TRENT CaterSense V2 Installation and operation manual

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 1 01-15

Model: CaterSense V2

CaterSense V2 &

CS-V2+ATSC-02-08

MULTI FUNCTION

GAS SUPPLY CONTROLLER

INSTALLATION and COMMISSIONING

INSTRUCTIONS

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 2 01-15

Model: CaterSense V2

Product Overview

The CaterSense system is based on a range of products and ancillary equipment designed to meet the

ever changing requirements of the catering industry and associated regulations.

CaterSense V2 intelligent controller with Multi function solutions

The controller has a unique “self-set” system which makes for easy system commissioning.

Contents

1.0 General Info

1.01 Opening the unit

1.02 Fixing details

1.02.A Standard control unit

1.02.B Inbuilt speed control unit

1.03 Cable entry

1.03.A Standard control unit

1.03.B Inbuilt speed control unit

1.04 Electrical connections

1.04.A Standard control unit

1.04.B Inbuilt speed control unit

1.05 System set-up (locations)

2.0 Set-up and commissioning

2.01 Initial Set-up

2.02 System Set-up

2.03 System Checking

2.04 Functional Operation

2.05 Troubleshooting

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 3 01-15

Model: CaterSense V2

1.0 General Information

1.01 Opening the unit

1) To open the enclosure, first remove the snap-in clips at the bottom of the two side

panels: using a flat bladed screwdriver push the clip from below away from each side

panel.

2) Press the release pad on each side at the bottom of the enclosure and lift off each

side panel in turn by first pulling the bottom towards you. This will reveal the four

facia plate fixing screws.

X 2

1.

2.

3.

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 4 01-15

Model: CaterSense V2

3) Unscrew these four screws and lift the facia plate from the back box, ensuring that the

ribbon cable between the two PCBs has been unplugged at the main PCB end.

Place the screws, snap-in clips, side panels and facia plate in a safe place until the back box

has been fixed, wired and is ready for reassembly and set-up

*Please note if using a CaterSense V2 with inbuilt twin speed control you will

also need to remove the top plate (4) and front control box (5) as shown in the

diagrams below.

* IMPORTANT – Please ensure that when reassembling the CaterSense V2 with

inbuilt speed control unit that both the main power plug and control cable plug

are firmly fitted before powering the unit.

4.

5.

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 5 01-15

Model: CaterSense V2

1.02 Fixing details

1.02A For standard control unit:

The CaterSense V2 unit has six (6) mounting holes which can be used (as shown below)

Note: Ensure that the enclosure is mounted on a clean and level surface away from the direct cooking

area or wet surfaces.

1.02B For inbuilt speed control unit:

The CaterSense V2 + ATSC unit has four (4) mounting holes which can be used (see

Diagram 2)

Note: Ensure that the enclosure is mounted on a clean and level surface away from the direct cooking

area or sinks and other wet areas.

223

248

92.5

235

111.5

53

48

Diagram 2: Fixing details

168

230

244

BOTTOM

TOP

200

270

48

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 6 01-15

Model: CaterSense V2

1.03 Cable entry

1.03A For standard control unit:

The CaterSense V2 enclosure has an area of 190 x 25 mm which can be drilled for conduit

entry on the top edge of the enclosure.

1.03B For inbuilt speed control unit:

The CaterSense V2 & ATSC has two main areas for cable entry: the top area (223 x 40mm)

and the back of the enclosure (130 x 30mm located at the top).

For ease of installation, most of the connections you will need are made in the enclosure for

the ATSC. The inter-connections between the ATSC and the CaterSense controller are

achieved via two pre-made cable looms.

1.04 Electrical connections

1.04A For standard control unit:

The CaterSense system has two sets of terminals all mounted along the top edge of the main

PCB circuit board.

Terminals 1 to 22 are the smaller terminals (1.5 mm² cable) and are used for the

sensors, inter-locking devices, remote speed and on/off control,

screened cable must be used (we recommend Beldon 8723 but

that should be the choice of the installer and dependant on the

individual installation).

Terminals 23 to 34 are the larger terminals (4 mm² cable) and are for the power

connections for the fans, gas valve and power supply to the unit.

The terminals are of the rising clamp type protection.

All cabling should be kept to the top of the unit within the designated area. No cables should

be placed or laid across the PCBs as this may cause damage.

SENSOR 1 SENSOR 2 FIRE

ALARM

REMOTE

KOPB

CONTROL OUTPUTS

VOLT-FREE

OP1 OP2

CONTROL OUTPUTS

0-10V SPEED SIGNAL

OP3 OP4

START / STOP

POWER SIGNALS

FAN 1 FAN 2

GAS VALVE

OUTPUT

POWER

SUPPLY

E NL

E N

L

E E L NL N

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

REMOVE JUMPER LINK TO ACTIVATE DEVICE

J27 J26 J23 J25

4 Amp Max

24v 0vS+ S- 24v 0vS+ S- S+ 0v Scr S+ 0v Scr

1.04B For inbuilt speed control unit:

The ATSC-02-xx system has two sets of terminals all mounted along the top edge of the main

PCB circuit board.

Terminals 1 to 16, are the smaller terminals (1.5 mm² cable) and are used for the

sensors and inter-locking devices including motor thermal contacts.

Screened cable must be used (we recommend Beldon 8723 but

that should be the choice of the installer and dependant on the

individual installation).

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 7 01-15

Model: CaterSense V2

Remaining Terminals are the larger terminals (4 mm² cable) and are for the power

connections for the fans, gas valve and power supply to the unit.

The terminals are of the rising clamp type with protection.

All cabling should be kept to the top of the unit within the designated area. No cables should

be placed or laid across the PCBs as this may cause damage.

1.05 System set-up

The CaterSense V2 unit has a number of intelligent control solutions. Each of which is set via

a DIL (DIP) switch mounted on the main PCB circuit board. The CaterSense also has a

unique “Self-set” system commissioning tool which makes for easy system commissioning.

These devices are located on the main PCB as detailed in Diagram 3.

2.0 Set-up and Commissioning

The set-up and commissioning of your CaterSense system is in two parts, Initial and

System.

2.01 Initial Set-up

Once all of the wiring has been completed and tested and the system is ready to be set-up

and commissioned, the following sequence MUST be followed to ensure the CaterSense and

system operate correctly.

OFF

ON

1 2 3 4

R113

R114

SENSOR 1

SENSOR 2

KNOCK-OFF

FIRE ALARM

SET-UP

CONTROLLER

MODE DIL SWITCH

SYSTEM

SET-POINT 2

SYSTEM

SET-POINT 1

INPUT SELECTION

JUMPERS

ENGINEERS SYSTEM

SELF-SET BUTTON

MAIN PCB

SINGLE FAN

RIBBON CABLE

SOCKET

J27

J26

J25

J23

J13

J5J3

Diagram 3: PCB locations

Sensor 4

Sensor 3

Sensor 2

J8

J7

SMALL EXPANSION MODULE

IF REQUIRED

FIRE

ALARM

KNOCK

OFF

(open on l rm)

Sensor 1

8765

4321

34

CATERSENSE V2 - MAIN PCB

33

EXTRACT

FAN

SUPPLY

FAN

32

E

313029

L N

282726252423

22212019

E

181716

L N

1514131211109876543

E

2

L N

GAS

SOLENOID

VALVE

1

Tel: 01782 - 844688 F x: 01782 - 844772

JH-PCS-WD-V2

E L N

9876543210

DATE: DRAWING No: DRAWN BY

AUTOMATIC SPEED

CONTROL OUTPUT

(0-10 / 5-10Vdc)

HEATER

BATTERY

OUTPUT

(0-10Vdc)

J5

J3

SENSOR 1

SENSOR 2

KNOCKOFF

FIRE ALARM

SINGLE

J27

J26

J25

J23

J13

SETUP

ON

OFF

1234

CATERSENSE V2

FAN SART

HEATER

BATTERY

ENABLE

*we recommen Bel on 8723 but

that shoul be the choice of the installer

an epen ant on the in ivi ual installation*

*

*

POWER SUPPLU

(240V c, 50Hz)

LOCAL

ISOLATOR

22/04/2015

MAIN (REGULATING)

AUXILIARY

NEUTRAL

EARTHE

C

A

M

CS-WD-V2S

LOCAL

ISOLATORS

(See Note: 1)

THERMAL

ENABLE

15 1613 14

- +

ALL TRIM POTS

ON

OFF

DRAWN BYDRAWING No:DATE:

0 1

NOTES:

MOTOR SPEED

AD USTMENT

POTS

RATIO

MTR 2 MTR 1

MAX SPDMIN SPD

2

L

345

N

E

6 7 8 9

POWER SUPPLY

(240Vac, 50 Hz,

See Note: 3)

PRE-WIRED CONNECTIONS

(LOW VOLTAGE)

PRE-WIRED CONNECTIONS

(240Vac)

L N

E

PWR IN

SCREEN CABLE

BELDON 8723 TYPE

E C A M

EE

CONNECTION DETAILS - ATSC PCB

INTERNAL

USE ONLY

LNNL

GAS

SOLENOID

VALVE

(open on alarm)

KNOCK

OFF

FIRE

ALARM

9 17 6 5

SUPPLY

FAN

EXTRACT

FAN

NL

E

101112 3 2

AUX OUT

L N

E

MOTOR 2 OUTPUTMOTOR 1 OUTPUT

E C A M

KNOCK

OFF

FIRE

ALARM SENSOR 2

0v

SIG

+24v

SENSOR 1

0v

SIG

+24v

Tel: 01782 - 844688 Fax: 01782 - 844772

CATERSENSE V2

TWIN SPEED CONTROLLER

WIRING & CONNECTION DIAGRAM H-P

1) LOCAL ISOLATION MUST BE PROVIDED IN ACCORDANCE

WITH THE CURRENT EDITION OF THE IEE REGULATIONS.

2) CHECK MANUFACTURER'S WIRING DETAILS FOR CORRECT

CONNECTIONS AND SET-UP REQUIREMENTS.

3) ENSURE THAT THE POWER SUPPLY IS CORRECTLY RATED

TO THE SIZE OF BOTH FAN MOTORS AND GAS VALVE

34

CATERSENSE V2 - MAIN PCB

3332313029282726252423

22212019181716151413121110987654321

5

3

SENSOR 1

SENSOR 2

KNOCKOFF

FIRE ALARM

SINGLE

27

26

25

23

13

SETUP

ON

OFF

1234

*we recommen Bel on 8723 but

that shoul be the choice of the installer

an epen ant on the in ivi ual installation*

18 18

*

SCREENED CABLE RECOMMENDED

THRM

SELECT

THERMAL

CUT OUT

(See Note: 6)

MOTOR 1

1413

COMMON

AUXILIARY WINDING

MAIN WINDING

ME

TYPICAL WIRING ARRANGEMENT FOR A

SINGLE PHASE MOTOR (3 WIRE - See Note: 5)

AC

LOCAL

ISOLATOR

(See Note: 1)

MOTOR 1

OUTPUT

Sensor 4Sensor 3

8

7

87654321

Sensor 2 Sensor 1

FAN START

HEATER

BATTERY

ENABLE

HEATER BATTERY

OUTPUT (0-10Vdc)

*

22/04/2015

Tel: 01782 - 844688 Fax: 01782 - 844772

JH-P

SENSORS-WD01

9876543210

DATE: DRAWING No: DRAWN BY

SENSOR CONNECTIONS

4 2 1

t

CAPILLAR

THERMOSTAT

(remove link if required,

open on low temp)

GW

E L N VAL3P.....VALVE

& ACTUATOR

flex

BLACK

WHITE

RED

B 1413NLE

3-PORT VALVE ADDITIONAL

CONNECTION BOX

CS-VPP-01

C

AIR DIFFERENTIAL

PRESSURE SWITCH

N/O

EXTRACT AIR

TEMPERATURE

SENSOR

CO2

SENSOR

SUPPL AIR

TEMPERATURE

SENSOR

GAS PRESSURE

TRANSDUCER

OUT 0v24v

1716

OUT 0v24v

G G01

OUT 0v24v

1 3 2

OUT 0v24v

132

22/04/2015

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 11 01-15

Model: CaterSense V2

a) DIL (DIP) switch set-up

Ensure the correct system code has been selected on the DIL switch.

IMPORTANT: Ensure power supply is switched OFF before adjusting DIL mode

switch

*Please note – If using manual or step transformer speed controllers,

ensure that DIL (DIP) switch 2 is in the disabled position.

1 2 3 4

Enable

Disable

DIL 1 Is used to enable or disable Gas Pressure Proving

DIL 2 Is used to enable or disable Automatic Fan Speed Control

DIL 3 Is used to enable or disable CO2 Monitoring

DIL 4 Is used to enable or disable System Demand

MODE DIL (DIP)

position

Fan Start /

Stop

Gas

pressure

proving

Automatic

fan speed

control

CO2

Monitoring

System

Demand

Heater battery control

LPHW only

Electric /

Gas fired

1

N/A Enable with

jumper J21

2

N/A Enable with

jumper J21

3

Enable with

jumper J21

4

N/A Enable with

jumper J21

5

Enable with

jumper J21

6

Enable with

jumper J21

7

N/A Enable with

jumper J21

8

Enable with

jumper J21

9

Enable with

jumper J21

10

Enable with

jumper J21

11

Enable with

jumper J21

12

Enable with

jumper J21

See Page 13

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 12 01-15

Model: CaterSense V2

b) Setpoint allocation and set-up

The CaterSense V2 has two 270° turn pots called R113 and R114 (as shown

below). These pots are used to allocate different setpoints dependent on the DIL (DIP) switch.

R114

R113

POTS Sensor Inputs

MODE DIL (DIP)

position R113 setpoint R114 Setpoint Sensor 1 Sensor 2 Sensor 3 Sensor 4

1

N/A Supply

Temperature N/A Supply

Temp sensor N/A N/A

2 N/A Supply

Temperature

Gas pressure

sensor

Supply

Temp sensor N/A N/A

3

N/A Supply

Temperature N/A Supply

Temp sensor N/A N/A

4 N/A Supply

Temperature

Supply Temp

sensor CO2 sensor N/A N/A

5 N/A Supply

Temperature

Gas pressure

sensor

Supply

Temp sensor N/A N/A

6 N/A Supply

Temperature

Supply Temp

sensor CO2 sensor N/A N/A

7 N/A Supply

Temperature

Gas pressure

sensor CO2 sensor Supply

Temp sensor N/A

8

N/A Supply

Temperature

Gas pressure

sensor CO2 sensor Supply

Temp sensor N/A

9 Demand

Temperature

Supply

Temperature

Supply Temp

sensor

Demand

Temp sensor N/A N/A

10 Demand

Temperature

Supply

Temperature

Gas pressure

sensor

Supply

Temp sensor

Demand

Temp sensor N/A

11 Demand

Temperature

Supply

Temperature

Supply Temp

sensor CO2 sensor Demand

Temp sensor N/A

12 Demand

Temperature

Supply

Temperature

Gas pressure

sensor CO2 sensor Supply

Temp sensor

Demand

Temp sensor

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 13 01-15

Model: CaterSense V2

* To enable the Electric or Gas Fired Heater Battery Control you must ensure the

jumper J21 is fitted as per image below.

(Jumper J21)

c) Input Jumpers / Sensor Links ON = OFF =

IMPORTANT: Ensure power supply is switched OFF before adjusting input jumpers

or sensor links.

J25 (KNOCKOFF) - If using a remote knockoff circuit in terminals 11 and 12, ensure that

J25 is OFF. Otherwise, ensure J25 is ON.

J23 (FIRE ALARM) - If using a fire alarm circuit in terminals 9 and 10 OR a fan hold-off

thermostat OR thermal cut outs are connected ensure that J23 is OFF. Otherwise, ensure

J23 is ON.

J13 (SINGLE) - If only using one fan, ensure J13 is ON. Otherwise, ensure J13 is OFF.

d) Inter-lock circuits

Ensure that the fire alarm and knock-off switches (if fitted) are all in the operational

position.

e) Gas pressure range

Whenever the system is initialised with the "start" pad, a pipework integrity test is carried

out. This opens the gas solenoid valve for 10 seconds, and then closes the valve for 30

seconds and monitors the pressure. If this pressure drops by 10% or more during this 30

seconds stage, the system will alarm and not start.

When all of the above stages have been

completed, re-assemble the CaterSense

unit by reversing the sequence described

above in section 1.01.

NOTE: Ensure the ribbon cable is plugged

in correctly with the key pin (red stripe) at

the top on the main PCB, and at the

bottom on the facia (see Diagram 5).

Otherwise this may cause damage to the

PCB and the unit will not function correctly.

Diagram 5: Ribbon cable

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 14 01-15

Model: CaterSense V2

2.02 System Set-up – CaterSense V2

Once the above has been carried out, the system is ready to be powered up.

Within the step-by-step sequence of set-up instructions the CaterSense unit will give you

feedback on the system via audible “beeps” and coloured LEDs.

Set-up sequence:

1) Activate "SETUP" mode on controller

2A) Manual speed control fan power monitoring set-up

OR

2B) Automatic speed control fan power monitoring set-up

OR

2C) Electronic speed control fan power monitoring set-up

3) CO2 monitoring alarm stages (if required)

4) Heater battery set-up (if required)

5) Demand extract air control set-up (if required)

The sequence detailed above MUST be followed to enable the CaterSense unit to program its

parameters. Ensure that the system is allowed to settle and become stable before moving on

to the next stage. DO NOT RUSH.

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 15 01-15

Model: CaterSense V2

1) Activate "SETUP" mode on controller

Then go to:

2A) Manual speed control fan power monitoring set-up

OR

2B) Automatic speed control fan power monitoring set-up

OR

2C) Electronic speed control fan power monitoring set-up

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM / THERMAL FAN 2

CO2 MONITORING

Ensure LED’s status is as above then:-

PRESS SETUP

(Hold until system beep)

OFF

ON

1 2 3 4

R113

R114

SENSOR 1

SENSOR 2

KNOCK-OFF

FIRE ALARM

SET-UP

MAIN PCB

SINGLE FAN

J27

J26

J25

J23

J13

J5J3

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 16 01-15

Model: CaterSense V2

2A) Manual speed control fan power monitoring set-up

In this set-up the set-up button can be pressed numerous amount of times to

eliminate accidental or double presses.

Once the air balancing procedure has been carried out, ensure the fans are running. Set each

fan to the lowest speed and allow them to run and settle.

The system will produce a short beep. Change the speed of the fans to the next speed up.

Allow system to run and settle. (If using an analogue speed controller, split the space

between min and max speed into approx 10 equal parts).

Repeat this process until all fan speeds have been saved.

Once this has been successfully completed.

The set-up is now complete and the system is ready to run. However we recommend that the

system is run through the systems checking procedure (2.03) to ensure the unit is

successfully commissioned.

3) PRESS

SYSTEM

STOP

GAS SHUT OFF

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM / THERMAL FAN 2

CO2 MONITORING

2) PRESS SYSTEM CONDITION

GAS VALVE

FAN 1, FAN 2

All other LEDs

1) PRESS SYSTEM CONDITION

GAS VALVE

FAN 1, FAN 2

All other LEDs

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 17 01-15

Model: CaterSense V2

2B) Automatic speed control fan power monitoring set-up

The CaterSense will then display the following.

The fans will start at full speed. Using the and pads in conjunction

with the min and max pots on the ATSC-02-xx PCB ensure that the system has been

correctly balanced, and you have correctly set the minimum and maximum speeds for each

fan.

The ratio pot adjusts the speed of fan 2 relative to fan 1, to allow you to balance the make-up

air with the amount of air extracted.

IMPORTANT: Ensure that you do not set the minimum speed to a level that will cause the

fan to overheat. Trent Products recommend a minimum voltage output to the fans of no less

than 140Vac between the "M" and "C" terminals on the speed control PCB. Consult the fan

manufacturer for more details. Once you have setup the fan speeds, return the fan speed to

maximum by using the ‘B’ button before continuing.

PRESS SETUP

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM FAN 2

CO2 MONITORING

Diagram 5: Speed adjustment pots

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 18 01-15

Model: CaterSense V2

The system will produce a short beep. The CaterSense will slowly reduce the speed of the

fans to establish the characteristics of your system. DO NOT INTERRUPT THIS PROCESS.

After approximately two minutes, the system will have fully recorded the running currents of

your fans. If you have an electric or gas fired heater battery connected, the fans will run on

for a further 5 minutes. Otherwise, the fans will stop straight away.

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM FAN 2

CO2 MONITORING

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM / THERMAL FAN 2

CO2 MONITORING

FAN SPEED

UP

DOWN

UP

DOWN

2 mins

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 19 01-15

Model: CaterSense V2

2C) Electronic speed control fan power monitoring set-up

The CaterSense will then display the following.

The fans will start at full speed. Press and hold the For 5 seconds until the LED

display is as follows:

Using the and pads and a multi-meter between terminals 13 and 14

you can now set the minimum speed for fan 1 to 0 VDC.

The CaterSense will then display the following.

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM FAN 2

CO2 MONITORING

PRESS SETUP

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM FAN 2

CO2 MONITORING

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM FAN 2

CO2 MONITORING

CaterSense the Intelligent answer

CS-INSTV2-0.01 Page 20 01-15

Model: CaterSense V2

Using the and pads and a multi-meter between terminals 13 and 14

you can now set the maximum speed for fan 1 to 10 VDC.

If you are using two fans you will need to repeat the above procedure for the second fan.

Using the and pads in conjunction with the min and max pots in the

electronic speed controller ensure that the system has been correctly balanced, and you have

correctly set the minimum and maximum speeds for each fan.

The system will produce a short beep. The CaterSense will slowly reduce the speed of the

fans to establish the characteristics of your system. DO NOT INTERRUPT THIS PROCESS.

After approximately two minutes, the system will have fully recorded the running currents of

your fans. If you have an electric or gas fired heater battery connected, the fans will run on

for a further 5 minutes. Otherwise, the fans will stop straight away.

PRESS SETUP

PRESS SETUP

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM FAN 2

CO2 MONITORING

POWER ON GAS VALVE

SYSTEM CONDITION GAS PRESSURE

REMOTE KNOCK OFF FAN 1

FIRE ALARM / THERMAL FAN 2

CO2 MONITORING

FAN SPEED

UP

DOWN

UP

DOWN

2 mins

This manual suits for next models

1

Popular Controllers manuals by other brands

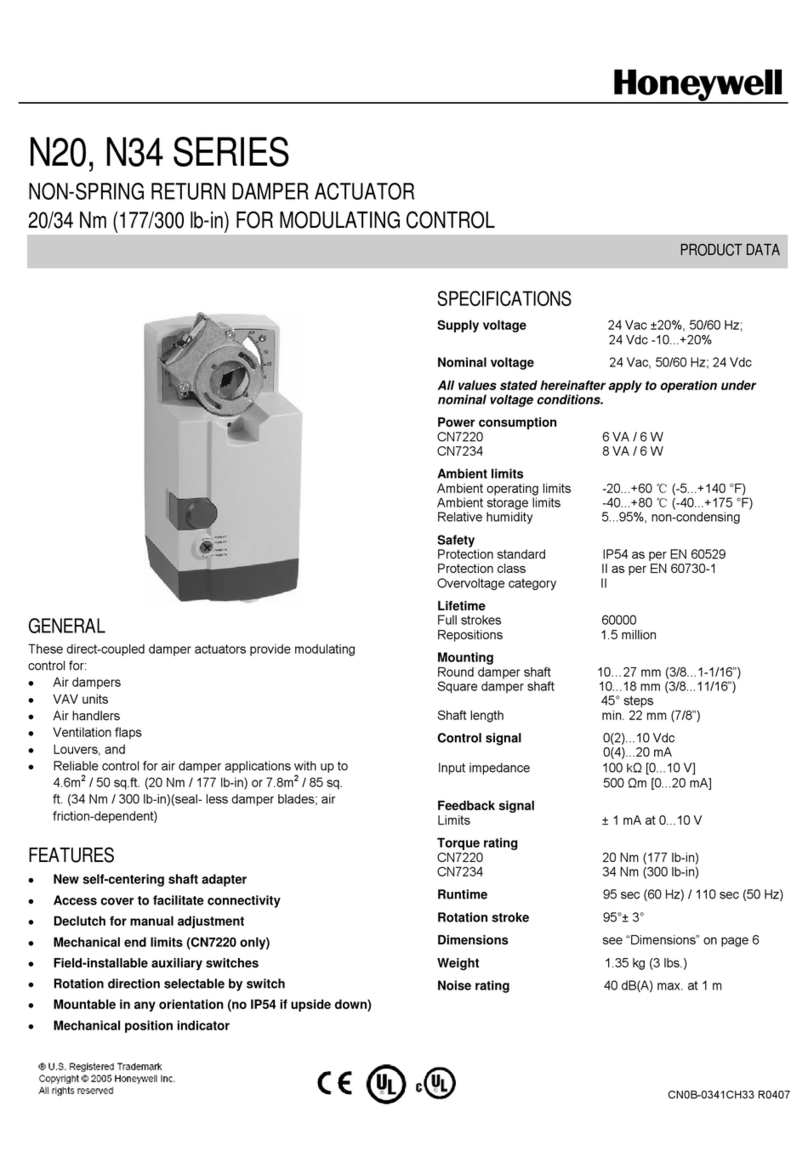

Honeywell

Honeywell 5 Nm Series Product data

Lilin

Lilin PIH-931D instruction manual

Sun21

Sun21 CCS Series user manual

thomann

thomann STAIRVILLE DMX-Master MK II ENC user manual

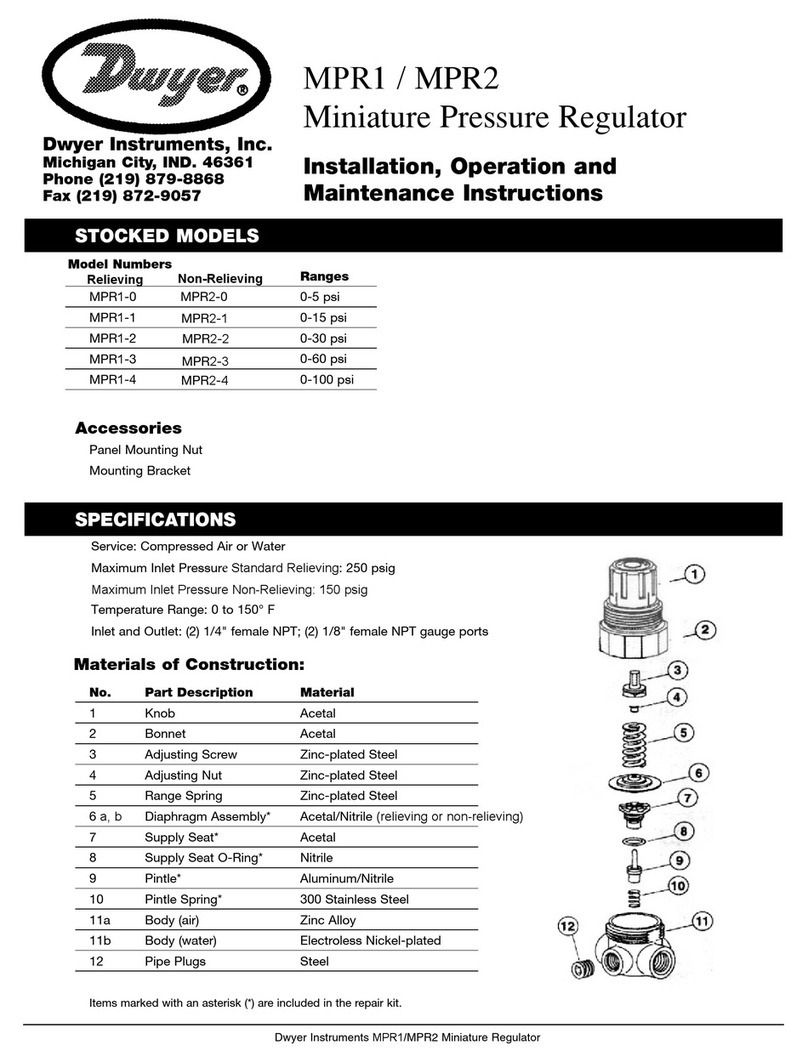

Dwyer Instruments

Dwyer Instruments MPR1 Installation, operation and maintenance instructions

Smartgen

Smartgen HAT530N user manual