9

DW7000

It is also essential that:

x Nothing is allowed to touch the moving parts.

x There is no attempt to modify or alter the unit

or filter in any way

x Water or other liquids enter the unit in any

way – in particular the motor and fan, the

filter or the battery.

Make sure that the headpiece fits the user's face

perfectly. Only then the efficiency of the system

is sufficient. The protective factor of the

complete system is reduced if the seal of the

headpiece is not fitted properly, for example due

to beards or long hair intervening into the seal

line. There is a possibility that the hose to the

head unit may become caught up in use. The

blower unit should be positioned on the person in

such a way as to reduce this possibility.

Filters cannot be fitted directly to the head units

and should not be adapted to do so. Correct

respiratory protection will not be provided if any

parts of the equipment are modified.

At very high work rates the pressure in the

device may become negative at peak inhalation

flow. STRATA RESPIRATOR systems are for use

only by competent, trained personnel. Filters

should not be modified to fit different blower

units.

ATTENTION! If any of these conditions is not

kept or followed, the warranty automatically

invalid.

The user is advised to leave the

contaminated area immediately if:

The Manufacturer’s Minimum Design

Flow (MMDF) warning Alarm sounds.

Breathing becomes difficult.

Dizziness or distress occurs.

Any part of the system becomes damaged.

Airflow into the Head-Unit decreases or stops.

Contaminant can be smelt or tasted inside

the Head-Unit

Materials that may come into contact with

the user’s skin are not known to cause

allergic reactions to the majority of individuals

but in the unlikely event of a reaction, the

user should immediately leave the

contaminated area, remove the unit and

seek medical advice.

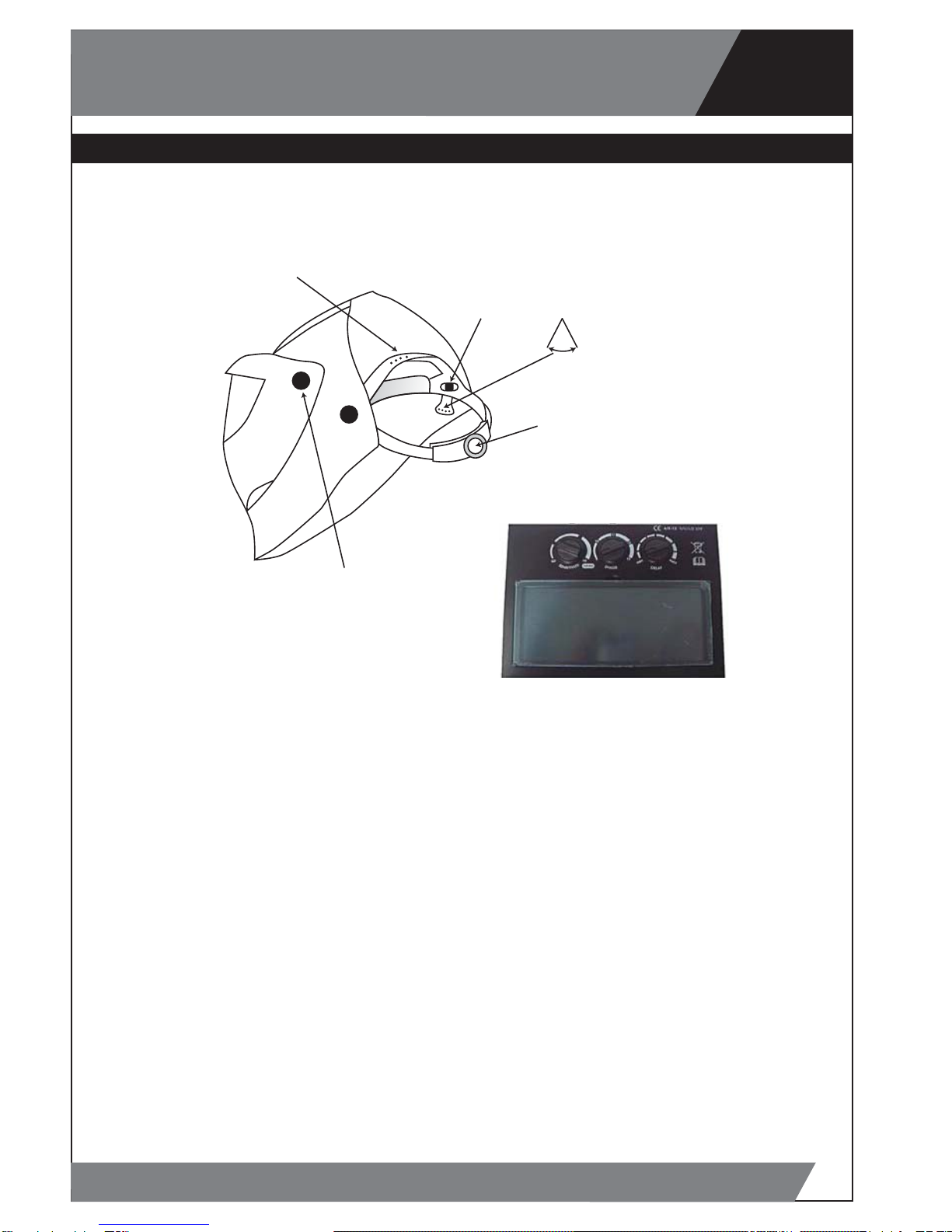

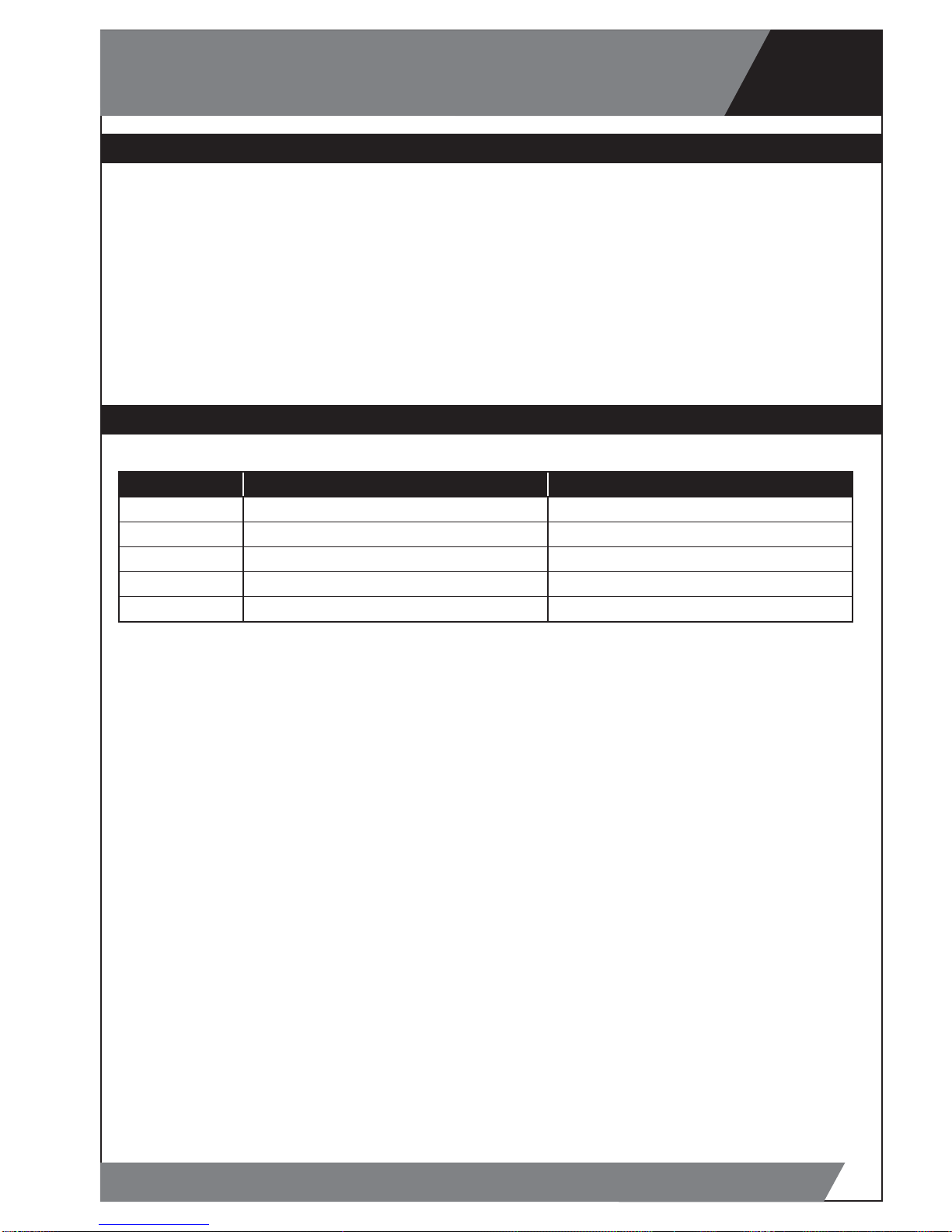

4. System Overview:

The STRATA Respirator unit is a belt mounted

powered respirator with a replaceable,

disposable high efficiency particle filter system.

The helmet covers head sizes from 535 to

600mm circumference.

The STRATA Respirator unit contains a

removable 8hr rechargeable battery pack.

The STRATA Respirator unit will warn the user

when the MMDF of 170 L/min, is not achieved

with its audible alarm.

In operation once the alarm sounds, the user

must immediately leave the work area and

reach an area nominated to be safe. The unit

has audible and visual alarms for a low battery

and a blocked filter. Depending on the fault, the

user should replace the Pre Filter with a new

one (In very dusty environments the Pre Filter

will need changing frequently) and or re-charge

or change the battery for a fully charged one. If

the blocked filter alarm continues to sound the

main filter should be changes. Only when the

unit will function with the alarm switched off

and the flow rate has been tested to be

acceptable, should the user return to the work

place.

The filter has been developed especially for this

unit. It is used to filter the air the user will

breathe. It is essential that the user checks the

filter for any signs of damage or deformation

that could potentially let contaminated air into

the unit. The filter must be disposed of if the

filter is damaged or if clogged to the point of

triggering the systems alarm mechanism.

The removable rechargeable battery used is a

Lithium Ion cell. When supplied the battery may

hold a small charge, the unit should be run flat

and then charged for sixteen hours before the

first use.

www.strata.co.nz