StoneAge amerigo User manual

1

Installation and Operation Instructions

Stone Age Amerigo™ and Mezzo™ Pizza Ovens

1.0 Introduction

The following provides instructions for the instal-

lation, operation and care of Stone Age Mezzo™

and Amerigo™ Pizza Ovens, manufactured y

Stone Age Manufacturing, Collinsville, Oklahoma.

Three generations of wood- urning oven

knowledge and experience have gone into the de-

sign, construction and use of these pizza ovens. A

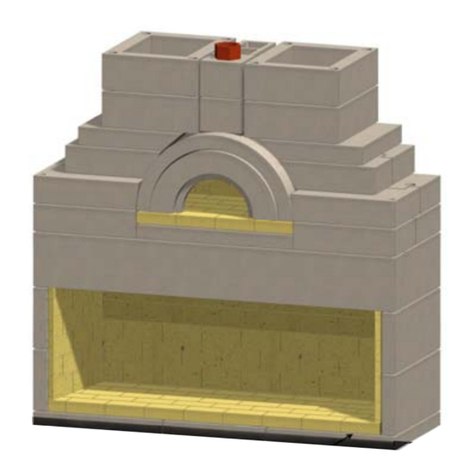

completed Amerigo oven, finished in rock and in-

stalled a ove a triple Amerigo ca inet unit, is

shown in Figure 1.

Figure 1. Amerigo™ Pizza Oven

The only difference etween the Amerigo and

Mezzo ovens is size. Ta le 1 shows the compo-

nents and dimensions of the two.

Table 1

Amerigo Mezzo Dimensions

Size (In.) Amerigo Mezzo

Width 48 36

Depth 42 33

Height 31 24

Door opening 25.5x12.5 15.5x8

This manual also provides instructions for the in-

stallation of the pizza oven ase ca inet, an option-

al unit.

If installing the oven on something other than the

ase ca inet, make sure that it will support the

weight of the oven.

2.0 Pizza Oven Components

Components for the Amerigo and Mezzo Pizza

Ovens are shown in Figure 2.

Figure 2. Pizza Oven Components

Components and part num ers are identified in

Ta le 2. Item num ers in Ta le 2 correspond with

the item num ers in Figure 2.

3.0 Safety

Working around an oven that can generate up to

800°F can e dangerous if proper clothing and

tools are not used. Also, com usti le materials in

the vicinity of the oven may e at risk.

WARNING: When working around a pizza

oven, make sure that proper

clothing is worn and proper tools

are used. Make sure that com-

bustible materials not necessary

to baking pizza are kept away

from the oven.

2

4

5

1

3

6

2

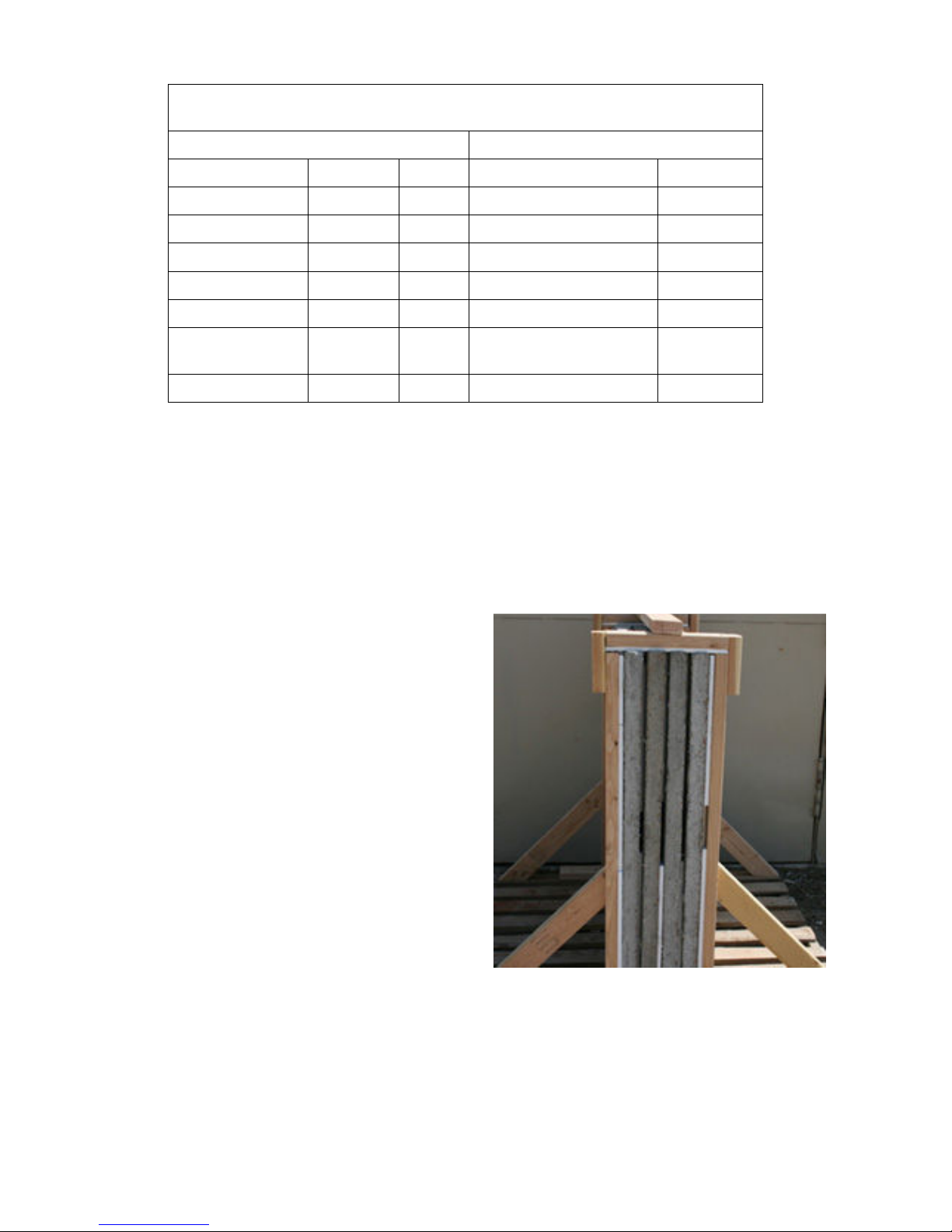

Table 2

Pizza Oven Components

Amerigo™ Pizza Oven Mezzo ™ Pizza Oven

Description Part No. Qty Part No. Qty.

Base Plate (1) APO 1 1 MPO 1 1

Roof (2) APO 2 1 MPO 2 1

Front Wall (3) APO 3 1 MPO 3 1

Rear Wall (4) APO 4 1 MPO 4 1

Chimney (5) SAFLAPO 1 SAFLAPO 1

Door (Not shown) SA-APOD-

ML

1 SA-MPOD-ML 1

Fire Brick (6) SA-1006 50 SA-1006 30

3.1 Clothing

A. It is advisa le that long-sleeved shirts e

worn when inserting and removing pizzas in-

to/from the oven.

B. Use a non-com usti le oven mitt when stok-

ing and adding wood to the fire.

C. Use the non-com usti le mitt when inserting

and removing or turning pizzas.

3.2 Tools

Special tools are availa le for the management of

oven fires and inserting and removing pizzas.

These tools can e o tained from Stone Age Manu-

facturing and are shown later in this manual.

4.0 Installation

The pizza ovens and associated ase ca inets are

not specifically designed as a “do it yourself” pro-

ject. This is primarily ecause of component

weight and the care required when applying mor-

tar. However, it can e done if one has the neces-

sary weight lifting equipment, and can use a

mortaring trowel. We recommend that you contract

with a professional mason or landscape contractor

to install and finish your installation.

Although not included with the oven package, an

optional ase ca inet, used primarily for storage, is

availa le from Stone Age Manufacturing. This

manual includes procedures for installing oth the

oven and its ase ca inet.

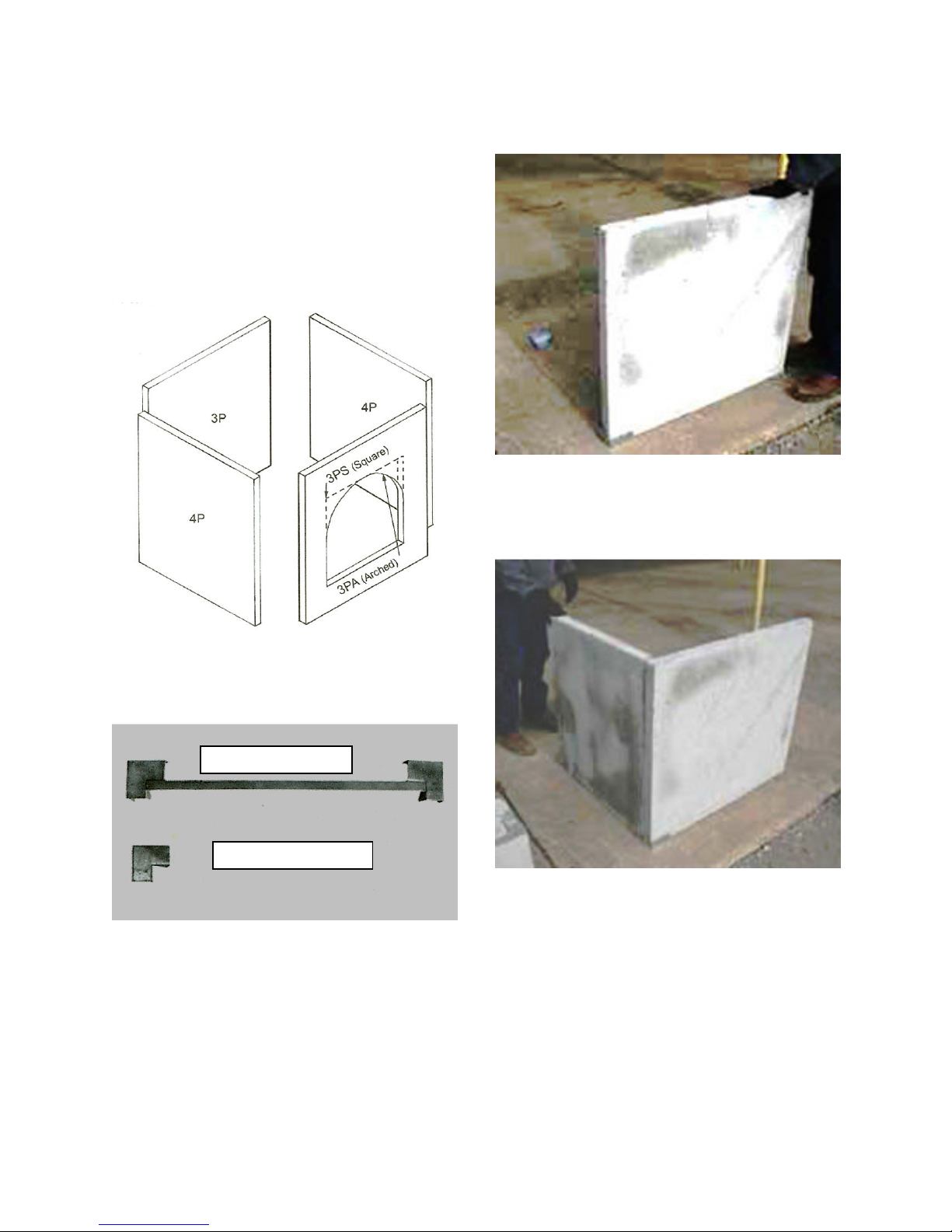

4.1 Installing the Base Cabinet

Like the pizza oven, the ase ca inet is delivered

as a kit, as shown in Figure 3. Each of the two piz-

za ovens has its own ca inet. Except for size, they

are identical.

Tools required for this installation include a mallet

or dead low hammer, mason’s or rock hammer,

masonry trowel, caulk gun and a power saw with

masonry lades.

Figure 3. Base Cabinet Delivered

A 4-inch steel-reinforced concrete pad or patio

should e constructed large enough to have an out-

side order to support finish material, if required.

The pad should have piers elow the frost line if

required in your geographic location.

3

A. Lay a chalk line on the pad to visualize the

layout.

B. Leave the foam shipping form in the front

panel opening until the panel is in place.

C. Arrange the panels as shown in Figure 4.

WARNING: Each of the panels weighs about

200 pounds. Handle with ex-

treme care with proper weight

handling equipment.

Figure 4. Panel Arrangement

Brackets, shown in Figure 5, are provided to hold

the panels together and provide support.

Figure 5. Cabinet Brackets

D. At the ack wall position of the ox,

place a corner single racket (Figure 6)

on the pad. These lower rackets may e

glued if desired.

E. Lay a 2-inch ead of Sonolastic® adhe-

sive or a landscape lock adhesive along

a line where the panels will rest.

F. Set the ack panel (3P), shown in Figure 4,

into the racket as shown in Figure 6.

Place all panels with the rough side out.

Figure 6. Place Back Panel in Bracket

G. Place a side panel (4P) into the racket,

utting against the ack panel. See Figure

7.

Figure 7. Place Side Panel

H. Slide single corner racket under the front

end of panel 4P.

I. Apply adhesive mortar etween the two

panels. Sonolastic adhesive is recom-

mended.

J. Install front panel into racket, in front of

panel 4P. Apply mortar etween the two

panels. Then, install a front-to- ack rack-

et, connecting the tree panels together, as

shown in Figure 8.

Front-to-Back Bracket

Corner Single Bracket

4

Figure 8. Install Front Panel

K. Install the other side panel in the same

manner.

L. Once the last front-to- ack racket is in-

stalled and all joints are mortared, the in-

stallation is complete, as shown in Figure

9.

Figure 9. Installation Complete

Remove the foam shipping form from the front

door opening. See Figure 4. Remove y sawing it

out rather the knocking it out as the opening is sus-

cepti le to damage until the finish material has

een applied.

4.2 Installing the Pizza Oven

Always consult local uilding code requirements

efore installation of a Stone Age pizza oven. If

local codes exceed Stone Age’s requirements, al-

ways a ide y local code. Stone Age pizza ovens

are designed and intended for outdoor use only.

Never install an oven within 4 feet of com usti le

materials on the front, ack, sides and top of the

oven. If the oven is to e installed under a covered

structure, maintain a minimum clearance of 6 feet

from the top of the oven door opening to the ceil-

ing, if roof or ceiling structure is constructed of

com usti le materials. Never terminate the oven

chimney under com usti le material or an en-

closed roof or ceiling. If this type of installation is

necessary, install a commercial-grade vented hood

and maintain proper clearances and spacing from

oven chimney to vented hood. Always refer to

hood manufacturer’s specifications for spacing and

clearance requirements.

If chimney is to penetrate the roof or ceiling of a

covered structure, allow a minimum 12 inches of

clearance to com usti le materials from all sides of

the oven chimney. Never terminate the oven chim-

ney less than 2 feet a ove the roofline of a covered

structure. Never add more than 10 feet of addi-

tional chimney height to the oven. Always use a

chimney cap, or keep chimney flue covered when

not in use, and keep oven door closed when oven is

not in use.

The ase ca inet is installed and ready to receive

the ase for the pizza oven. If the ase ca inet is

not used, it is assumed that a satisfactory ase sur-

face has een prepared from concrete locks or

other materials; is at the desired height, and will

receive the weight of the pizza oven.

A. Install the ase plate on top of the ase

ca inet or other ase you have selected.

Check the level from front to ack, side

to side.

B. Install fire rick from side to side using

refractory mortar. Stone Age All Purpose

Redi-Mix is recommended. See Figure

10.

Figure 10. Install Firebrick on Baseplate

C. Figure 11 shows how the oven compo-

nents go together. After the fire rick mor-

tar sets up, lay a 2-inch ead of the same

5

mortar along each side of the fire rick

surface.

Figure 11. Oven Components

D. Lift the roof and place it onto the fire-

rick. Because of the extreme weight of

the roof, it is est to extend a eam under

the roof and lift the eam from oth ends

with a person on each side to help guide

the roof into position or lift with a ma-

chine. See Figure 12.

WARNING: The roof of the pizza oven

weighs 400 (Mezzo) to 600

(Amerigo) pounds. Be extremely

careful in lifting. If dropped, it

will easily chip and at the least,

crack. Make sure you have suffi-

cient help in lifting it.

igure 12. Install Roof

E. Inspect the mortared joint on oth sides,

inside and out and make sure it is

smoothed out with no gaps.

F. Install the chimney on top of the oven.

Mortar inside as well as on top, as shown

in Figure 13.

Figure 13. Mortar Chimney Inside of Oven

G. Install the rear wall, using the same mor-

tar. Carefully fill the joints with mortar,

including the inside joints, as shown in

Figure 14.

Figure 14. Mortar Inside Joints

Install the front panel and carefully fill all

joints with mortar, as shown in Figure 15.

Figure 15. Install Front Wall

6

Installation of the oven is now complete and ready

for the outside finish to e installed. Brick, rock or

any masonry/concrete compati le material can e

used for the exterior finish, depending on your de-

sires and the motif of your outside kitchen/patio.

Two types of finish are shown in Figure 16.

As with any cooking appliance, heat transfer will

occur from the inside cooking cham er to the out-

side walls of the oven. Thermal cycling can also

cause expansion and contraction in the oven com-

ponents and the mortar joints. This can e visi le

in the exterior veneer, especially in the mortar

joints when it is applied directly to the surface of

the oven and will vary on each application. These

expansion and contraction cracks do not compro-

mise the structural integrity of the oven and are

only cosmetic. If the visi ility of these hairline

cracks is not desired, it is recommended that the

oven e encapsulated with concrete lock, metal

framing with concrete oard attached or surround-

ed with other non-com usti le material. If this

method is used, leave a minimum of 3 inches of air

space etween the encapsulating walls and oven

unit. This space can e left void or filled with insu-

lating materials like perlite or vermiculite to further

insulate and stop any heat transfer. The outside

profile of the oven can e changed to create any

shape or architectural design when using this

method.

Another option is to cover the oven with a ceramic

fi er lanket wrapped with metal lathe and scratch

coated with cement efore applying veneer materi-

als.

Amerigo™ Pizza Oven Mezzo™ Pizza Oven

Figure 16. Pizza Oven Finishes

5.0 Building a Fire

The owner should wait a minimum of 28 days after

construction is completed to uild the first fire. It is

important that all moisture e gone from the oven

efore the first fire is laid. After that, the first three

fires should e small to gently season and reak in

the oven.

Failure to allow full curing of the mortar may re-

sult in expansion cracking in the oven’s mortar

joints and finish. This is not a structural defect and

does not harm the product integrity, ut may affect

the appearance.

In order to reduce the possi ility of moisture col-

lection, it is recommended that the ovens exterior

veneer e treated with a water sealer after comple-

tion of the exterior.

WARNING: Do not start a fire in a unit that

has been exposed to excessive

moisture.

To protect from moisture, keep the oven door in

place and cover the chimney when the oven is not

in use.

5.1 Selection of Wood

Any cured wood that is suita le for smoking meats

can e used in pizza ovens. Hickory, pecan and

mesquite wood are good. Oak is good for heating

ovens and generating a ed of coals. Flavored

wood such as apple and cherry fruitwoods, soaked

in water, can e used for smoking when the cook-

ing starts.

Charcoal and natural lump charcoal are also an

option for cooking along with fruitwood chips for

flavor.

Avoid use of green uncured wood as it will have a

much stronger smoke flavor which can e over-

earing, and will produce more soot and oils.

Caution: Do not use paper, trash, synthetic logs,

or wood treated with petroleum or other

chemicals.

5.2 Starting and Keeping a Fire

It takes time and experience to learn the nature of a

wood-fired oven. There are a lot of varia les af-

fecting cooking such as type and quantity of wood,

am ient temperature, size of oven and the dish e-

ing cooked.

Recommended length of wood sticks is 6-12 inches

for the Mezzo oven 6-18 inches for the Amerigo.

Stores selling BBQ supplies will have smoking

7

wood in chunks or cut smaller for smokers and

wood fired ovens.

Just like the oven inside your home or an outdoor

gas cooking appliance a wood fired oven will re-

quire a certain amount of cleaning and mainte-

nance after usage.

By design the chimney flue of wood fired ovens

are undersized for maximum heat retention. This

will cause smoke spillage out of the front of the

oven opening and leave soot, creosote or smoke

stains on the face of the ovens exterior. This spill-

age and staining is common on all rands of wood-

fired ovens without power vented chimneys. The

degree of staining will vary depending type of

wood used for cooking, how cured the wood is,

amount and length of usage, wind direction and

speed along with several other factors that will

vary with each application. This adds character and

gives an authentic old world appearance to your

oven ut the staining can easily e removed with a

wire rush and water or y using a masonry clean-

ing solution for soot and smoke that can e pur-

chased at most hardware stores, home

improvement stores, specialty fireplace retailers or

on the internet.

Fire management tools are shown in Figure 17.

Figure 17. Fire Management Tools

The sequence for uilding a fire is as follows:

• Build a fire in the center of the oven floor

and develop a good a ed of coals. The

size will depend on what is to e cooked

and the quantity.

• Heat the oven to 350° to 600°F. This may

take as much as two hours. Heating a ove

800°F is not recommended.

• When desired temperature is reached, push

the fire and coals to the rear and sides of

the oven. Sweep fine ashes to the sides and

ack of the oven using a wire ash rush.

Use one of the tools shown in Figure 14.

• Insert pizzas and cook directly on the oven

floor.

• Add wood as necessary to maintain de-

sired temperature. If cooking several piz-

zas, it may e necessary to pull the fire

ack to the middle to reheat the floor and

repeat the process.

5.3 Cooking

If the oven has een exposed to moisture 48 hours

prior to use, uild a small fire and heat the oven to

250-300°F for two hours efore increasing the heat

to cooking temperature. An easy solution is to urn

an 8-10 pound ag of match lite charcoal and let it

urn completely. This will slowly dry out the mois-

ture that the oven has a sor ed.

As stated, we recommend cooking in a temperature

range of 350° to 600°F. Time of cooking will de-

pend on the temperature and the item eing

cooked. The floor is the heat source that will do

most of the cooking. An infra-red temperature

gauge like that shown in Figure 18 can e used to

measure temperature at any location in and around

the oven.

Cooking pizza in a wood-fired oven is somewhat

like grilling or smoking meats in that there are

many varia les such as the type of wood used, am-

ient temperature and humidity, oven temperature

and thickness of crust and toppings, that affect the

outcome, Be prepared to spend a few times testing

recipes and techniques. Practice and experimenta-

tion will show how to est cook your favorite style

of pizza.

• A traditional Italian pizza with a thick

crust and a thin layer of toppings should

cook at 600°F or hotter for 3-6 minutes.

• For thicker pizzas with heavier toppings,

lower temperatures are required to thor-

oughly cook without urning.

• A medium pizza with heavy toppings may

cook est at 400°F-500°F and will require

a longer cooking times, perhaps 15-25

minutes.

Cook the pizza directly on the floor of the oven.

Place it in the oven using a long-handled paddle

called a peel, using hot mitts or hot pads. Slide the

pizza from the preparation surface to the peel, and

then onto the cooking surface using a slight jerking

technique.

8

WARNING: Be mindful of the hot surfaces of

your pizza oven. Because of the

high temperatures, extra caution

should be used when cooking

with a wood-fired oven. Use

proper, long-handled tools and

protective mitts when working

around the opening or reaching

into the hot oven.

Tools required for cooking pizza are shown in Fig-

ure 18 and are availa le from Stone Age Manufac-

turing.

Figure 18. Cooking Tools

6.0 Cleaning, Inspection and

Maintenance

As is the case with most other equipment, cleanli-

ness is the est maintenance practice and will con-

tri ute to many hours use.

WARNING: Do not clean the oven when it is

hot.

Let the fire and coals completely urn out and

cool efore cleaning. It is est to wait until the

next day efore removing ashes.. Ashes should e

placed in a metal container with a tight-fitting lid,

and removed from all com usti le materials,

pending final disposal. If the ashes are disposed

of y urial in soil or otherwise locally dispersed,

they should e retained in the closed container

until all cinders have thoroughly cooled.

Spot check the refractory ricks and mortar for

small cracks. It will expand slightly with the heat,

then contract as it cools. Replace refractory ricks

when the cracks open more than ¼”; or when pits

ecome extensive and deeper than 3/16” when ov-

en is at am ient temperature and not in use; or

when any piece of refractory larger than 2 inches in

diameter ecomes dislodged.

If creosote has accumulated, it should e removed

to reduce the risk fire. Remove creosote using a

wire rush and/or a creosote liquid detergent de-

signed for this purpose. Also there are manufac-

tured logs availa le that are designed for the

removal of creosote. These products will e avail-

a le at most local hardware stores, home improve-

ment stores, specialty fireplace retailers or on the

internet.

Keep the door in place and a cap on the chimney

when not in use to protect the interior cooking

cham er of the oven from exposure to moisture.

10 and 14” Pizza Pan

Pizza Handling Tools

Pan Gripper Tool

Infrared Thermometer

Wood & Metal

Pizza Peels

9

Sonolastic® is a registered trademark of BASF Chemical Company

Rev: MPOAPO1012

October, 2012

LIMITED WARRANTY

The products of Stone Age Manufacturing, Inc. (“Stone Age”) have

een carefully manufactured and the components assem led to give the

customer a quality product. Stone Age warrants to the original purchaser

the materials that it provides to the customer against defects in manufac-

ture for a period of twenty-five (25) years from the date of purchase on

UL-127 listed fireplaces, for a period of five (5) years from the date of

purchase on all unlisted fireplaces, fire pits, and other masonry compo-

nents. Other accessory items or components offered, ut not produced

y Stone Age Manufacturing, Inc., shall e covered y their manufac-

turer’s warranties. This Limited Warranty covers only actual manufac-

turing defects in the Stone Age product and does not cover defects or

faulty workmanship in the installation of the product or the masonry or

other structure in which it is installed. Also this warranty does not cover

items that have een damaged due to over-heating, modification, im-

proper storage or maintenance. Stone Age shall repair or replace, at its

option, any defective Stone Age product component upon receipt of

written notice addressed to Stone Age. This Limited Warranty covers

only replacement of any defective components within the product itself

occurring during the warranty period and does not cover the cost of in-

stallation or removal from a fixed location. NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, ARE MADE, INCLUDING

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR PARTICULAR PURPOSES WHICH ARE SPECIFICALLY

DISCLAIMED. Stone Age is not lia le for damages or injury to persons

or property or other incidental or consequential damages.

Stone Age Manufacturing, Inc.

11107 E. 126

th

St. N., Collinsville, OK 74021

WWW.Stoneagefireplaces.com

This manual suits for next models

1

Table of contents

Other StoneAge Kitchen Appliance manuals