StoneAge Caminetto SA-CMO63 User manual

1

Installation and Operation

Instructions

Stone Age Caminetto™

Medeo Fireplace-Pizza Oven

Combo

1.0 Introduction

The following provides instructions for the installa-

tion and operation of the Stone Age Caminetto™

Series Fireplace-Pizza Oven Combo, manufactured

by Stone Age Manufacturing, Collinsville, Oklaho-

ma.

Three generations of fireplace knowledge and expe-

rience have gone into the design and construction of

the Caminetto™ Series.

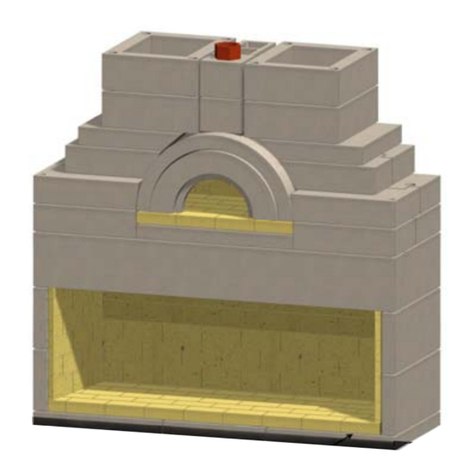

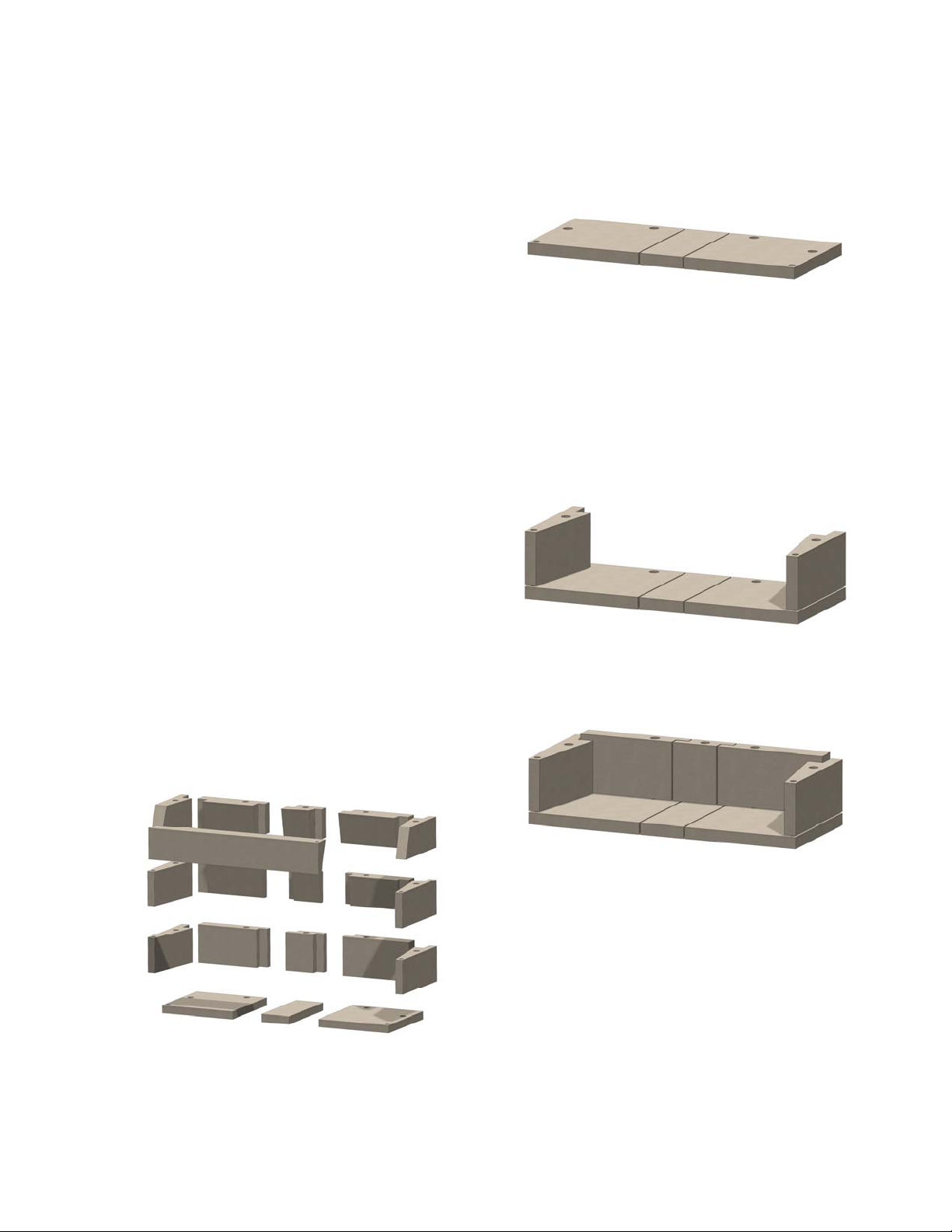

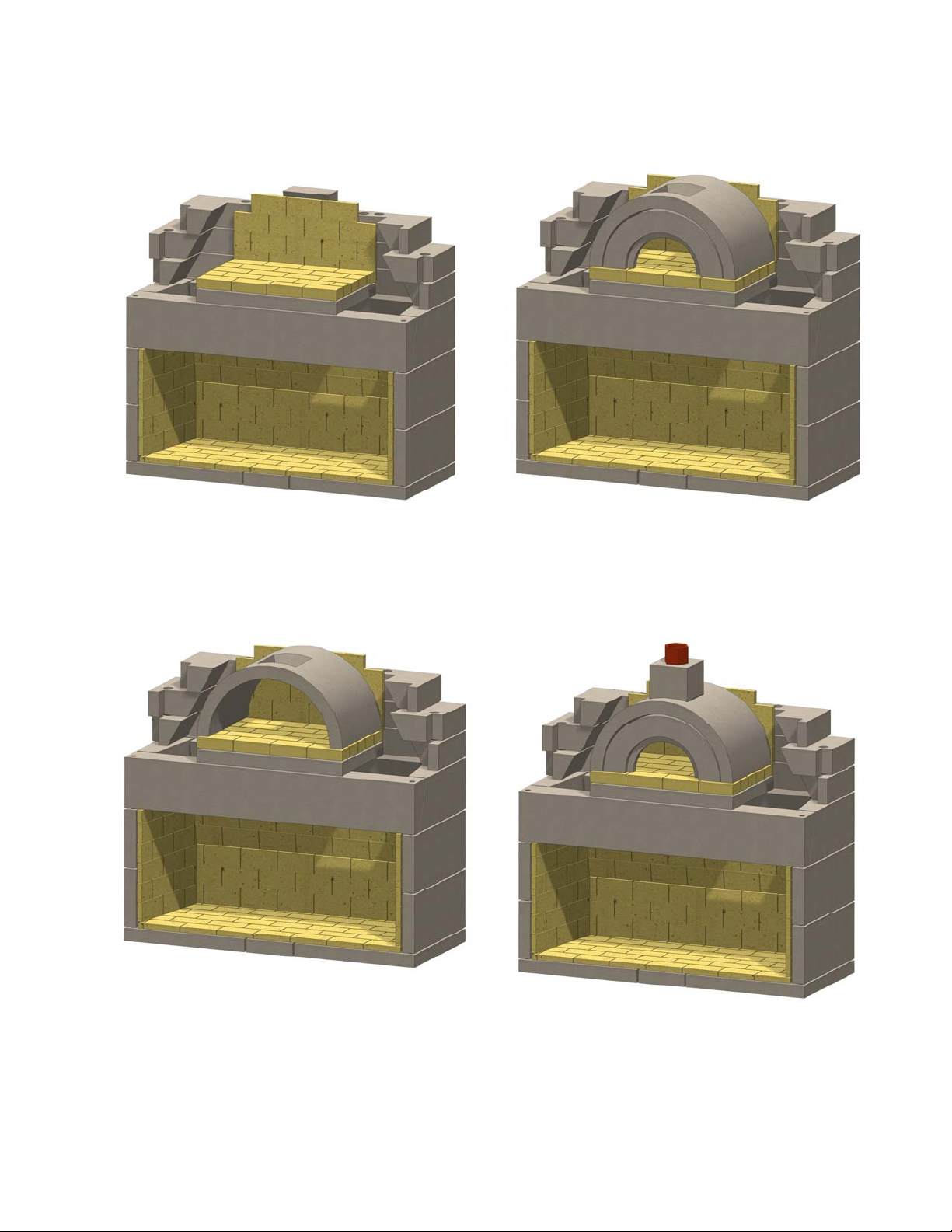

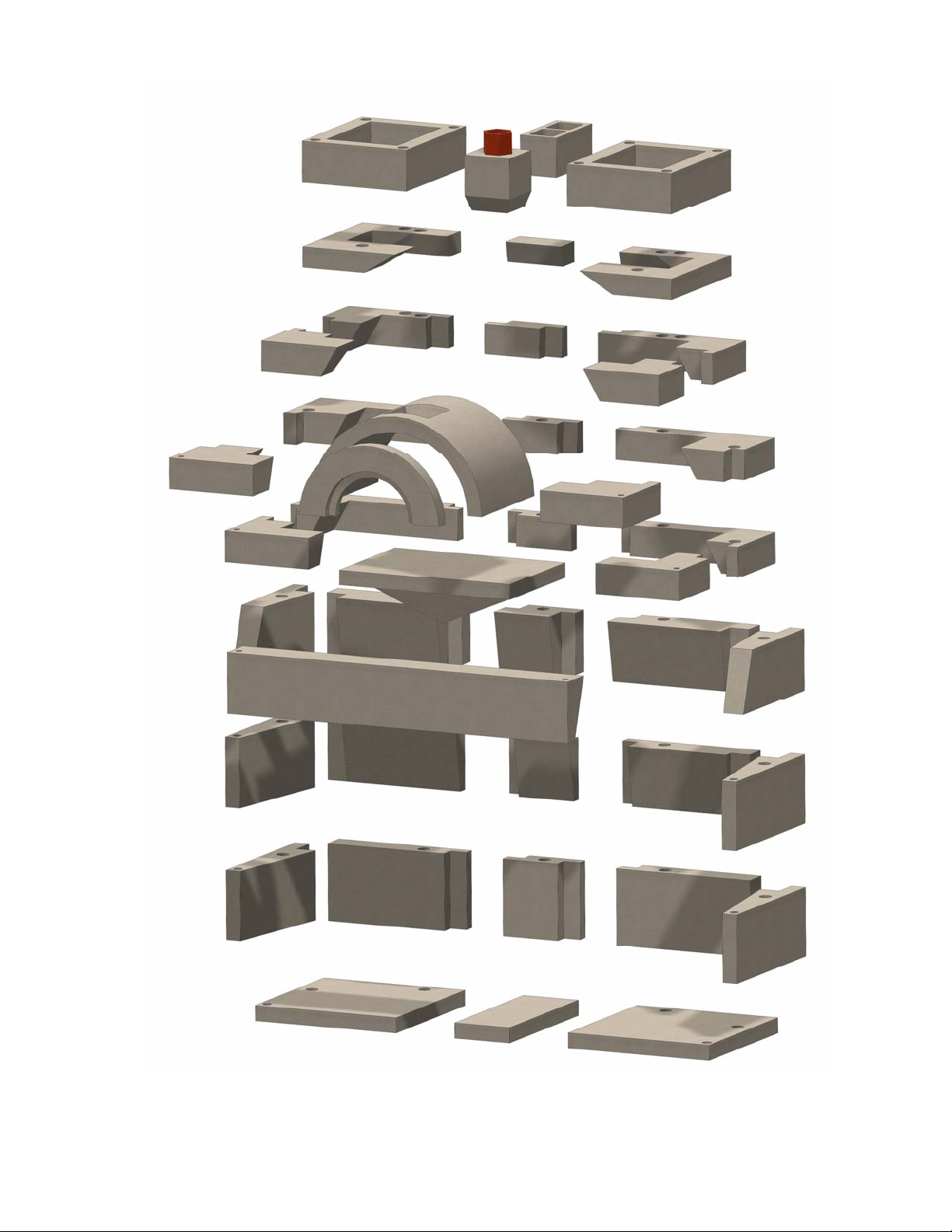

Assembly and Cutaway views of a SA-CMO63 fire-

place-pizza oven are shown in Figure 1.

It is recommended that this fireplace be installed by a

professional installer, or by a builder in new con-

struction. Installation by a non-qualified person may

negate the warranty.

Keep these instructions for future use.

2.0 Description

The fireplace-pizza oven combo is delivered as a kit

with all components necessary to complete the

rough-in installation.

The kit will be delivered on 3 forklift pallets, and

should be assembled in order by pallet number. It

is recommended that each pallet be inspected for

damage upon arrival, but that all components are

kept together on their original pallets until it is

time for the pallet’s assembly.

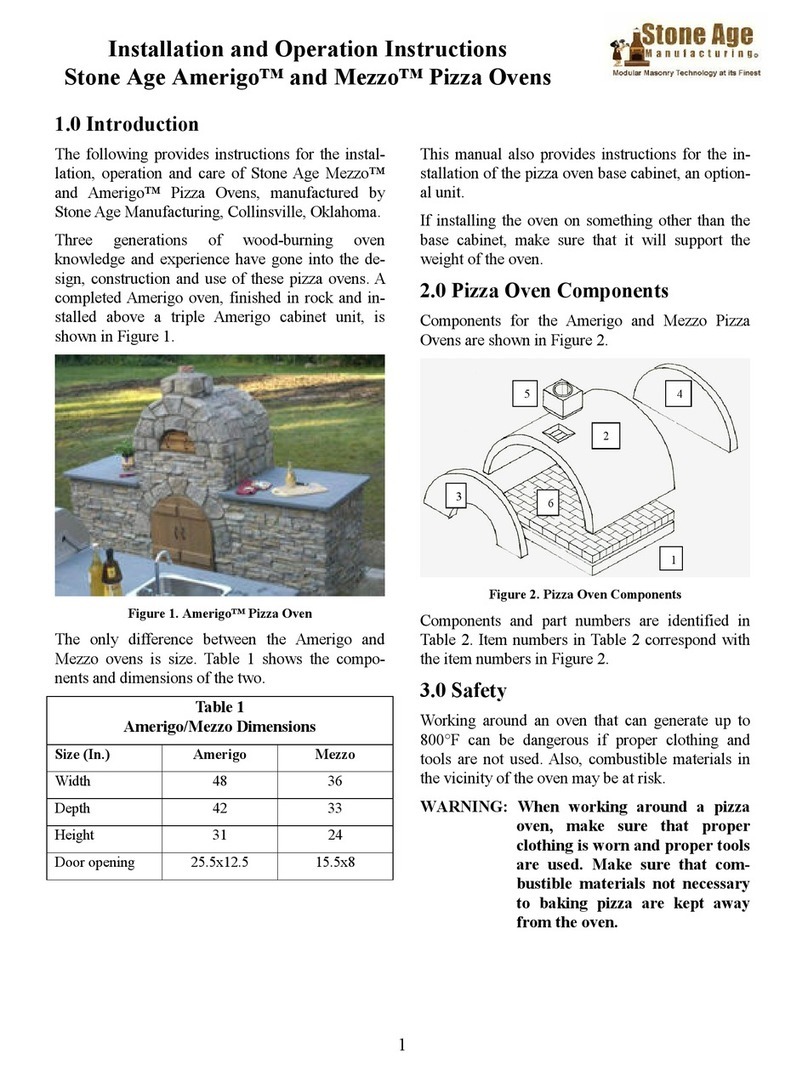

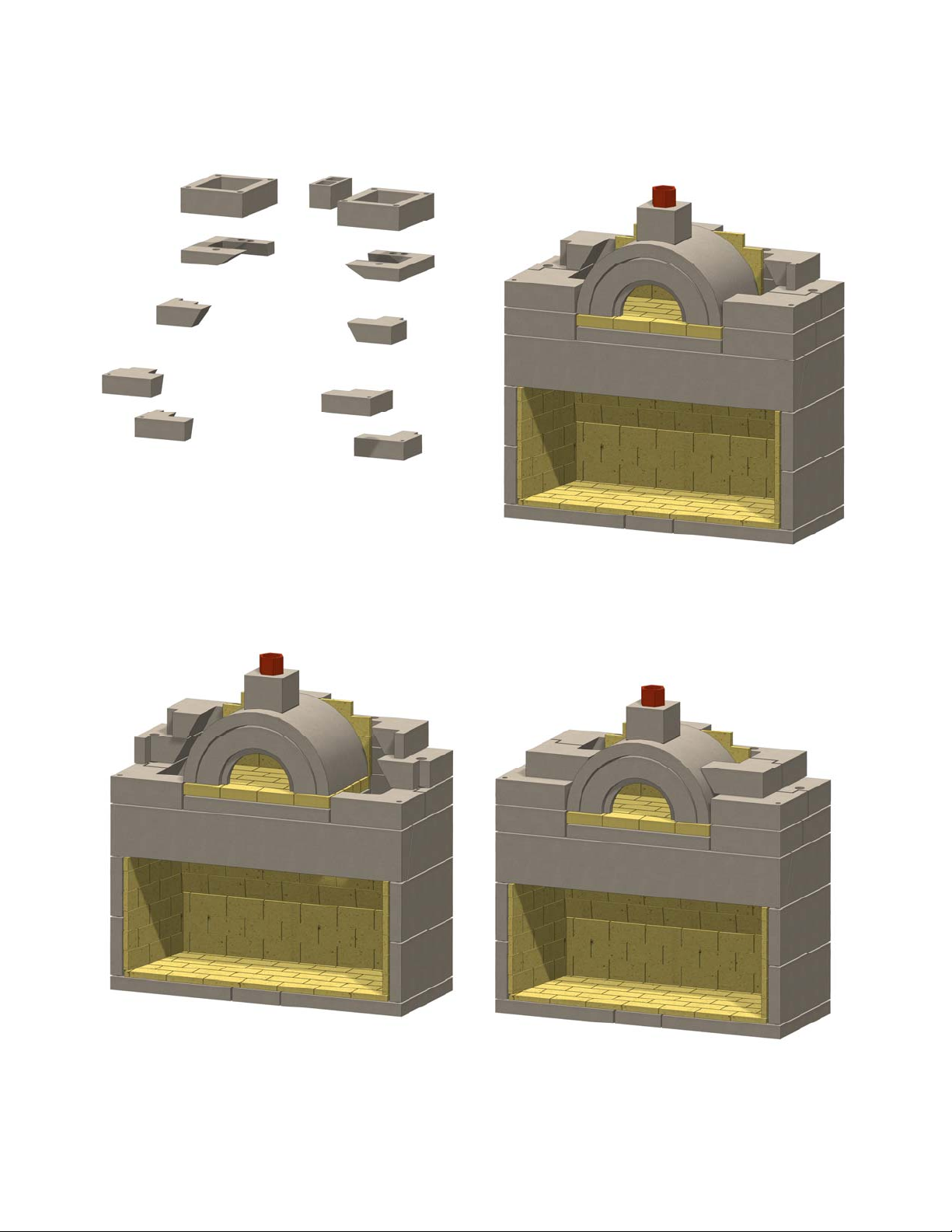

Figure 2 shows the kit component arrangements,

with each pallet’s contents numbered in a different

color.

Pallet 1 (Red numbers) includes the main firebox

components of the fireplace and its firebrick.

Pallet 2 (Blue numbers) contains the back wall com-

ponents of the fireplace throat and the pizza oven,

and two types of firebrick for the pizza oven.

Pallet 3 (Yellow numbers) contains the front wall

components of the fireplace throat and chimney flue.

A larger view of Figure 2 is repeated on page 16 of

this document. Component names are listed in Table

1. Specifications and clearance recommendations

are shown in Table 2.

A completed installation should include the follow-

ing:

A. Fireplace items shown in Figure 2 and listed in

Table 1.

B. Chimney Cap (sold separately) (Shown in Fig-

ure 24).

C. Fireplace Grate (sold separately) (Shown in

Figure 28).

D. Stone Age Multi-Purpose Ready-Mix Cement

(sold separately).

The Stone Age Caminetto™ fireplace-pizza oven

combo has designed for outdoor use.

Ensure that appropriate building permits required by

local codes are obtained before installation.

SA-CMO63

Front View

Figure 1.

SA-CMO63 Assembl

y

& Cutawa

y

View

Side

Cutaway

V

iew

2

Table 1. Kit Components

Item Description

1 Base Plate

1C Base Plate Extension

2 Lower & Middle Sidewall

3A Lower Back Plate - Left

3B Lower Back Plate - Right

3C Lower Back Plate – Center Extension

4A Middle Back Plate - Left

4B Middle Back Plate - Right

4C Middle Back Plate – Center Extension

5A Upper Back Plate - Left

5B Upper Back Plate - Right

5C Upper Back Plate – Center Extension

6 Upper Slanted Sidewall - Right

7 Upper Slanted Sidewall - Left

8 Front Header

9 Oven Base Plate

10 Lower Throat – Left Rear

10C Lower Throat – Center Rear Extension

11 Lower Throat – Right Rear

12 Lower Mid Throat – Left Rear

12C Lower Mid Throat – Center Rear Extension

13 Lower Mid Throat – Right Rear

14 Middle Throat – Left Rear

14C Middle Throat – Center Rear Extension

15 Middle Throat – Right Rear

16C Throat Cap – Center Rear Extension

17 Oven Dome

18 Oven Front Panel

19 Oven Chimney Flue

20 Lower Throat – Right Front

21 Lower Throat – Left Front

22 Lower Mid Throat – Right Front

23 Lower Mid Throat – Left Front

24 Middle Throat – Right Front

25 Middle Throat – Left Front

26 Throat Cap – Left

27 Throat Cap – Right

28 Chimney Flue Outer Block

29 CMU Block

2.1 Specifications

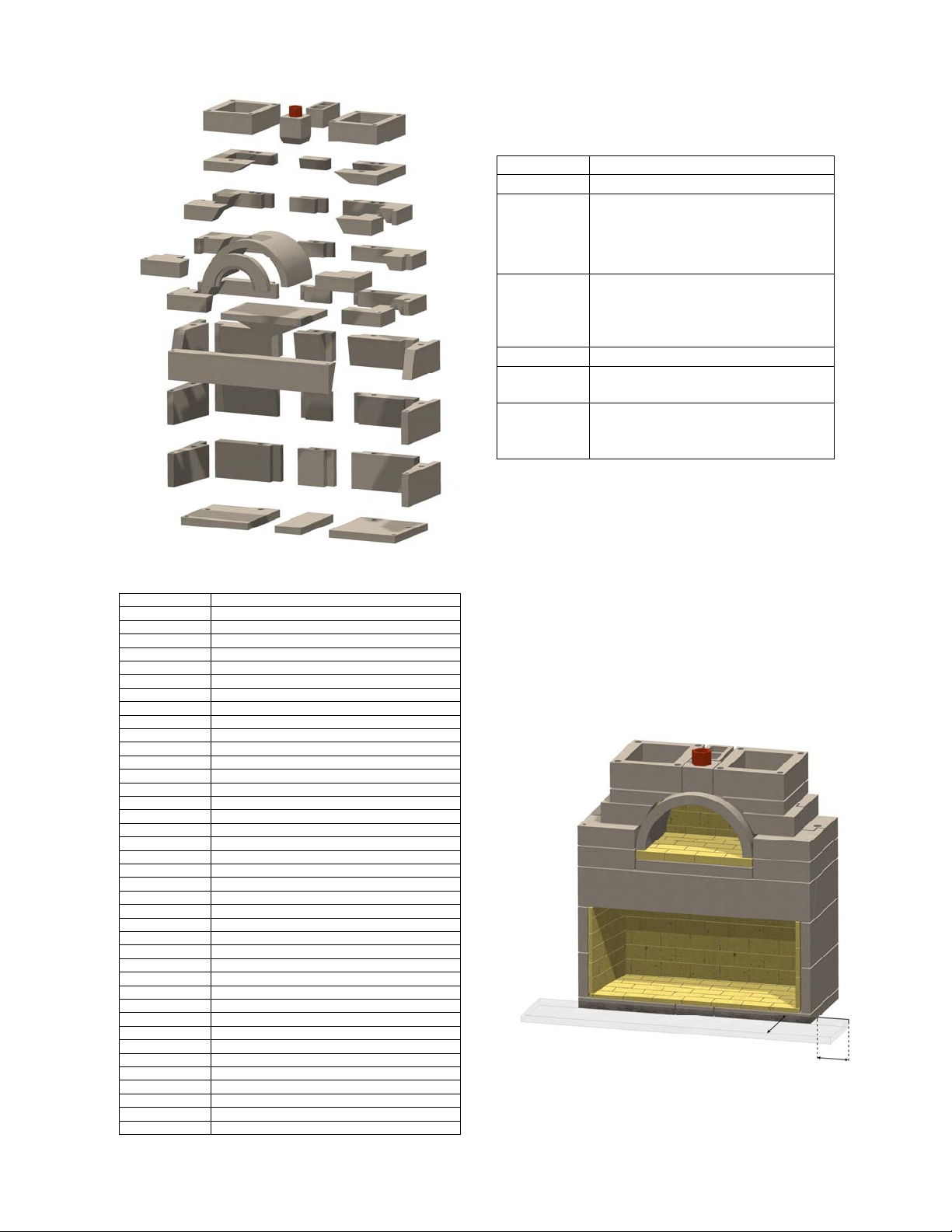

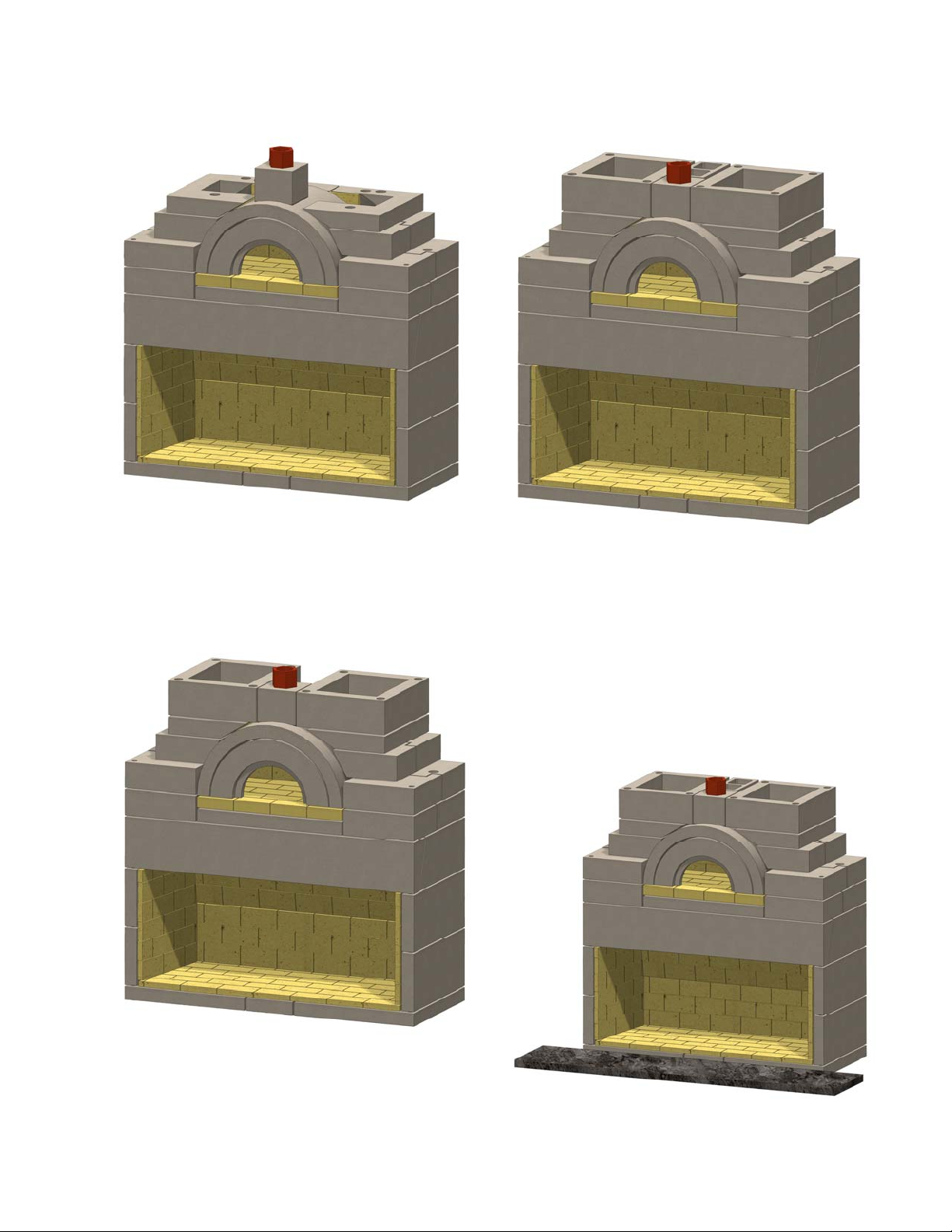

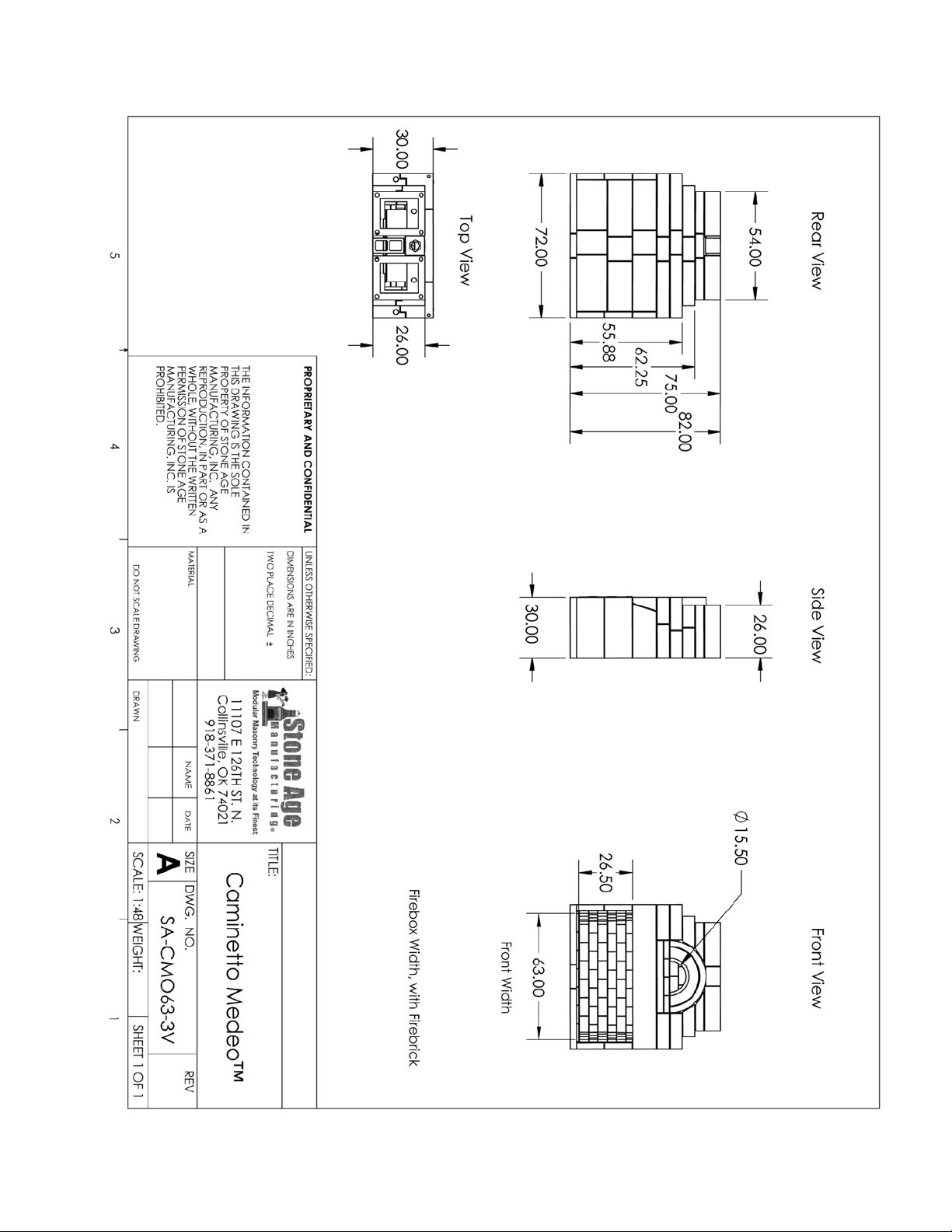

Table 2: Clearances (See Figure 3)

Caminetto™ Fireplace-Pizza Oven Combo

Item Clearance

Backwall 3”

Sidewalls 3” to Appliances

18” from Fireplace opening at

points in front of fireplace

Floor: Non

combustible

extending

as follows

20” when hearth is less than 6”

from floor

18” when hearth is greater than 6”

from floor

Side Trim 6” from fireplace opening

Hearth 20” in front of the opening and 12”

beyond each side

Clearance

around

chimney

3”

Note 1: This Fireplace is intended for use with solid wood

fuel or vented gas logs.

Note 2: This fireplace has not been tested for use with

glass doors.

Note 3: Do not use fireplace insert or other products not

specified for use with this model. Use a fireplace grate

when burning wood. A grate is not used in the oven.

Note 4: Clay flue liners installed in flue section meet the

specifications of ASTM Section C315-02.

Note 5: Ensure installation complies with local building

codes.

1

1

2

2

2

2

2

2

2

3

3A

A

3

3B

B

4

4A

A

4

4B

B

5

5A

A

5

5B

B

6

6

7

7

8

8

1

15

5

1

17

7

1

10

0

9

9

1

12

2

2

20

0

1

11

1

2

23

3

1

14

4

2

24

4

2

25

5

1

13

3

2

27

7

2

26

6

Figure 3. Clearances (Use with Table 2)

Figure 2. Kit Components

3

3C

C

4

4C

C

5

5C

C

2

29

9

2

22

2

1

10

0C

C

1

19

9

1

12

2C

C

1

14

4C

C

1

16

6C

C

1

1C

C

1

1

2

28

8

2

21

1

2

2

2

28

8

1

18

8

Hearth 20”

12”

3

2.2 Installation of Additional Equipment

WARNING: THIS FIREPLACE HAS NOT

BEEN TESTED FOR USE WITH

DOORS. TO REDUCE THE

RISK OF FIRE OR INJURY, DO

NOT INSTALL GLASS DOORS.

A. Do not install a fireplace insert unless it is tested

with this fireplace.

B. Cutting or drilling a hole into the fireplace’s

floor or walls for gas supply for a vented decorative

gas appliance (log), or an ash dump, is acceptable.

C. If a decorative gas appliance is installed, it must

be installed in accordance with the National Gas

Fire Code, ANSI Z223.1.

D. It must incorporate an automatic shutoff device.

E. Installation must comply with the Standard for

Decorative Gas Appliances in Vented Appliances,

ANSI Z21.60 (1991) or American Gas Association

draft requirements for Gas-Fired Log Lighters for

Burning Fireplaces, Draft No. 4 dated August 1993.

3.0 Installation of the Fireplace

WARNING: DO NOT USE SUBSTITUTE

MATERIALS IN THE

ASSEMBLY, INSTALLATION

OR OPERATION OF THIS

FIREPLACE. TO DO SO WILL

VOID THE WARRANTY AND

MAY RESULT IN FIRE AND

PERSONAL INJURY.

It is most important that the Stone Age fireplace be

installed according to the following instructions. It is

also important that local building codes be consulted

and followed. Improper installation could result in:

• Overheating, leading to fireplace failure

• Cracks and settling because of poor founda-

tions

• Combustion of materials adjacent to the

fireplace.

WARNING: THIS FIREPLACE HAS NOT

BEEN TESTED WITH AN

UNVENTED GAS LOG SET. TO

REDUCE THE RISK OF FIRE

OR INJURY, DO NOT INSTALL

AN UNVENTED GAS LOG SET

INTO THIS FIREPLACE.

Do not install this fireplace in a manufactured or

mobile home.

3.1 Preparations

Select a location in the home plans or outdoor living

area where all the minimum distances, as shown in

Table 2 and Figure 3 can be met. Proceed as follows.

Numbers in ( ) are item numbers from Table 1 and

Figure 2. Ensure the base on which the fireplace is

to be installed is a solid and level foundation and is

composed of non-combustible material, such as con-

crete.

Due to varying climates, soil conditions, building

codes, construction methods and materials in differ-

ent geographical regions, Stone Age recommends

installers review local building codes, consult with

local building officials and/or a structural engineer

before beginning the construction of any Stone Age

product.

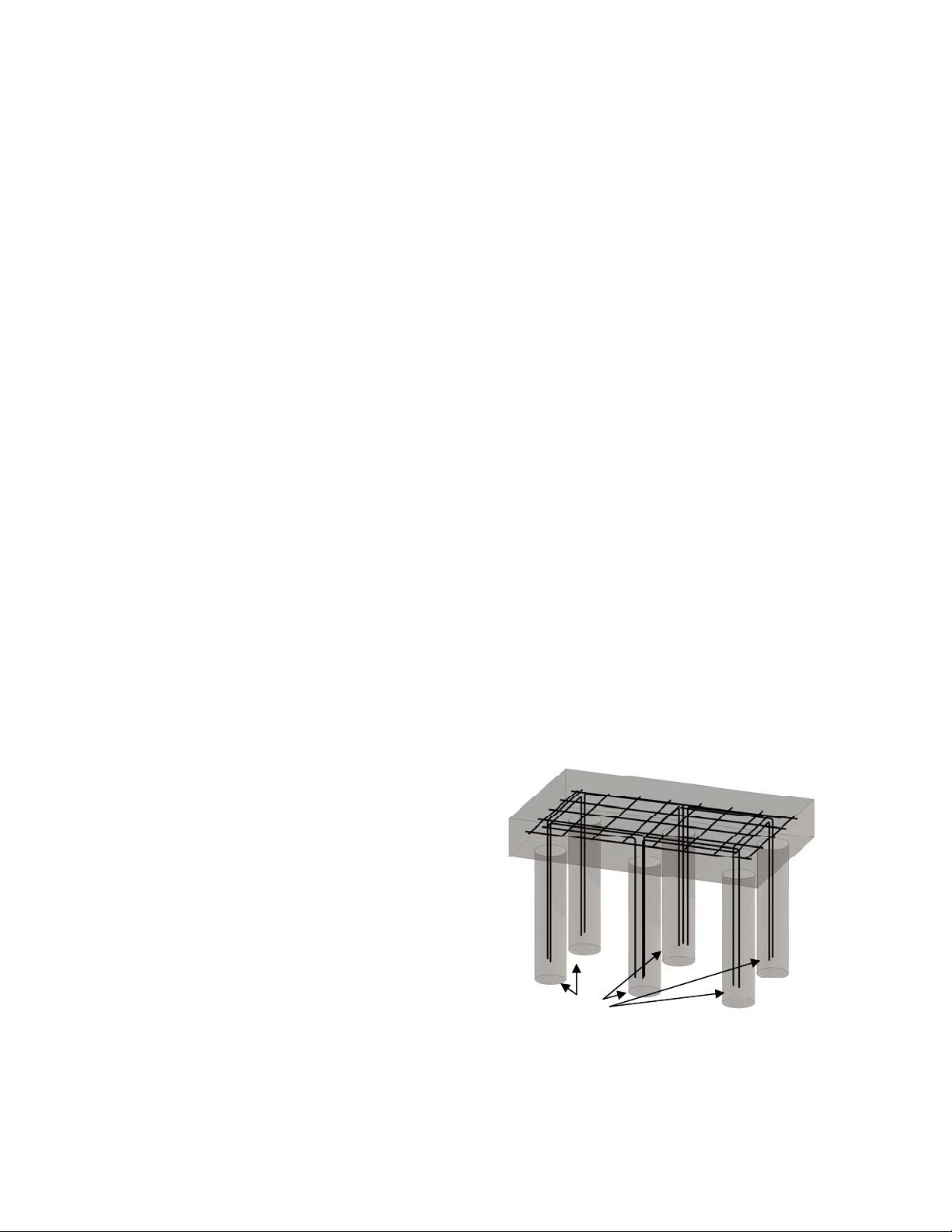

Pad or footings should be a monolithic pad con-

structed of steel reinforced concrete. Minimum foot-

ing specifications for fireplaces built on stable soil,

with overall height not exceeding 10 feet, are listed

in Table 3. Locations with unstable soil may require

a deeper footing or the addition of piers, to reach

more stable subsoil or bedrock. Areas with colder

climates may also require deeper footings or piers

that reach below the frost line to prevent frost heav-

ing. Piers should include steel reinforcement that

extends into the footing above. See Figure 4.

For taller applications, consult with an engineer to

determine the structural requirements based on the

overall height, and the weight of fireplace, chimney,

and finish materials. If custom hearths or additional

Figure 4. Footing with Piers - Cutaway View

Piers

4

masonry structure is to be attached to the fireplace

kit, the footing dimensions should be adjusted to in-

clude these customizations.

If local building code exceeds the manufacturer’s

specifications for footings, follow the local code.

Use Stone Age’s Multi-Purpose Ready-Mix, or an-

other high temperature fire clay or refractory cement

suitable for indoor or outdoor use, and mix according

to manufacturer’s instructions.

Once the fireplace-oven is constructed you must wait

at least 28 days before building a fire to give ade-

quate time to cure. This will provide ample time for

any water residue to evaporate, eliminating the ad-

verse reaction of the combination of water and fire.

Stone Age products are designed to be assembled

using a 3/8” fully bedded mortar joint for the kit

pieces. Do not “butter the edges” of the kit pieces.

3.2 Assembly of Components

Components that become broken during shipment

and handling can be mortared back together provid-

ing the breaks or cracks are clean and the original

alignment can be maintained. Components broken

into multiple pieces must be replaced.

The Caminetto™ ships as 3 pallets of material,

which must be assembled in numerical order. Begin

with pallet 1, then add the components from pallet 2,

and finish with the components from pallet 3. It is

recommended that you keep each pallet of materials

together until you are ready to install that pallet. The

components of Pallet 1 are shown in figure 5.

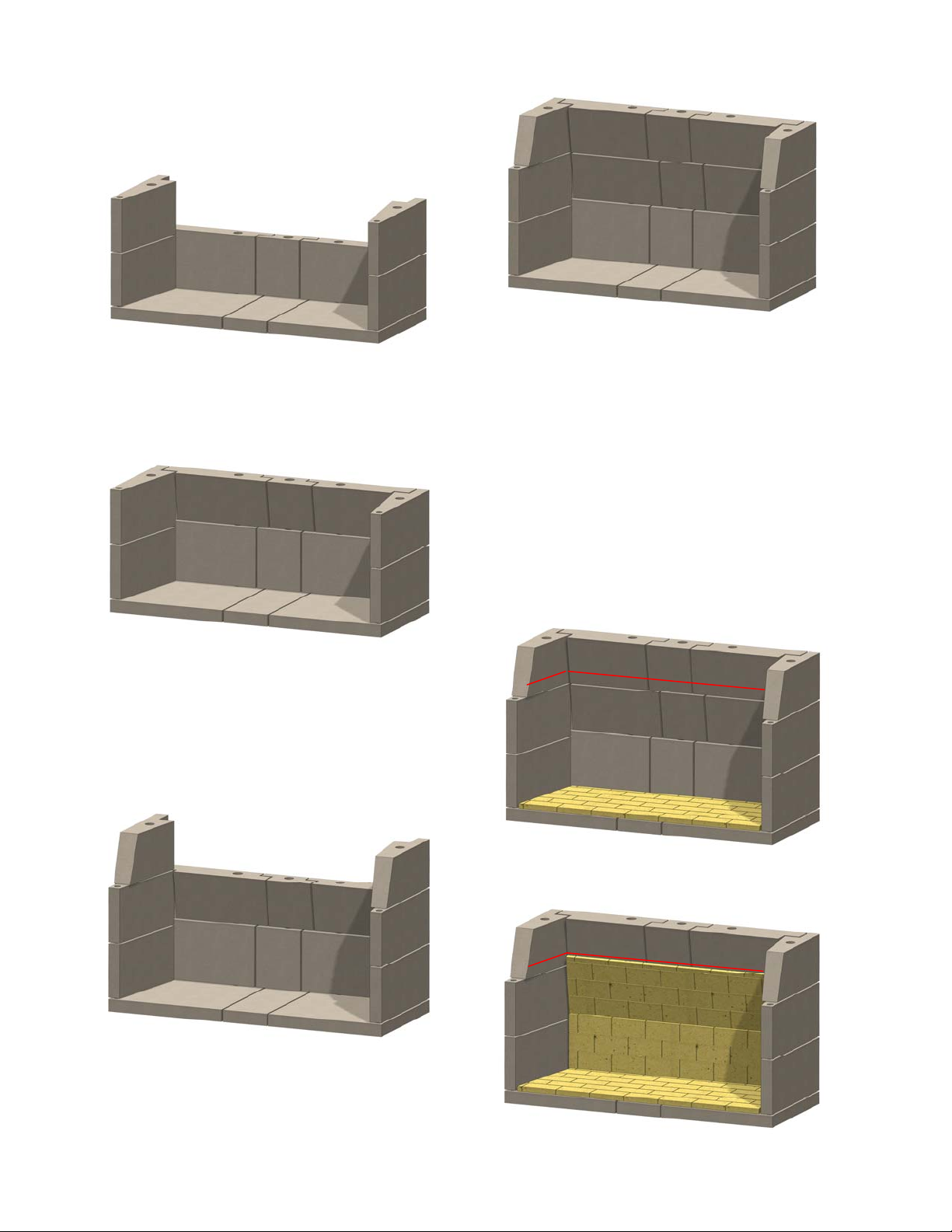

A. Start assembly with pallet 1. Begin kit assembly

by setting the base plate pieces (1 & 1C) on the

footing. Use a 3/8” joint of mortar between each

section, or slightly more if needed to reach the

proper overall width of 72” for this model. Level

the pieces from side to side and front to back. See

Figure 6.

B. On the first level, install the sidewalls (2) first,

then the back plates (3A, 3B, 3C). Use 3/8” joint of

mortar between each section, and repeat with all

remaining assembly steps, except for the firebrick.

Note that the back plates will be taller than the

sidewalls at this level. Smooth out mortar and en-

sure sections remain level. See Figures 7 and 8.

Figure 6. Base Plate

3B

3A

1C

Figure 8. Lower Back Plates & Sidewalls

3C

1

1

Figure 5. Pallet 1 Components

2

2

Figure 7. Bottom Sidewalls

5

C. Install the second level sidewalls (2), followed

by the middle back plate pieces (4A, 4B, 4C). See

Figures 9 and 10.

D. Lay a straightedge across the left and right side-

wall to ensure plumb and level are maintained.

E. Install the slanted sidewalls (6 and 7), and the

upper back plates (5A, 5B, 5C). Check the sides

and the top with a level. See Figures 11 and 12.

F. After installation of the back plates and side-

walls, install the firebrick inside the firebox, using

full brick (2 ½” thick) on the floor and split (1 ¼”

thick) firebrick on the walls, with 1/8-inch mortar

joints. Cover the floor with 1/8-inch high tempera-

ture cement and install the floor before other sur-

faces. On the side walls and back wall, lay the

brick on its sides. Stack brick until it is 1 ½” to 2”

higher than the middle back plates (4A, 4B, 4C).

The red line shown is an approximate guideline.

See Figures 13, 142, and 15.

2

2

5A

5B

6

7

Figure 9. Middle Sidewalls

Figure 12. Upper Back Plates

Figure 13. Firebrick Floor Installation

Figure 14. Firebrick Back Wall

5C

5B

4A 4B

4C

Figure 10. Middle Back Plates

Figure 11. Upper Sidewalls

Full Firebrick

6

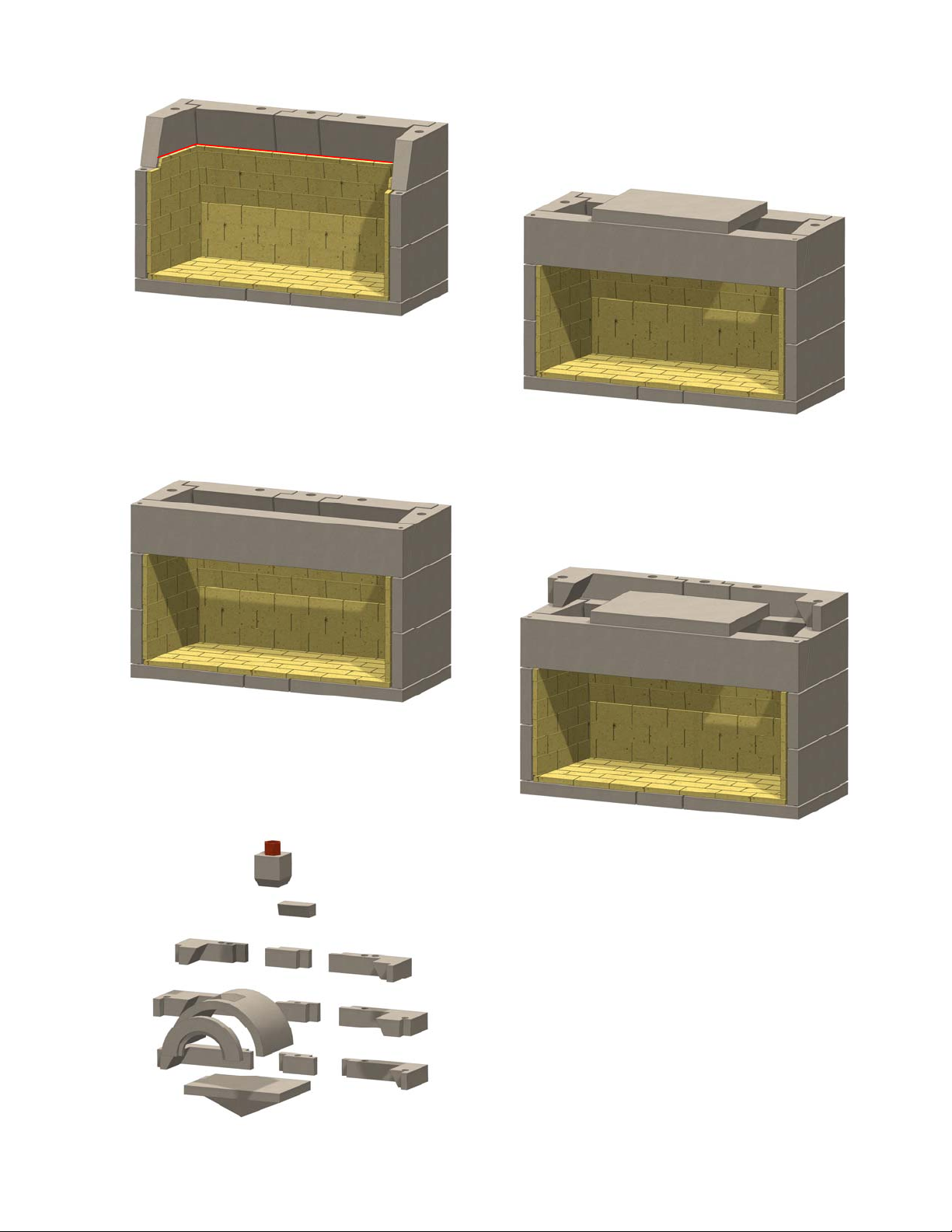

G. After fire brick installation is complete, install

the front lintel (8). See Figure 164.

H. Stage components of pallet 2 in preparation for

assembly. The components of pallet 2 are shown in

Figure 17.

I. Install pizza oven base plate (9), checking to

ensure it is level. See Figure 18.

J. Install lower level of rear throat pieces (Items 10,

10C and 11), checking them for level. See Figure

19.

8

9

11

10

Figure 18. Pizza Oven Base Plate

Figure 15. Firebrick Side Walls

Figure 17. Pallet 2 Components

Figure 19. Lower Rear Throat

Figure 16. Lintel

10C

7

K. Install the middle level of rear throat pieces

(items 12, 12C and 13). See Figure 20.

L. Install the upper level of rear throat pieces (14,

14C and 15). See Figures 21.

M. Install the rear throat cap extension (16C). See

Figure 22.

N. Install split (1 ¼” thick) firebrick along the back

wall of the fireplace throat. See Figure 23.

13

12

14 15

Figure 23. Oven Back Wall Firebrick

Figure 20. Middle Rear Throat

Figure 21. Upper Rear Throat

12C

14C

Split Firebrick

16C

16C

Figure 22. Rear Throat Cap Extension

16C

8

O. Install full (2 ½” thick) firebrick on the pizza

oven baseplate. See Figure 242.

P. Install the oven dome. See Figure 25.

Q. Install the oven front panel. See Figure 26.

R. Install the oven chimney flue. See Figure 27.

Figure 24. Oven Floor Firebrick

Figure 25. Oven Dome

Figure 27. Oven Chimney Flue

Full Firebrick

16C

17

18

19

Figure 26. Oven Front Panel

9

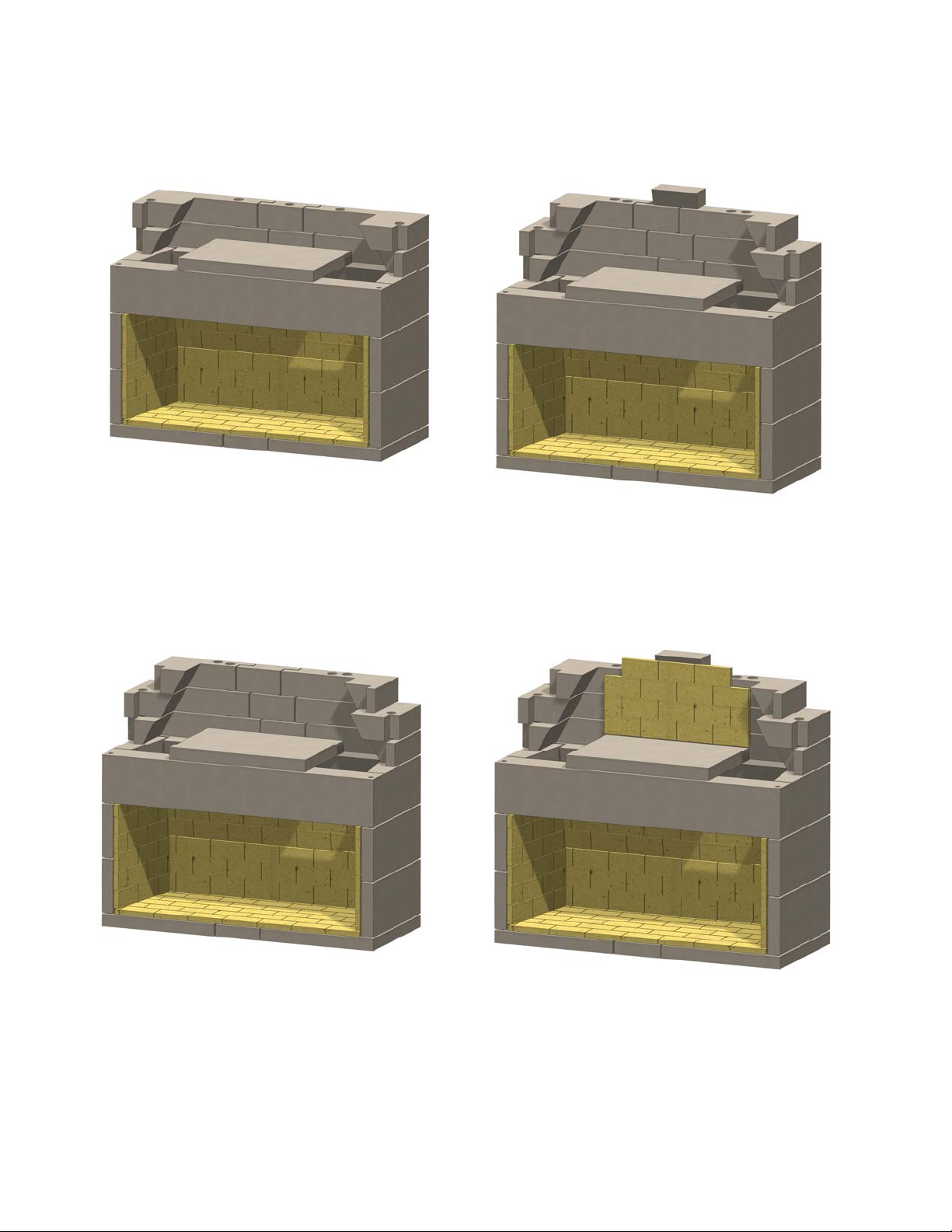

S. Stage components of pallet 3 in preparation for

assembly. The components of pallet 3 are shown in

Figure 28.

T. Install the lower throat left and right front piec-

es (20 & 21). See Figure 29.

U. Install the lower mid left and right front throat

pieces (22 & 23). See Figure 30.

V. Install the middle left and right front throat

pieces (24 & 25). See Figure 31.

Figure 28. Pallet 3 Components

Figure 31. Middle Front Throat Pieces

Figure 29. Lower Front Throat Pieces

Figure 30. Lower Mid Front Throat Pieces

21

20

23

22

25

24

10

W. Install the throat cap pieces (26 & 27). See

Figure 32.

X. Install the outer chimney blocks (28). See Fig-

ure 33.

Y. Install CMU block (29) to fill in the rear void.

See Figure 34.

Z. Install the hearth and or hearth extension. En-

sure the Table 2 and Figure 3 clearances and dis-

tances are maintained. Ensure that the hearth and

flooring under and in front of the hearth are made

of fully non-combustible materials, not just a non-

combustible floor covering. When the hearth in-

stallation is complete, you are now ready to install

the exterior. See Figure 35.

Figure 34. CMU Block

Figure 32. Throat Cap Pieces

Figure 33. Outer Chimney Blocks

27 26

28 28

29

Figure 35. Hearth

11

3.3 Exterior finishing

The exterior finish of an indoor fireplace will vary as

compared to an outdoor application and may be lim-

ited depending on location in the home and framing

that encompasses the fireplace. Exterior veneers

may be fabricated stone, thin veneer or full bed depth

natural stone, tile, brick or stucco.

If the exterior finish is going to be stucco, stain, tile

or manufactured thin stone wrap outside of firebox

with metal lathe. Attach metal lathe to firebox using

concrete nails, tapcons, masonry or concrete anchors.

Natural stone, full bed depth or thin veneer, full size

brick, concrete pavers, CMU block, etc. do not re-

quire metal lathe.

Ensure same refractory mortar is used.

4.0 Installation of Chimney

4.1 Stone Age Masonry System

The Stone Age Masonry chimney system consists

of stacking Stone Age chimney blocks and in-

stalling an optional clay flue inside.

A. Place a clay flue inside the chimney block. The

holes in each corner of the chimney block allow the

placement of rebar and mortar for additional rein-

forcement, if desired.

B. Continue with stacking the outer blocks and

clay flues until the desired height is reached. Mor-

tar the flue sections together, and mortar the chim-

ney block sections together. There will be dead air

space between the flue and chimney block sections.

C. The chimney is completed by stacking as many

flue sections as necessary to reach chimney height.

D. Dual masonry chimneys taller than 12 feet

should be tied into the surrounding structure for

additional support, due to the weight of the dual

flue system. Consult with an engineer to determine

the best way to do so for your project.

E. If unit is under a roof and the chimney exit

opening does not already exist locate the point

where the chimney will exit the roof by plumbing

down to the center of the fireplace chimney. Drive

a nail into the roof to mark the center.

F. Measure to all sides of the nail and mark the

required opening, and then cut a hole in the roof.

Remember that the hole is measured on the hori-

zontal, and then projected to the roof. The hole

may then be larger, depending on the pitch of the

roof.

G. Frame the opening in the roof.

H. Continue to add flue sections, extending the

chimney through the roof.

I. Install roof flashing appropriate to the roof

pitch.

J. Use mortar to create a slope away from the clay

flue, running out to the edge of the finish material,

to assist with water drainage. Install the chimney

cap following instructions provided. This will pro-

tect the chimney from rain, birds, animals and

leaves.

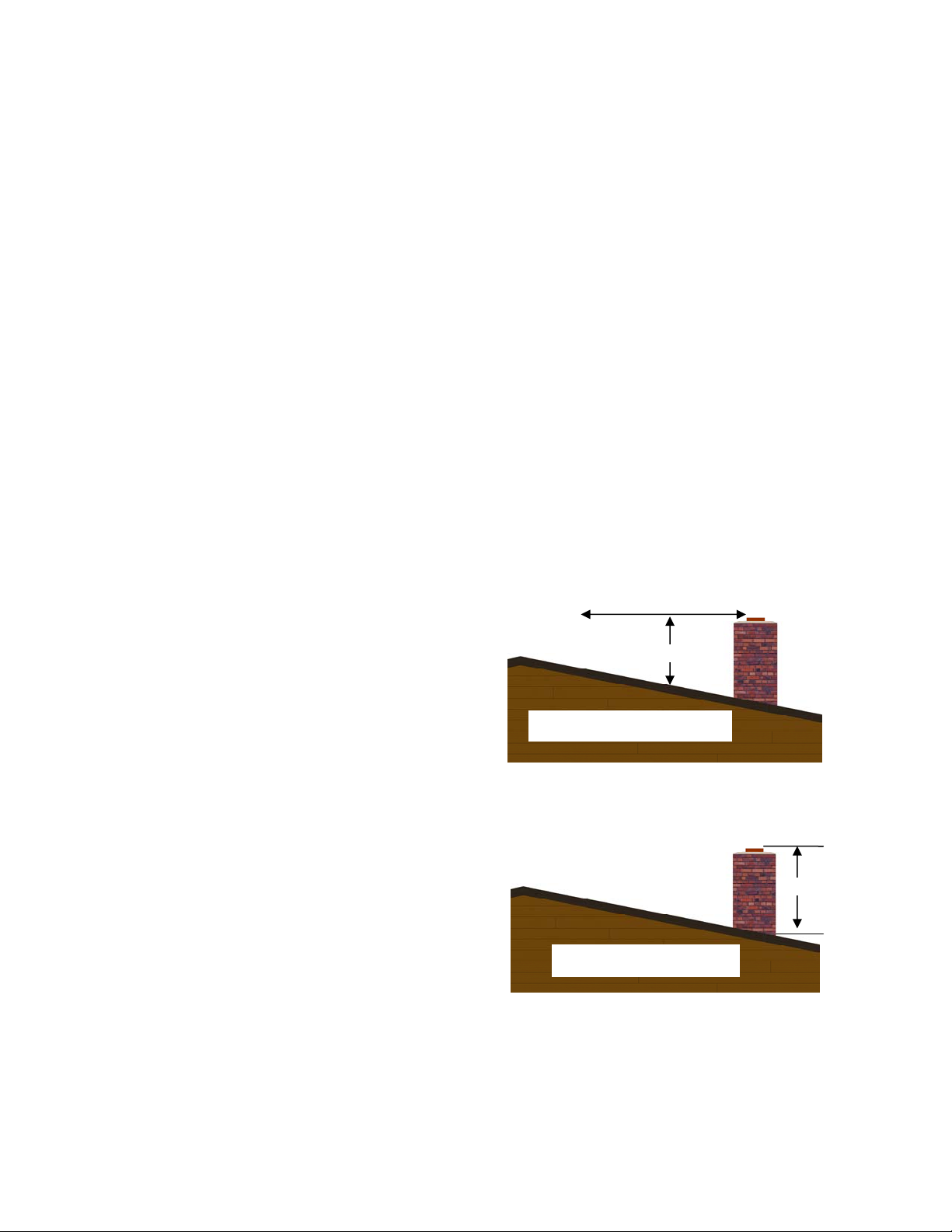

4.2 Height of Chimney

Figure 36 illustrates the proper height of the chim-

ney top. Correct height depends on the chimney’s

location on the roof and distance from the peak of

the roof. Surrounding trees, other buildings and

hills may also be a consideration.

If the chimney top is not high enough, unusual

downdrafts may occur, resulting in undesired smoke

spillage. For a more thorough explanation of the

figure 33 illustration, this is the traditional 2/10 rule.

Figure 36. Chimney Height

2’ Higher

Chimney Must be at Least 2’ Taller

Than Anything Within a 10’ Radius

10’ Radius

Chimney Must at Least 3’ Above

The Roof Penetration Point

3’ Above

12

The center of your chimney should be a minimum of

two feet higher than any roof or projection within ten

feet horizontally from the chimney center. This

means the chimney does not have to extend above

the peak of the roof. Once the chimney is ten feet

away and extended two feet above roof structure at

that distance, the height is sufficient, but it should

never be less than three feet taller than the point

where it penetrates the surface of the roof.

5.0 Operating Instructions

5.1 Safety Precautions

A fireplace and pizza oven can bring many hours of

enjoyment, warmth, and great cooking, if operated

and maintained properly. Certain safety precautions

must be observed to eliminate the dangers associated

with fire and provide a satisfactory fire with minimal

smoke. A pizza oven can easily generate tempera-

tures of 800°F or more, and can be dangerous if

proper clothing and tools are not used. Using the

fireplace and oven simultaneously will also require

taking extra precautions to protect against the poten-

tial for burns. Combustible materials in the vicinity

of the oven and fireplace openings may be at risk.

WARNING: WHEN OPERATING THE

CAMINETTO™, WEAR

PROPER CLOTHING AND USE

PROPER OVEN AND

FIREPLACE TOOLS WITH

EACH APPLIANCE. ENSURE

THAT COMBUSTIBLE

MATERIALS NOT REQUIRED

FOR THEIR OPERATION, ARE

KEPT AWAY FROM THE UNIT.

A. When burning wood use solid, seasoned wood

only. Do not use scrap wood or artificial wax

based logs, treated coal or woods dipped in pine tar

or pitch.

B. Never use gasoline or other combustible liquids

when starting a fire.

C. Keep a screen in front of the fireplace except

when tending the fire.

D. Keep combustible furniture/pillows at least four

feet from the opening.

E. Never leave the fire unattended.

F. Be extremely careful when adding wood and

handling fireplace tools. Never throw, kick or by

any other means force wood into the firebox as this

could damage the firebrick and fireplace walls that

could result in permanent damage and void the war-

ranty. Stress cracks from thermal cycling are nor-

mal.

G. Do not alter the fireplace or pizza oven to the

extent that it would jeopardize the structural integ-

rity of the unit. Drilling or cutting a hole for a gas

line, fresh air vent or ash dump is acceptable. Use

only Stone Age authorized equipment with this

fireplace.

H. It is advisable that long-sleeved shirts be worn

when inserting and removing wood or food in-

to/from the oven.

I. Use a non-combustible oven mitt when stoking

and adding wood to the fire, and when inserting

and removing or turning food.

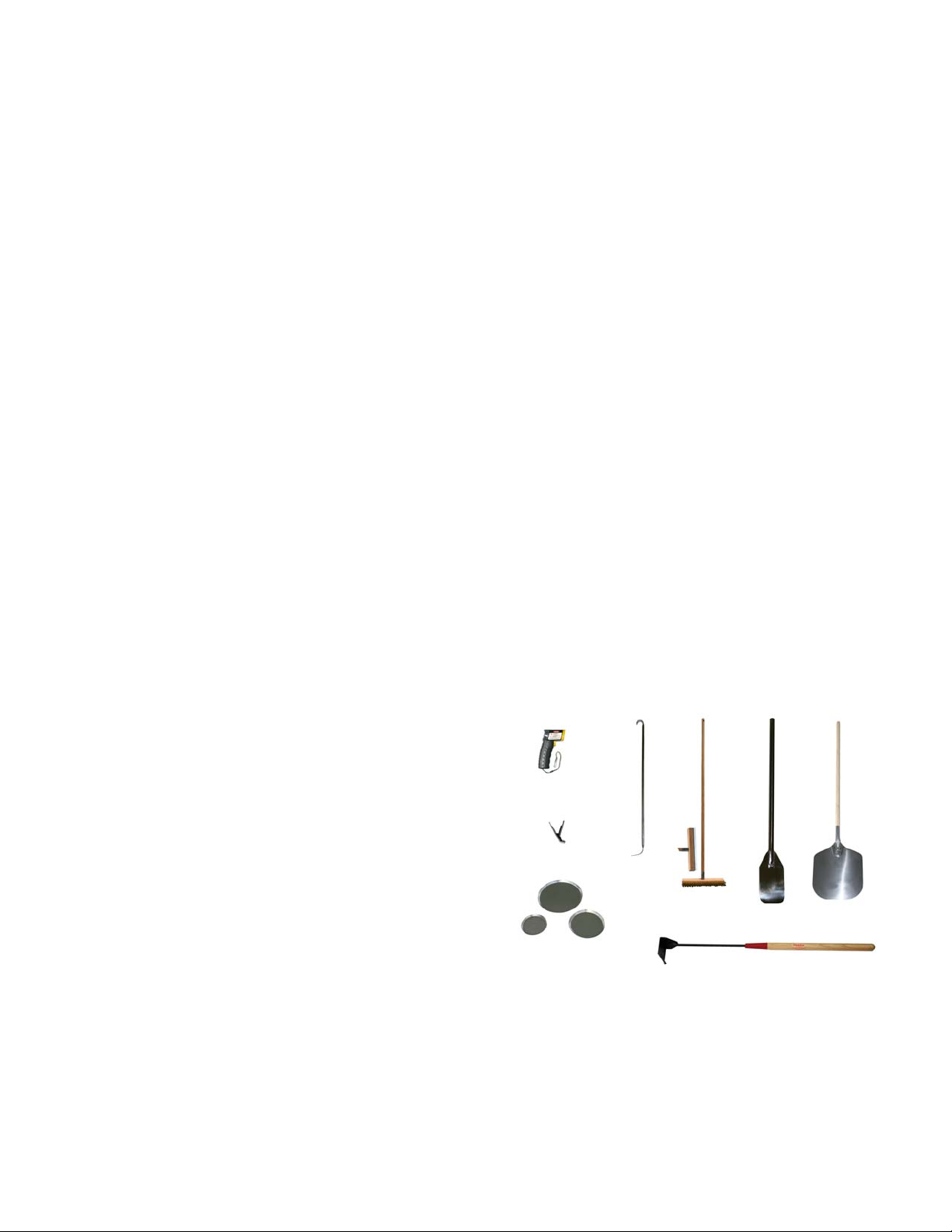

5.2 Tools

Special tools are available for the management of

fireplace and oven fires and inserting and removing

wood and food. These tools can be obtained online,

or from local retailers. Some choices are shown in

Figure 37.

5.3 Selection of Wood

Use cured wood logs only. Scrap wood produces

sparks. Treated wood, coal, or woods dipped in pine

Figure 37. Fireplace and Pizza Tools

IR Thermometer

Pizza Pans Fire Management Tool

Bubble Popper

Brush

Turning Paddle Peel

Pan Gripper

13

tar should not be used because they may leave a

combustible residue in the fireplace and chimney.

Use of seasoned wood is preferred.

The amount of heat available from logs will depend

on the type of wood, its dryness, quantity of wood

and the size of the logs. Ten pounds of twigs will

produce as much heat as a 10 pound log, but will

produce it much faster because the air supply is more

available.

5.4 Softwood vs. Hardwood

Wood is divided into two classes, hard and soft

woods. Each has a use in a fireplace and each has

advantages and disadvantages.

The hardwood category includes such woods as oak,

walnut, birch, elm and maple. Softwoods include

pine, fir, cedar and spruce.

Selection of wood depends on the type of fire you

want. Softwoods are good to offset a morning chill

because the fire develops faster. Hardwoods are

preferable for a slower burning and uniform heat

output.

Softwoods contain a highly flammable resin that will

leave creosote soot in the chimney flue. This often

results in sparking. Burning softwood exclusively

will require more frequent inspection and cleaning of

the chimney.

Experienced fire builders often use small amounts of

softwood kindling and newspaper when starting a

split hardwood log fire.

5.5 Seasoned Wood

Most freshly cut “green” wood will not burn well

and will smoke. The pressure of moisture and resin

inside green wood will build under heat and explode

as sparks. Therefore, it is recommended that only

seasoned wood be used in your fireplace.

Most wood requires 9 to 12 months of seasoning and

drying to reduce the moisture content enough to pro-

duce good steady fires. Ensure that you buy only

seasoned wood, or if you buy green wood (usually

cheaper), store it properly to aid in the seasoning

process. The following steps will assist in the sea-

soning process.

A. Stack wood loosely to permit maximum air cir-

culation.

B. Do not stack wood on the ground. Use a wood

rack or stack on scrap lumber. Storage on the

ground will cause rotting and insect infiltration.

C. Cover wood stacks with a tarp so that it is not

excessively exposed to the elements such as snow

and rain.

D. Do not stack wood against the walls of your

home.

5.6 Building a Fire

A. Use a log grate (sold separately) with your fire-

place. This will contribute to good air circulation

around the wood, and keep the wood out of the ash.

This grate is shown in Figure 38.

B. Close windows located near the fireplace when

first lighting a fire to reduce the possibility of

smoking. It can be reopened once a draft has been

created through the chimney.

WARNING: NEVER USE GASOLINE,

GASOLINE-TYPE LANTERN

FUEL, KEROSENE,

CHARCOAL LIGHTER FLUID

OR SIMILAR LIQUIDS TO

START OR “FRESHEN UP” A

FIRE IN THE FIREPLACE.

KEEP ALL SUCH LIQUIDS

WELL AWAY FROM THE

FIREPLACE WHILE IT IS IN

USE.

C. Do not overload the wood grate with wood.

Three to four logs on the fire at one time are suffi-

cient. Too much wood on the fire at one time can

result in “over firing,” and too much heat in the

firebox, causing damage to the fireplace.

D. When lighting a fire in a cold chimney, a

downdraft may be created, letting a little smoke

into the room. To correct this, hold a wadded

newspaper in the firebox and light it. This will cre-

ate an updraft and clear the flue of cold air.

The following steps are recommended when starting

a fire.

Figure 38. Log Grate

14

A. Remove any excess ash from the fireplace.

Excessive ash may reduce airflow. Some owners

prefer to leave a small layer to insulate the cold re-

fractory brick below the grate, helping fire starting.

B. Open and close the damper to ensure it operates

properly. Leave it in the full open position when

starting a fire and while the fire is burning.

C. Center the grate over the bottom hearth of the

firebox.

D. Crumble several newspapers across the fire

area underneath the grate. Criss-cross kindling

wood on top of the grate, above the newspaper.

E. Lay three logs on the grate; two side by side

and the third in pyramid fashion on top. Split logs

will start faster. Ensure there is space between the

logs for air circulation. As the air is heated, it is

drawn upwards through the space between the logs,

creating more combustion.

F. Light the paper at both sides of the firebox.

Caution: The fireplace requires air for operation.

Ensure there is sufficient air so that other

fuel burning appliances are not starved of

combustion, ventilation, and dilution air.

G. Set the screen in front of the firebox to prevent

the escape of sparks and embers.

H. Ensure the fire remains centered in the firebox.

Don’t let it move to the front part. Move it back

with the poker.

I. Add wood to the fire as necessary.

CAUTION: Be extremely careful when adding

wood to the fire. Use proper fireplace

tools and wear gloves. If adding an un-

split log, it is possible that it may want to

roll out.

5.7 Cooking

If the oven has been exposed to moisture 48 hours

prior to use, build a small fire and heat the oven to

250-300°F for two hours before increasing the heat

to cooking temperature. An easy solution is to burn

an 8-10 pound bag of match lite charcoal and let it

burn completely. This will slowly dry out the mois-

ture that the oven has absorbed.

As stated, we recommend cooking in a temperature

range of 350° to 600°F. Time of cooking will depend

on the temperature and the item being cooked. The

floor is the heat source that will do most of the cook-

ing. An infra-red temperature gauge like that shown

in Figure 18 can be used to measure temperature at

any location in and around the oven.

Cooking in a wood-fired oven is somewhat like grill-

ing or smoking meats in that there are many varia-

bles such as the type of wood used, ambient

temperature and humidity, oven temperature and

thickness of crust and toppings, that affect the out-

come, Be prepared to spend a few times testing reci-

pes and techniques while learning the nature of

cooking on your Caminetto. Practice and experimen-

tation will show how to best cook your favorite

foods.

Tips for cooking Pizzas :

• A traditional Italian pizza with a thick crust

and a thin layer of toppings should cook at

600°F or hotter for 3-6 minutes.

• For thicker pizzas with heavier toppings,

lower temperatures are required to thorough-

ly cook without burning.

• A medium pizza with heavy toppings may

cook best at 400°F-500°F and will require a

longer cooking times, perhaps 15-25

minutes.

Cook the pizza directly on the floor of the oven.

Place it in the oven using a long-handled paddle

called a peel, using hot mitts or hot pads. Slide the

pizza from the preparation surface to the peel, and

then onto the cooking surface using a slight jerking

technique.

WARNING: Be mindful of the hot surfaces of

your Caminetto oven. Because of

the high temperatures, extra cau-

tion should be used when cooking

with a wood-fired oven. Use prop-

er, long-handled tools and protec-

tive mitts when working around

the opening or reaching into the

hot oven.

6.0 Cleaning, Inspection and

Maintenance

As is the case with most other equipment, cleanliness

is the best maintenance practice and will contribute

too many hours of warmth and pleasure.

WARNING: DO NOT CLEAN THE FIRE-

PLACE WHEN IT IS HOT.

15

A. Creosote – Formation and Removal. When

wood is burned slowly, it produces tar and other

organic vapors, which combine with expelled mois-

ture to form creosote. The creosote vapors con-

dense in the relatively cool chimney flue of a slow

burning fire. As a result, creosote residue accumu-

lates on the flue lining. When ignited, this creosote

makes an extremely hot fire. The chimney shall be

inspected at least twice a year during the heating

season to determine when a creosote buildup has

occurred. If a significant layer of creosote has ac-

cumulated (3 mm or more), it should be removed to

reduce the risk of a chimney fire.

B. Disposal of ashes - Ashes should be placed in a

metal container with a tight-fitting lid, and taken

outside and placed on the ground, well away from

all combustible materials, pending final disposal. If

the ashes are disposed of by burial in soil or other-

wise locally dispersed, they should be retained in

the closed container until all cinders have thorough-

ly cooled.

C. The grate may be removed from the firebox for

cleaning. However, ensure it is returned prior to

laying the next fire.

D. Keep the fireplace screen clean so air flows

freely through it.

E. Spot check the refractory bricks and mortar for

small cracks. It will expand slightly with the heat,

and then contract as it cools. Replace refractory

bricks when the cracks open more than ¼”; or when

pits become extensive and deeper than 3/16”; or

when any piece of refractory larger than 2 inches in

diameter becomes dislodged.

F. If creosote has accumulated, it should be re-

moved to reduce the risk of a chimney fire. Clean

the chimney as outlined below or have the chimney

cleaned by a professional chimney sweep.

WARNING: DO NOT USE CHEMICAL

CHIMNEY CLEANERS THAT

ARE POURED ON A HOT FIRE.

THE CHEMICAL CLEANER

CAN BE DANGEROUS AND

GENERALLY WILL ONLY

WORK ON THE FLUE

SECTION NEAREST THE FIRE,

LEAVING THE REST OF THE

FLUE UNAFFECTED.

G. Inspect the top cap and opening in your chim-

ney top and remove any debris that could clog it. If

possible, birds will often nest there, and it must be

kept clear of nest material.

H. Check the metal flashing and seals around the

chimney. Seal any cracks or loose nail heads to

prevent roof leaks.

I. Cover the firebox opening with a damp sheet

and seal with masking tape to retain soot in the

firebox while cleaning.

J. Inspect the entire flue from the top down for

obstructions. Use a flexible handled cleaning

brush. If the chimney contains offset/return el-

bows, clean from the top down to the offset, then

from the firebox up to the offset.

K. Check the flue from inside the fireplace with

the damper open for obstructions.

L. After completion of cleaning, use a vacuum

cleaner to remove all soot and residue from the

firebox.

16

1

1

2

2

2

2

2

2

3

3A

A

3

3B

B

4

4A

A

4

4B

B

5

5

A

A

5

5B

B

6

6

7

7

8

8

1

1

5

5

1

17

7

1

10

0

9

9

1

12

2

2

20

0

1

11

1

2

23

3

1

1

4

4

2

24

4

2

25

5

1

13

3

2

2

7

7

2

2

6

6

Figure 2. Kit Components

(Larger View)

3

3C

C

4

4C

C

5

5C

C

2

2

9

9

2

22

2

1

10

0C

C

1

1

9

9

1

12

2C

C

1

1

4

4

C

C

1

1

6

6

C

C

1

1C

C1

1

2

28

8

2

21

1

2

2

2

28

8

1

18

8

17

18

Stone Age Fireplace-Oven

Instructions Model SA-CMO63

Revised October 2019

Printed in USA © 2018-2019, All Rights Reserved

Stone Age Manufacturing, Inc

LIMITED WARRANTY

The products of Stone Age Manufacturing, Inc. (“Stone Age”) have

been carefully manufactured and the components assembled to give the

customer a quality product. Stone Age warrants to the original purchas-

er the materials that it provides to the customer against defects in manu-

facture for a period of twenty-five (25) years from the date of purchase

on UL-127 listed fireplaces, for a period of five (5) years from the date

of purchase on all unlisted fireplaces, fire pits, and other masonry com-

ponents. Other accessory items or components offered, but not pro-

duced by Stone Age Manufacturing, Inc., shall be covered by their

manufacturer’s warranties. This Limited Warranty covers only actual

manufacturing defects in the Stone Age product and does not cover de-

fects or faulty workmanship in the installation of the product or the ma-

sonry or other structure in which it is installed. Also this warranty does

not cover items that have been damaged due to over-heating, modifica-

tion, improper storage or maintenance. Stone Age shall repair or re-

place, at its option, any defective Stone Age product component upon

receipt of written notice addressed to Stone Age. This Limited Warran-

ty covers only replacement of any defective components within the

product itself occurring during the warranty period and does not cover

the cost of installation or removal from a fixed location. NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, ARE MADE, INCLUDING

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR PARTICULAR PURPOSES WHICH ARE SPECIFICALLY

DISCLAIMED. Stone Age is not liable for damages or injury to per-

sons or property or other incidental or consequential damages.

Stone Age Manufacturing, Inc.

11107 E. 126th St. N., Collinsville, OK 74021

WWW.Stoneagefireplaces.com

Table of contents

Other StoneAge Kitchen Appliance manuals