Strand Lighting 48/96 Manual/Memory User manual

Installation Manual - 300 Series Consoles & 310 Show Controller

Welcome

Warning

Thank you for buying Strand Lighting control equipment. We hope that you

will find that your lighting needs are met by your new system and that you

will enjoy exploring the new facilities that your new system offers. You are

provided with essential information to help you install and operate your sys-

tem. Please look through all the documents and keep them safely for future

use. If you have any difficulties, please do not hesitate to contact Strand

Lighting, or any authorised Strand service centre for advice.

This equipment is designed to operate from the mains electricity supply

and contains voltages which, if touched, may cause death or injury. It should

only be operated in accordance with the instructions provided and for the

purpose of a lighting control system.

Avoid spilling liquid on the equipment. If this should happen, switch the equip-

ment off immediately. To reduce the risk of fire or electric shock, do not expose

the equipment to rain or moisture.

For indoor use only.

This equipment is designed and manufactured to comply with international safety

standards IEC950, UL1950, CS950 and is intended for use as part of a lighting

control system. It must not be used for other purposes where there is a risk of

safety to persons. The equipment contains power voltages, socket outlets shall

be installed near to the equipment and be easily accessible.

•Working Voltage/Current 100-120 (2A) 220-240 (1A)

•Frequency 50/60 Hz

•Max Ambient Temp 35oC

•Do not restrict ventilation

This manual describes the installation procedures for the following Strand

Lighting 300 Series consoles.

•24/48 Manual/Memory

•48/96 Manual/Memory

•Memory 125

•Memory 250

•Memory 400

•Memory 600

•120 Submasters

•310 Show Controller

Page 1

Document No: 40/B973

Date: March 2000

Installation Manual - 300 Series Consoles & 310 Show Controller

Offices and Service Centres

Phone numbers do not include country code or other international access data.

World Wide Web: http://www.strandlighting.com/

Strand Lighting Asia Ltd: 7/F Corporation Square, 8 Lam Lok Street, Kowloon

Bay, Hong Kong.

Tel: 852 2757 3033, Fax: 852 2757 1767

Strand Lighting Inc (Los Angeles): 18111 Santa Fe Avenue, Ranch

Dominguez, CA 90221, USA.

Tel: (310) 637 7500, Fax: (310) 632 5519, Fax: 800 775-LEKO,

Email: [email protected]

Strand Lighting Inc (New York): 2nd Floor, 151W-25th St, New York

Tel: (212) 242 1042, Fax: (212) 242 1837,

Email: [email protected]

US Service & Support: 800 4 STRAND (800.478.7263)

Strand Lighting (Canada) Inc (Toronto): 2430 Lucknow Drive #15,

Mississauga, Ontario, L5S 1V3, Canada

Tel: 905 677 7130 or 800-387-3403, Fax: 905 677 6859, E mail:

Strand Lighting Limited (Kirkcaldy): Mitchelston Industrial Estate, Kirk-

caldy, Fife, KY1 3LY, Scotland,

Tel: 01592 652333, Fax: 01592 653528

Software Registration: 01592 653499, E mail:

Strand Lighting Limited (Paris): 1 rue de l’Arc de Triomphe, Paris 17,

France

Tel: 00 331 553 70033, Fax: 00 331 553 70233,

Strand Lighting GmbH (Berlin): Strand Lighting GMBH, Ullsteinstrasse

114-142, 12109 BERLIN, Tel: 004930 707 9510, Fax: 004930 707 95199

Strand Lighting Italia Srl - (Pomezia): Via delle Gardenie, 33, 00040

Pomezia – Roma, Italia,

Tel: 00 39 06 914 7123, Fax: 00 39 06 914 7138

Strand Lighting Limited (Moscow): Novinsky Boulevard 20A, Buildings 3-

6, 121069 Moscow, Russia,

Tel: 007 095 290 2092, Fax: 007 095 290

Page 2

Installation Manual - 300 Series Consoles & 310 Show Controller

Unpacking

Open the packaging and check that the following components are contained within.

If any parts are missing, or damaged, please contact the carrier and your nearest

Strand Lighting office.

Package 1

300 Series Processor Unit, or 310

Show Controller complete with the

following:

(i) Operator’s Guide, CD Rom,

(ii) Password Disk

(iii) Power Cable

Note: The 310 Show Controller is

normally supplied as a stand-alone

lighting controller. In this case,

Package 2 is not included

Package 2

24/48 Manual/Memory console

comprising a command module

plus three fader modules.

or 48/96 Manual/Memory console

comprising a command module

plus five fader modules

Mounting

Brackets

300 series

Processor

Unit

or

310 Show

Controller

Page 3

Installation Manual - 300 Series Consoles & 310 Show Controller

or Memory 125 or 250 console

comprising a command module

and one 24 submaster fader

module

or Memory 400 or 600 console

comprising a command module

and one 24 submaster fader

module and two LCD monitor

modules.

or 120 submaster console

comprising a command module

plus five submaster fader

modules.

and the following items:

(i) Microsoft Intellimouse trackball

(ii) LCD cables (400 and 600

Memory Consoles only)

(iii) 3 Metre Cat 5 cable with RJ45

connectors – Control Console to

Processor

Unpacking

Page 4

Installation Manual - 300 Series Consoles & 310 Show Controller

Getting Started

The processor unit is designed to sit on a desk, or to be mounted onto, or under

a desk, or wall-mounted, or mounted within a 19 inch rack unit. Multi-purpose

brackets are supplied with the unit as shown.

Mounting the processor unit

(including 310 Show Controller)

Under Desk

Mounting

Fixed to Desk

Fixed to Wall

Note: Allstandardmodelsaresupplied

daisy-chained with a line terminator on

the last module. Additional modules

can be added to the daisy chain, and

the line terminator moved to the last

module. Alternatively, remote modules

can be connected to one of the other

RJ45 Sbus connectors.

Important Note: Do not fit or remove

the Sbus connectors unless the con-

sole has completely powered down.

Underside of command

module

Cat 5 cable

RJ45 Sbus connector

on Processor unit

Connecting The processor to the

Command Module

(Optional on 310 Show Controller)

19 in Rack Unit

Page 5

Note: The equipment can be mounted

to a wall with the brackets supplied.

Ensurethefixings(e.g.wallscrews)are

suitable for the weight of the unit and

are of sufficient size for the slots

provided in the back plate. The unit

can be regarded as wall mounted

moveable equipment. The means of

fasteningmustpermitreadyremovalfor

maintenance and repair. Therefore

after hanging the unit on its brackets,

do not tighten the screws fully, so that

the unit can be lifted from the wall.

When rack mounting, ensure that no

hazardous conditions are created due

to uneven mechanical loading.

Ensure that reliable earthing of the

equipment is maintained at all times.

Consideration should be given to the

supply circuit feeding the equipment

and the effect that overloading might

have on overcurrent protection and the

supply wiring.

Installation Manual - 300 Series Consoles & 310 Show Controller

Getting Started (cont.)

Connecting an External Monitor

(Optional on 310 Show Controller

and on 400 and 600 Memory

Consoles)

Connecting LCD Monitors

(two supplied as standard on 400

and 600 Memory Consoles only)

LCD1

Connector

Rear of

Processor Unit

Rear of

LCD Monitors

Connecting the Mouse

(Optional on 310 Show Controller)

Note: The mouse will not operate until

the mouse net node and port has

been set up in the User Setup Screen.

(Refer to the Introduction Section of

the User Guide)

LCD2

Connector

Mains supply

Rear of

Command Module Connection to COM2

port using adaptor

Connection to PS2 port

Connection to COM1

port using adaptor Connection to mouse PS2 port

on rear of Processor Unit

Alternative

mouse

connections

LCD

Cables

Max. 10mtrs

Page 6

Rear of Processor Unit

Installation Manual - 300 Series Consoles & 310 Show Controller

Getting Started (cont.)

Connecting a Printer (Optional)

Connecting an External Keyboard

(Optional)

Keyboard

Rear of

Command Module

Alternative

connection to

keyboard PS2

port on rear of

Processor Unit

PS2

port

Rear of

Processor

Unit

Rear of

Processor Unit

Connecting to the Mains Supply

100 - 120, (2A) / 220 - 240V ( 1A), 50/60Hz

Page 7

Installation Manual - 300 Series Consoles & 310 Show Controller

Positioning Hinged Modules

Getting Started (cont.)

Positioning and Support for Command Module and Fader Module, or Fader

Module and Fader Module

Command module or

fader panel

Position for best viewing

Hinge

LCD monitor

Hinged foot rest

Positioning and Support for Command Module and LCD Monitor module

Hinged fader module

Command module or

fader module

Hinged foot rest

Hinge Support

bracket

Page 8

Installation Manual - 300 Series Consoles & 310 Show Controller

Getting Started (Cont.)

Power Up/Power Down

Note: To shutdown, refer to the shut-

down procedure described in the User

Guide. Do not shut down by removing

the mains plug.

Operating the Lighting Consoles Operating instructions for the GeniusPro/Lightpalette software installed in your

console are provided in the Operator’s Guide supplied with this console. A

detailed operator’s manual and tutorial are also available on the CD supplied.

Channel Level and

State Screen

Channel Levels

Screen State Screen

Press button or ‘P14’

key on Command Module

Press button or ‘P14’

key on Command Module

Connecting the DMX Outputs

DMX Outputs to Dimmers,

etc. Refer to Operator’s

Manual.

DMX 1 DMX 2

Page 9

Installation Manual - 300 Series Consoles & 310 Show Controller

Connecting Advanced Functions of the 300 Series Consoles

Connecting to an Ethernet Network

(Standard on 310 Show Controller

and all 300 Series Memory

Consoles)

Connecting to a Macro Tablet

(Including 310 Show Controller)

Connecting a SMPTE Clock

(Standard on 310Show Controller.

Optional on 300 Series Consoles)

Connecting MIDI (Standard on

310Show Controller. Optional on

300 Series Consoles)

Refer to Operator’s Guide/Manual or On-Screen Help.

SMPTE clock input.

Refer to Operator’s Guide/Manual or On-Screen Help.

Rear of Processor Unit

Rear of Processor Unit

Macro Tablet

Refer to Operator’s Manual or On-Screen Help.

Rear of Processor Unit

Rear of Processor Unit

COM1port or COM2 port on

Command Module

Ethernet

connection to

network (refer to

Operator’s

Manual/

On-Screen Help)

Page 10

Installation Manual - 300 Series Consoles & 310 Show Controller

Connecting Advanced Functions of the 300 Series Consoles

Connecting External Submaster

Macros (Standard on 310Show

Controller. Optional on 300 Series

Consoles)

Submaster 1-12 Macros Submaster 13 -24 Macros

Connecting Hand-held Remotes

and Other Devices

(Standard on 300 Consoles and

310 Show Controller)

AUX 1 AUX 2

Auxiliary Inputs for Hand-Held

Remotes and other devices. Refer to

Operator’s Manual or On-Screen

Help.

External Submaster Macro

Inputs. Refer to Operator’s

Manual or On-Screen Help

Page 11

Each of the 24 submaster macro inputs consist of a signal/ground pair on adja-

cent pins of a D type connector. The required number of contact closure devices

are coupled to the connector(s) using twisted pair cables. It is recommended to

use 24AWG twisted pair wires for each contact. CAT5 UTP cable is suitable.

Installation Manual - 300 Series Consoles & 310 Show Controller

Changing the Module Configuration and Adding New Modules

Changing the Module

Configuration

Screw -in pins and hinge assembly are located in the tool box on the rear of the

module, as shown.

Page 12

Screw-in module coupling pins

The modular concept of the 300 Series consoles, allows the user to change the

configuration of modules and to add fader modules or LCD display modules as

required. Fader modules can be physically coupled to the hinge assembly, or

coupled to either side of the control module and to each other to form a

conventional control console. A maximum of two LCD modules can to be coupled

to the hinge assembly and set at the best viewing angle. You can also position

individual modules, or physically coupled modules separated by up to 100metres

from the command module.

Note: For portable units, no more than six modules should be physically con-

nected together, (three modules on the horizontal plane and three mounted on

the hinge).

Fitting and removing a hinged module

LCD modules are always fitted to the hinge on the back of a horizontal module

and the command module always fitted as a horizontal module. However, fader

modules may be fitted in either position to suit the operator’s preference and the

layout of the control room. A hinge assembly and module coupling pins are

supplied with each module, where no module is fitted to the hinge. In this way, the

user can change the configuration of the fader modules. Similarly when addi-

tional modules are supplied, hinge assemblies and coupling pins are included.

Important Note: Before making any changes to the console configuration, en-

sure that the mains supply is switched off and the mains plug removed.

Before fitting or removing a hinge assembly, separate the horizontal units by turning

the two half-turn fasteners counter-clockwise and pulling the modules apart.

Installation Manual - 300 Series Consoles & 310 Show Controller

Changing the Console Configuration and Adding New Modules

Rotating a Fader Panel Fascia When a fader panel is moved from a horizontal position to a hinged position, or

vice-versa, the panel fascia must be rotated such that the controls are facing the

correct way.

To rotate the panel fascia, remove the Sbus connector, then remove the four

panel screws, turn the panel facia, refit the screws and refit the Sbus connector.

Place one hinge assembly in the position shown and tighten the allen screw us-

ing the allen key provided. Place the tubed section of the module over the spigot

on the top of the hinge, ensuring that the locating pin is located in the recess, as

shown. Hold the module in position, while fitting the opposite hinge assembly. To

remove a module from the hinge, reverse this procedure.

Page 13

Installation Manual - 300 Series Consoles & 310 Show Controller

Changing the Console Configuration and Adding New Modules

The diagram below shows a typical expanded system incorporating seven fader

panels and two LCD monitors connected to one command module and one

processor unit.

Page 14

Expanding Your System

Anti-Theft Device

Holes for Kensington-type anti theft device

This manual suits for next models

8

Table of contents

Popular Controllers manuals by other brands

TechnoKiss

TechnoKiss TERRA Quick starter guide

Electromaten

Electromaten TS 959 installation instructions

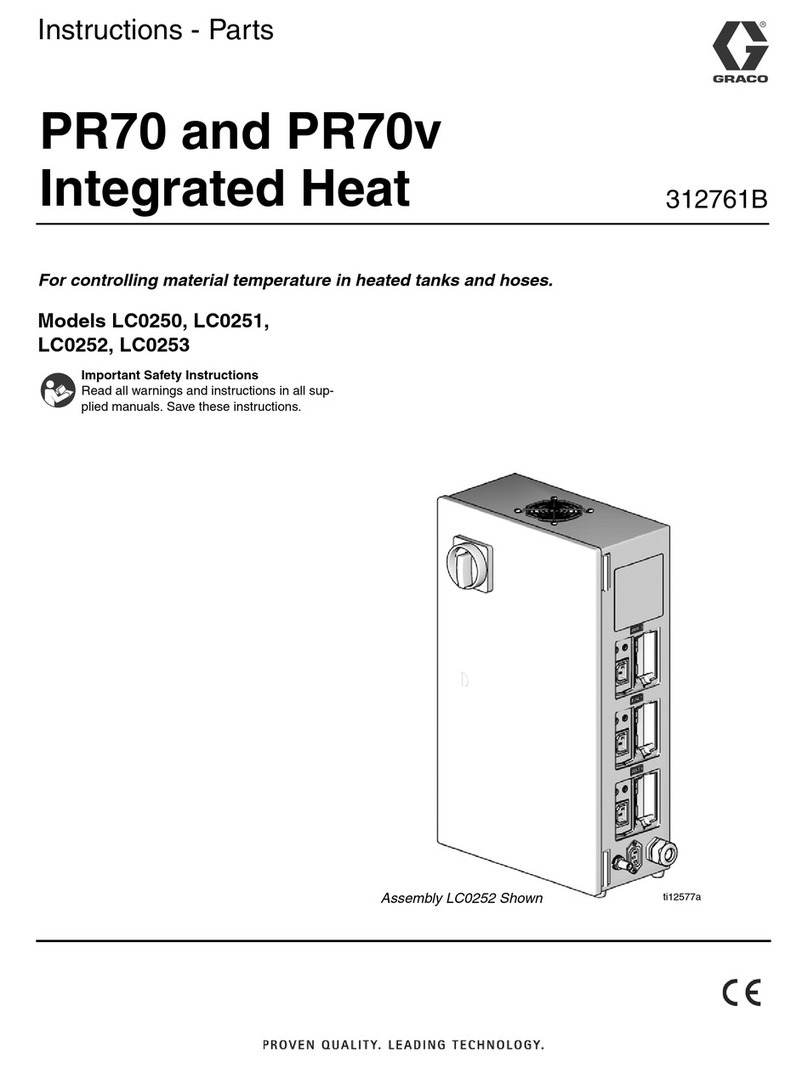

Graco

Graco LC0250 Instructions - parts

Zennio

Zennio MAXinBOX 16 Plus Technical documentation

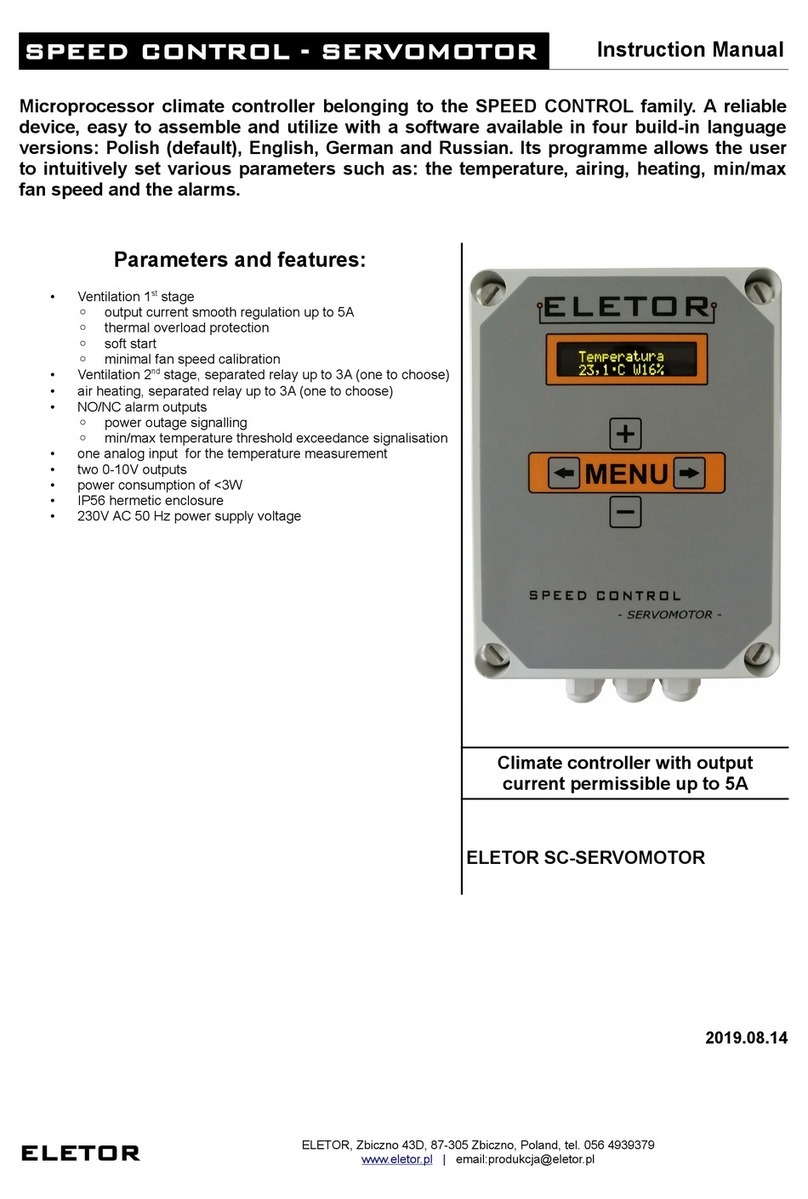

eletor

eletor Speed Control Series instruction manual

BFI Automation

BFI Automation CFC 4000L Original operating instructions