STOLZENBERG TwinSweep 900E User manual

htttp://www.stolzenberg.de

!

Instruction Manual

(Translation of the Original Version)

EN

TwinSweep 900E

2021-01-11

2

This operating manual contains instructions for using the

sweeper.

Carefully keep the operating manual so that you can refer to it

later.

Our products are being continuously improved. Design changes

after going to print may therefore not be considered. If you have

any questions, please contact our Service department (for

contact details, see page 17).

Carefully study the operating manual and the general

safety instructions before you unpack the machine

any further or undertake first start up.

The operating manual is to be read attentively and followed by

any person that operates the sweeper.

3

1.1 CONTENTS

1 CONTENTS / CONTENTS / GENERAL

1.

Contents, General

….3

1.1

Contents

.…3

1.2

Proper Use

….3

1.3

EC Conformity Declaraon

.…3

1.4

Rang Plate

.…3

1.5

Explanaon of Symbols

.…4

2.

Construcon, Funcon, Technical Data

.…4

2.1

Packing Contents

.…4

2.2

Funcon

.…4

2.3

Operang and Funconal Components

.…4

2.4

Technical Data

.…5

3.

Safety

.…6

3.1

Safety Instrucons

.…6

3.2

Symbols in the Operang Manual

.…6

3.3

Symbols on the Sweeper

.…6

3.4

Safety Equipment

.…6

4.

Seng Up/Before Start Up/Start Up/Transport

....7

4.1

Unpacking the Sweeper

.…7

4.2

Waste Disposal / Recycling

.…7

4.3

Adjusng the Transport Bar

.…7

4.4

Fing the Side Brushes

.…7

4.5

Opening the Front Panel

.…8

4.6

Closing the Front Panel

.…8

4.7

Before Start Up/Transport Weight

.…8

4.8

Baeries / Charger

.…8/9

4.8.1

Fing Baeries and Connecng

.…9

4.8.2

Baery Connecon Diagram

.…9

4.8.3

Charging Baeries / Baery Charge Indicator (LBF)

.…10

4.8.4

Charger

.…10

4.8.5

Removing Baeries

.…10

4.9

Start Up

.…11

5.

Operaon

.…11

5.1

Starng Sweeper

.…11

5.2

Driving Sweeper

.…11

5.3

Sweeping Operaon with Side Brushes, Roller Brush

and Fan

.…11

5.4

Switching Off Sweeper

.…12

5.5

Transporng the Machine

.…12

5.6

Cleaning the Dust Filter

.…12

5.7

Emptying the Dirt -

Hopper

.…12

6.

Troubleshoong

….

13

7.

Care and Maintenance (Minor Repairs)

.…12/13

7.1

General Cleaning

.…14

7.2

Changing / Cleaning the Filter

.…14

7.3

Inserng the Filter

.…15

7.4

Tipping the Sweeper

.…15

7.5

Changing the

Roller Brush

.…15

7.6

Seng Roller Brush Clearance

.…16

7.7

Changing the Side

Brushes

.…16

7.8

Seng the Side Brushes

.…16

7.9

Changing the Front Sealing Rubber

.…16

7.10

Changing the Side Sealing Rubber

.…17

7.11

Seng / Replacing the Drive Bowden Cable

.…17

7.12

Seng / Replacing the Side Brush Bowden Cable

.…17

7.13

Important Spare Parts and Consumables / Contact

.…17

7.14

Contact Data

.…18

7.15

Maintenance Work / Maintenance Table

.…18

8

Shut Down, Dismantling, Disposal

.…19

9

Circuit Diagram

.…20

Only use the sweeper according to the specifications in this

operating manual.

The sweeper is only intended for sweeping hard standing areas

(e.g.: car parks, pavements, warehouses). The sweeping

environment must not be wet.

The sweeper must only be operated by reliable, instructed

personnel.

Prevent it from being used by children, young people and other

unauthorised persons, e.g. by removing the key after use.

Any other usage beyond this is deemed to be improper use (see

“Safety Instructions”, chapter 3). The manufacturer is not liable

for any damage resulting from this.

The user is solely responsible for the risk.

Proper use also includes following the operating manual, the

safety instructions and keeping to the servicing and

maintenance specifications.

Only operate in expressly assigned routes and places.

Observe the maximum climbing ability specified in the technical

data and maximum possible slope inclination for operating

across slopes. Due to an abrupt change of direction, particularly

on slopes, the sweeper may tip. Adapt your operating manner

and speed to the conditions.

Follow the instructions on suitable ground (asphalt, screed,

industrial floors, concrete, paving stones etc.)

The rating plate is attached on the top of the frame below

the front panel.

1.4 RATING PLATE

1.4 EG KONFORMITÄTSERKLÄRUNG

1.2 PROPER USE

1.3 EC DECLARATION OF CONFORMITY

4

1.5 EXPLANATION OF SYMBOLS

DANGER! ......indicates a possibly dangerous situation

that can cause death or serious injuries.

CAUTION! ......indicates a possibly dangerous situation

that can cause minor injuries.

INSTRUCTION .....indicates important information.

WARNING ...indicates a possibly dangerous situation

that may cause material damage.

Stolzenberg GmbH & Co. KG

Hamburger Str. 15-17

49124 Georgsmarienhütte

Germany

www.stolzenberg.de Made in Germany 2020

MODEL:

SERIAL NUMBER:

PROTECTION:

GVW:

TwinSweep 900E PRO

XXXXXXXXX

IPX3

165 kg

max. 2%

TwinSweep 900E

The TwinSweep 900E is a battery-operated, hand-driven

pedestrian-controlled vacuum sweeper fitted with the tandem

roller system (TRS).

The TRS allows large sweeping materials to be swept up without

difficulty. The sweeper has a powerful vacuum function.

2 CONSTRUCTION, FUNCTION, TECHNICAL DATA

In the tandem roller system (TRS), sweeping materials are first

conveyed by means of the side brush (a) from the corners and

edges of the sweeping area into the centre of the machine and

therefore towards the two counter-rotating roller brush (b).

From this, the sweeping material is taken up and conveyed into

the dirt-hopper (c) situated at the back.

The dust stirred up by the sweeping process is vacuumed up by

a vacuuming system (fan) (d), filtered by flat-pleat filter (e) and

thus separated from the clean air.

Electro-mechanical filter cleaning (f) removes the dust caked

onto the flat-pleat filter and allows this to drop into the

dirt-hopper.

2.3 OPERATING AND FUNCTIONAL COMPONENTS

Overview:

2.2 FUNCTION

a

b

c

d

f

e

111

11

2

11

5

11

4

11

6

117

11

10

11

11

11

8

11

3

11

9

11

12

11

13

11

11121117 15 16 14

11

18

11

19

11

20

12

* The version of the machine may differ from the illustration

* The version (Basic, Plus or Pro) of the

machine may differ from the illustration

2.1 PACKAGING CONTENTS

TS900E

LED

* External charger only for Basic version

** The machine may differ from the illustration

**

*

13 Key Switch (Main Switch)

14 Side Brush Switch

15 Roller Brush Switch

16 Fan/Shaker Selector (Only Pro)

17 Charge Indicator/Hours Meter

18 Battery/Batteries (Basic 1x50Ah /

Plus 1x75 Ah / Pro 2x50Ah)

19 Charger on Board

(only Plus and Pro, Basic External Charger)

20 LED Front Light (only Pro)

21 Filter cover

22 Side Sealing Rubber

23 Front Sealing

1 dirt-hopper

2 Shaker rod (Basic + Plus)

3 filter cleaning

Mechanical (Basic + Plus)

electrical “by touch of a button” (Pro)

4 Transport Bar

5 Transport Lever

6 Brush Selector

7 Roller Brush

8 Flat-Pleat Filter

9 Control Panel

10 Side Brushes

11 Vacuuming System (Fan)

5

21

11121122

11

12

11

23

6

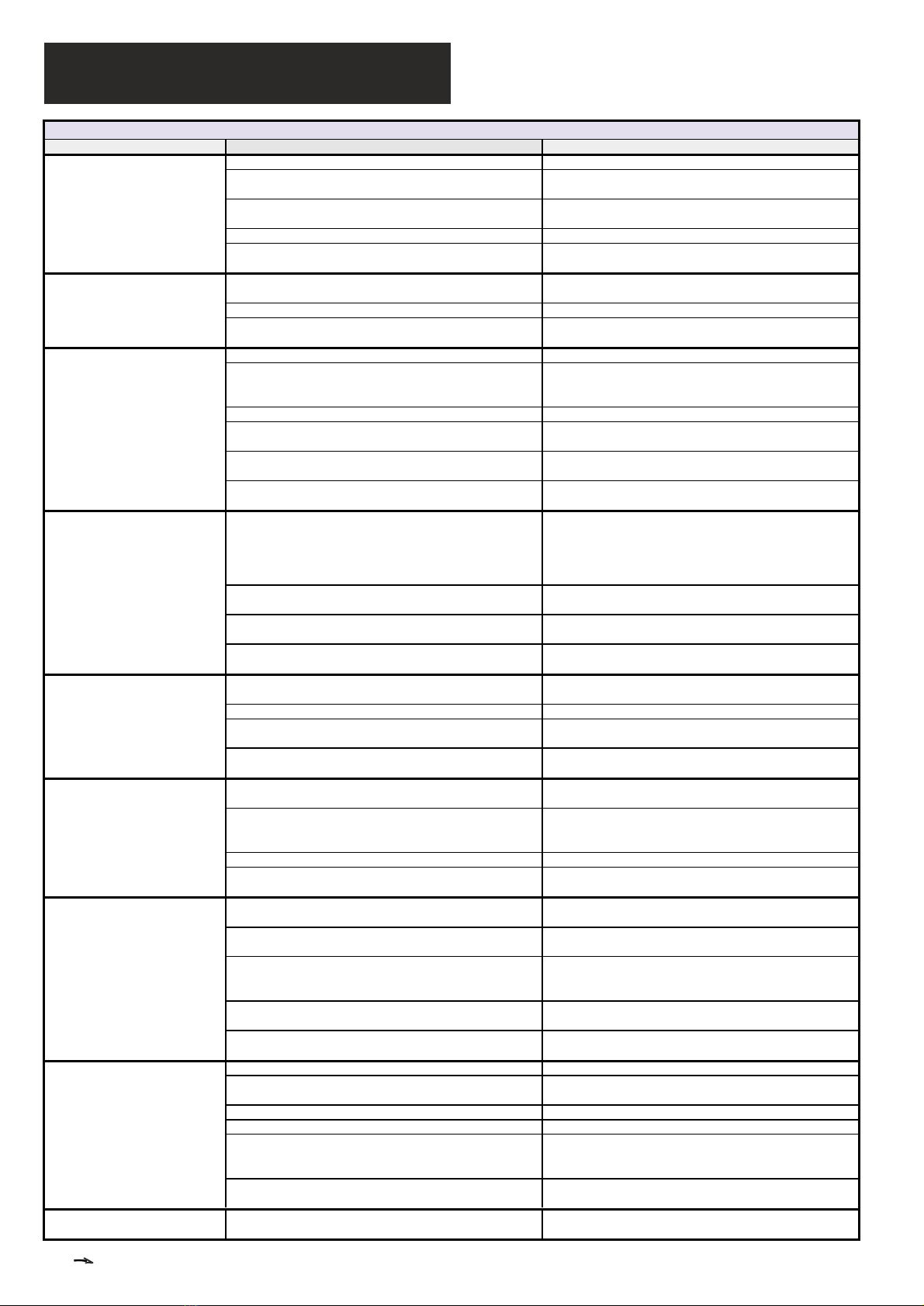

2.4 TECHNICAL DATA

Basic Plus Pro

Length x width x height (pusing handle unfolded) max mm

Length x width x heigth (without pusing handle) mm

Length x width x height (pusing handle folded in) mm

Weight (without batteries) kg 83 90 94

Weigth (with batteries) kg 98 114 124

Permissible overal weight kg

Driving and sweeping speed km/h

Climbing capability (max.) %

Incline (max.) %

Center-brush length mm

Center-brush diameter mm

Side-broom diameter mm

Theoretical sweeping performance (at 4 km/h) m2/h 4400

Effective sweeping performance (70%) m2/h 3080

Sweeping width with folded-out side-brooms (mm) mm 1100

Sweeping width with folded-in side-brooms (mm) mm

Sweeping width - center brush mm

Dirt-hopper size l

Permissible maximum payload dirt - hopper kg

IPX-protection type --

Type -- 12V 50Ah (C20) AGM 12V 75Ah (C20) AGM 2x 12V 50Ah (C20) AGM

Capacity Ah 50 (20h) 75 (20h) 100 (20h)

Weigth kg 15,1 24,2 30,2

Charging time for fully discharged battery(80%) h 4 6 8

Run time up to h 2,5 2 2,5

Charger -- External On board On board

Mains voltage V~

Output voltage V

Charging current A

Mains frequency Hz

Central relay A

Circuit breaker forward traction A -- 25 25

Circuit breaker center-brush A 20 20 20

Circuit breaker side-broom A 10 10 10

Circuit breaker filter-shaker A -- -- 10

Circuit breaker suction system A 15 15 15

Deep discharge protection --

Filter cleaning electrical

Filter area m²

Filter class --

Operating tempreture °C

Chraging tempreture °C

Sound pressure Level L

pA dB(A)

Uncertainty KWA

Sound power level L

WA + Uncertainty KWA dB(A)

Vibration m/s2

1085x820x790

Technical data

Machine data

1085x820x1200

1085x820x710

500

165

4

2

2

500

195

354

3600

2520

--

900

Electrical fuses

75

40

IPX 3

Battery

Charger

100-240V AC

12

10

50/60

62

70

Battery indicator (LBF)

Filter- und vacuum-system

mechanical

2,5

M

Working conditions

-15 bis +40

-15 bis +40

Values according to EN 60335-2-72

3

83

<2,5

dB

3 USAGE

INTRODUCTION / PROPER

3 USAGE

INTRODUCTION / PROPER

3 USAGE

INTRODUCTION / PROPER

3 USAGE

INTRODUCTION / PROPER

3 USAGE

INTRODUCTION / PROPER

3 USAGE

INTRODUCTION / PROPER

Switching

Driving Switching on

Switching

Driving Switching on

3 • To avoid damage to health, smoking, eating and drinking

in the area of the battery charging station is to be

avoided.

• The battery must only be charged with the front panel open

and secured by the cover holder.

• Ensure safe and environmentally-friendly disposal of

operating and auxiliary materials, as well as replacement

parts, particularly batteries!

Safety Instructions for Care and Maintenance

• Before cleaning and maintaining the equipment,

replacing parts or changing to a different function, the

equipment is to be switched off

and the ignition key is to be pulled out.

• Spare parts must correspond to the requirements laid down

by the manufacturer. This is always guaranteed for original

spare parts.

• Accessories and spare parts must only be installed by an

authorised customer service department.

• For work on the electrical system, the battery is to be

disconnected.

• The equipment must not be cleaned

with a hosepipe or high-pressure water jet (risk of short-

circuits or other damage).

• Repairs must only be made by the permitted customer

service centres or by experts in this field familiar with all the

relevant safety regulations.

• Follow the safety review according to the locally -applicable

regulations for mobile industrial equipment.

• Always wear suitable gloves when working on the

equipment.

SAFETY

3.1 SAFETY INSTRUCTIONS

As well as the operating manual and the binding regulations

for accident prevention applicable in the country of usage and

at the place where it is deployed, recognised rules for safety

and expert working, and environmental protection, are also to

be followed.

Safety Instructions for Operation

• The machine is to be inspected before usage for its perfect

condition and operational safety. If it is not in perfect

condition, it must not be used.

• In particular, have any errors that may affect safety

rectified immediately.

• Operating the machine in buildings at risk of

explosion is prohibited.

• Sweeping up of flammable, toxic or explosive materials and

combustible gases or undiluted acids and solvents, burning or

smouldering objects is prohibited.

• The device is not suitable for accepting fluids, ropes, twines,

wires or similar items.

• Only use the machine with the dirt-hopper inserted

to prevent injuries due to parts being projected.

• Do not make any alterations or additions to the machine

without the approval of the manufacturer.

• Persons (including children) who, due to their

physical, sensory or mental capacities or their inexperience or

lack of knowledge, are not capable of using the machine safely

must not use this machine without the supervision or

instruction of a responsible person. Children must be

supervised to ensure that they do not play with the machine.

• Caution: Loose items of clothing may be drawn into

rotating parts and cause serious or fatal injuries.

• Transporting loads with the sweeper is not permitted.

• Observe the maximum climbing ability specified in the

technical data and maximum possible slope inclination for

operating across slopes. The equipment may tip, particularly

on slopes. Adapt your operating manner and speed to the

conditions.

• The machine is not permitted for use on roads.

• Suitable, non-slip footwear is to be worn to avoid accidents.

Safety Instructions on Batteries

• The operating instructions of the battery manufacturer for

their product and the specifications of the legislator on

handling batteries are to be followed.

• Charge flat batteries directly after usage and only keep in

well-ventilated rooms.

• Keep away from naked flames and electrical sparks in

the charging area, as a highly-explosive gas mixture

can be produced when charging batteries.

• Note that the batteries may be filled with battery acid.

• Always keep batteries clean and dry to avoid

leakage currents. Never short circuit the battery

terminals.

7

WARNING! CAUTION! DANGER! THE

INSTRUCTIONS DESCRIBED MUST BE

FOLLOWED

WEAR BREATHING PROTECTION!

WEAR PROTECTIVE GOGGLES!

WEAR GLOVES!

FOLLOW THE INSTRUCTION!

3.2 SYMBOLS IN THE OPERATING MANUAL

3.3 SYMBOLS ON THE SWEEPER

WARNING! CAUTION! DANGER! THE

INSTRUCTIONS DESCRIBED MUST BE

FOLLOWED!

FOLLOW THE OPERATING INSTRUCTIONS!

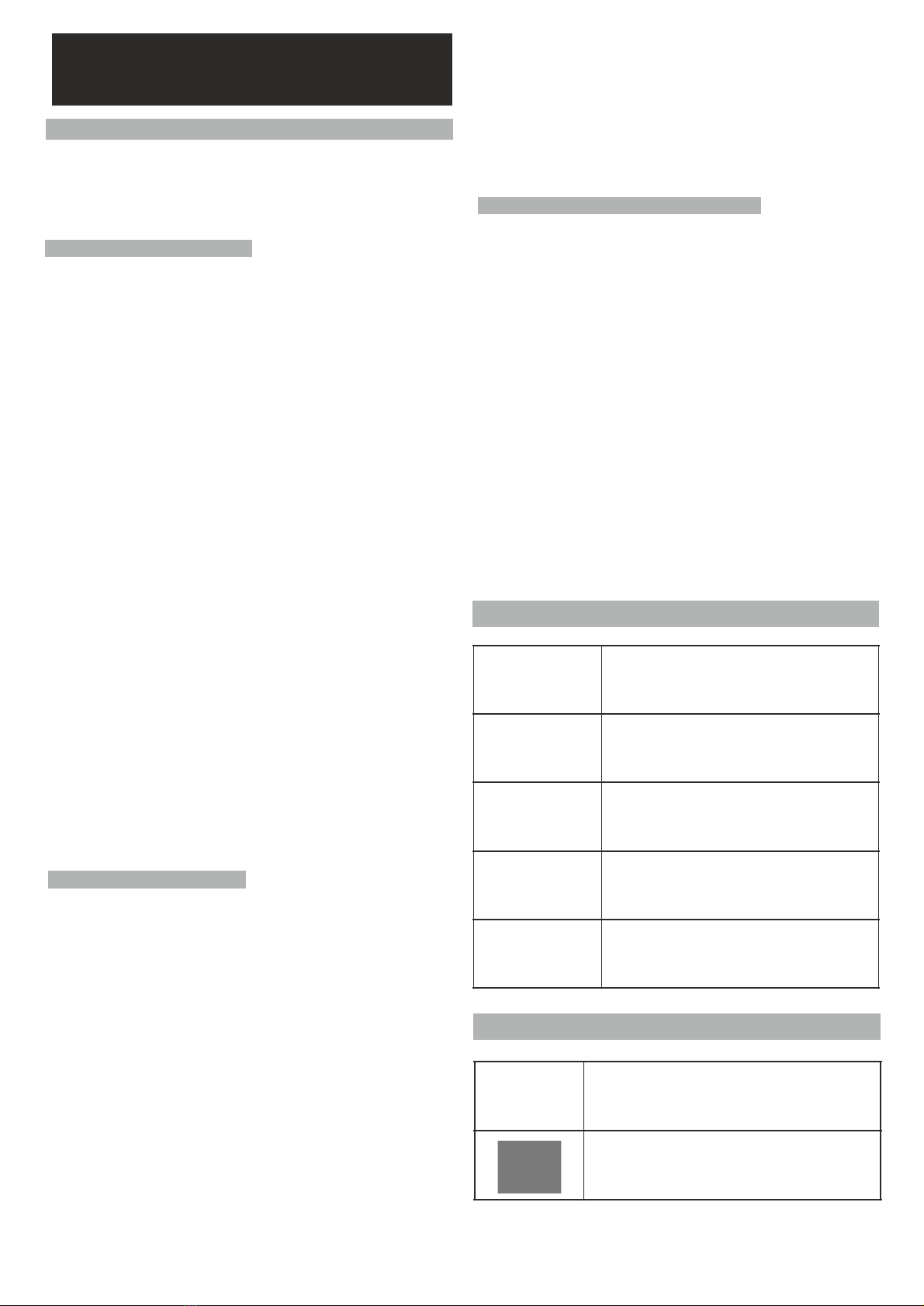

4.3 ADJUSTING THE TRANSPORT BAR

HINWEIS! Bitte befragen Sie zur Entsorgung des Gerätes Ihren Lieferanten.

3.4 SAFETY EQUIPMENT

8

HINWEIS! Bitte befragen Sie zur Entsorgung des Gerätes Ihren Lieferanten.

4 .5 OPENING EQUIPMENT PANEL

4 .5 OPENING EQUIPMENT PANEL

4 .5 OPENING EQUIPMENT PANEL

- Safety equipment is to be inspected for functioning before

starting work.

• Undo star screws of the raster fastening on the frame (I)

• Fold out lower transport bar (II)

• Retighten star screws (III)

• Undo star screws on the upper transport bar (IV)

• Set out the upper transport bar

• Adjust the transport bar for the operator using the star

screws (III + IV + VI)

• Tighten all star screws (VII)

- Only allow the sweeper to be switched on if the following

conditions are met:

a) The start key is in the ON position.

b) The filter box is closed

c) The dirt-hopper is closed .

The power supply to the sweeper is interrupted when:

a) The start key is switched to the OFF position

b) The filter box is open

c) The dirt-hopper is open

The safety equipment attached to the machine must not be

bypassed or put out of operation.

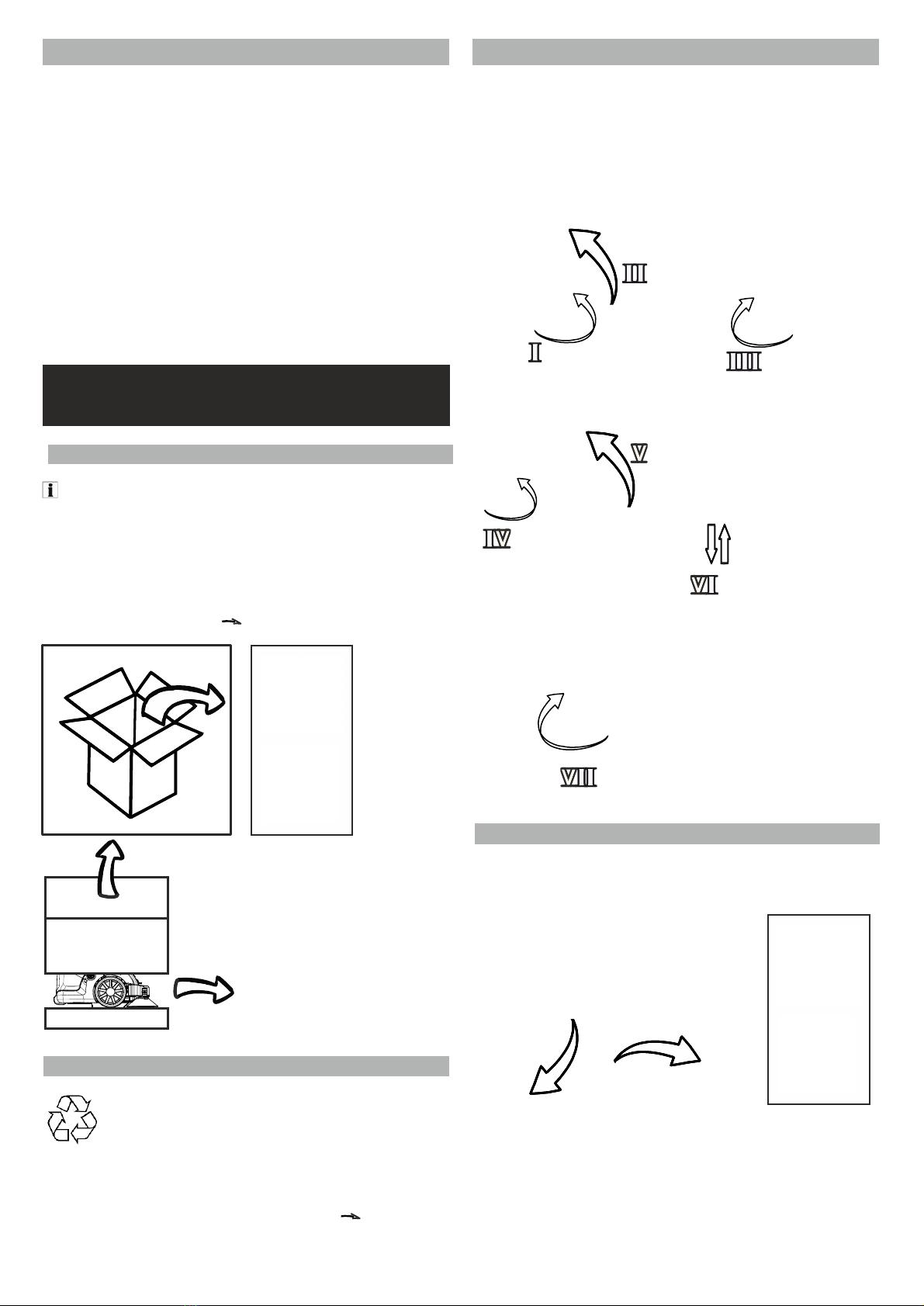

4.1 UNPACKING THE SWEEPER

- Remove the box.

- Remove wooden blocks for securing the wheels.

- Stop the transport bar in the desired position using the star

handle.

See also: PACKING CONTENTS Chapter 2.1

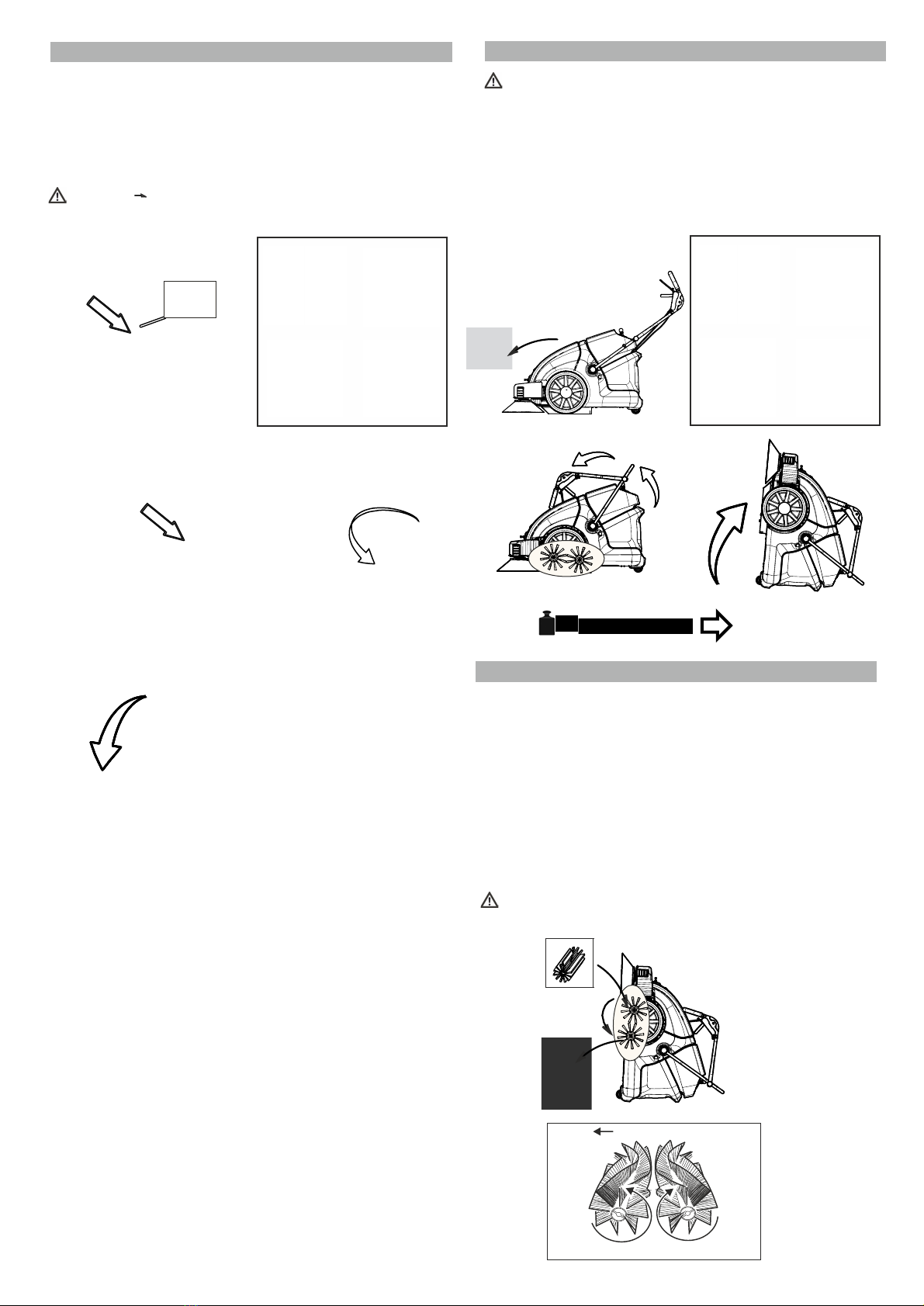

4.4 FITTING THE SIDE BRUSHES

Put the side brushes onto the take-up of the driver (Fig. 2) and

screw tight with the wing bolts (includes: washer, serrated lock

washer, O-ring and wing bolt - Fig. 3).

Fig. 1

(Initial

Assembly)

4.2 WASTE DISPOSAL / RECYCLING

Recycling packaging materials. Do not dispose of

packaging materials in normal waste but forward for

reprocessing.

For the disposal of all packaging materials, the disposal

conditions specific for the location are applicable.

See also: Putting Out of Operation / Recycling

Chapter 8

Fig. 2 Fig. 3 Fig. 4

4 STTING UP/ B S U /

O T

Instruction Look out for damage in transit and if there is

any, indicate this to your specialist dealer without delay.

9

4 .5 OPENING EQUIPMENT PANEL v• Connect the terminal (red cable) to the plus pole of the

battery.

• Push the side brushes on the driver and screw

tightly.

• Close the equipment panel and the dirt-hopper

• Stop the transport bar using the star handle into the

desired position.

4.8 BATTERIES / CHARGER

Safety Instructions on Batteries

You must note the followi ng warning instructions for handling

batteries:

4.5 OPENING THE FRONT PANEL

The front panel is unlocked with a panel

key (rotate clockwise).

Remove the key and open the front panel

and pull to its highest position,

the panel will engage automatically.

To do this, you must read the General Safety Instructions,

particularly the Battery Warning Instructions Chapter 3!

Recommended Batteries

Please use original spare parts and contact Customer Services.

4.8.1 FITTING BATTERIES AND CONNECTING

4.6 CLOSING THE FRONT PANEL

Raise the front panel slightly to close it and push the backplate

(holds the equipment panel) back slightly and close. The

equipment panel engages automatically.

There is a risk of crushing. When closing remove all

body parts from the danger area.

• Open front panel

• Undo the charger holder (star

handle) and fold upwards.

• Place batteries onto the

mounting plate (2).

• Connect any connection

cable of the battery.

• Secure batteries with the

relevant holding strap (1).

* The battery/ies may differ

from the illustration

4.7 B S U T W

• The terminal

(red cable) is to be attached to the plus pole (+) of the battery.

• Attach the connection table (short red cable only for 2

batteries) respectively to the plus pole (+).

• Terminal to the minus pole (-)

• Only use batteries with pole cover!

INSTRUCTION Attach the batteries according to the

specification

See (Fig. 1-2 - CONNECTING BATTERIES Chapter 4.8.3)

INSTRUCTION Charge the batteries before putting the

equipment into operation! (Ch. 4.8.3 +4.8.4)

INSTRUCTION Charge the battery fully!

4.8.2 BATTERY CONNECTIONDIAGRAM

DANGER!

Risk of injury and/or damage! Take care of the weight of the

equipment when charging!

CAUTION! Only operate with the front panel and

dirt-hopper closed.

CAUTION! Charge the battery fully!

• Make sure you are satisfied that the machine has been

supplied undamaged and complete.

Fig. 1: Battery Version Basic + Plus

See also UNPACKING THE SWEEPER Chapter 4.1

• If you have any complaints, contact your specialist dealer

or our Service department.

• Read the SAFETY INSTRUCTIONS Chapter 3.1

• Read the operating manual of the charger provided. Take

note of the warning instructions for the battery! Fig. 2: Batteries - Pro Version

TRANSPORT WEIGHT

Version BASIC PLUS PRO

WEIGHT empty 83 90 94

WEIGHT with batteries 98 114 124

WARNING! CAUTION! DANGER! THE

DESCRIBED INSTRUCTIONS MUST BE

FOLLOWED!

FOLLOW THE OPERATING MANUAL OF THE

SWEEPER!

WARNING! - WEAR GLOVES WHEN WORKING IN THE

AREA OF THE BATTERY TO AVOID INJURIES

WARNING! CAUTION! DANGER! THE

INSTRUCTIONS DESCRIBED MUST BE

FOLLOWED!

FOLLOW THE INSTRUCTIONS ON THE

BATTERY, IN THE USER INSTRUCTIONS FOR

THE BATTERY AND THE OPERATING

INSTRUCTIONS.

11

1

11

2

10

After charging, unplug the on-board

• charging unit mains cable.

• Unwind the mains cable from the charger cable bracket.

• Close the equipment panel.

Charging external charger

• Open the equipment panel

• Plug in the charger charging cable into the

charging terminal of the sweeper.

• Plug the mains plug of the charger into the socket and

switch on the charger.

After charging, unplug the external charger

• Switch o ffthe charger and disconnect from the mains.

• charging cable on the equipment.

• Close the equipment panel.

4.8.3 CHARGING BATTERIES

DANGER Risk of injury, the charger must only be

put into operation if the mains cable is

not damaged. A damaged mains cable is to be replaced

without delay by the manufacturer, Customer Services or

a qualified person.

DANGER Danger of electric shock. Follow

mains and use the correct fuse. Only user charger in

dry rooms with sufficient (i.e. open front panel)

ventilation. Observe charging times.

DANGER Risk of injury! Follow the

safety instructions when handling batteries. Follow usage

instructions of the charger manufacturer.

Battery charge indicator

INSTRUCTION The equipment is fitted as standard with

maintenance-free batteries.

4.8.5 REMOVING BATTERIES

• Open front panel. (See Chapter 4)

• Disconnect any charging plug

•

•

•

Disconnect terminal from minus pole (-

Disconnect terminal from plus pole (+).

Unscrew battery connection cable.

Undo the charger holder (star handle)

and fold upwards.

Undo holding strap.

Remove battery.

Dispose of used batteries according to

•

4.8.4 CHARGER

INSTRUCTION Read the operating manual of the charger

manufacturer.

INSTRUCTION Batteries must only be charged at room

temperature.

Charging on-board charger

• Open the equipment panel

• Plug the mains plug of the charger into the socket.

INSTRUCTION The charger is electronically controlled and

stops charging automatically. All functions of the sweeper are

automatically interrupted during charging.

-

If the battery or batteries is/are charged, the yellow light of

the charger is lit.

-

The battery is fully charged if the light of the

charger is lit green.

•

•

•

the applicable provisions (see Ch. 3 Environmental

Protection).

Operational lit yellow

Charge battery lit red

Protection against deep discharge flashes (equipment shuts down)

11

Switching on

4.9 S U

General Instructions

DANGER! Risk of injury! Switch off equipment before

removing the dirt-hopper.

CAUTION! Only operate with the front

bonnet and dirt-hopper closed.

INSTRUCTION

5.2 DRIVING SWEEPER

• Pull drive lever The sweeper moves forwards.

The drive speed is according to the lever setting

steplessly controllable.

• Releasing the drive lever stops the sweeper.

• The sweeper may also be pushed without the drive.

Running Over Obstacles

• Fixed obstacles up to a height of 45mm may be run over

slowly and carefully.

• Obstacles must always be run over with a ramp to protect

the machine.

5.3 S O - W S B, R B A F

CAUTION!

Sweeping material that is too large or non-uniform may be

disposed of via the raised filter lid directly into the

dirt-hopper.

Risk of dust! Wait 5-10 seconds before opening the filter

cover.

CAUTION!

Do not sweep up any straps, wires or similar as this may cause

damage to the sweeping mechanism.

INSTRUCTION

The fan should be switched on in general.

As required:

• Lower the side brushes accordingly (operate pedal)

• Side brush switch in Pos. I (ON), Pos.0 (OFF)

• Roller brush switch in Pos. I (ON), Pos.0 (OFF)

• Shaker in Pos. I (ON), Pos.0 (OFF)

• Operate selector

(side brushes swivel out to the side)

MUST BE FOLLOWED! B S U , .

• Make sure you are satisfied that the machine has been

supplied undamaged and complete. See BOX CONTENTS, chapter 2.1

See UNPACKING, chapter 4.1

• If you have any complaints, contact your specialist dealer

or our Service department.

MUST BE FOLLOWED!

You must only carry out the work described in this chapter if

you have completely read and understood the operating

manual, particularly Chapter 1-4.

INSTRUCTION Safety equipment is to be inspected for

functioning before starting work.

See also Safety, chapter 3

DANGER! If the equipment is used for extended

circulatory disorders in your hands due to vibrations

may be caused. A generally-applicable usage time cannot

be specified, as this depends on several influencing

factors: These include a firm grip, low ambient

temperature and personal disposition. It is recommended

that you take regular breaks, and put the driving bar in an

optimum position.

INSTRUCTION

Please adjust driving speed to the conditions (different

ground surface, type and amount of sweeping material), to

obtain a good sweeping result.

INSTRUCTION

When in operation, the dust filter must be cleaned at

regular intervals and as required.

INSTRUCTION

When in operation, the dirt-hopper must be

emptied at regular intervals and as required.

BASIC Version

Pos I (ON)

Pos 0 (OFF)

Pos I (ON)

Pos 0 (OFF)

PLUS Version

Pos I (ON)

Pos 0 (OFF)

Pos I (ON)

Pos 0 (OFF)

Pos I (ON)

Pos 0 (OFF)

See also

See also

C D F , C .

E D-H, , ..

5.1 S S

• Put the key into the key switch and turn it clockwise to

the “ON” position. The drive motor starts.

PRO Version

Pos I (FAN ON)

Pos I (ON)

Pos 0 (OFF)

Pos 0 (Fan OFF)

Pos I (ON)

Pos 0 (OFF)

Pos II (Operate shaker)

5 OPERATION (USAGE AND OPERATION)

12

5.4

SWITCHING OFF SWEEPER

• Set down the machine on a level, dry and

protected ground surface.

• Switch off the roller brush, side brushes and

vacuuming system.

• Put the key into the “OFF” position

(anticlockwise) and pull out.

• Fold in the side brushes.

• Raise the side brushes with the pedal.

• When setting down, the machine has to be secured

against inadvertent movement.

5.6 CLEANING THE DUST FILTER

CAUTION!

Risk of crushing when closing

the filter box.

5.5 TRANSPORTING THE MACHINE

DANGER! Risk of crushing! Observe the weight of the

machine!

INSTRUCTION!

Do not kink any Bowden

cables!

• Switch off sweeper and pull out the ignition key.

• Fasten the wheels of the machine with chocks.

• Fasten the machine with tensioning belts or ropes.

• While transporting in vehicles or trailers, the

machine has to be secured, according to the

relevant applicable guidelines, against sliding and

tipping.

• Two fastening areas for belts:

a) Machine vertically fastened (fastened to

the floor as illustrated)

b) Machine horizontally fastened (fastened to

the wall as illustrated)

Instruction Ensure that the dirt-hopper has been

inserted.

• When using the electric shaker (I), operate it

for approximately 15-20 seconds.

• When using the mechanical shaker, operate the shaking rod on

the ball knob several times (5-10 times)

(alternately to the left and right)

Instruction It is recommended waiting 5-10 seconds until the

fine dust has settled before emptying the dirt-hopper.

5.7

E D-H

DANGER!

Risk of injury! Switch off equipment before

removing the dirt - hopper.

Instruction The maximum permitted load (sweeping

material) of the dirt-hopper is 40 kg.

Instruction The dirt-hopper must be emptied at

regular intervals to enable perfect sweeping.

• Clean the dust filter regularly.

• Remove the dirt-hopper from the

sweeper using the handle on the top.

• Empty the dirt-hopper thoroughly after

finishing sweeping work.

• Empty the dirt-hopper into a suitable

container.

• Push the dirt-hopper back into the machine.

a) b)

CAUTION! Risk of crushing when closing

the dirt-hopper!

Help for faults

Fault Possible cause Remedy

Device does not start

Battery state ≤20% ►Charge battery

Battery cable not correctly connected or loose ►Check cabling of the batteries and connect correctly

Safety switch in the filter cover not operated ►Close filter cover and insert dirt-hopper correctly.

Overload or fault with the main relay ►Check and replace main relay

Cause unclear

►Notify your dealer or customer services

Drive motor running, but device

is not operating

Bowden cable of the traction drive has extended or is not functioning ►Check and adjust Bowden cable of the drive

Lack of power transmission of the drive belt ►Check and adjust drive belt of the drive

Cause unclear

►Notify your dealer or customer services

Device stops on a slope when

operating

Slope >2% ►Travel on a route with smaller slope

Bowden cable has extended and the power transmission of the

drive belt is no longer sufficient

►Check and adjust Bowden cable of the drive

Lack of power transmission of the drive belt ►Check the drive belt of the drive

Permitted total weight of the machine exceeded by full

dirt-hopper.

►Empty dirt-hopper.

Main relay or relay for the drive has been overloaded and is/are

faulty

►Check relay for the drive

Cause unclear

►Notify your dealer or customer services

Roller brushes are not running

Straps, large packaging residues etc. have been swept up

►Turn key switch to "0" (switch off sweeper). Check roller brushes

for jammed or picked-up objects such as, for example, straps,

cables etc., remove them and check the roller brush for damage

and free running.

Functional fault of the toothed belt or gear wheels (e.g. toothed

belt has come off)

►Check toothed belt and gear wheels

Roller brush motor overloaded (check brushes for free running, as

appropriate)

►Check and replace relay of the roller brush motor

Cause unclear

►Notify your dealer or customer services

Bad sweeping in the edge region

Side brushes worn ►Check for wear, readjust as required or replace the side

brushes

Side brushes have not lowered ►Lower the side brushes

Functioning of the side sealing rubber restricted by wear, a fault

or similar.

►Replace side sealing rubbers as appropriate

Cause unclear

►Notify your dealer or customer services

Swivelling the brushes in and out

not working

Bowden cable has extended or is not functioning ►Check and adjust Bowden cable of the side brushes

Leg spring in the side brush not working (side brush does not

swivel out)

►Check leg springs in the side brushes for damage and correct

seating and replace as necessary

Side brush jammed by dirt Clean side brush suspension

Cause unclear

►Notify your dealer or customer services

Sweeper does not sweep correctly

Roller brushes or sweeping tunnel blocked by sweeping material ►Check sweeping tunnel for contamination or blockages and

remove them

Roller brushes or side brushes worn or not set correctly ►Check roller brushes and side brushes for wear, readjust or

replace as required

Sealing rubber damaged by foreign bodies or running over

obstacles without a ramp

►Check front, side and rear sealing rubber for damage and

correct seating and replace as necessary

Roller Brushes are not installed according to their direction of rotation ►Remove roller brushes and fit according to the direction of rotation

Cause unclear

►Notify your dealer or customer services

Device raises dust

Dust filter no longer cleaned ►Check, clean or replace dust filter

Sealing rubber faulty, so that the vacuuming system cannot

work properly

►Check front, side and rear sealing rubber for damage and

correct seating

Dirt-hopper is full ►Empty dirt-hopper.

Sealing section fastened wrongly or faulty ►Check sealing section on the filter cover and replace as

Sweeping tunnel blocked by bulky sweeping material so that no

sweeping material can be transported into the dirt-hopper

any longer

►Remove contaminations or blockages in the sweeping tunnel

Cause unclear

►Notify your dealer or customer services

Electrical fault Overload or wear of electrical components or cause unclear ►Notify your dealer or customer services

5 FEHLERSUCHE UND STÖRUNGSBESEITIGUNG

6 TROUBLESHOOTING

See Contact Data, chapter 7.14 13

14

CAUTION! Before starting to change or clean the dust

filter, clean off the dust filter and empty the dirt- hopper

Wear dust protection mask and protective goggles when

working on the filter system. Follow the safety instructions

for handling fine dust!

Regular maintenance of the sweeper is useful for the

serviceability of the machine, its components and the

sweeping result. As a result of the following described and

regularly undertaken maintenance work, the lifetime of the

machine can be extended. INSTRUCTION

INSTRUCTION

Clean the dust filter before changing

Empty the dirt-hopper before

changing

DANGER There is a risk when

cleaning. During cleaning, always wear a dust protection

mask, as well as protective goggles and gloves. See

See

See

CLEANING DUST FILTER , chapter 5.6

SWITCHING OFF SWEEPER, chapter 5.4

EMPTYING D-H, chapter 5.7

INSTRUCTION

Repair work is only to be carried out by permitted customer

service centres or specialists for these machines, familiar with

all the safety-relevant regulations.

INSTRUCTION For any care or maintenance:

Set down the machine on a level surface.

Secure the machine from rolling away.

Always switch o ffthe machine and pull out the ignition key.

INSTRUCTION For work on the electrical system, disconnect

the battery.

7.1 GENERAL CLEANING

CAUTION! There is a risk of damage to the machine. The

sweeper must not be cleaned with a hosepipe or high-pressure

water jet. There is a risk of damage to the machine or the

electrics.

• Start mechanical or electrical filter cleaning.

Switch o ffthe sweeper, pull out the ignition key.

Raise the filter cover until this engages in the backplate.

Hold the filter holder firmly and undo the filter lock on the

left and right.

Slowly release the filter holder inc. filter until this is held.

Take the filter out of the machine.

Clean or replace as required.

As required, carefully blow out with compressed air.

Insert filter again.

•

•

•

•

•

•

•

•

See also INSERTING FILTER chapter 7.3

INSTRUCTION! The filter may be damaged by blowing from

from too small a distance from the filter material with too

much pressure.

1

7.2 CHANGING / CLEANING FILTER

5 FEHLERSUCHE UND STÖRUNGSBESEITIGUNG

7 (No Repair)

Care and Maintenance

15

7.3 INSERTING THE FILTER

• Insert filter in the installation direction (see symbol

on the filter) into the filter holder.

• Lock the filter on the left and right.

• Remove hand from the risk area to avoid crushing.

• Close the filter cover.

7.4 TIPPING THE SWEEPER

CAUTION! Risk of injury!

• Put ignition key into the “OFF” position and pull out.

•

Open front panel.

•

Disconnect batteries and remove.

•

Close front panel.

•

Put the drive bar into the highest position and fold in drive bar.

•

Tip the machine rearwards with the help of a second person

(first put steering roller in position - parallel to the direction of

running) and set up.

DANGER!

RISK OF CRUSHING when closing the

filter box.

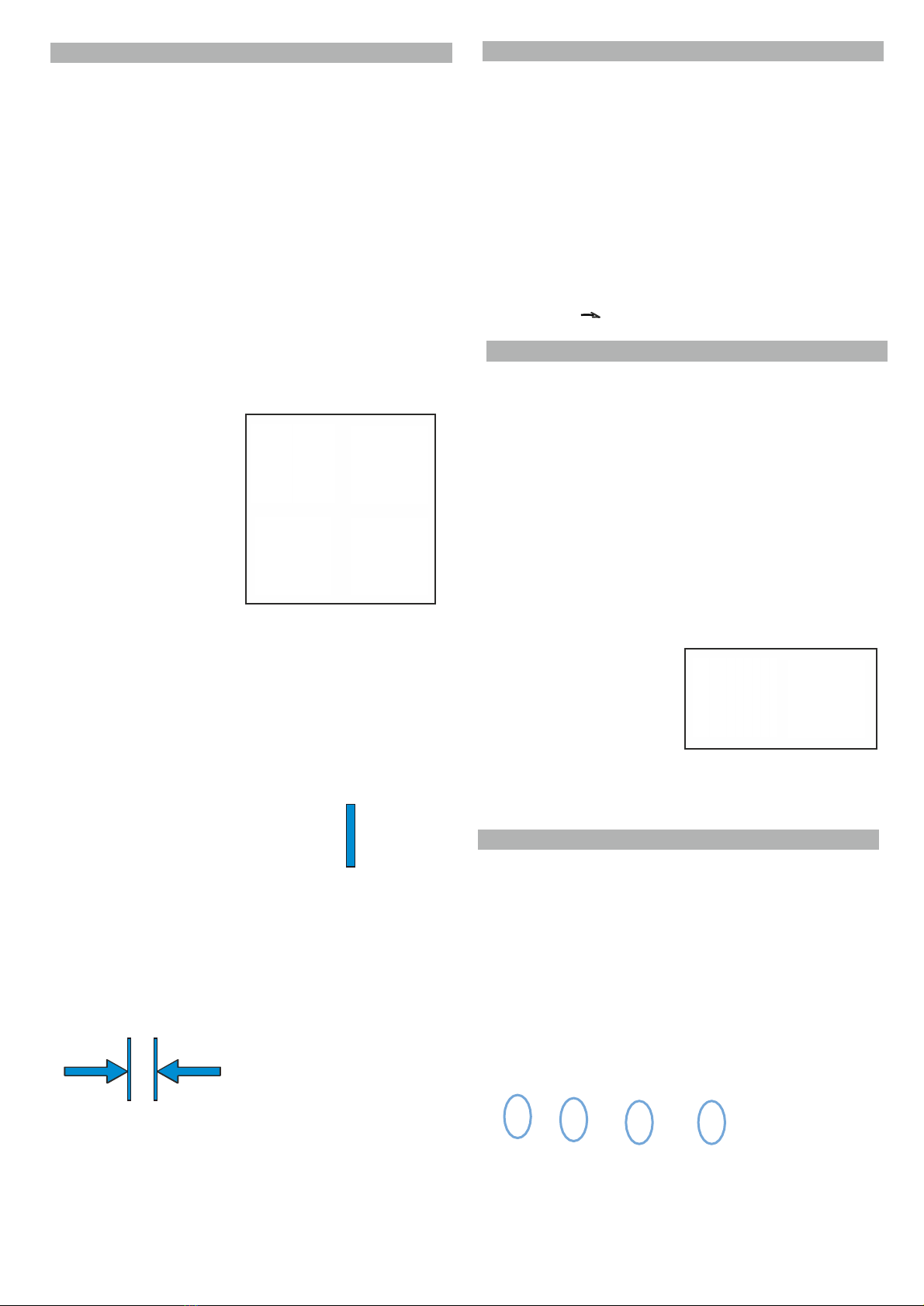

7.5 CHANGING THE Roller Brushes

- The front brush is not subject to any wear and must not be

replaced, except where it is damaged.

- The roller brush does not have to be replaced if the

sweeping result is visibly worse due to wear of the brushes,

and readjustment of the roller brush is no longer possible.

- The roller brush consists of two segments connected by six

screws. Unscrew the screws using a suitable tool and remove the

segments individually.

- Insert the new segments into the roller brush and fasten

again with six screws.

- The direction of movement of the roller brushes Fig. 2

must be followed.

CAUTION! There is a risk of damage to the roller brush

if the brushes become jammed during fitting.

Fig.1

Forward direction of

running

Fig.2

Movement direction of the

roller brushes

30-40mm

16

7.6 S S R B C 7.7 CHANGING THE SIDE BRUSHES

The side brushes are subjected to wear. On abrasive surfaces,

wear to the brushes is faster than on smooth floors.

It is necessary to change the side brushes if these are

worn or damaged. Changing due to wear is necessary if the

sweeping result of the side brushes is visibly worsened and it

is no longer possible to readjust.

• Put ignition key into the “0” position and pull out.

• Raise the side brushes (transport position)

• Remove the side brushes (undo wing bolt).

• Change the side brushes.

• Put the side brushes on the take-up of the driver and fasten.

• Switch of the sweeper.

• Operate with the sweeper on level and smooth ground

that is recognisably covered with dust, sand or chalk.

• Open the front panel and set the roller brushes

adjustment to the centre position of the whole setting

area.

• Close front panel.

• Switch on the machine and allow the roller brushes to

rotate for approximately 15 seconds.

• Run the sweeper from the sweeping clearance.

• The impression of the roller brush (=sweeping

clearance) must be clearly visible on the ground. The

shape of the sweeping clearance forms a uniform

rectangle that is between 30 -40mm wide.

• Lowering the roller brush adjustment lever raises the

roller brush.

• As appropriate, repeat the pprocess until the desired

sweeping clearance is reached.

• Close front panel.

See also FITTING THE SIDE BRUSHES, chapter 4.4 Fig. 2-4

7.8 SETTING THE SIDE BRUSHES

It is necessary to adjust the side brushes if the wear of the

brushes visibly makes the sweeping result of the side brushes

worse.

• Set down the sweeper onto a level, dry and protected

surface.

• Raise the side brushes (transport position)

• Open front panel

• Undo the knurled nuts at the front left and/or right of the

side brush adjustment.

• Turn adjustment forwards to lower the side brushes further

• Fasten both knurled nuts again.

• Close front panel.

7.9 CHANGING THE FRONT SEALING RUBBER

The front sealing rubber must be replaced if there are tears

or it is worn, to guarantee a good sweeping result.

• Put ignition key into the “OFF” position and pull out.

• Raise the side brushes (transport position).

• Undo all four screws of the front sealing rubber and

remove.

• Remove the front seal completely.

• Replace the front sealing rubber.

Centre of

roller

brush

• Raise the side brushes.

17

7.10 SETTING / REPLACING SIDE SEALING RUBBER

The basic setting of the side sealing rubber is 1mm.

• Put ignition key into the “OFF” position and pull out.

• Tip the machine as required.

• To set the height, undo the fastenings (2 screws), readjust or

replace the side sealing rubber, align and fasten. 7.14 CONTACT DATA

Manufacturer: Stolzenberg GmbH &

Co. KG Hamburger Straße

15-17 49124

Georgsmarienhütte

T: +49 (0) 5401 / 8353-0

F: +49 (0) 5401 / 8353 - 11

E: service@stolzenberg.de

7.11 SETTING DRIVE BOWDEN CABLE /CANGING

Readjusting the Bowden cable is required if the driving force of

the machine is no longer sufficient.

• Put ignition key into the “0” position and pull out.

• Undo the lock nut.

• Setting/readjusting the Bowden cable

• Screw the lock nut tightly.

Dealer:

7.12

Readjusting the Bowden cable is required if the side brush no

longer folds in completely.

Folding out is done with springs

• Put ignition key into the “OFF” position and pull out.

• Undo the lock nut under the drive bar cover plate.

• Setting/readjusting the Bowden cable.

7.13 IMPORTANT SPARE PARTS AND CONSUMABLES

SETTING SIDE BRUSH BOWDEN CABLE /CANGING

Flat filter Item No. 100223

Roller Brush PA 0.4 V Item No. 114128

Item No. 110526

Side Brushes PA 0.6

18

7.15 MAINTENANCE WORK / MAINTENANCE TABLE

Instruction: The following maintenance work must be carried out by instructed and

authorised specialist staff at the set intervals.

RISK!

Risk of Injury The motor(s) need(s) to overrun for several seconds after being shut off.

In this time, you must keep clear of the drive area.

CAUTION! • Allow the equipment to cool down sufficiently before all maintenance and repair work

• Unplug the charger from the socket.

•

Disconnect the plus terminal from the battery.

You must read

T T S

, .

Activity Interval

Daily Weekly Every 50 hours

Chapter

Check machine for damage

and functional faults and remedy as appropriate. •

Check the battery charge; charge batteries as appropriate. • 4.8.3/

4.8.4

Empty the dirt-hopper • 5.8

Check roller brushes & roller brushes housing for damage, for foreign

clean or replace the roller brushes. •

7.5

Check side brushes for foreign bodies, straps etc.;

remove/clean as appropriate. •

Check side brush setting;

readjust or replace side brushes as appropriate • 7.7/

7.8

Check the condition of the dust filter; clean as appropriate • 5.7

Check the charge of the batteries before each usage •

4.8.3

Undertake all daily maintenance work

•

Check the sealing rubber in the roller brush area for

wear and damage; replace as appropriate

• 7.9/

7.10

Check dust filter for damage; replace as appropriate

• 5.7

Functional test of the entire machine

•

Check all toothed belts for tension, wear and

operation; replace as appropriate

•

Check the Bowden cables and all moving parts for

their smooth running; replace as appropriate

• 7.11/

7.12

Check the Bowden cables for extension of the pull cable

• 7.11/

7.12

Check safety components (end switch filter cover)

•

Conduct all daily and weekly maintenance work

•

Check battery condition; replace as appropriate

• 4.8.3

Check smooth running of the wheels (possibly replace any bearings)

•

Check all bearings for damage

•

Check all screws and fastenings

•

Check all covers and steel parts for firm seating

•

Check the operation of the charger

•

CAUTION! In the event that damage to the machine is

established, it must not be used until the damage has

been remedied by specialist staff.

bodies and for wear; remove any foreign bodies/

8

19

L

ONG

-TERM STOPPAGE OF THE SWEEPER

• INSTRUCTION

If it is stopped for a long period, the batteries must charge at

intervals of approximately 2 months so they are not damaged

by a deep discharge.

• Set down the sweeper onto a level, dry and protected

surface.

• Put ignition key into the “OFF” position and pull out.

• Secure sweeper against rolling away.

• Raise roller brush. To do this, adjust the lever to the

lowest position and stop.

• Raise the side brushes.

• Clean the dust filter.

• Empty the dirt-hopper.

• Clean the sweeper inside and out.

• Disconnect the battery.

S R

After the useful life of the machine is over, it must be

disposed of expertly. However, individual parts may

be thoroughly reused.

For the disposal of all equipment parts, the

disposal conditions specific for the location are

applicable.

INSTRUCTION Please ask your supplier about disposal

of the equipment.

WASTE DISPOSAL / ENVIRONMENTAL PROTECTION , chapter 4.2

See also

D

S, D,

9 C

20

M

M

M

M

M

M

M1 = Mainbrush

M2 = Shakerr

M3 = Fan

M4 = Sidebrush left

M5 = Sidebrush right

M6 = Drive

S1 = Main-/Keyswitch

S2 = Brushes ON/Off

S3 = Fan / Shaker

S4 = Sidebrushes On/Off

D1 = Working light

K1..K3 = Relay (max.70A)

F1 = Therm.Breaker Mainbrush 20A

F2 = Therm.Breaker Drive 25A

F3 = Filterbloc with switches and shaker 10A

F4 = Fan 15A

F5 = Sidebrushes 10A

Battery12V

M1 M2 M3 M4 M5 M6

K2 K3

S2 S3 S4

F1

F2

F3

F4

F5

D1

battery indicator

rt

br

grsw

ws

K1

S1

Charger

with charge-detection

cover-switch

chargecontact

1

1

2

2

3

3

4

4

5

5

6

6

7

7

A

A

B

B

C

C

D

D

E

E

Table of contents

Other STOLZENBERG Blower manuals

STOLZENBERG

STOLZENBERG KSV 910 User manual

STOLZENBERG

STOLZENBERG MATRIX MTX-900-V TRS User manual

STOLZENBERG

STOLZENBERG US 5 User manual

STOLZENBERG

STOLZENBERG NU5 User manual

STOLZENBERG

STOLZENBERG NU9 User manual

STOLZENBERG

STOLZENBERG CS 650 User manual

STOLZENBERG

STOLZENBERG KSE 910 User manual

STOLZENBERG

STOLZENBERG Tandem 900 KSE User manual