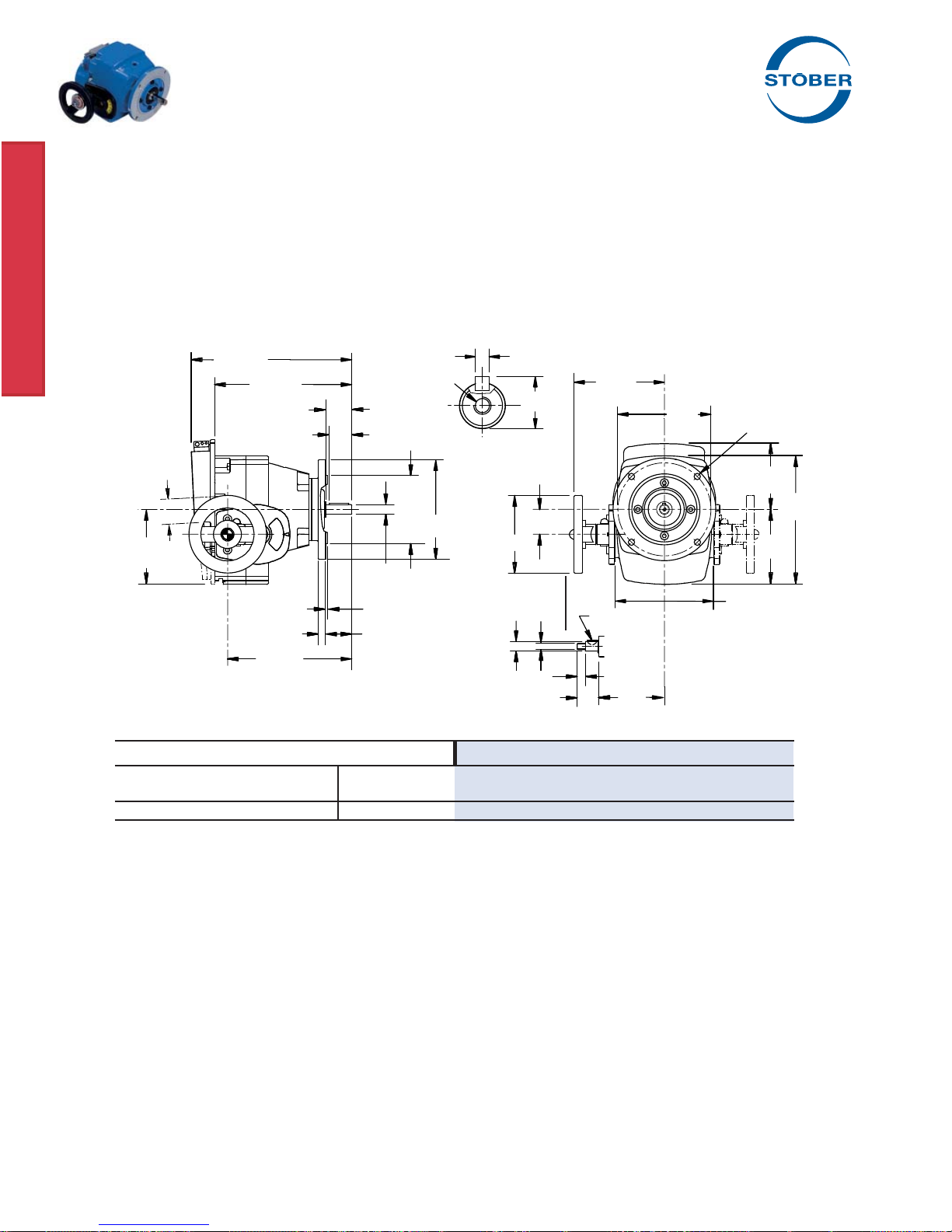

ComTrac®Adjustable Speed Drives

1.0 HP @ 1750 RPM

All TD27 units are available with 56C and 143TC input.

Part No. – 33 lbs.

TD270FK143

Flange Style

143TC Input

56C Output

10.67

8.86

1.87

4.41

4.72

8.07

.47

.625

+.0000

-.0005

4.500

+.000

-.001 6.50

2.06

.12

.1875 +.0000 / -.0005

x 1.38 Lg.

.71

#12-24 NC

1.57

4.92

M10

.5903

+.0000

-.0005 4.29

1.30

.51

5.875 3/8-16 NC

5.67

.20 x .26

1.65

6.22

8.11

Handwheel Shaft Dimensions

2.09

5.55

2,180 24.4 0.84 821 66 0.86 311 66 0.33

STOBER Drives Inc. • ComTrac2012 • www.stober.com 9

Motor Slide

Adjustment

All ratings shown are based on 1750 RPM motor speed and are rated to provide constant torque through the entire speed range. Contact STOBER for

constant horsepower applications. MOTOR MUST BE ORDERED SEPARATELY.

1) Speed tolerance at rated load is ±3%. At less than rated load, minimum speed may increase 5%.

2) The ComTrac drive operates at constant horsepower above transition values and at constant torque below transition values. Note shaded area.

Engineering advances may cause slight changes to the information shown.

Constant Horsepower Range Constant Torque Range

MAXIMUM TRANSITION

(2) MINIMUM

RPM (1) in.lbs. HP RPM (1) in.lbs. HP RPM (1) in.lbs. HP

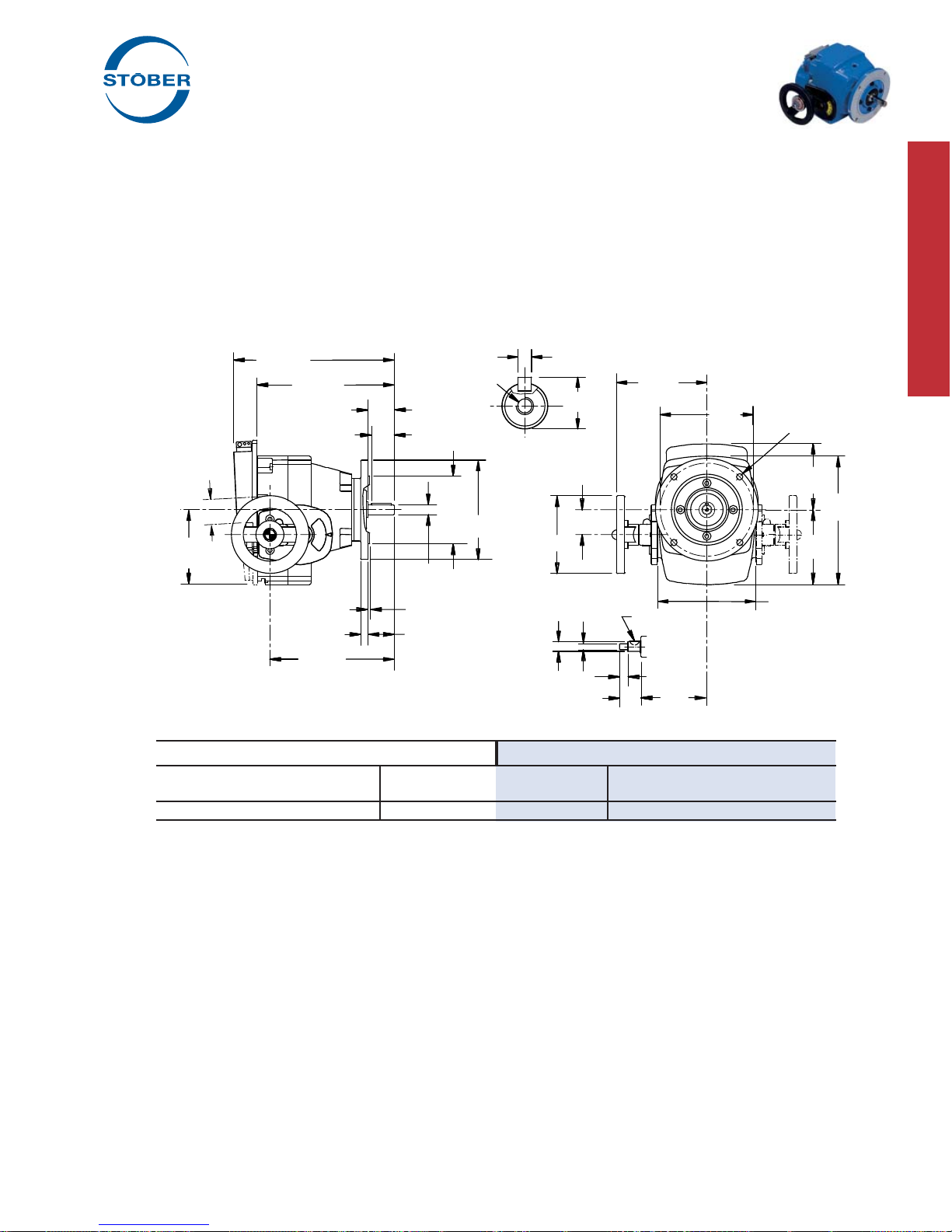

ComTrac®Adjustable Speed Drives

1.5 HP @ 1750 RPM

Part No. – 51 lbs.

TD370FK145

Flange Style

145TC Input

143TC Output

11.69

9.88

2.24

4.37

5.94

9.09

.47

.875

+.0000

-.0005

4.500

+.000

-.001 6.50

2.13

.12

.1875 +.0000 / -.0005

x 1.77 Lg.

.96

1/4-20 NC

2.05

4.92

M10

.5903

+.0000

-.0005 4.53

1.30

.51

5.875 3/8-16 NC

5.91

.20 x .26

1.97

6.69

9.72

Handwheel Shaft Dimensions

2.17

5.67

2,100 38 1.27 856 97 1.31 420 97 0.64

10 STOBER Drives Inc. • ComTrac2012 • www.stober.com

Motor Slide

Adjustment

All ratings shown are based on 1750 RPM motor speed and are rated to provide constant torque through the entire speed range. Contact STOBER for

constant horsepower applications. MOTOR MUST BE ORDERED SEPARATELY.

1) Speed tolerance at rated load is ±3%. At less than rated load, minimum speed may increase 5%.

2) The ComTrac drive operates at constant horsepower above transition values and at constant torque below transition values. Note shaded area.

Engineering advances may cause slight changes to the information shown.

Constant Horsepower Range Constant Torque Range

MAXIMUM TRANSITION

(2) MINIMUM

RPM (1) in.lbs. HP RPM (1) in.lbs. HP RPM (1) in.lbs. HP

ComTrac®Adjustable Speed Drives

2.0 HP @ 1750 RPM

2,100 51 1.70 1,162 97 1.79 420 97 0.65

Part No. – 51 lbs.

TD370FK145

Flange Style

145TC Input

143TC Output

11.69

9.88

2.24

4.37

5.94

9.09

.47

.875

+.0000

-.0005

4.500

+.000

-.001 6.50

2.13

.12

.1875 +.0000 / -.0005

x 1.77 Lg.

.96

1/4-20 NC

2.05

4.92

M10

.5903

+.0000

-.0005 4.531.30

.51

5.875 3/8-16 NC

5.91

.20 x .26

1.97

6.69

9.72

Handwheel Shaft Dimensions

2.17

5.67

STOBER Drives Inc. • ComTrac2012 • www.stober.com 11

Motor Slide

Adjustment

All ratings shown are based on 1750 RPM motor speed and are rated to provide constant torque through the entire speed range. Contact STOBER for

constant horsepower applications. MOTOR MUST BE ORDERED SEPARATELY.

1) Speed tolerance at rated load is ±3%. At less than rated load, minimum speed may increase 5%.

2) The ComTrac drive operates at constant horsepower above transition values and at constant torque below transition values. Note shaded area.

Engineering advances may cause slight changes to the information shown.

Constant Horsepower Range Constant Torque Range

MAXIMUM TRANSITION

(2) MINIMUM

RPM (1) in.lbs. HP RPM (1) in.lbs. HP RPM (1) in.lbs. HP

ComTrac®Adjustable Speed Drives

3.0 HP @ 1750 RPM

2,100 81 2.70 970 177 2.72 420 177 1.18

Part No. – 59 lbs.

TD470FK182

Flange Style

182TC Input

143TC Output

12.48

9.96

2.24

5.59

6.93

9.13

.47

.875

+.0000

-.0005

4.500

+.000

-.001 6.50

2.13

.12

.1875 +.0000 / -.0005

x 1.77 Lg.

.96

2.60

6.30

M10

.5903

+.0000

-.0005 5.241.30

.51

5.875

3/8-16 NC

6.81

.20 x .26

1.97

8.11

11.57

Handwheel Shaft Dimensions

2.80

7.20

1/4-20 NC

12 STOBER Drives Inc. • ComTrac2012 • www.stober.com

Motor Slide

Adjustment

All ratings shown are based on 1750 RPM motor speed and are rated to provide constant torque through the entire speed range. Contact STOBER for

constant horsepower applications. MOTOR MUST BE ORDERED SEPARATELY.

1) Speed tolerance at rated load is ±3%. At less than rated load, minimum speed may increase 5%.

2) The ComTrac drive operates at constant horsepower above transition values and at constant torque below transition values. Note shaded area.

Engineering advances may cause slight changes to the information shown.

Constant Horsepower Range Constant Torque Range

MAXIMUM TRANSITION

(2) MINIMUM

RPM (1) in.lbs. HP RPM (1) in.lbs. HP RPM (1) in.lbs. HP

ComTrac®Adjustable Speed Drives

5.0 HP @ 1750 RPM

2,100 137 4.56 1,102 266 4.65 420 266 1.77

Part No. – 88 lbs.

TD570FK184

Flange Style

184TC Input

182TC Output

15.98

13.39

2.75

6.30

8.11

12.32

.83

1.125

+.0000

-.0005

8.500

+.000

-.001 9.00

2.62

.26

.25 +.0000 / -.0005

x 2.20 Lg.

1.24

3/8-16 NC

3.35

7.87

M12

.7871

+.0000

-.0005 6.541.50

.59

7.250 1/2-13 NC

8.31

.20 x .30

2.40

9.61

13.43

Handwheel Shaft Dimensions

3.11

8.11

STOBER Drives Inc. • ComTrac2012 • www.stober.com 13

The STOBER Electric Remote Control (ERC) is a compact double

reduction gearmotor which is pinion mounted to the motor slide

track in place of the handwheel. A mechanical clutch within the

unit indicates the end of vertical motor travel in both directions by

making a clicking noise.

The ERC can be operated by push button or other type of control

(not included) to adjust the drive's speed. In many applications

it is advisable to use a limit switch with the ERC to prevent over-

speed or underspeed conditions.

Features:

• Speed changes can be made when the unit is stationary or

running.

• STOBER ERC can be quickly and easily added to existing

ComTrac drives without special tools.

• All STOBER ERC units are designed for washdown/severe

duty applications and are available from stock.

• Available voltages:

– 115V, single phase, 60 Hz

– 230/460V, three phase, 60 Hz

ComTrac®Adjustable Speed Drives

Electric Remote Control

Table No. 1 ERC – Dimensions (Inches)

ComTrac Model Number

Size Single Phase Three Phase A B C

TD27 ERC27-1 ERC27-2 6.18 7.09 9.72

TD37 ERC37-1 ERC37-3 6.14 7.05 9.68

TD47 ERC47-1 ERC47-3 7.12 8.03 10.67

TD57 ERC57-1 ERC57-3 7.56 9.06 11.10

Motor dimensions may vary slightly from values shown.

Reference point for handwheel center.

Motor Clearance

On some TD27 ComTrac units, the motor can be lower than the base of the unit when adjusted to the slowest setting. The following formula

will determine a value based on the length of the motor to be installed.

XX = .055 x B (When "B" = motor length)

XX

B

ERC for ComTrac sizes: TD57

1.85

9.96

2.72

BA

C2.28

2.09

4.92

ERC for ComTrac sizes: TD27, TD37, and TD47.

1.85

9.96 2.72

BA

C

2.28

2.09

4.92

Footed unit shown for illustration only.

This style is no longer available.

14 STOBER Drives Inc. • ComTrac2012 • www.stober.com

Selection:

The ComTrac drives shown in the selection tables are rated for

constant torque operation – where required horsepower varies di-

rectly in proportion to the speed of the driven machine. All ratings

shown are based upon standard NEMA C-face motor designs with

1750 RPM input speed. Contact STOBER technical support for

selection assistance for motor speeds other than 1750 RPM.

Basic selection procedure is as follows:

1. Establish the maximum horsepower required by the driven

machine at maximum speed.

If only the driven equipment's maximum torque (T) require-

ment is known, use the following formula to convert the torque

value to horsepower: T x RPM

HP =

63,025

2. Select the drive which meets or exceeds the maximum HP

rating of the driven machine at maximum speed.

Since the typical ComTrac application requires constant torque

over the entire speed range, there will be an adequate service

factor to protect the traction ring from damage.

Use the output speed ratings shown in the tables to select an out-

put speed which meets or exceeds the requirement of the driven

machine. Read across the table to determine if the drive's actual

minimum and maximum speed, torque, and horsepower ratings

meet the requirements of the driven equipment.

If the maximum output speed shown in the table is too low, go to

the next higher speed. Should the torque or horsepower ratings

shown be below the driven equipment's requirements, consult the

next higher horsepower rating in the selection data.

Motor Performance

The ratings shown in the ComTrac selection tables are based on

standard NEMA motors with the following specifications:

• 1750 RPM speed

• 60 Hz operation

Application Matched Options

Several options for ComTrac drives, such as remote controls, are

included in this catalog. In addition, the following options are also

available:

• 50 Hz operation for export

• Motor enclosures

For application and selection assistance for these options and

others, contact your local STOBER distributor.

Non-Standard Application Conditions

For constant horsepower applications, or any of the nonstandard

application conditions shown below, contact STOBER technical

support.

Unusual Loading Conditions:

• Heavy shock load

• High inertia load

• Load reversals or overhauling loads

• More than ten starts per hour

Unusual Environmental Conditions:

• High altitudes – above 5000 feet

• Corrosive chemicals

• Excessively dusty or abrasive environments

• Ambient temperatures below 25° F or above 125° F

Nonstandard Motors:

• Motor frame sizes other than those shown in the tables

Nonstandard Mounting:

• Output shaft up or down (V5 or V6 mounting)

Not Recommended for Mounting:

• Explosive environment of any type

Performance Characteristics

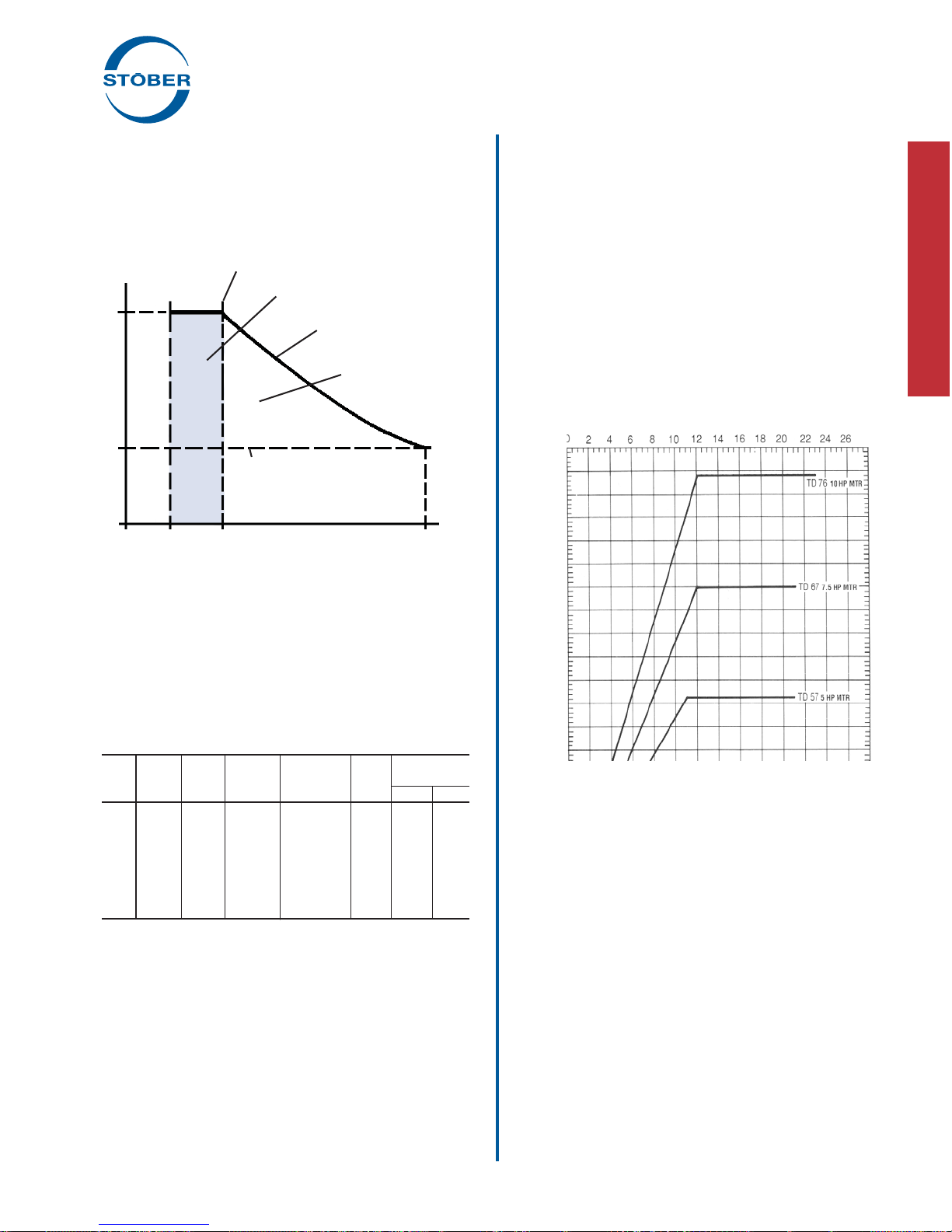

Because of its mechanical operation, the ComTrac drive gener-

ally produces constant output torque. While the induction motor

produces constant horsepower and constant speed, the two are

combined in a manner that provides optimum utility and economy.

As the ComTrac Performance Chart shows, the drive has two

operating regions.

1. Constant torque between the drive's absolute minimum

speed and transition speed.

2. Constant horsepower between the transition speed and

maximum speed.

When selecting a ComTrac drive, it is important to choose a unit

which will not allow the cone and ring system to be over powered

by the motor. As shown in the ComTrac Performance Chart, Com-

Trac drives should always be selected so that the output torque

required is well below the torque capability of the cone and the

ring system.

ComTrac®Adjustable Speed Drives

Selection and Performance Characteristics

STOBER Drives Inc. • ComTrac2012 • www.stober.com 15

TRANSITION SPEED

Output Torque (in.lbs.)

Min. Trans. Max.

Output Speed (RPM)

Torque Capacity of the Cone/Ring System

Constant Torque Operating Range

Constant Motor Output HP

Constant HP Operating

Range

Torque Rating at Maxi-

mum Speed

ComTrac®Adjustable Speed Drives

Selection and Performance Characteristics

Table No. 1

ComTrac Series 0F Specifications

Output C-Face Output Speed

Motor NEMA Torque Model Output Speed Range (RPM)

HP Frame in.lbs. Number Flange Range Max. Min.

.50 56C 16 TD270F 56C 7:1 2180 311

.75 56C 24 TD270F 56C 7:1 2180 311

1.00 143TC 32 TD270F 56C 7:1 2180 311

1.50 145TC 48 TD370F 143/145TC 5:1 2100 420

2.00 145TC 64 TD370F 143/145TC 5:1 2100 420

3.00 182TC 99 TD470F 143/145TC 5:1 2100 420

5.00 184TC 168 TD570F 182/184TC 5:1 2100 420

Minimum output torque rating based on 1750 RPM maximum input

speed.

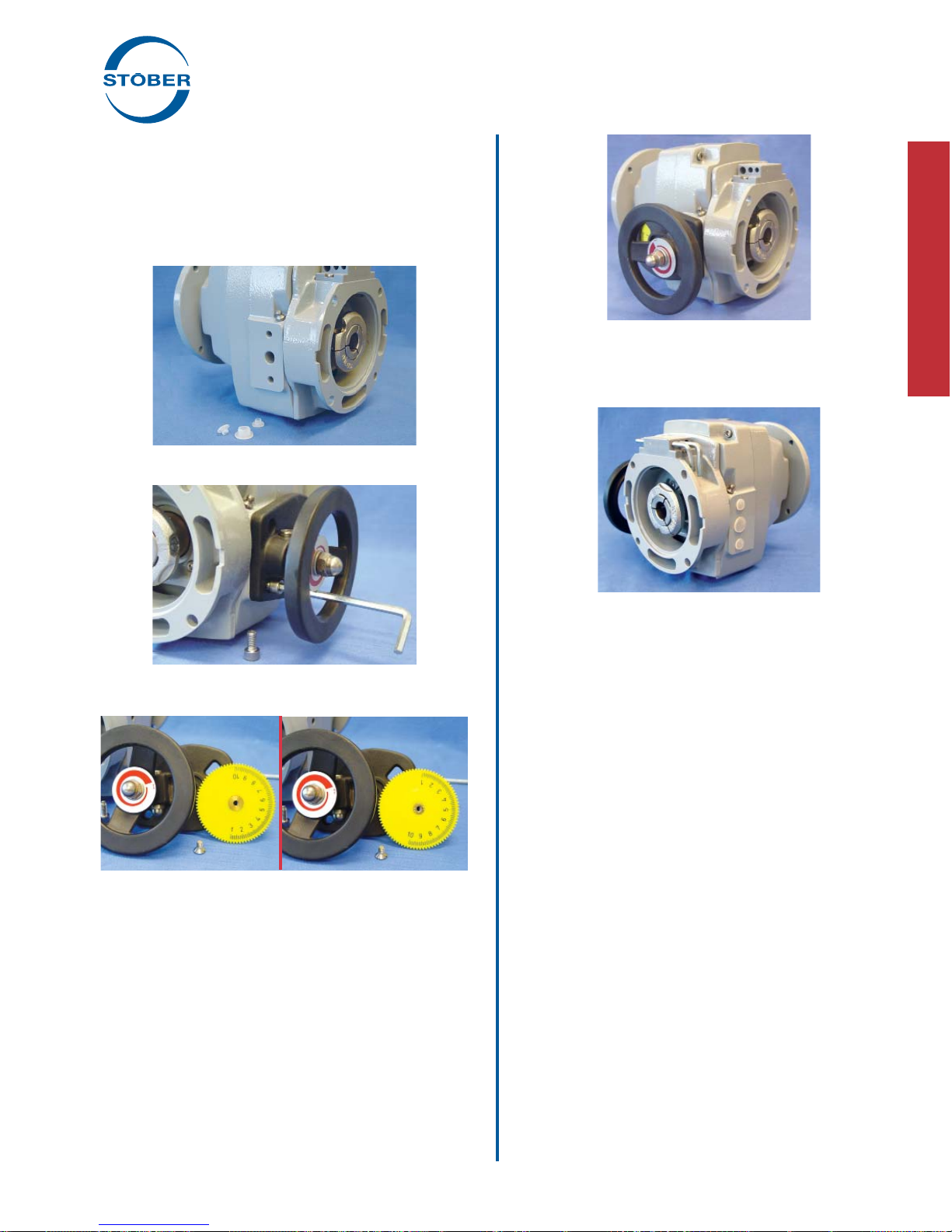

0 2 4 6 8 10 12 14 16 18 20 22 24 26

Output Speed (RPM x 10)

Output Horsepower (HP) Rating

Graph No. 2 ComTrac Series 0F Output HP

TD57, 5 HP motor

TD47, 3 HP motor

TD37, 2 HP motor

TD37, 1.5 HP motor

TD27, 1.0 HP motor

TD27, .5 HP motor

TD27 .75 HP motor

7

6

5

4

3

2

1

Graph No. 1 ComTrac Performance Chart

Overhung Loads

16 STOBER Drives Inc. • ComTrac2012 • www.stober.com

Step 4 – Through the access hole, tighten the hex socket screw

on the motor clamp hub to the tightening torque shown in the table

below. The correct size hex wrench is

provided. DO NOT OVERTIGHTEN.

SHOWN WITHOUT MOTOR FOR

DEMONSTRATION.

Table No. 1

Clamp Ring Setscrew Tightening Torque

ComTrac Size in. lbs.

TD27 88.5

TD37 88.5

TD47 221

TD57 434

Step 5 – Reattach access cover.

When couplings, gears, sprockets or pulleys are mounted on the

output shaft, be sure to mount them as close as possible to the

housing to minimize the effects of overhung loads on shafts and

bearings.

CAUTION: Do not drive couplings, sprockets, gears or pulleys

onto the output shaft with hard hammer blows, since damage to

internal gears or bearings will result. All output shafts have a met-

ric centering thread for attachment of transmission devices. They

can be pulled on gently with a bolt and plate.

ComTrac®Adjustable Speed Drives

Installation Instructions

ComTrac Series 0F

Units with C-face input and output are de-

signed to attach to any speed reducer with

a NEMA C-face input. Care must be taken

to follow the speed reducer manufacturer's

recommended mounting instructions.

NOTE: ComTrac Series 0F drives do not

have mounting feet. The drive and motor assembly is mounted on

the speed reducer which must support the reducer, ComTrac, and

the motor. If there is concern for the ability of the reducer mount-

ing feet to support the entire assembly, a larger speed reducer

may be required.

The output shaft of the ComTrac drive is shipped from the factory

with a protective coating. Remove this coating with a suitable

nonflammable solvent. Precaution must be taken not to allow the

solvent to contact the output shaft oil seal, since damage to the

seal may occur.

Motor Installation

Step 1 – Remove the access cover.

Step 2 –Lubricateandinsertkeyed motor shaft into the slottedbore

of the drive cone shaft.

NOTE: For ease of installation, secure the key to the motor shaft.

(Staking near the end of the keyway or a temporary adhesive

works well.)

Step 3 – Tighten the four motor flange bolts.

IMPORTANT: Jog the motor several revolutions before

tightening the motor clamp to assure proper position of the

drive cone on the motor shaft. See Page 5 for illustration.

STOBER Drives Inc. • ComTrac2012 • www.stober.com 17

ComTrac®Adjustable Speed Drives

Installation Instructions

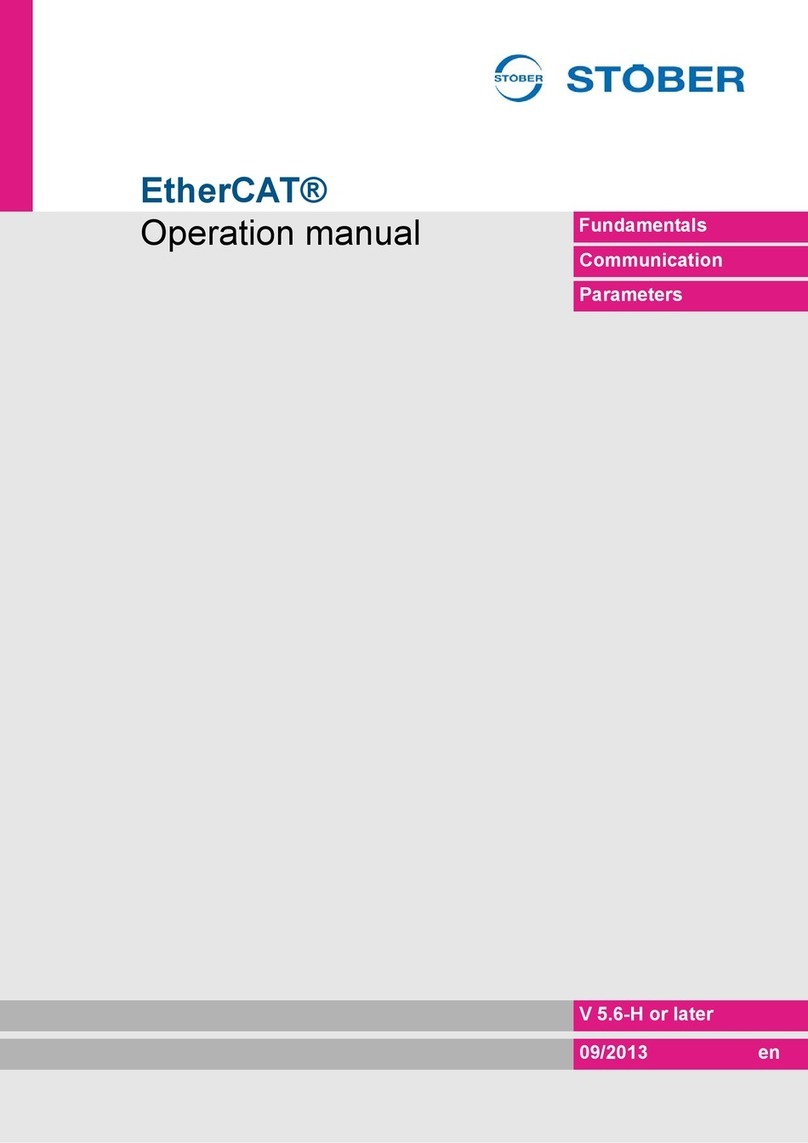

Handwheel Position

ComTrac drives are furnished with the speed control handwheel

on the left, as viewed from the output shaft end of the drive. If it is

necessary that the handwheel be moved to the opposite side, this

can be accomplished very easily with the hex wrenches provided

with each drive.

Procedure for Changing Handwheel Position:

Step 1 – Remove the three (3) plastic plugs in the housing on the

side opposite the handwheel.

Step 2 – Remove the handwheel and indicator assembly by remov-

ingthetwo(2)socket-headcapscrews which secure the handwheel

indicator assembly to the housing.

Step 3 – Turn the yellow numbered position indicator wheel around

byremovingtheslottedscrew.(Besuretoremovethetapecovering

to expose position numbers on the other side of the wheel.)

Step 4 – Replace the slotted screw.

Step5–Placepinion,handwheelandindicatorondesiredsideofthe

drive's housing (from where the three plastic plugs were removed),

andsecurewiththetwosocket-headcapscrewsremovedpreviously.

Step6–Relocatetheplasticplugstotheholeswherethehandwheel

was originally mounted.

Lubricate the motor slide and rack (both sides) with one (1) stroke

with a grease gun through the fittings provided in the housing.

IMPORTANT: Do not over lubricate the motor slide. Under nor-

mal conditions, maintenance of the motor slide and rack should

only be required one time per year.

Electric Remote Control (ERC) Installation

The Electric Remote Control consists of a small gearmotor

mounted on the ComTrac drive in place of the manual handwheel

control.

Procedure

Attaching the ERC is accomplished by simply removing the two

(2) socket-head capscrews that secure the handwheel and indica-

tor assembly to the drive's housing.

Replace the handwheel/indicator assembly with the ERC and

secure it to the housing with the same two screws.

Lubricate the motor slide and rack (both sides) with one (1) stroke

with a grease gun through fittings in the housing.

The ERC is operated by pushbutton or other form of contact

(furnished by customer). A mechanical clutch is contained within

the gearmotor which indicates the end position of travel, in either

direction, by making a clicking noise. Also, the ERC can be oper-

ated while the drive is stationary.

Power required for the ERC is 230 volt, 3 phase, 60 hertz, or 115

volt, single phase, 60 hertz.

The wiring diagram for the ERC is inside the motor's conduit box.

The ERC motor and drive should be protected from excessive

dust, flying chips, and oil splashes.

18 STOBER Drives Inc. • ComTrac2012 • www.stober.com

Maintenance and Lubrication

WARNING: Before beginning any work on the ComTrac drive

system, disconnect the power source (lock-out the motor

starter, and unload breakers, backstops, etc.). Failure to

do so may cause serious personal injury and/or machinery

damage.

Series 0F

These units require lubricant only in the cam and bearing

chamber and are shipped with the lubricant in them. There is a

sufficient quantity of lubricant to allow mounting the non-geared

ComTrac Drive in any position.

Table No. 1

Series "0" – Bearing and Cam Chamber Oil Quantity

ComTrac Size fluid oz.

TD27-0 1.5

TD37-0 1.7

TD47-0 1.9

TD57-0 4.4

For normal indoor installations the handwheel or ERC control pin-

ion and motor slide rack should be lubricated through the grease

fitting every six months using NLGI No. 2 grease. One stroke of

a grease gun is sufficient. When the drive is operating under wet

conditions, increase the frequency of lubrication to once a month.

Under normal operating conditions the synthetic oil in the cam

and bearing chamber does not need to be replaced. If for any

reason some quantity of lubricant is lost, remove the rest of the

lubricant from the cam and bearing chamber and replace it with

the type and quantity of oil listed in the lubrication table shown.

Table No. 2 Bearing and Cam Oil Manufacturers

Lubricant

Manufacturer AGMA Lubricant ( No. 5EP)

Darmex 9140

Exxon Spartan 220

Mobil * Mobilgear 630

Gulf HD220

Keystone KSL-366

Lubriplate APG90

* Mobile SHC626 is used for the initial fill. If refill is necessary, any of

the above products may be used.

For installations in the food, dairy, beverage and baking indus-

tries, where special lubricants are required, a suitable grease of

the user's preference should be used.

When a ComTrac Drive with C-face output (Series 0F) is attached

to a speed reducer, follow the manufacturer's lubrication instruc-

tions for the reducer mounting before start-up.

ComTrac®Adjustable Speed Drives

Maintenance and Lubrication Instructions

In order to obtain long life and trouble-free operation from your

ComTrac®drive, it is essential that proper installation and operat-

ing procedures be followed.

The torque required by the application must not exceed the

reducer torque capacity shown on the nameplate. For safety pur-

poses a safety coupling should be installed between the reducer

and the driven load. Otherwise, overload may cause damage to

the interior parts of the reducer which may result in breaking the

reducer housing. As a result, persons could be injured by flying

parts or splashing hot gear oil.

This catalog includes basic directions for mounting and start-up of

the ComTrac®drive, as well as lubrication information. Failure to

follow these instructions will void the drive's warranty.

If you have questions about the installation, operation or mainte-

nance of your ComTrac®drive, please contact your local STOBER

distributor for assistance.

WARNING:

Safety is the most important consideration when operating any

type of drive. Through proper application, safe handling methods,

and wearing appropriate clothing, you can prevent accidents and

injury to yourself and fellow workers.

The shafts of ComTrac®drives rotate at very high speeds and

can cut off or severely injure hands,

fingers, and arms. Use appropriate

guards for shafts and other rotating

parts at all times. Follow all directions

in the service instruction manual.

Obey all federal, state and local safety

regulations when operating the drive.

• Always be sure electrical power is off while making electrical

connections and during installation and maintenance of the

unit.

• Keep clothing, hands, and tools away from ventilation open-

ings on motors and from all rotating parts during operation.

• Lift drive with a double rope sling or other proper lifting

equipment of adequate strength. Make sure load is secured

and balanced to prevent shifting when unit is being moved.

Lifting heavy drives by hand may be dangerous and should be

avoided.

• The intended use of lifting lugs is to handle the weight of the

unit only. Never use a lifting lug to lift attached assemblies.

• Never operate drive at speeds higher than those shown on

the nameplate, or personal injury may result. Contact STO-

BER Drives Inc., if there is any change of operating conditions

from those for which the unit was originally sold (as stamped

on the nameplate). Failure to comply could result in personal

injury and or machinery damage.

• Always follow good safety practices at all times.

Each drive is tested before delivery. Before installation, however,

it is advisable to examine the unit for possible damage which

might have occurred during transit. If damage is discovered, it

should be immediately reported to the transport agent.

If installation is delayed after receipt of the MGS speed reducer,

the drive should be stored in a clean, dry place until put into ser-

vice. Long term storage requires special procedures. If not kept

in a heated, dry area, consult STOBER Drives, Inc. for storage

instructions.

NOTE: If it is necessary to clean drive shafts, take care to protect

the oil seals.

IMPORTANT: Do not use any device to hammer the unit onto the

output shaft during installation since the bearing races could be

damaged.

WARNING

Cover rotating

parts with safety

guard before

turning on

power.

Table of contents

Other Stober Inverter manuals

Stober

Stober MDS 5000 User manual

Stober

Stober POSIDYN SDS 5000 User manual

Stober

Stober POSYDYN SDS 4281 Operator's manual

Stober

Stober POSIDRIVE FDS 5000 series User manual

Stober

Stober POSIDRIVE FDS 5000 series User manual

Stober

Stober POSITool MDS 5000 User manual

Stober

Stober POSIDRIVE MDS 5000 User manual

Stober

Stober POSIDRIVE MDS 5000 User manual