STOLZENBERG MATRIX MTX-900-V TRS User manual

MATRIX MTX-900- V TRS

MATRIX MTX-900- B TRS

MATRIX MTX-900-VB TRS

·MATRIX MTX-900-V/-B/-VB TRS · 20122006

STOLZENBERG

Kehrmaschinen

STOLZENBERG

Kehrmaschinen

GB

Operating instructions Matrix,

the battery-operated manual sweeper

2

1

3

-3-

-2-

STOLZENBERG

Kehrmaschinen

·MATRIX MTX-900-V/-B/-VB TRS ·20122006

STOLZENBERG

Kehrmaschinen

·MATRIX MTX-900-V/-B/-VB TRS · 20122006

Introduction

About these Operating Instructions.

These Operating Instructions pertain to the operation of the .

Our products are subject to continuous improvement;constructive changes that have been

made after the printing of these operating instructions could not be taken into account. If you

have any questions, feel free to contactour service department.

The Operating Instructions must be read and observed by anybody using or operating the

manual sweeper .

Besides applying the Operating Instructions, the operator isreminded to observe the

legislator's accident prevention regulations as well as general rules of professional and safe

working methods.

Matrix MTX-900-x TRS

Matrix MTX-900-x TRS

Safety Information

The manual sweeper is designed and built in accordance with

state of the art know-how and standard safety regulations. In spite of this, physical danger

to the operator or third parties or the impairment of the manual sweeper or other valuable

objects may arise during operation.

Always use the manual sweeper in a flawless condition and in a way that accords with

general rules of operational and personal safety, and always observe these

Operating Instructions! Eliminate malfunctions that may impair operational safety

immediately!

Keep Operating Instructions ready at hand wherever the manual sweeper is used!

In addition to the Operating Instructions, observe the generally applicable legal or other

binding guidelines for accident prevention and environmental protection!

Do not modify, expand, or reconstruct the manual sweeper in any way without explicit

approval by the manufacturer.

Replacement parts must comply with the specifications defined by the manufacturer. This

will always be the case if only original replacement parts are applied.

Observe the prescribed maintenance intervals and those stated in these Operating

Instructions!

Be sure to dispose of operational and auxiliary materials as well as replacement parts in a

safe and environmentally sound way!

Matrix MTX-900-x TRS

Correct Application

The manual sweeper is intended exclusively for cleaning hard surfaces of dry

sweepings. e. g. : parking lots, industrial buildings, warehouses, sidewalks.

Any application different from or exceeding this definition is incorrect.

The manufacturer is not to be held responsible for any damage arising from such

applications.

Any risk is to be assumed by the operator.

Correct application includes the observation of Operating Instructions as well as inspection

and maintenance intervals.

Never use this machine to sweep inflammable or toxic or explosive substances.

The manual sweeper is not suitable for taking up cords, strings, wires or similar

materials.

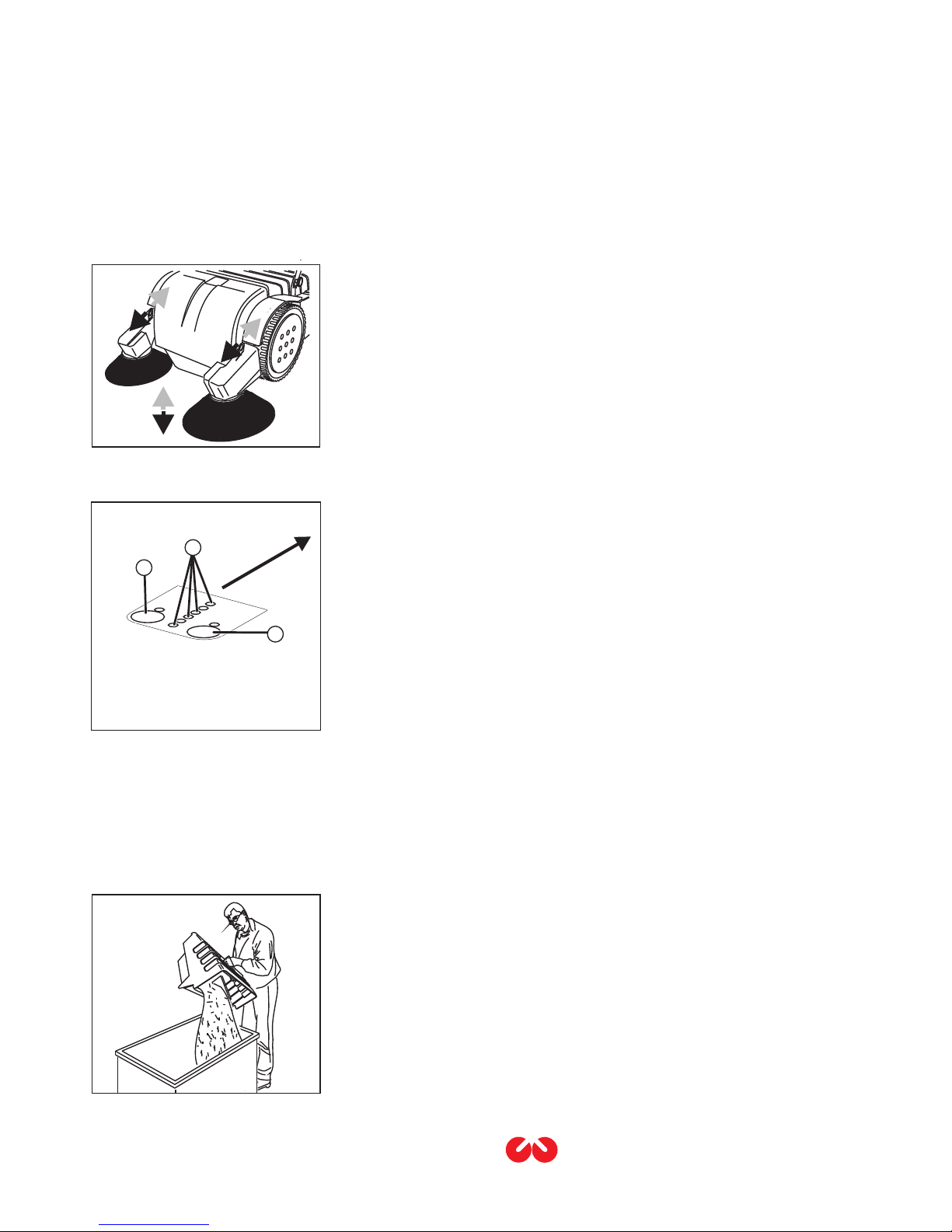

Control panel

Steerable rear wheel

running wheel

dustbin

control panel

handle

hood

Height adjustment

for side brush

side brushes

Sweeper description

The battery-operated sweeper has been equipped with two side brushes and two

counter-rotating brush rollers.

The sweeping mechanism features two side brushes which convey the refuse to the

two brush rollers that are mounted parallel to the direction of motion.

The brushes throw the refuse overhead in the rear dirt collector.

A chain drives the brush rollers, and a V-belt drives the side brushes through the

forward motion of the running wheel.

The top model of the Matrix series is the Matrix MTX-900-VB TRS, which has been

equipped with a dust extraction unit (V) and a brush roller drive (B).

The modular design of the Matrix series allows for retrofitting the Matrix MTX-900-V

TRS

with a brush roller drive (standard model features a dust extraction unit) and the

Matrix MTX-900-B TRS with a dust extraction unit (standard model features a brush

roller drive).

The electronic system provides for a soft start feature, which ensures that the drive

does

not run at full power all of a sudden.

The Matrix MTX-900-x TRS sweeper is driven by manual power only, in other words,

by

1091 mm

760 mm

460 mm

22 - 50 kg

500 mm

700 mm

900 mm

12 V

28 Ah bzw.

Dust Container Volume 50 ltr

Start/Stop button of the brush roller

drive (applies to B and VB models)

Start/Stop button of the suction system

Battery status display

-1-

-2-

-3-

driving hoop

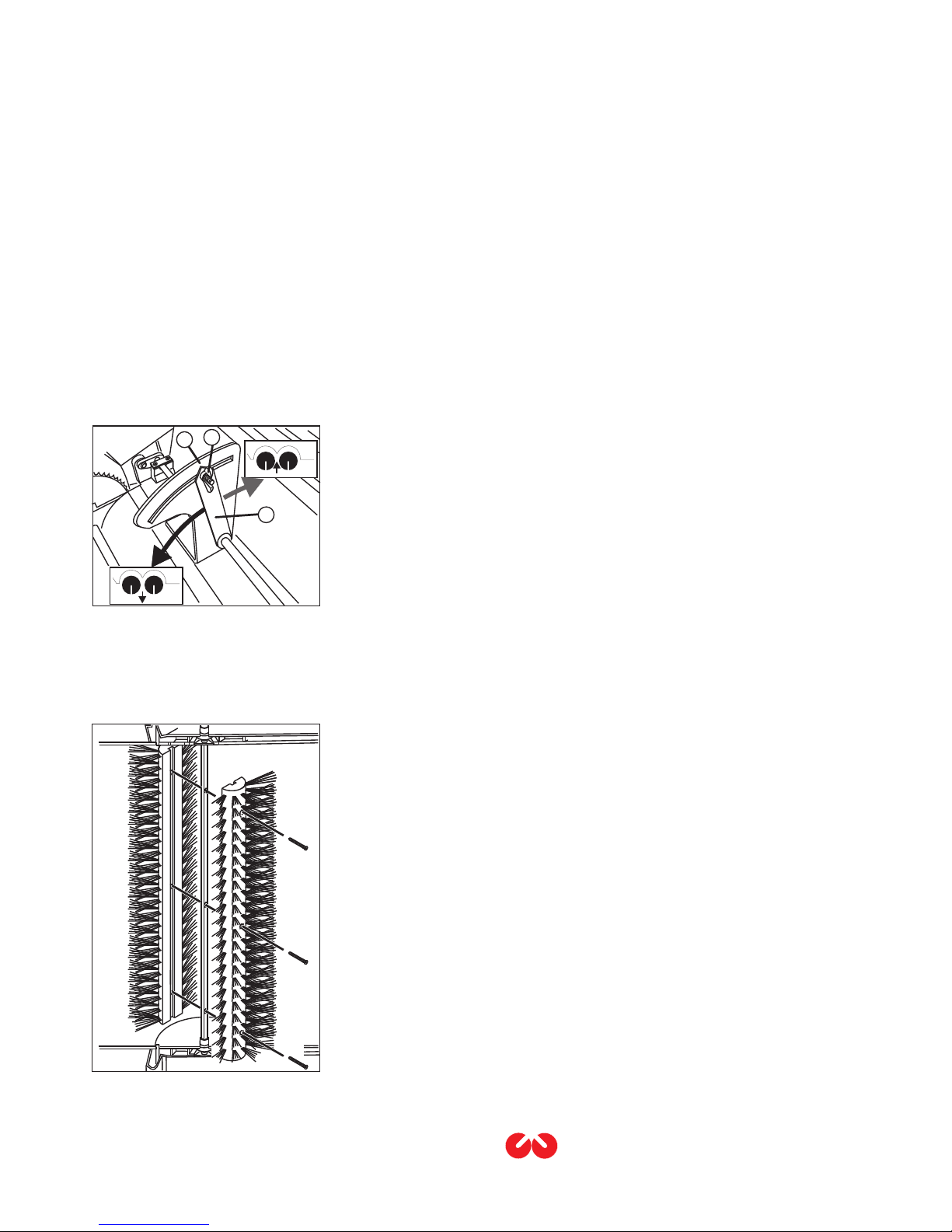

Initial start-up

Open the packaging and carefully lift the machine off the pallet.

Reach under the frame of the machinery to lift it. There is a risk of injury if you

attempt to lift the machinery at the hood, the side brush retainer, or the dustbin.

Remove the star knobs from the driving hoop retainers and remove the square necked

bolts.

Place the driving hoop on the retainers.

Slide the square necked bolts through the bore holes in the driving hoop and the retainer.

Use the star knobs to secure the square necked bolts.

Set the side brush arms to the top position.

Position the side brushes under the side brush retainers.

Turn the side brushes until the bore holes of the side brush disc line up with the pins of

the side brush retainer.

Push the side brushes into the side brush retainers until you feel the side brushes lock

into place.

Set the side brush arms in their bottom position.

Connect the battery. See technical data - switching diagram.

The sweeper is ready for operation.

Unpacking and assembly

Caution! Danger of injury!

•

•

•

•

•

•

•

•

•

•

•

forward drive

forward drive

Dimension and Weight

Length:

Width:

Height:

Weight:

Sweeping Width:

with one side brush

- with two side brushes

Main sweeping roller-

-

Technical Data

Battery voltage

(Battery) capacity

2

1

3

-3-

-2-

STOLZENBERG

Kehrmaschinen

·MATRIX MTX-900-V/-B/-VB TRS ·20122006

STOLZENBERG

Kehrmaschinen

·MATRIX MTX-900-V/-B/-VB TRS · 20122006

Introduction

About these Operating Instructions.

These Operating Instructions pertain to the operation of the .

Our products are subject to continuous improvement;constructive changes that have been

made after the printing of these operating instructions could not be taken into account. If you

have any questions, feel free to contactour service department.

The Operating Instructions must be read and observed by anybody using or operating the

manual sweeper .

Besides applying the Operating Instructions, the operator isreminded to observe the

legislator's accident prevention regulations as well as general rules of professional and safe

working methods.

Matrix MTX-900-x TRS

Matrix MTX-900-x TRS

Safety Information

The manual sweeper is designed and built in accordance with

state of the art know-how and standard safety regulations. In spite of this, physical danger

to the operator or third parties or the impairment of the manual sweeper or other valuable

objects may arise during operation.

Always use the manual sweeper in a flawless condition and in a way that accords with

general rules of operational and personal safety, and always observe these

Operating Instructions! Eliminate malfunctions that may impair operational safety

immediately!

Keep Operating Instructions ready at hand wherever the manual sweeper is used!

In addition to the Operating Instructions, observe the generally applicable legal or other

binding guidelines for accident prevention and environmental protection!

Do not modify, expand, or reconstruct the manual sweeper in any way without explicit

approval by the manufacturer.

Replacement parts must comply with the specifications defined by the manufacturer. This

will always be the case if only original replacement parts are applied.

Observe the prescribed maintenance intervals and those stated in these Operating

Instructions!

Be sure to dispose of operational and auxiliary materials as well as replacement parts in a

safe and environmentally sound way!

Matrix MTX-900-x TRS

Correct Application

The manual sweeper is intended exclusively for cleaning hard surfaces of dry

sweepings. e. g. : parking lots, industrial buildings, warehouses, sidewalks.

Any application different from or exceeding this definition is incorrect.

The manufacturer is not to be held responsible for any damage arising from such

applications.

Any risk is to be assumed by the operator.

Correct application includes the observation of Operating Instructions as well as inspection

and maintenance intervals.

Never use this machine to sweep inflammable or toxic or explosive substances.

The manual sweeper is not suitable for taking up cords, strings, wires or similar

materials.

Control panel

Steerable rear wheel

running wheel

dustbin

control panel

handle

hood

Height adjustment

for side brush

side brushes

Sweeper description

The battery-operated sweeper has been equipped with two side brushes and two

counter-rotating brush rollers.

The sweeping mechanism features two side brushes which convey the refuse to the

two brush rollers that are mounted parallel to the direction of motion.

The brushes throw the refuse overhead in the rear dirt collector.

A chain drives the brush rollers, and a V-belt drives the side brushes through the

forward motion of the running wheel.

The top model of the Matrix series is the Matrix MTX-900-VB TRS, which has been

equipped with a dust extraction unit (V) and a brush roller drive (B).

The modular design of the Matrix series allows for retrofitting the Matrix MTX-900-V

TRS

with a brush roller drive (standard model features a dust extraction unit) and the

Matrix MTX-900-B TRS with a dust extraction unit (standard model features a brush

roller drive).

The electronic system provides for a soft start feature, which ensures that the drive

does

not run at full power all of a sudden.

The Matrix MTX-900-x TRS sweeper is driven by manual power only, in other words,

by

1091 mm

760 mm

460 mm

22 - 50 kg

500 mm

700 mm

900 mm

12 V

28 Ah bzw.

Dust Container Volume 50 ltr

Start/Stop button of the brush roller

drive (applies to B and VB models)

Start/Stop button of the suction system

Battery status display

-1-

-2-

-3-

driving hoop

Initial start-up

Open the packaging and carefully lift the machine off the pallet.

Reach under the frame of the machinery to lift it. There is a risk of injury if you

attempt to lift the machinery at the hood, the side brush retainer, or the dustbin.

Remove the star knobs from the driving hoop retainers and remove the square necked

bolts.

Place the driving hoop on the retainers.

Slide the square necked bolts through the bore holes in the driving hoop and the retainer.

Use the star knobs to secure the square necked bolts.

Set the side brush arms to the top position.

Position the side brushes under the side brush retainers.

Turn the side brushes until the bore holes of the side brush disc line up with the pins of

the side brush retainer.

Push the side brushes into the side brush retainers until you feel the side brushes lock

into place.

Set the side brush arms in their bottom position.

Connect the battery. See technical data - switching diagram.

The sweeper is ready for operation.

Unpacking and assembly

Caution! Danger of injury!

•

•

•

•

•

•

•

•

•

•

•

forward drive

forward drive

Dimension and Weight

Length:

Width:

Height:

Weight:

Sweeping Width:

with one side brush

- with two side brushes

Main sweeping roller-

-

Technical Data

Battery voltage

(Battery) capacity

2

1

3

-4-

1

3

2

1

230V

2

-5-

STOLZENBERG

Kehrmaschinen

·MATRIX MTX-900-V/-B/-VB TRS · 20122006

STOLZENBERG

Kehrmaschinen

20122006·MATRIX MTX-900-V/-B/-VB TRS ·

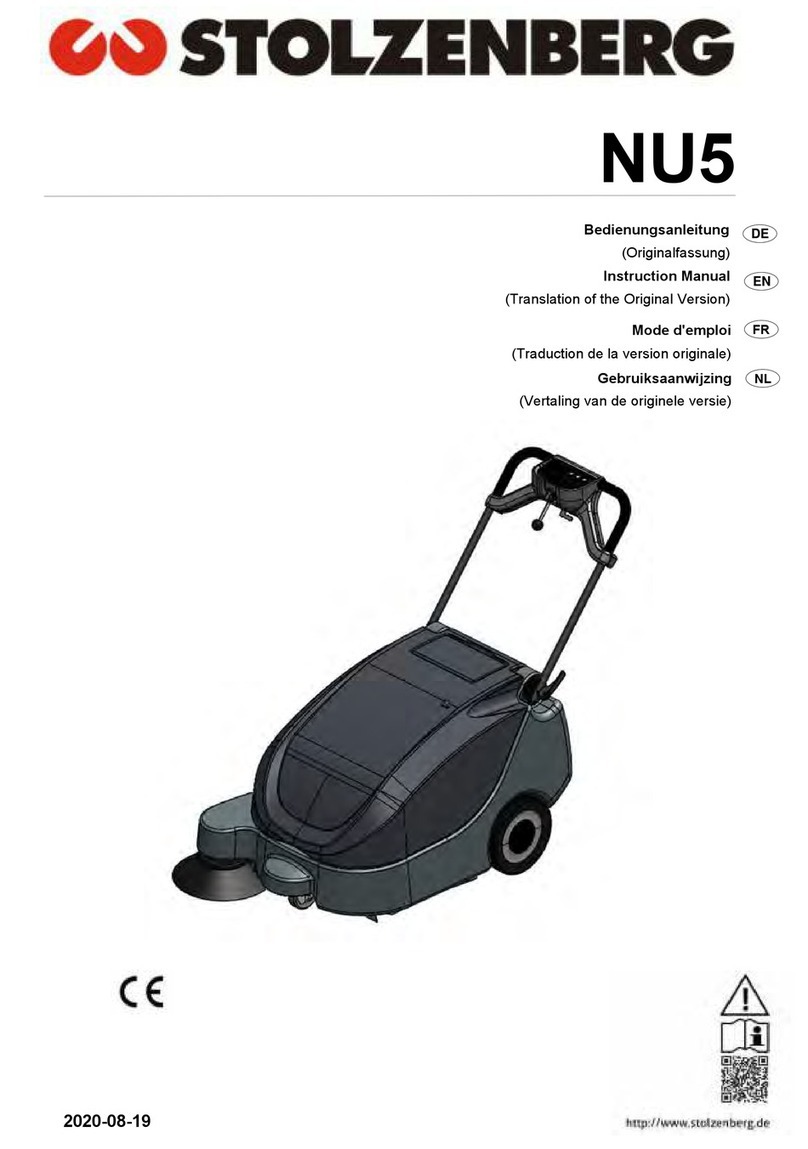

Emptying the dustbin

In order to ensure proper sweeping performance, the dustbin has to be emptied at

regular intervals.

A handle is located on the top of the dustbin.

Do not park the sweeper with a full dustbin. Always empty the dustbin once you've

finished sweeping.

•

•

•

Hold on to the handle and lift the dustbin out of the sweeper's frame.

Empty the dustbin in a suitable container.

Insert the dustbin back into the sweeper.

Sweeping

•

•

•

•

•

Lower the side brushes.

To turn on the desired sweeping function, select and push the button for the desired

function on the control panel.

Always use the button on the right first, regardless of the model.

(Models B and VB: Turn on the brush roller drive/Model V: Make ready for operation)

Only then push the button on the left on the V and VB models.

(Dust extraction unit on)

No function has been assigned to the button on the left on the Matrix MTX-900-B TRS.

Push the sweeper across the area to be swept at a normal pace.

Caution!

Since the sweeping performance depends on the speed of the brush rollers, you

should neither walk to slowly nor too quickly. (e.g. run)

The side brushes remove dirt from corners and edges.

The sweeping mechanism will only work if the sweeper is pushed forward as it has

been fitted with a free-wheel coupling to avoid whirling up dust unnecessarily.

.

After sweeping

•

•

•

•

Push the respective button on the control panel to turn off all the actuators and park the

sweeper in a safe location.

Empty the dustbin in a suitable container.

Insert the dustbin back into the sweeper.

Set the side brushes to their top position.

Make sure the container is appropriate for this type of refuse.

Unless the side brushes are set to their top position, the bristles of the side brushes

will be put under permanent load in their off-position and consequently will wear

prematurely when used.

Height adjustment of the side brushes

The side brush arms are located on the front side of the sweeper.

The height adjustment fixtures for the side brushes are located on the side brush arms.

You can lower or raise both or just one side brush as needed.

To lower a side brush:

To raise a side brush:

•

•

Push the lever of the side brush adjustment fixture to the front.

Pull the lever to the rear.

Operation

Safety Information

.The Sweeping & Suction Machine may only be operated by dependable persons.

Only deploy trained and instructed staff. The areas or responsibility of staff must be clearly

defined Examine the Sweeping & Suction Machine before starting and check serviceability

and technical safety. Do not use the machine in case of malfunctions of any kind.

Only drive on specifically assigned pathways and lots.

Such objects may wind around the moving parts of the machinery and result in reducing the

sweeping performance (tie up bristles) or they may clog the sweeper.

After you've finished sweeping, always park the sweeper on level ground and make sure it

is secured from rolling away by accident.

It is prohibited to use the sweeper to transport loads. Try to avoid sweeping up

packing band, wires, or similar items.

Control panel

Start/Stop button of the brush roller

drive (applies to B and VB models)

Start/Stop button of the suction system

Battery status display

-1-

-2-

-3-

forward drive

Safety information

Only complete the type of maintenance work described in the following chapter. The

authorised dealer or the manufacturer is responsible for performing any other maintenance

work.

Closely follow the steps listed in the maintenance instructions. The improper completion of

maintenance tasks may result in malfunctions when using the sweeper and may possibly

render the warranty granted null and void.

To complete any work on the sweeper, it will have to be secured from rolling away by

accident.

The sweeper will have to be turned off.

The electric motors must not be running when performing any maintenance work on or

troubleshooting the electric motors.

Use only flawless and appropriate tools to complete maintenance work.

Replacement parts have to meet manufacturer specifications.

This is always ensured by using genuine replacement parts.

If covers and/or safety devices were removed during maintenance work/repairs, they will

have to be re-attached prior to starting the sweeper.

Battery

Safety Information for Battery Handling

When servicing the batteries, please absolutely observe the following warning information

and safety regulations:

Avoid spark formation while handling cables and electrical devices.

Never short-circuit battery poles. Danger of injury by highly charged sparks.

Always keep batteries in a clean and dry place to avoid leak current.

Only charge batteries in well ventilated rooms. Don't smoke and keep away open flames

and electric sparks, because the charging process produces a highly explosive combustive

mixture.

In order to prevent health impairment do not smoke,eat, or drink in the vicinity of the battery

charging device.

Explanations of the LED displays

on the control panel

Charging the battery.

The machine has an on-board-charger.

Position the machine on an approprate surface close to a socket.

Switch the machine completely of.

Make sure the machine is blocked against possible movement

Open the cover.

Connect plug 1 of the charger using the cable delivered with the machine and connect plug

2 to the 230 V socket.

Only the original charging-cable is to be used: the use of a different cable makes

you lose warranty on the machine and might cause damage.

When charging is finished, the green LED on the charger will on.

(Meaning of the LED: see appendix: operators manual of the charger).

The machine can only be operated if disconnected after charging.

Make sure the machine is charged before use. The charger contains an electronic device

that keeps current of the battery on a constant level so the machine can be kept on the

charger for a longer period without causing any damage.

The machine contains a deep-discharge protection and automatically switches of if such

level is reached to protect battery from damage.

-1-

-2-

-3-

ready/battery charge ok

ready/battery charge low

ready/battery charge not ok

forward drive

Service and Maintenance

2

1

3

-4-

1

3

2

1

230V

2

-5-

STOLZENBERG

Kehrmaschinen

·MATRIX MTX-900-V/-B/-VB TRS · 20122006

STOLZENBERG

Kehrmaschinen

20122006·MATRIX MTX-900-V/-B/-VB TRS ·

Emptying the dustbin

In order to ensure proper sweeping performance, the dustbin has to be emptied at

regular intervals.

A handle is located on the top of the dustbin.

Do not park the sweeper with a full dustbin. Always empty the dustbin once you've

finished sweeping.

•

•

•

Hold on to the handle and lift the dustbin out of the sweeper's frame.

Empty the dustbin in a suitable container.

Insert the dustbin back into the sweeper.

Sweeping

•

•

•

•

•

Lower the side brushes.

To turn on the desired sweeping function, select and push the button for the desired

function on the control panel.

Always use the button on the right first, regardless of the model.

(Models B and VB: Turn on the brush roller drive/Model V: Make ready for operation)

Only then push the button on the left on the V and VB models.

(Dust extraction unit on)

No function has been assigned to the button on the left on the Matrix MTX-900-B TRS.

Push the sweeper across the area to be swept at a normal pace.

Caution!

Since the sweeping performance depends on the speed of the brush rollers, you

should neither walk to slowly nor too quickly. (e.g. run)

The side brushes remove dirt from corners and edges.

The sweeping mechanism will only work if the sweeper is pushed forward as it has

been fitted with a free-wheel coupling to avoid whirling up dust unnecessarily.

.

After sweeping

•

•

•

•

Push the respective button on the control panel to turn off all the actuators and park the

sweeper in a safe location.

Empty the dustbin in a suitable container.

Insert the dustbin back into the sweeper.

Set the side brushes to their top position.

Make sure the container is appropriate for this type of refuse.

Unless the side brushes are set to their top position, the bristles of the side brushes

will be put under permanent load in their off-position and consequently will wear

prematurely when used.

Height adjustment of the side brushes

The side brush arms are located on the front side of the sweeper.

The height adjustment fixtures for the side brushes are located on the side brush arms.

You can lower or raise both or just one side brush as needed.

To lower a side brush:

To raise a side brush:

•

•

Push the lever of the side brush adjustment fixture to the front.

Pull the lever to the rear.

Operation

Safety Information

.The Sweeping & Suction Machine may only be operated by dependable persons.

Only deploy trained and instructed staff. The areas or responsibility of staff must be clearly

defined Examine the Sweeping & Suction Machine before starting and check serviceability

and technical safety. Do not use the machine in case of malfunctions of any kind.

Only drive on specifically assigned pathways and lots.

Such objects may wind around the moving parts of the machinery and result in reducing the

sweeping performance (tie up bristles) or they may clog the sweeper.

After you've finished sweeping, always park the sweeper on level ground and make sure it

is secured from rolling away by accident.

It is prohibited to use the sweeper to transport loads. Try to avoid sweeping up

packing band, wires, or similar items.

Control panel

Start/Stop button of the brush roller

drive (applies to B and VB models)

Start/Stop button of the suction system

Battery status display

-1-

-2-

-3-

forward drive

Safety information

Only complete the type of maintenance work described in the following chapter. The

authorised dealer or the manufacturer is responsible for performing any other maintenance

work.

Closely follow the steps listed in the maintenance instructions. The improper completion of

maintenance tasks may result in malfunctions when using the sweeper and may possibly

render the warranty granted null and void.

To complete any work on the sweeper, it will have to be secured from rolling away by

accident.

The sweeper will have to be turned off.

The electric motors must not be running when performing any maintenance work on or

troubleshooting the electric motors.

Use only flawless and appropriate tools to complete maintenance work.

Replacement parts have to meet manufacturer specifications.

This is always ensured by using genuine replacement parts.

If covers and/or safety devices were removed during maintenance work/repairs, they will

have to be re-attached prior to starting the sweeper.

Battery

Safety Information for Battery Handling

When servicing the batteries, please absolutely observe the following warning information

and safety regulations:

Avoid spark formation while handling cables and electrical devices.

Never short-circuit battery poles. Danger of injury by highly charged sparks.

Always keep batteries in a clean and dry place to avoid leak current.

Only charge batteries in well ventilated rooms. Don't smoke and keep away open flames

and electric sparks, because the charging process produces a highly explosive combustive

mixture.

In order to prevent health impairment do not smoke,eat, or drink in the vicinity of the battery

charging device.

Explanations of the LED displays

on the control panel

Charging the battery.

The machine has an on-board-charger.

Position the machine on an approprate surface close to a socket.

Switch the machine completely of.

Make sure the machine is blocked against possible movement

Open the cover.

Connect plug 1 of the charger using the cable delivered with the machine and connect plug

2 to the 230 V socket.

Only the original charging-cable is to be used: the use of a different cable makes

you lose warranty on the machine and might cause damage.

When charging is finished, the green LED on the charger will on.

(Meaning of the LED: see appendix: operators manual of the charger).

The machine can only be operated if disconnected after charging.

Make sure the machine is charged before use. The charger contains an electronic device

that keeps current of the battery on a constant level so the machine can be kept on the

charger for a longer period without causing any damage.

The machine contains a deep-discharge protection and automatically switches of if such

level is reached to protect battery from damage.

-1-

-2-

-3-

ready/battery charge ok

ready/battery charge low

ready/battery charge not ok

forward drive

Service and Maintenance

12

3

-7-

-6-

STOLZENBERG

Kehrmaschinen

20122006·MATRIX MTX-900-V/-B/-VB TRS ·

·MATRIX MTX-900-V/-B/-VB TRS · 20122006

STOLZENBERG

Kehrmaschinen

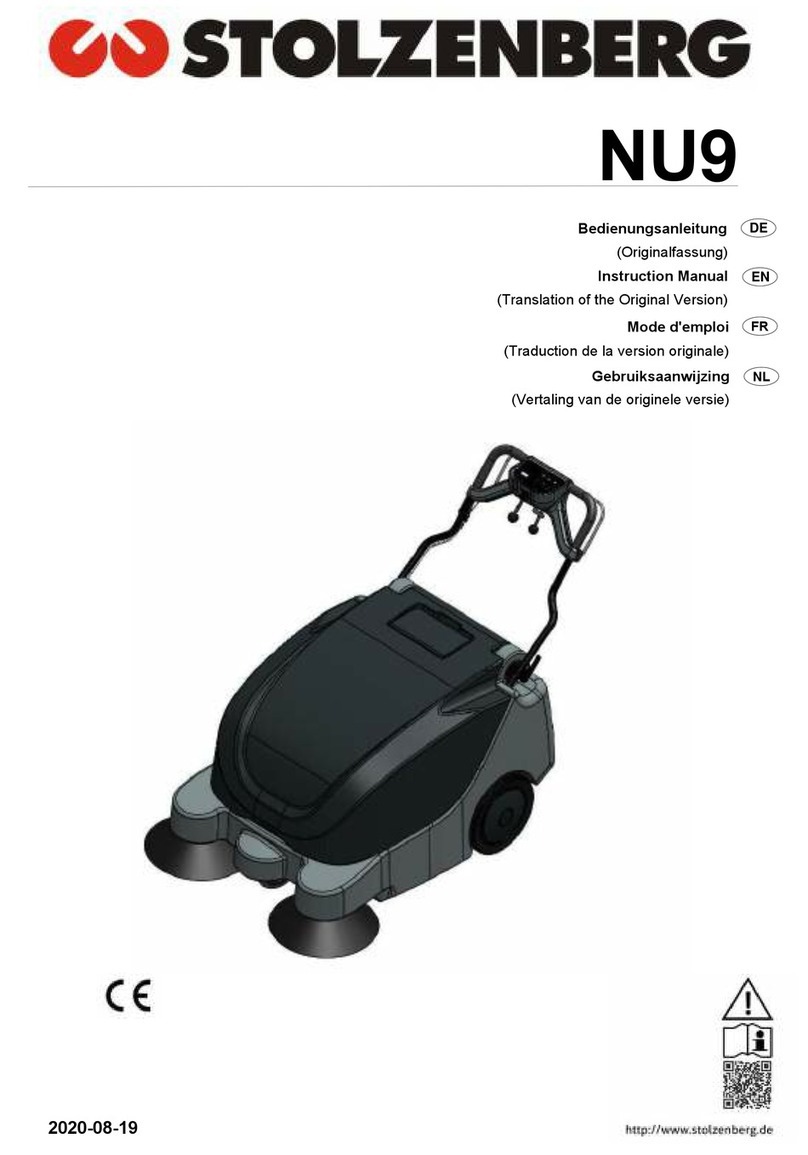

Readjusting the brush rollers

The height of the brush rollers can be adjusted to obtain the best possible cleaning results of

the area to be swept and to effectively exploit the efficiency of the brush rollers.

The brush rollers need to be lowered once the sweeping performance starts to wane due to

wear and tear of the brush rollers, or if the area to be swept is not level (bumpy).

If pushing the sweeper seems to become harder and you can hear the brush rollers

scratching the ground, you will have to raise the brush rollers to ensure you use the sweeper

ergonomically and to prevent the brush rollers from wearing prematurely.

On principle, the brush rollers should be set to ensure that they touches the ground at slight

pressure.

To raise the brush rollers

•

•

•

•

Undo wing nut on the height adjustment bracket .

Push down the rocker arm -3- in the direction of the dustbin.

Tighten wing nut on the height adjustment bracket .

Test the sweeper.

Readjust if necessary

-2- -1-

The brush rollers are raised.

-2- -1-

To lower the brush rollers

•

•

•

•

Undo wing nut on the height adjustment bracket .

Push down the rocker arm -3- in the direction of motion.

Tighten wing nut on the height adjustment bracket .

Test the sweeper.

Readjust if necessary

-2- -1-

The brush rollers are lowered.

-2- -1-

Setting the brush rollers

•

•

•

Park the sweeper on level ground that has been designated (assigned) for this purpose.

Make sure the sweeper has been secured from rolling away by accident.

Open the hood.

The rear trim panel of the frame reveals the height adjustment bracket to adjust the height of

the brushes.

Brush roller replacement

Removing the brush rollers

Installing the brush rollers

Every brush roller consists of two split shells with brushes.

Screws join the split shells.

Park the sweeper on level ground that has been designated (assigned) for this purpose.

Make sure the sweeper has been secured from rolling away by accident.

Remove the dustbin.

Turn the sweeper on its side.

Turn the top running wheel until you can see the screwed connections on the brush roller.

Undo the screwed connections.

Lift the split shells with the brush rollers off the shaft.

If needed clean the running gear box and the shaft.

The split shells have square recesses, which retain the brush roller shaft.

Position the first split shell under the square shaft of the brush roller.

.

Position the second split shell on top of the square shaft of the brush roller.

To tighten use three screws for each set of brushes. Tighten until you can no longer see a

gap between the split shells.

•

•

•

•

•

•

•

•

•

•

•

Make sure the running wheels can move freely.

Make sure the shaft fits flush into the recess of the split shell.

Side brush replacement

Removing the side brushes

Mounting the side brushes

•

•

•

•

•

•

•

•

•

•

Park the sweeper on level ground that has been designated (assigned) for this purpose.

Make sure the sweeper has been secured from rolling away by accident.

Lift the side brushes.

Reach under the side brushes.

With your fingers squeeze together the snap-in fixtures in the centre of the side brush

retainer.

With a downward motion, pull off the side brushes.

Replace the side brushes.

Position the side brushes under the side brush retainers.

Turn the side brushes until the bore holes of the side brush disk line up with the pins of the

side brush retainer.

Push the side brushes into the side brush retainers until you feel the side brushes lock

into place.

Changing the chain

De-tentioning or tentioning of the chain is proceeded by turning/ moving the DC-motor or the

sprocket-support.

Position the machine on a appropriate surface.

Make sure the machine is blocked against possible movement

Open the cover.

Loosen the screws of the DC-motor or the sprocket-support to move the support by rotating

it around the front/ first screw.

By lowering the DC-motor or the sprocket-support, the chain is de-tentioned e.g. for

changing the chain.

Moving up the DC-motor or the sprocket-support tentiones the chain.

Tighten the screws before operating the machine.

The tention of the chain is supported by the automatic chain-tentioner.

Cleaning the sweeper

Do not clean the sweeper with a pressure washer. Just use a dry broom to brush off the

sweeper. Remove dirt, strings, etc. from the brush rollers, side brushes, and shafts.

The Sweeping & Suction Machine is a machine with

electrical system components.

Humidity will damage the electronics and the mechanics of the machine.

Moisture may lead to leak current and short-circuits.

Do not use high-pressure cleaning devices.

The Sweeping & Suction Machine may only be dry-cleaned.

Please observe!

12

3

-7-

-6-

STOLZENBERG

Kehrmaschinen

20122006·MATRIX MTX-900-V/-B/-VB TRS ·

·MATRIX MTX-900-V/-B/-VB TRS · 20122006

STOLZENBERG

Kehrmaschinen

Readjusting the brush rollers

The height of the brush rollers can be adjusted to obtain the best possible cleaning results of

the area to be swept and to effectively exploit the efficiency of the brush rollers.

The brush rollers need to be lowered once the sweeping performance starts to wane due to

wear and tear of the brush rollers, or if the area to be swept is not level (bumpy).

If pushing the sweeper seems to become harder and you can hear the brush rollers

scratching the ground, you will have to raise the brush rollers to ensure you use the sweeper

ergonomically and to prevent the brush rollers from wearing prematurely.

On principle, the brush rollers should be set to ensure that they touches the ground at slight

pressure.

To raise the brush rollers

•

•

•

•

Undo wing nut on the height adjustment bracket .

Push down the rocker arm -3- in the direction of the dustbin.

Tighten wing nut on the height adjustment bracket .

Test the sweeper.

Readjust if necessary

-2- -1-

The brush rollers are raised.

-2- -1-

To lower the brush rollers

•

•

•

•

Undo wing nut on the height adjustment bracket .

Push down the rocker arm -3- in the direction of motion.

Tighten wing nut on the height adjustment bracket .

Test the sweeper.

Readjust if necessary

-2- -1-

The brush rollers are lowered.

-2- -1-

Setting the brush rollers

•

•

•

Park the sweeper on level ground that has been designated (assigned) for this purpose.

Make sure the sweeper has been secured from rolling away by accident.

Open the hood.

The rear trim panel of the frame reveals the height adjustment bracket to adjust the height of

the brushes.

Brush roller replacement

Removing the brush rollers

Installing the brush rollers

Every brush roller consists of two split shells with brushes.

Screws join the split shells.

Park the sweeper on level ground that has been designated (assigned) for this purpose.

Make sure the sweeper has been secured from rolling away by accident.

Remove the dustbin.

Turn the sweeper on its side.

Turn the top running wheel until you can see the screwed connections on the brush roller.

Undo the screwed connections.

Lift the split shells with the brush rollers off the shaft.

If needed clean the running gear box and the shaft.

The split shells have square recesses, which retain the brush roller shaft.

Position the first split shell under the square shaft of the brush roller.

.

Position the second split shell on top of the square shaft of the brush roller.

To tighten use three screws for each set of brushes. Tighten until you can no longer see a

gap between the split shells.

•

•

•

•

•

•

•

•

•

•

•

Make sure the running wheels can move freely.

Make sure the shaft fits flush into the recess of the split shell.

Side brush replacement

Removing the side brushes

Mounting the side brushes

•

•

•

•

•

•

•

•

•

•

Park the sweeper on level ground that has been designated (assigned) for this purpose.

Make sure the sweeper has been secured from rolling away by accident.

Lift the side brushes.

Reach under the side brushes.

With your fingers squeeze together the snap-in fixtures in the centre of the side brush

retainer.

With a downward motion, pull off the side brushes.

Replace the side brushes.

Position the side brushes under the side brush retainers.

Turn the side brushes until the bore holes of the side brush disk line up with the pins of the

side brush retainer.

Push the side brushes into the side brush retainers until you feel the side brushes lock

into place.

Changing the chain

De-tentioning or tentioning of the chain is proceeded by turning/ moving the DC-motor or the

sprocket-support.

Position the machine on a appropriate surface.

Make sure the machine is blocked against possible movement

Open the cover.

Loosen the screws of the DC-motor or the sprocket-support to move the support by rotating

it around the front/ first screw.

By lowering the DC-motor or the sprocket-support, the chain is de-tentioned e.g. for

changing the chain.

Moving up the DC-motor or the sprocket-support tentiones the chain.

Tighten the screws before operating the machine.

The tention of the chain is supported by the automatic chain-tentioner.

Cleaning the sweeper

Do not clean the sweeper with a pressure washer. Just use a dry broom to brush off the

sweeper. Remove dirt, strings, etc. from the brush rollers, side brushes, and shafts.

The Sweeping & Suction Machine is a machine with

electrical system components.

Humidity will damage the electronics and the mechanics of the machine.

Moisture may lead to leak current and short-circuits.

Do not use high-pressure cleaning devices.

The Sweeping & Suction Machine may only be dry-cleaned.

Please observe!

-9--8-

2

2131

6

6

5

4

STOLZENBERG

Kehrmaschinen

20122006·MATRIX MTX-900-V/-B/-VB TRS ·

·MATRIX MTX-900-V/-B/-VB TRS · 20122006

STOLZENBERG

Kehrmaschinen

Filter cleaning

To consistently attain the best possible cleaning results, you must always clean the

lamellar filter prior to emptying the dust bin.

Likewise, you should also clean the filter if particularly dusty areas are swept, or if

dust is whirled up during sweeping.

The sweeper has been equipped with a mechanically operated vibrating device to

clean the lamellar filter.

To remove stubborn dirt, you should use a brush to clean off the filter or take out the

filter and gently knock off the dirt.

•

•

•

•

•

Turn off the sweeper (all actuators).

Make sure the sweeper has been secured from rolling away by accident.

Open the hood.

On the top of the ejector's trim panel two slides are located.

Swiftly slide these slides back and forth.

-3- -1-

These slides initiate a vibrating mechanism, which works loose the dust from the lamellar

filter. The worked off dust drops directly into the dustbin.

Removing the filter

The sweeper has to be off if you're planning to take out the filter.

(all actuators off)

-2- -3-

•

•

•

•

•

•

Turn off the sweeper (all actuators).

Make sure the sweeper has been secured from rolling away by accident.

Remove the dustbin.

Open the hood.

Remove these wing nuts.

Pull out the filter frame with the filter from the trim panel of the ejector in the

direction of the dustbin retainer

Two wing nuts are located on the trim panel of the ejector .

-4- -5- -2-

In addition, the following applies to MTX-900-V TRS and MTX-900-VB TRS

Disposal

Disposal of defective parts, specifically electric component parts, batteries and plastic

elements in compliance with legislator's waste disposal regulations.

Installing the filter

The sweeper has to be off if you're planning to install the filter.

(all actuators off)

-5- -4-

-4- -5-

-3- -6-

-2-

•

•

•

•

Set the filter in the filter frame .

Make sure the filter fits correctly.

Insert the filter frame with the filter from the side of the dustbin retainer into the trim

panel of the ejector in such a way as to ensure the cup square neck bolt of the filter

frame will fit through the bore holes of the trim panel of the ejector.

Make sure the bolts fit correctly. The square of the bolt has to fit into the square recess of

the filter frame.

Firmly push the filter with its filter frame against the trim panel of the ejector.

Screw tight the two wing nuts on the threads of the cup square neck bolts of the filter

frame.

Maintenance Chart

Daily maintenance

After each 50 operating hours also

-

-

Charge battery.

Check if machine is damaged or impaired in any way.

Empty dust container.

Search brush - roller tunnel for jammed particles and seized up dirt that may narrow the brush tunnel and

obstruct free roller brush movement.

Check condition of dust filter and clean if necessary.

Check if sweeping rollers are worn or cluttered. Replace if required.

Check sweeping contour, readjust if required.

Check if side brush adjustment is worn, if required readjust or replace.

Check cable isolation, replace cables if required.

Search suction for obstacles, clean.

Check if roller drive chain is elongated or loosened.

Check all bearings for wear.

Check if seals are damaged or dislocated.

Check if cable connections are tight.

Clean dust filter, replace if necessary.

-

-

-

-

-

-

-

-

-

-

-

-

-

After each 100 operating hours also

In addition, the following applies to MTX-900-V TRS and MTX-900-VB TRS

In addition, the following applies to MTX-900-V TRS and MTX-900-VB TRS

No operation of one of

the electrical consumers:

Sweeping result

unsatisfactory:

Check plug connections

Charge battery

Lower

Adjust

Check if roller trim panel is impaired by jammed

debris. Correctly fitted?

if required switch off side brushes

Dismount brush rollers and clean them

Check side brushes and remove obstacles

Jack up the Sweeping & Suction Machine

check wheels and free running

Open the ventilation flap

Clean filter

check for tight fit

check if false air is sucked in

Check ventilator wheel and remove any obstruction

F

B

S

Drive wheels obstructed

F

F

mer

ault in electrical wiring

attery empty

Side brush(es) or main sweeping rollers

not lowered

ide brush(es) or main sweeping

rollers worn

Trajectory clogged by dirt

Sweeping roller(s) do not operat

Brush rollers are jammed by dirt,

cords, strings or the like

ilter heavily polluted

ilter not correctly fitted

Leakage and subsequent aspiration of

false air in the filter chamber

Ator does not move freely

Disturbances - Disturbance Display and Remedy

Disturbance Possible Cause Remedy

In addition, the following applies to MTX-900-V TRS and MTX-900-VB TRS

-9--8-

2

2131

6

6

5

4

STOLZENBERG

Kehrmaschinen

20122006·MATRIX MTX-900-V/-B/-VB TRS ·

·MATRIX MTX-900-V/-B/-VB TRS · 20122006

STOLZENBERG

Kehrmaschinen

Filter cleaning

To consistently attain the best possible cleaning results, you must always clean the

lamellar filter prior to emptying the dust bin.

Likewise, you should also clean the filter if particularly dusty areas are swept, or if

dust is whirled up during sweeping.

The sweeper has been equipped with a mechanically operated vibrating device to

clean the lamellar filter.

To remove stubborn dirt, you should use a brush to clean off the filter or take out the

filter and gently knock off the dirt.

•

•

•

•

•

Turn off the sweeper (all actuators).

Make sure the sweeper has been secured from rolling away by accident.

Open the hood.

On the top of the ejector's trim panel two slides are located.

Swiftly slide these slides back and forth.

-3- -1-

These slides initiate a vibrating mechanism, which works loose the dust from the lamellar

filter. The worked off dust drops directly into the dustbin.

Removing the filter

The sweeper has to be off if you're planning to take out the filter.

(all actuators off)

-2- -3-

•

•

•

•

•

•

Turn off the sweeper (all actuators).

Make sure the sweeper has been secured from rolling away by accident.

Remove the dustbin.

Open the hood.

Remove these wing nuts.

Pull out the filter frame with the filter from the trim panel of the ejector in the

direction of the dustbin retainer

Two wing nuts are located on the trim panel of the ejector .

-4- -5- -2-

In addition, the following applies to MTX-900-V TRS and MTX-900-VB TRS

Disposal

Disposal of defective parts, specifically electric component parts, batteries and plastic

elements in compliance with legislator's waste disposal regulations.

Installing the filter

The sweeper has to be off if you're planning to install the filter.

(all actuators off)

-5- -4-

-4- -5-

-3- -6-

-2-

•

•

•

•

Set the filter in the filter frame .

Make sure the filter fits correctly.

Insert the filter frame with the filter from the side of the dustbin retainer into the trim

panel of the ejector in such a way as to ensure the cup square neck bolt of the filter

frame will fit through the bore holes of the trim panel of the ejector.

Make sure the bolts fit correctly. The square of the bolt has to fit into the square recess of

the filter frame.

Firmly push the filter with its filter frame against the trim panel of the ejector.

Screw tight the two wing nuts on the threads of the cup square neck bolts of the filter

frame.

Maintenance Chart

Daily maintenance

After each 50 operating hours also

-

-

Charge battery.

Check if machine is damaged or impaired in any way.

Empty dust container.

Search brush - roller tunnel for jammed particles and seized up dirt that may narrow the brush tunnel and

obstruct free roller brush movement.

Check condition of dust filter and clean if necessary.

Check if sweeping rollers are worn or cluttered. Replace if required.

Check sweeping contour, readjust if required.

Check if side brush adjustment is worn, if required readjust or replace.

Check cable isolation, replace cables if required.

Search suction for obstacles, clean.

Check if roller drive chain is elongated or loosened.

Check all bearings for wear.

Check if seals are damaged or dislocated.

Check if cable connections are tight.

Clean dust filter, replace if necessary.

-

-

-

-

-

-

-

-

-

-

-

-

-

After each 100 operating hours also

In addition, the following applies to MTX-900-V TRS and MTX-900-VB TRS

In addition, the following applies to MTX-900-V TRS and MTX-900-VB TRS

No operation of one of

the electrical consumers:

Sweeping result

unsatisfactory:

Check plug connections

Charge battery

Lower

Adjust

Check if roller trim panel is impaired by jammed

debris. Correctly fitted?

if required switch off side brushes

Dismount brush rollers and clean them

Check side brushes and remove obstacles

Jack up the Sweeping & Suction Machine

check wheels and free running

Open the ventilation flap

Clean filter

check for tight fit

check if false air is sucked in

Check ventilator wheel and remove any obstruction

F

B

S

Drive wheels obstructed

F

F

mer

ault in electrical wiring

attery empty

Side brush(es) or main sweeping rollers

not lowered

ide brush(es) or main sweeping

rollers worn

Trajectory clogged by dirt

Sweeping roller(s) do not operat

Brush rollers are jammed by dirt,

cords, strings or the like

ilter heavily polluted

ilter not correctly fitted

Leakage and subsequent aspiration of

false air in the filter chamber

Ator does not move freely

Disturbances - Disturbance Display and Remedy

Disturbance Possible Cause Remedy

In addition, the following applies to MTX-900-V TRS and MTX-900-VB TRS

DIN EN ISO 12100

EN 294

DIN EN 60335-2-29

DIN EN 60335-2-67

DIN EN 60335-2-72

DIN EN 61000-6-4

DIN EN 60335-2-72

EMV Richtlinie 98/336/EWG

Niederspannungsrichtlinie

Geräusch-Richtlinie 2000/14/EG

2006/95/EG

EG Declaration of Conformity

The manufacturer:

he product

the EG-Guidelinie 89/392/EWG

The Standards and/or technical specifications

in compliance with EG-Guidelinie

declares as solely responsible party, that

this declaration refers to, observes

and correspondes to it regarding all relevant safety and health requirements.

have been applied in a way that ensures the appropriate implementation of

safety and health regulations cited in the EG Guideline.

89/392/EWG

Stolzenberg Maschinenfabrik GmbH Co.KG

Hamburger Straße 15 - 17

D-49124 Georgsmarienhütte

MATRIX MTX-900-V TRS, MATRIX MTX-900-B TRS, MATRIX MTX-900-VB

TRS

&

a

Georgsmarienhütte,01.01.2006

...................................................

Kai Stolzenberg

(Dipl. Wirtsch. Ing.,

battery-operated manual sweeper

DIN EN ISO 12100

EN 294

DIN EN 60335-2-29

DIN EN 60335-2-67

DIN EN 60335-2-72

DIN EN 61000-6-4

DIN EN 60335-2-72

EMV Richtlinie 98/336/EWG

Niederspannungsrichtlinie

Geräusch-Richtlinie 2000/14/EG

2006/95/EG

EG Declaration of Conformity

The manufacturer:

he product

the EG-Guidelinie 89/392/EWG

The Standards and/or technical specifications

in compliance with EG-Guidelinie

declares as solely responsible party, that

this declaration refers to, observes

and correspondes to it regarding all relevant safety and health requirements.

have been applied in a way that ensures the appropriate implementation of

safety and health regulations cited in the EG Guideline.

89/392/EWG

Stolzenberg Maschinenfabrik GmbH Co.KG

Hamburger Straße 15 - 17

D-49124 Georgsmarienhütte

MATRIX MTX-900-V TRS, MATRIX MTX-900-B TRS, MATRIX MTX-900-VB

TRS

&

a

Georgsmarienhütte,01.01.2006

...................................................

Kai Stolzenberg

(Dipl. Wirtsch. Ing.,

battery-operated manual sweeper

This manual suits for next models

3

Table of contents

Other STOLZENBERG Blower manuals

STOLZENBERG

STOLZENBERG TwinSweep 900E User manual

STOLZENBERG

STOLZENBERG Tandem 900 KSE User manual

STOLZENBERG

STOLZENBERG US 5 User manual

STOLZENBERG

STOLZENBERG CS 650 User manual

STOLZENBERG

STOLZENBERG NU5 User manual

STOLZENBERG

STOLZENBERG KSV 910 User manual

STOLZENBERG

STOLZENBERG KSE 910 User manual

STOLZENBERG

STOLZENBERG NU9 User manual

Popular Blower manuals by other brands

Craftsman

Craftsman 358.794560 instruction manual

Craftsman

Craftsman 358.794311 instruction manual

Gardebruk

Gardebruk DBLL003 instructions

Toro

Toro ProForce 44538 Operator's manual

Columbus

Columbus AKS 80 operating manual

Hearth and Home Technologies

Hearth and Home Technologies GFK-160A Installation and operating instructions