STOWE MARINE DATALINE-X COMPASS User manual

USER GUIDE FOR

DATALINE-X

COMPASS

Stowe Marine Ltd. www.stowemarine.com Tel +44(0)1590 610071

Dataline-X Compass Manual, Part Number 06267SM, Issue 2, Dec 1995.

Warning

The equipment to which this manual applies must only be

used for the purpose for which it was designed. Improper use

or maintenance may cause damage to the equipment and/or

injury to personnel. The user must be familiar with the

contents of the manual before attempting to operate or work

on the equipment.

Simrad Ltd disclaims any responsibility for damage or injury

caused by improper installation, use or maintenance of the

equipment.

1996

©Simrad Ltd 1996

The information contained within this document remains the sole

property of Simrad Ltd. It must not be reproduced in whole or in

part, except under an agreement with the consent in writing of

Simrad Ltd.

Contents

CONTENTS

Part 1 Introduction

Part 2 Operation

Part 3 Installation

Part 4 Setting Up

Part 5 Fault Finding

Part 6 Maintenance

Appendix A Received NMEA 0183 Messages

Part 1

Introduction

Page 1

CONTENTS

1.1 The Dataline-X System

1.2 Dataline-X COMPASS Specification

1.3 Dataline Heading Sensor Specification

1.4 Robertson RFC250 Heading Sensor Specification

1.1 The Dataline-X System

The Dataline-X System, as its name implies, uses a single cable to carry both

power and data around the vessel to each instrument. This is done using a

NMEA 0183 serial digital communication link, which is an established industry

standard. Because of this, instruments from other manufacturers may be

interfaced to the Dataline-X System - assuming that they have a NMEA output or

input.

This User Guide describes the Navigation System Repeater digital display, known

as Dataline-X COMPASS, used within the Dataline-X System.

This User Guide also describes the installation and use of the Dataline

HEADING SENSOR and the Robertson RFC250 HEADING SENSOR with

the COMPASS display.

Introduction

Part 1

Page 2

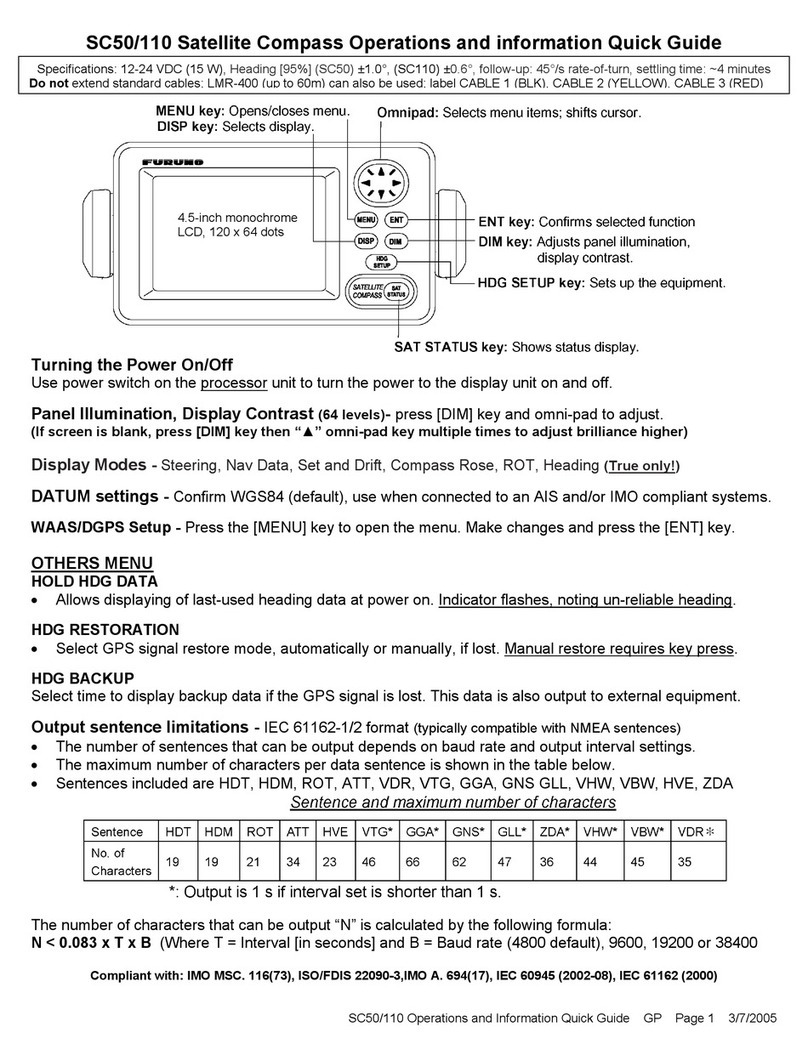

Figure 1.1 - Dataline-X System Diagram

Part 1

Introduction

Page 3

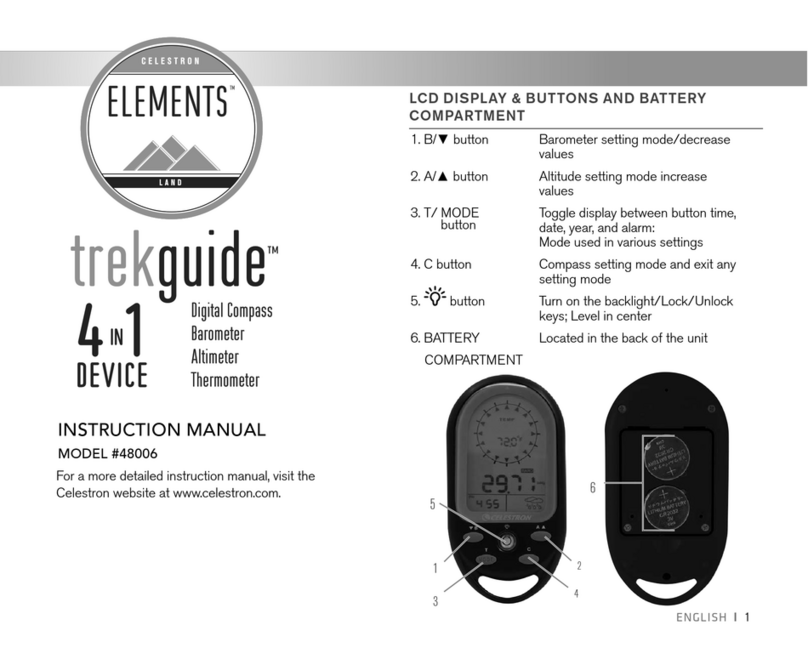

Figure 1.2 - Dataline-X COMPASS Instrument

Introduction

Part 1

Page 4

1.2 Dataline-X COMPASS Specification

Heading Functions

Heading Display (Digital) 0 to 359°

Heading Precision 1°

Heading Reference True or Magnetic North (See Note 2.)

Locked Course Functions

Locked Course Display (Digital)0 to 359°

Locked Course Precision 1°

Off Course Precision 1°

Off Course Reference Heading

Additional Functions

Compass Auto-Swing Calibration(With Dataline Heading Sensor)

Calibration Facility

Display Backlighting Levels Seven levels plus Off

Display Backlighting Colours Three colours, (Red, Green, Yellow)

Display Backlighting Control Two independent lighting banks.

General

Power Requirement 10 to 16V, 70 mA, (100 mA max with lighting)

Size 110 x 110 x 18 mm (above panel)

Mounting Hole Size 50 mm (2 inches)

Total Depth Below Panel Front 32 mm

Weight 210 grams

Environmental Rating IP65

Temperature Range 0°C to 70°C

Alternative Transducers

If any of the system transducers are not fitted to the Databox, but there is

alternative heading or course NMEA data being transmitted from another sensor

to the Databox, then this alternative data will be used.

Part 1

Introduction

Page 5

Notes:

1. Values and functions given relate to the display; the heading sensor

installed will determine the actual values and functions.

2. All headings and bearings may be referenced to either True or

Magnetic North. If True North is selected, and True data is not directly

available then the local magnetic variation may be entered (or received

from a suitable Radio Navigator via NMEA).

3. The battery voltage range is dependent on the power supply voltages

supplied to the Databox - i.e., the 12 volt Databox will measure over

the range 10V to 16V, while the 24 volt Databox will measure over the

range 20V to 30V.

1.3 Dataline Heading Sensor Specification

Power Requirement 10.6 to 32V, 70 mA

Size (Overall) 120 x 193 x 83 mm

Mounting Centres 130mm

Weight 700 grams

Cable Length 7m

Environmental Rating IP55

Compass Safe Distance Grade 1 (0.5 inch) = 1220mm

Grade 2 (1 inch) = 1220mm

Resolution 1 degree

NMEA Data Transmitted No Standard Messages.

1.4 Robertson RFC250 Heading Sensor Specification

Power Requirement

Size (Overall) 126mm x 160mm diameter

Mounting Centres 140mm radius

Weight 700 grams

Cable Length 15m

Resolution 1 degree

NMEA Data Transmitted HCHDM, HCUHW

Introduction

Part 1

Page 6

Part 2

Operation

Page 7

CONTENTS

2.1 General Description

2.1.1 The Dialplate

2.1.2 The LCD Display

2.1.3 The Buttons

2.2 Powering Up

2.3 The Heading and Locked Course Displays

2.3.1 The Heading Display

2.3.2 The Locked Course Display

2.3.3 Locking and Changing the Set Course

2.4 To Set The Display Backlighting

2.5 Heading Sensor Error Displays

2.6 Demonstration Mode

2.1 General Description

The display is divided into two sections, the pointer, and the LCD.

2.1.1 The Dialplate

The dialplate is printed with a scale which shows degrees and N, S, E, W. (See

Part 4). The pointer always shows True or Magnetic Heading.

2.1.2 The LCD Display

There are two arrows at the top of the LCD which show which data is being

displayed at any one time. The right arrow points to LOCK on the dialplate for

'Locked Course Mode', the left arrow points to HEADING on the dialplate.

The data indicated by the LCD in each mode is as below:

Mode Data

Heading Mode Heading

Locked Course Mode Off Course Error

Operation

Part 2

Page 8

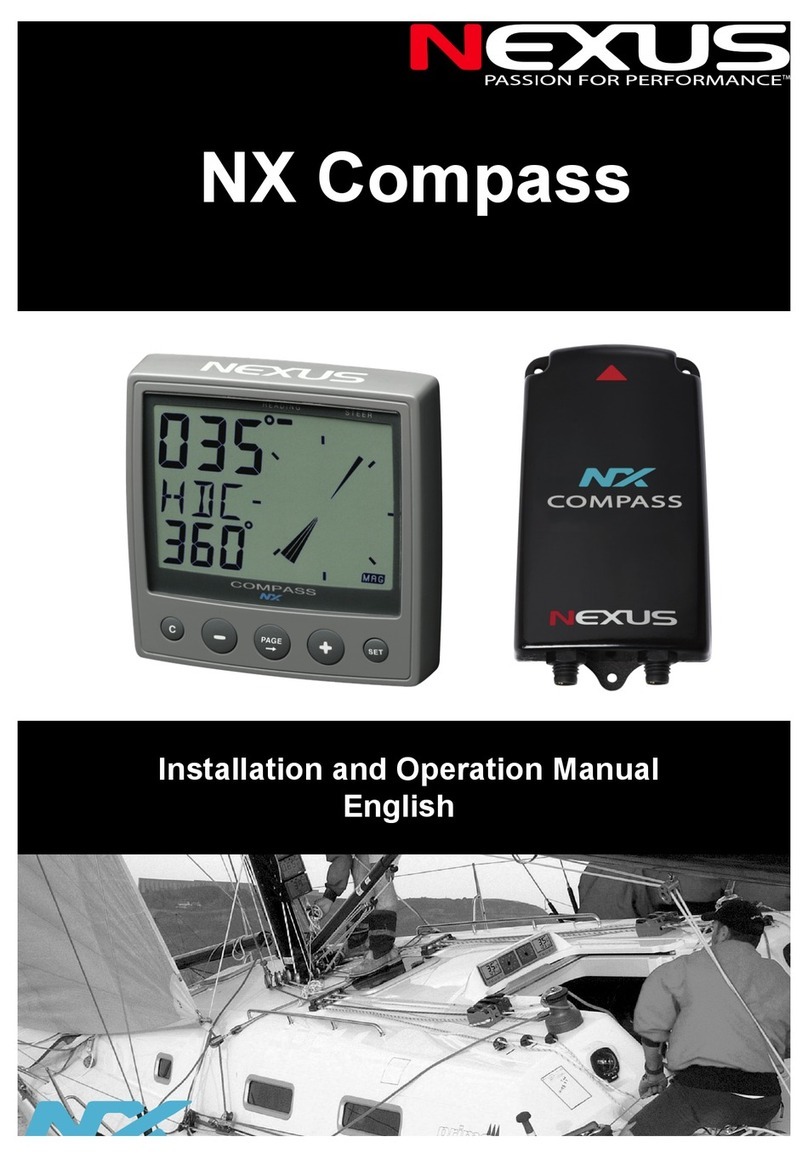

2.1.3 The Buttons

The word below the button indicates the main function for that button.

The HEADING button changes the current display mode to heading.

The LOCK button acts in heading and locked course modes to re-lock the locked

course and enable it to be changed. If this button is held down it sets the

lighting level.

When a function has been selected, a BEEP will be heard to confirm correct

operation.

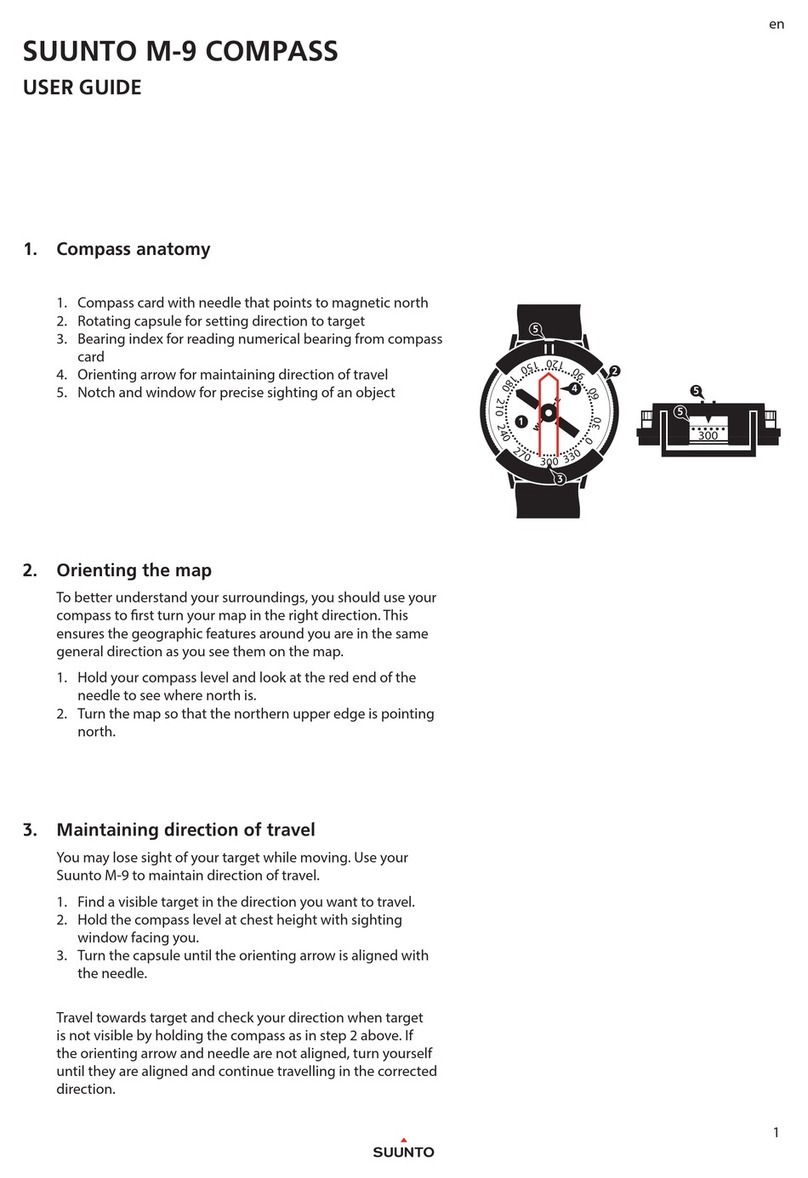

Figure 2.1 - The Buttons

2.2 Powering Up

When powering up the instrument, it will beep, the pointer will move to the top

of the display, and will show all the LCD segments for one second.

The display will then show the current heading if it is available.

2.3 The Heading and Locked Course Displays

These two displays will be available in all systems.

2.3.1 The Heading Display

The Heading Display is the first display that is shown after power up. It simply

shows the present heading on the LCD, followed by a degrees sign, '°', and with

the left LCD arrow lit. The pointer also shows the present heading.

When using the HEADING push-button to cycle around the display menu the

Heading Mode is indicated by the symbol ' HdG', for heading.

HEADING LOCK

Part 2

Operation

Page 9

Notes:

1. The heading may be referenced to either Magnetic or True North. If

only one type of data is available, and the other data is required then

the local magnetic variation may be entered, or it may be read in from

a Radio Navigator if one is fitted, and the correct NMEA message is

transmitted by it. This may for instance enable the display of True

data when only a magnetic referenced heading sensor is available.

2. If no data at all is available this display will be the only one that is

shown, and it will show four dashes, '----'.

2.3.2 The Locked Course Display

From the Heading Mode a single press of the LOCK push-button will cause the

display to show 'LOCK' for three seconds, and then to enter Locked Course

Mode. This will set the present heading as the locked course. Alternatively the

HEADING push-button may be pressed to leave Locked Course Mode, and this

will leave the locked course unchanged.

The Locked Course display shows the Locked Course on the LCD, followed by a

degrees sign, '°', and with the right LCD arrow lit. The pointer shows the

deviation of the vessel from the locked course. If the LCD shows >XXX then the

vessel needs to turn to starboard to steer back onto the correct course. The

opposite applies if the vessel is off course to port.

Note: If the heading data ceases to be available the pointer will return to the

centre position, and the LCD will show four dashes, '----'.

2.3.3 Locking and Changing the Set Course

Whenever the LOCK push-button is pressed in Locked Course Mode the Locked

Course will be set to the present heading.

If this is the course that is required then it can simply be left as it is. However,

for three seconds after the LOCK push-button has been pressed the degree sign

at the right of the LCD is flashed, and during this time if either of the two

buttons are pressed it will change the locked course in that direction. Small

changes may be made by individual presses of the buttons, but if a large course

change is required then the buttons may be held down. Every time that either

of the buttons is pressed the three second time-out is started again, until the

correct course is set.

The Locked Course is also set to the present heading if the LOCK push-button is

pressed to enter Locked Course Mode from Heading Mode.

Operation

Part 2

Page 10

2.4 To Set Display Backlighting

1. Press the LOCK button and hold. The display backlighting will

change from 0 to level 7, then level 6, then level 5, and so on to level

0. If the button is still held, the level will then increase back to 7

again.

2. At the desired display backlighting, release the LOCK button. This

will set the lighting on ALL displays on the Dataline-X system, which

are in the same Lighting Bank. The Dataline-X system has two

lighting banks, so that the internal lighting on a power boat may be

set differently to that on the flybridge, or the cockpit lighting may be

set differently to the chart table or mast display lighting on a yacht.

All displays are supplied set to bank 1. (See Part 4 for the bank set-

up information.).

Notes:

1. The lighting may not be set from the COMPASS display when it is in

Locked Course Mode, instead the lighting should be set from any

other display in the system.

2. If the COMPASS is in Heading Mode when the push-button is

pressed then it will return to Heading Mode after setting the lighting,

it will not go into Locked Course Mode.

3. On some Dataline Systems (not Dataline-X) only lighting levels 0, 3, 5

and 7 are available.

2.5 Heading Sensor Error Displays

If the COMPASS display is used with a Dataline Heading sensor then a

Compass Error display may be seen if there is a fault with the sensor.

This display will be shown instead of the normal display, and can be canceled by

pressing either button. If an error is seen then the heading sensor should not be

used for navigation until the error has been corrected.

The error messages consist of a display of 'Err' and a number which identifies

the nature of the error, as below:

'Err4' =Memory Error, contact your dealer for advice.

'Err6' =Battery Voltage is below 11 Volts.

If any other errors are seen (and the heading sensor is not in auto deviation

compensation mode - See Part 4) then consult your dealer for advice.

Part 2

Operation

Page 11

2.6 Demonstration Mode

The Demonstration Mode allows the user to familiarize himself/herself with all

the functions of the instrument with the device removed from the system.

Demonstration software within the instrument produces realistic values for the

display.

A +12V power supply will be required to be connected as follows:

0V to the BLACK (far right) terminal.

+12V to the RED (far left) terminal.

To enter the Demonstration Mode, press the LOCK button whilst applying

power to the instrument.

To leave the Demonstration Mode, switch off and re-apply power.

Notes:

1. The display will leave demonstration mode if any data is received.

2. The display can be set to automatically enter 'Shop’ demonstration

mode every time it is powered up. (See Part 4 for further details.)

Operation

Part 2

Page 12

Part 3

Installation

Page 13

CONTENTS

3.1 General

3.2 Installation of the COMPASS Display

3.3 Installation of the Dataline Heading Sensor

3.4 Installation of the RFC250 Heading Sensor

3.5 Compass System Wiring

3.6 Choosing the Cable Routes

3.7 Securing the Cable

3.1 General

The instrument head is fully waterproof and can, therefore, be installed on

deck or below. The connections should be protected from water penetration

and should, if possible, allow rear access to remove the desiccant pack, if

required. The position selected should, in the first instance, meet the

requirements of the helmsman, or crew.

The selected surface for the instrument must be flat and even to within 0.5mm.

Before installation, note the Serial Number and keep it in a safe place.

Great care should be taken when deciding on the location for the heading

sensor; it should be mounted away from areas of magnetic interference, and as

close the vessel’s centre of pitch and roll, as possible. The mounting should

also be solid and free of vibration. On steel vessels, the sensor should be

mounted on the mast, approximately one to three metres from the main

structure; although in other cases, do not install the sensor at the flybridge or

the mast as the display reading will swing as the boat rolls.

As a guide to minimising magnetic interference, the sensor should be a

minimum of:

ONE metre from:

Radios and loud-speakers

RDF Instruments

Other compasses

Cables carrying more than 1/2 Amp

Installation

Part 3

Page 14

Depth sounders, etc.

TWO metres from:

Engines / electric motors

Large masses of soft iron, e.g., keels

THREE metres from:

Radar magnetrons.

It is possible to use a small hand-held magnetic compass to check the

mounting location. Move the compass in a horizontal circle of approximately

30 cm (1 ft) radius around the desired mounting location. Be sure that the

lubber line is parallel to the midships line, and observe any heading - change

from the first noted reading. Not more than 50 deflection should be observed.

Repeat the same circle test, this time in a vertical circle. Little or no compass

card deflection should be observed. This check should be done with any nearby

equipment powered, and cables carrying their normal current.

The Dataline Heading sensor requires a mounting surface which is vertical,

and facing forwards. The RFC250 sensor requires a horizontal mounting

surface.

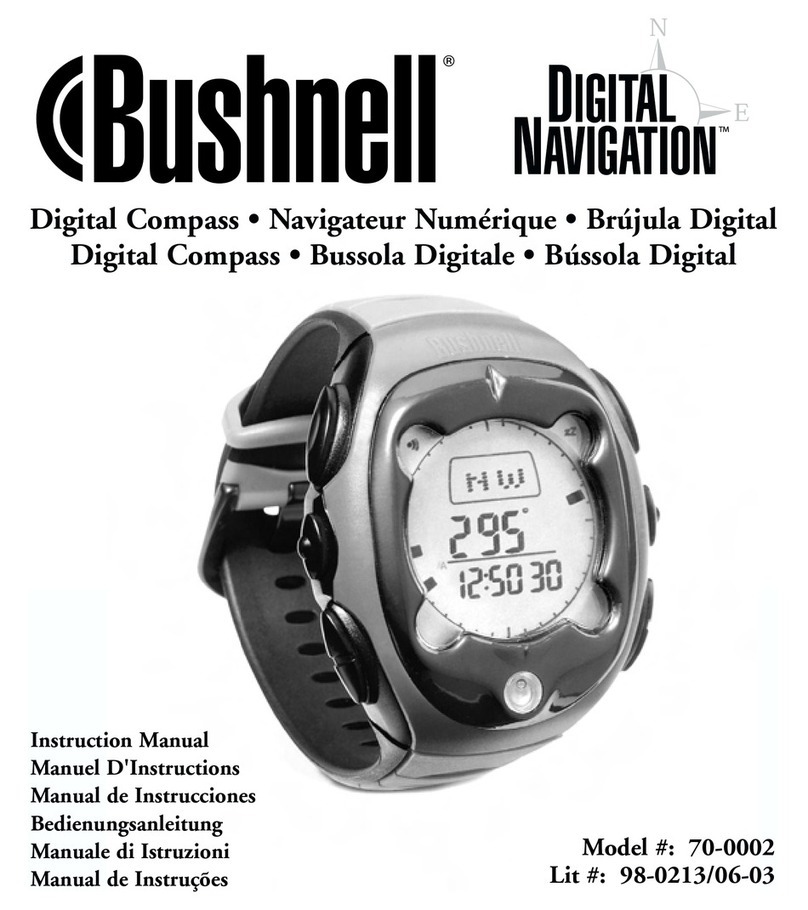

Figure 3.1 - Installation

Table of contents