Stress-Tek VULCAN ON-BOARD SCALES User manual

CONTENTS 1

V600 OWNER’S MANUAL

Table of Contents

V600 MENU TREE.................................................................................................5

V600 BASIC REFUSE SYSTEM SETUP.....................................................................6

1.0 VULCAN SINGLE LINE (VSL) TECHNOLOGY, V600 ELECTRONICS SYSTEM........7

1.1 Load Cells And Air Sensors...............................................................................10

1.2 VSL Vulcoders...................................................................................................11

1.3 V600 Meter........................................................................................................11

1.4 Explanation of Meter Channels..........................................................................12

1.5 Electronics Installation.......................................................................................13

2.0 V600 METER OPERATION............................................................................17

2.1 Power / Menu Button Operation ........................................................................17

2.1.1 Powering The Meter On / Off..................................................................17

2.1.2 Entering And Exiting The Meter Program Menu .....................................17

2.2 Arrow Buttons Operation ...................................................................................18

2.2.1 Changing Display Intensity .....................................................................18

2.2.2 Increase / Decrease Meter Program Settings.........................................18

2.3 Cycle Button Operation......................................................................................19

2.3.1 Locking The Meter On A Particular Channel...........................................19

2.3.2 Scroll Through The Meter Program Menu Functions..............................19

2.4 Enter Button Operation......................................................................................20

2.4.1 Selects / Enters Program Menu Items....................................................20

2.4.2 Stores Newly Adjusted Meter Settings....................................................20

2.4.3 Displays Time and Date..........................................................................20

2.4.4 Prints A Weight Ticket ............................................................................20

2.5 Tare / Zero Button Operation.............................................................................21

2.5.1 Zeroes Meter Values ..............................................................................21

2.5.2 Zeroes Meter Display In The Pick-up / Delivery Mode............................21

2.5.3 Displays Gross Weight In The Net And Pick-up / Delivery Modes..........21

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

2 CONTENTS

2.6 Vulcoder Updating.............................................................................................22

3.0 V600 - PROGRAM MENU (SYSTEM SETUP) ...................................................23

3.1 Entering The Program Menu .............................................................................23

3.2 Entering The Configure System Menu...............................................................24

3.2.1 Configure The Weight Mode (Gross, Net, Or Pick-Up)...........................25

3.2.2 Configure The Display Code...................................................................26

3.2.3 Configure The Set Points........................................................................28

3.2.3A Configure Relay 1 .....................................................................29

3.2.3B Configure Relay 2 .....................................................................31

3.2.3C Configure Delta Weight.............................................................32

3.2.3D Configure On Time....................................................................33

3.2.4 Configure The Channel Cycle Time........................................................35

3.2.5 Configure The RS232 Port .....................................................................36

3.2.6 Configure The Print Headers..................................................................37

3.2.7 Configure The Date ................................................................................39

3.2.8 Configure The Time................................................................................41

3.2.9 Configure The Scale ID ..........................................................................42

3.2.10 Configure The Lock (Tare and Cal Lockout)...........................................43

3.2.11 Exiting The Configure System Menu ......................................................44

3.3 Entering The Setup / Calibrate Menu ................................................................44

3.3.1 Setting The Tare Weight.........................................................................44

3.3.2 Setting The Cal Number.........................................................................46

3.3.3 Setting The Cal Weight...........................................................................47

3.3.4 Setting The Post Calibration...................................................................49

3.3.5 Setting The Grad Size ............................................................................51

3.3.6 Setting The Units (Lb or Kg)...................................................................51

3.3.7 Setting The Auto Zero Tracking Range ..................................................52

3.3.8 Setting The Sample Size.......................................................................53

3.3.9 Exiting The Configure System Menu ......................................................55

3.4 Sequencing Channels .......................................................................................55

3.4.1 Manual Sequencing................................................................................56

3.5 System Test Menu.............................................................................................57

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

CONTENTS 3

3.5.1 Test Keypad............................................................................................58

3.5.2 Test LED’s..............................................................................................58

3.5.3 Test Memory...........................................................................................59

3.5.4 Test VSL Comm .....................................................................................60

3.5.5 Test L / C Offset......................................................................................61

3.6 Exiting The Program Menu................................................................................62

4.0 V600 CALIBRATION.....................................................................................63

4.1 Weight Measuring Methods...............................................................................63

4.1.1 Gross Vehicle Weight.............................................................................64

4.1.2 Net Payload Weight................................................................................64

4.2 Procedure For Entering Tare Weights...............................................................64

4.2.1 Entering Tare Weight For A Typical 2 - Channel, Truck & Trailer

System....................................................................................................64

4.2.2 Entering Tare Weight For A Typical Short Logger System.....................66

4.2.3 Entering Tare Weight For A Typical Refuse System...............................68

4.3 Procedure For Entering Starting Calibration Numbers.......................................69

4.4 Fine Tuning The Calibration Number For Gross Vehicle Weight Method

When Only One Channel Per Truck Or Trailer Is Used .....................................71

4.5 Fine Tuning The Calibration Number For Gross Vehicle Weight And Net

Payload Weight Methods When More Than One Channel Is Used Per Truck

Or Trailer............................................................................................................74

5.0 MAINTENANCE.............................................................................................79

5.1 Driver's Daily Vehicle Inspection........................................................................79

5.2 Preventative Maintenance And Vulcan Torque Specifications...........................80

6.0 TROUBLESHOOTING.....................................................................................87

6.1 Vulcan Check-out Box.......................................................................................88

6.2 Load Cell Evaluation Tests................................................................................89

6.2.1 Leakage Test Procedure ........................................................................89

6.2.2 Tare Test Procedure...............................................................................90

6.2.3 Resistance Test Procedure.....................................................................93

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

4 CONTENTS

6.3 V600 Meter Error Codes....................................................................................94

6.3.1 Err 01......................................................................................................94

6.3.2 Err 02......................................................................................................94

6.3.3 Err 03......................................................................................................95

6.3.4 Err 04......................................................................................................95

6.3.5 Err 05......................................................................................................96

6.3.6 Err 06......................................................................................................96

6.3.7 Err 07......................................................................................................97

6.3.8 Err 08......................................................................................................97

6.3.9 Err 09......................................................................................................98

6.3.10 Err 10......................................................................................................98

6.3.11 Err 11......................................................................................................98

6.4 System Malfunctions .........................................................................................99

6.4.1 No Indicator Display Or Function Lights .................................................99

6.4.2 Unable To Enter Tare Or Calibration Numbers.....................................100

6.4.3 Meter Reading Drifts Or Wanders With Time .......................................100

6.4.4 Meter Reading Does Not Change When Truck Is Being Loaded..........102

6.4.5 Meter Stops Powering Up After Displaying All Digits............................102

6.4.6 Meter Displays LO-LO..........................................................................103

6.5 Troubleshooting Worksheet.............................................................................106

6.6 Troubleshooting Assistance And Replacement Parts......................................108

7.0 APPENDIX.................................................................................................109

7.1 Starting Calibration Numbers...........................................................................110

7.2 System Specifications .....................................................................................111

7.3 Assistance In Fine Tuning Your Scale System (Primarily For Two Channels

On One Truck Application Only)......................................................................112

7.4 Keeping Records.............................................................................................114

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

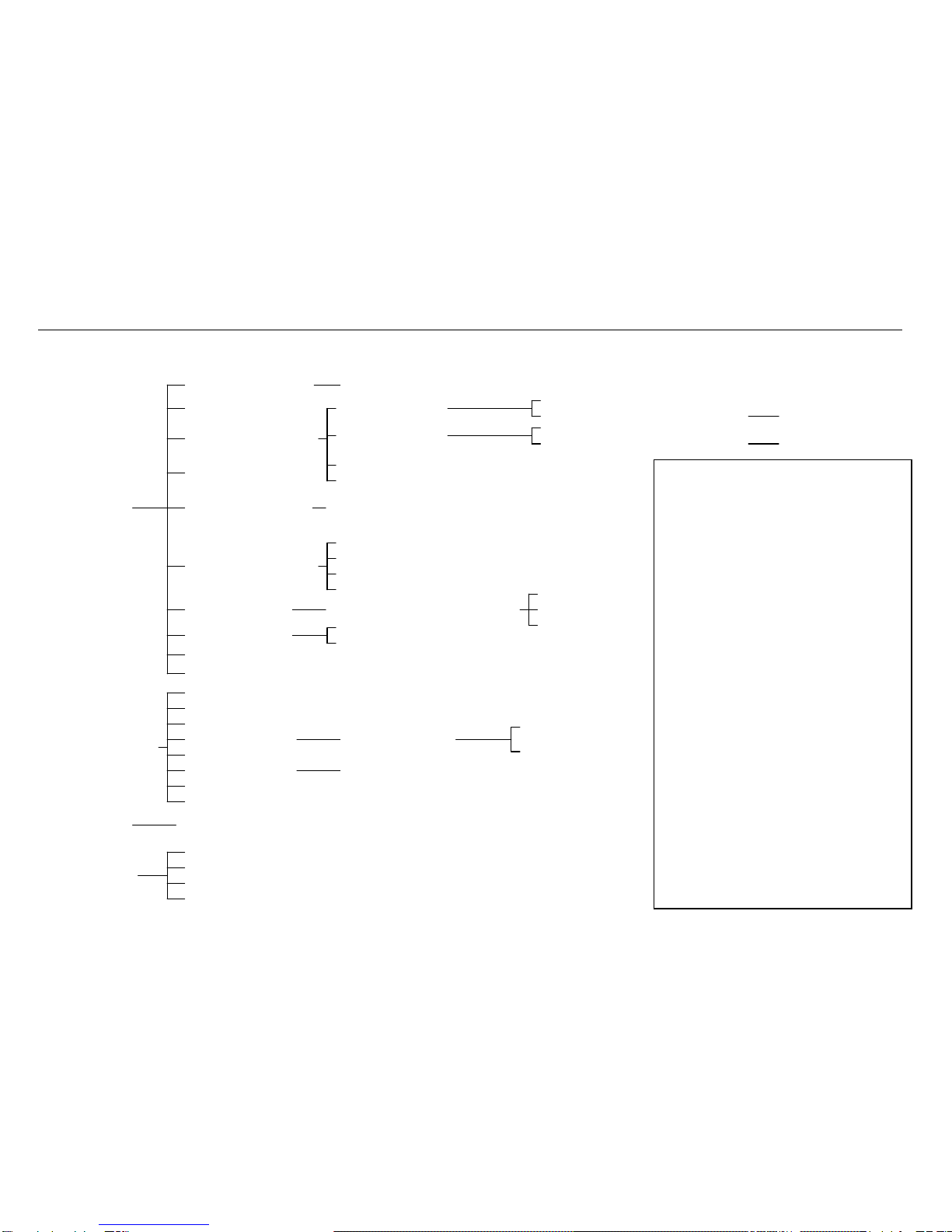

V600 MENU TREE 5

V600 MENU TREE

CONF: WT. MODE

CONF: DISP CODE

CONF: SET POINTS

CONF: CYCLE TIME

CONF: RS232 PORT

CONF: PRINT HDRS

CONF: DATE

CONF: TIME

CONF: SCALE ID

CONF: LOCK

SET: TARE WEIGHT

SET: CAL NUMBER

SET: CAL WEIGHT

SET: POST CAL

SET: GRAD SIZE

SET: UNITS

SET: AZT RANGE

SET: SAMPLE SIZE

START SEQUENCING

TEST: KEYPAD

TEST: LEDs

TEST: MEMORY

TEST: VSL COMM

WT MODE: [GROSS] [NET] [P/D]

CONF: RELAY 1

CONF: RELAY 2

CONF: DELTA WT.

CONF: ON TIME

FORMAT: [NONE] [PRINT] [WEIGHT] [OBC]

HEADER LINE 1

HEADER LINE 2

HEADER LINE 3

HEADER LINE 4

FORM: [MM/DD/YY] [DD/MM/YY]

CHANGE: HOURS

CHANGE: MINUTES

CH X POST CAL

UNITS: [LBS] [KGS]

R1: [OFF]

R1: [LOCKED ONLY] [CH A] ... etc

R2: [LOCKED ONLY] [CH A] ... etc

R2: [OFF] R1: ENT WT LIMIT

R2: ENT WT LIMIT

CHANGE: YEAR

CHANGE: MONTH

CHANGE: DAY

V600 GROSS WT

ACTUAL GROSS WT

CONFIGURE

SYSTEM

SEQUENCE

CHANNELS

SYSTEM TEST

TE

[SCRBRD3] [SCRBRD6]

SETUP/CALIBRA

V600 Menu Operation

1. To enter menu mode, press the

PWR/MENU button once.

2. To cycle through the menu options,

press the CYCLE button.

3. To select one of the menu options

or select a submenu, press the

ENTER button.

4. To change a value (such as Tare

Weight, Cal Number, etc.) which

appears in the upper display

window, or option values (such as

Wt Mode, RS-232 Port Format, etc)

which appear in brackets in the

lower display, press the UP or

DOWN arrow buttons.

5. To reset a value to zero, press the

TARE/ZERO button. Note: this

does not work for all values

6. To accept a value press the

ENTER button.

7. To cancel a selection or return to

the previous menu level, press the

PWR/MENU button.

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

6 V600 BASIC REFUSE SYSTEM SETUP

V600 BASIC REFUSE SYSTEM SETUP

1. Enter the Program Menu by pressing the PWR/MENU button after the meter has finished its start up routine, Section 3.1.

2. Configure System will be displayed on the smaller display. Press the ENTER button to enter the Configure System Menu, Section 3.2.

3. Configure the Weight Mode: Press the ENTER button to select the CONF: WT. MODE Menu. Most users will set the weight mode to the

Pickup/Deliver Mode by pressing the UP or DOWN ARROW buttons until [P/D] is displayed. Press the ENTER button to save the desired

selection. See Section 3.2.1 for more details.

4. Set the vehicle Tare Weight: Press the PWR/MENU button to return to the Configure System Menu. Press the CYCLE button to advance to the

Setup/Calibrate Menu. Press the ENTER button to enter the Setup/Calibrate Menu. Press the ENTER button to select the SET: TARE

WEIGHT Menu. Press either the UP or DOWN ARROW buttons to adjust the number to the desired Tare Weight. Most users will set the Tare

Weight to zero to monitor net payload. Press the ENTER button to save the desired Tare Weight. See Section 3.3.1 for more details.

5. Set the Grad Size: Press the CYCLE button to advance to the SET: GRAD SIZE Menu is displayed. Press the ENTER button to enter the SET:

GRAD SIZE Menu. Press either the UP or DOWN ARROW buttons to adjust the desired Grad Size. Most users find that leaving the Grad Size

set to 50 works well without being too sensitive. Press the ENTER button to save the desired Grad Size. See section 3.3.5 for more details.

6. Set the Auto Zero Tracking Range to Zero: Press the CYCLE button to advance to the SET: AZT RANGE Menu. Press the ENTER button to

enter the SET: AZT RANGE Menu. Press either the UP or DOWN ARROW buttons to adjust the AZT Range to zero. Press the ENTER button

to save the desired AZT Range. See section 3.3.7 for more details.

7. Exit the Program Menu: Press the PWR/MENU button until the display returns to the normal operating mode. See section 3.6 for more details.

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

CHAPTER 1 7

C H A P T E R 1 . 0

VULCAN SINGLE LINE (VSL) TECHNOLOGY

V600 ELECTRONICS SYSTEM

Vulcan On-Board Scales can be installed on all types of vehicles including, hook lifts, logging trucks,

flatbed trailers, chip trailers, front loaders, rear loaders, side loaders, roll-offs, transfer trailers, and

many other commercial vehicles requiring scales. Axle group weights, payload weights, gross vehicle

weights, and individual pick-up and drop-off weights can be measured using the Vulcan On-Board

Scale System.

The Vulcan On-Board Scale System consists of:

• Load Cells or Air Sensors - to sense load or air pressure.

• VSL Vulcoders - to convert the signals from the sensors to weight and communicate with

the meter.

• V600 Meter - to display the weights and run the scale system.

The number of VSL Vulcoders needed depends on the number of channels required. The number and

type of load cells needed depends on the truck’s configuration, such as length, type of suspension, load

capacity, etc. Only one V600 Meter is required per truck.

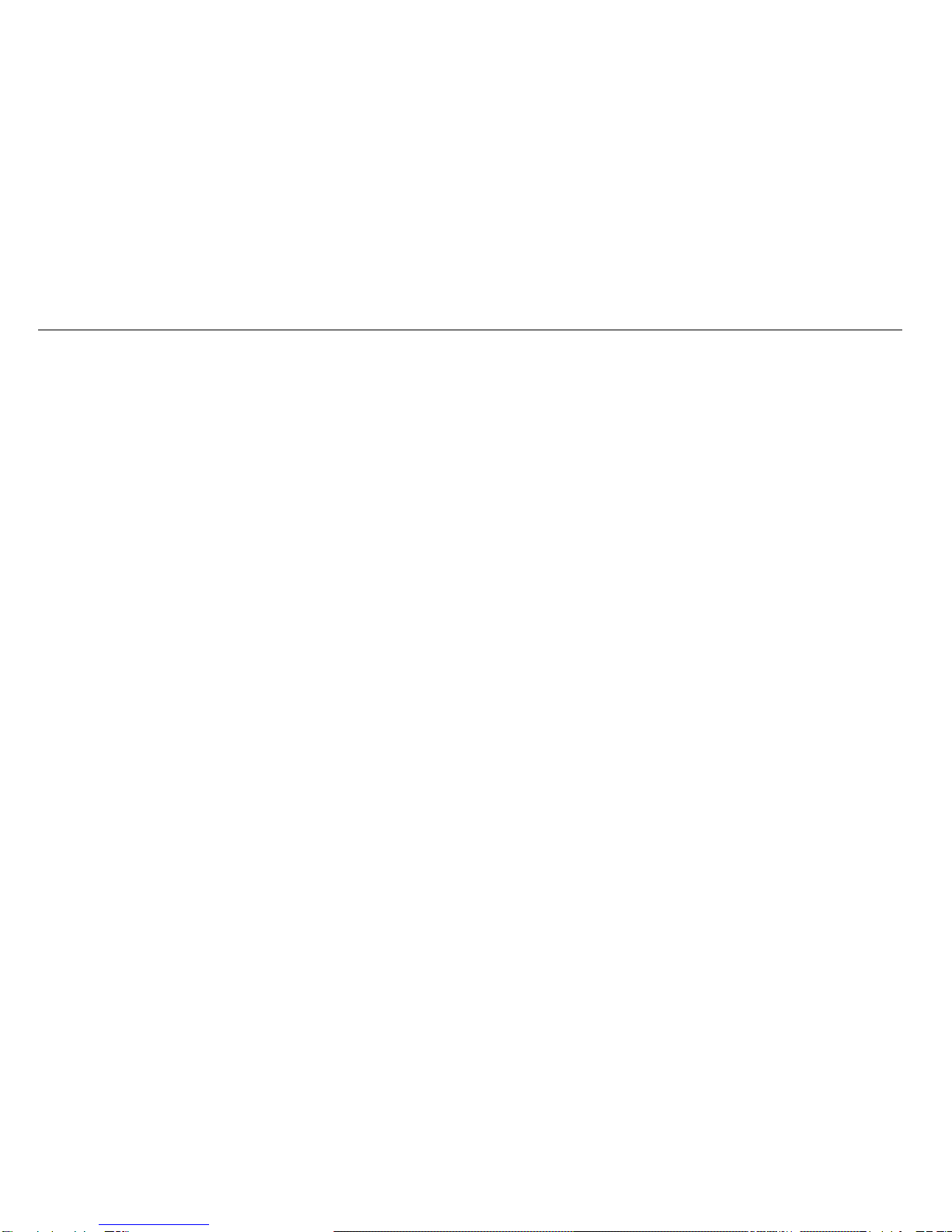

The new Vulcan Single Line (VSL) technology is a revolutionary way that the V600 Meter

communicates with each VSL Vulcoder. VSL technology uses a single 2-wire cable to provide the

communications between the meter and VSL Vulcoders. The single 2-wire communication cable

sends power and set-up data to each VSL Vulcoder while receiving weight data from each VSL

Vulcoder.

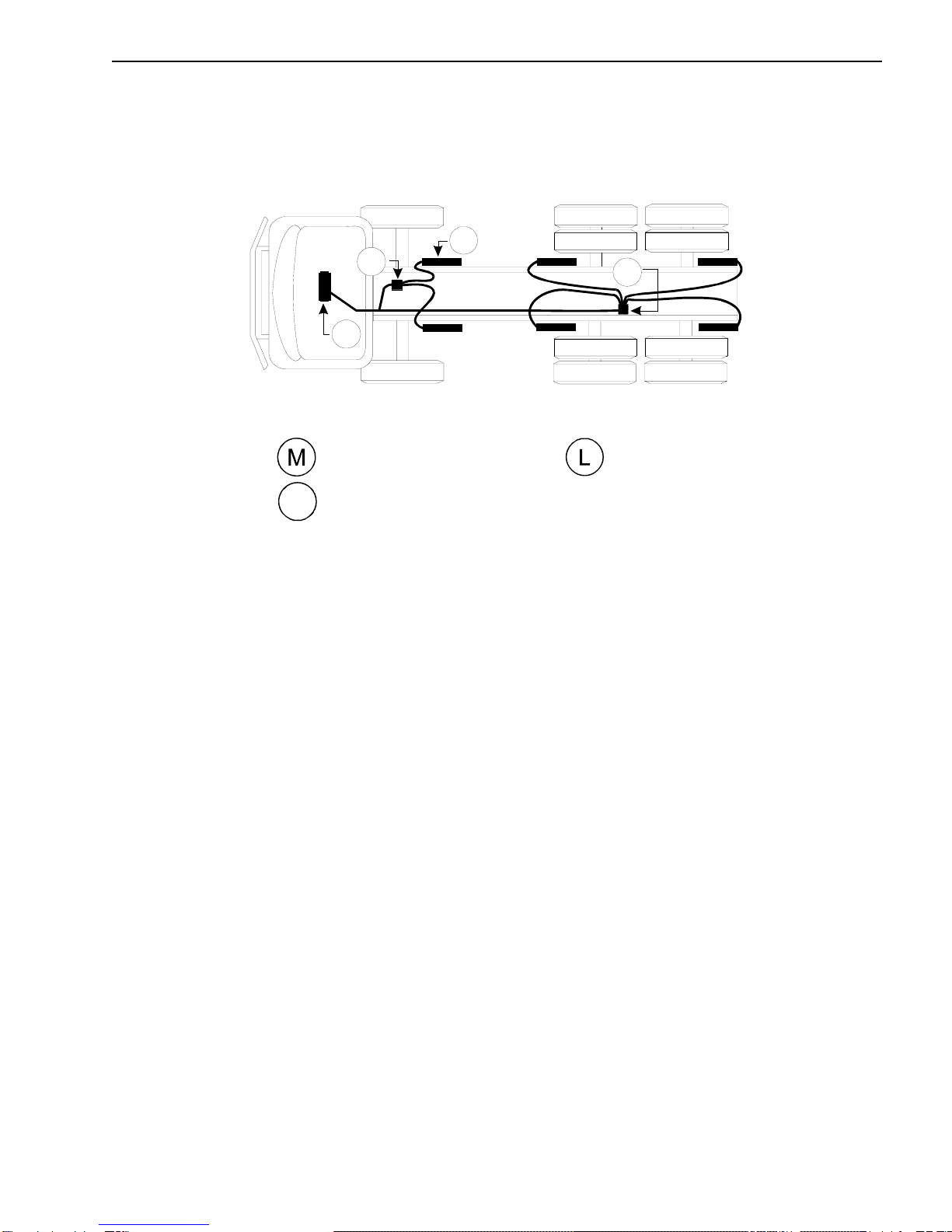

TRUCK

TRAILER

VSL

VULCODER

VSL

VULCODER

VULCODER

VSL

VULCODER

VSL

V

ULCAN SINGLE LINE (VSL)

LOAD CELL

OR

AIR SENSOR

LOAD CELL

OR

AIR SENSOR

LOAD CELL

OR

AIR SENSOR

LOAD CELL

OR

AIR SENSOR

Figure 1-A: VSL Single Line (VSL)

4-Channel System Example

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

8 CHAPTER 1

4 EACH

C

C

TRUCK / TRAILER

CONNECTO

R

= LOAD CELL

=

= VSL VULCODER

= V600 METER

V

V

V

Figure 1-B: Example - VSL Long Logger System

(Truck: 1-channel, Trailer: 1-channel)

L

M

C

TRUCK / TRAILER

CONNECTO

R

= LOAD CELL

=

= VSL VULCODER

= V600 METER

4 EACH

C

V

V

V

Figure 1-C. Example - VSL Short Logger System

(Truck: 2-channels, Trailer (not shown): 2-channels)

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

CHAPTER 1 9

M

VV

L

= LOAD CELL

= VSL VULCODER

= V600 METER

6 EACH

V

Figure 1-D. Example - VSL Refuse System with 6 Load Cells

(Truck: 2-channels)

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

10 CHAPTER 1

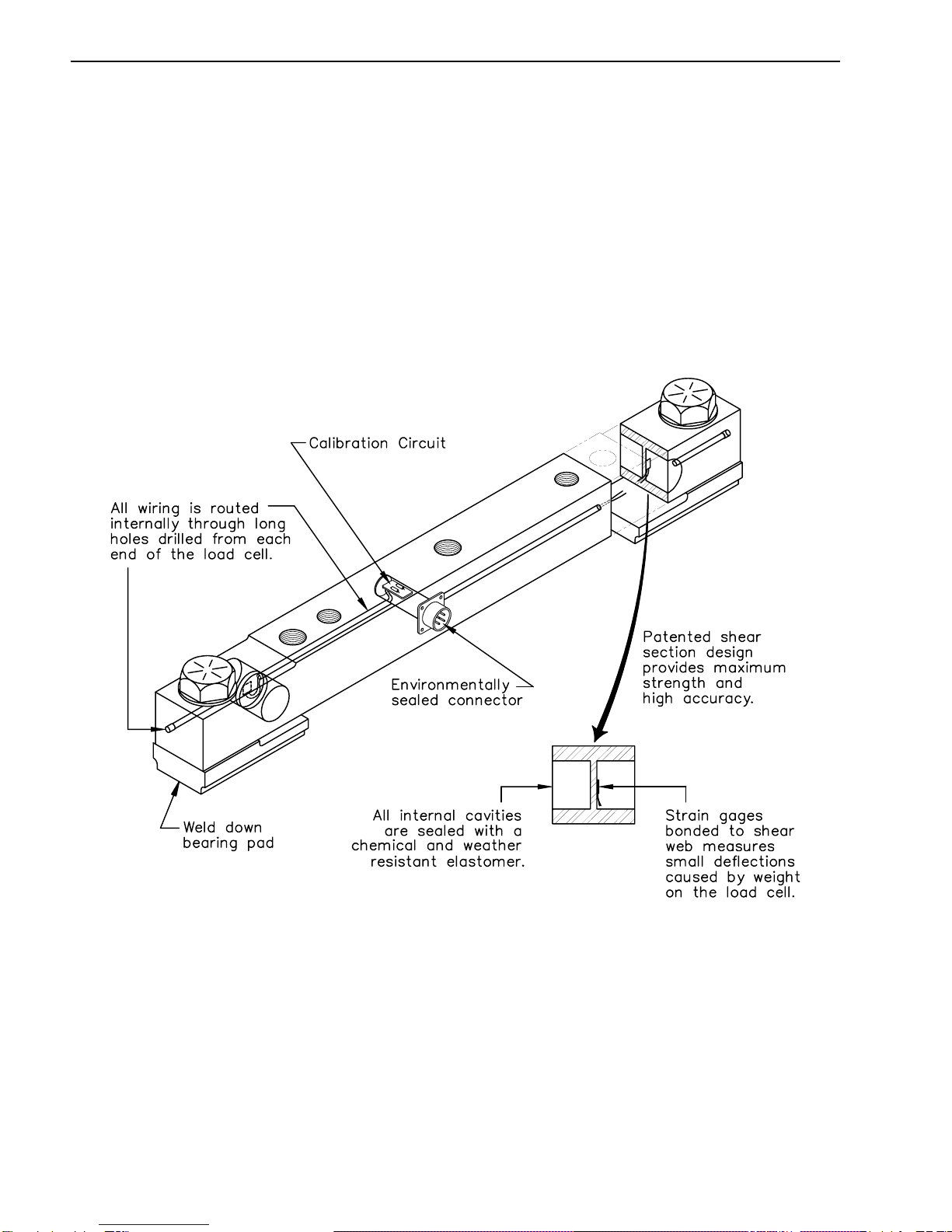

1.1 LOAD CELLS AND AIR SENSORS

Vulcan load cells and air sensors are machined from solid blocks of high strength steel. The Strain

gages are bonded inside the load cell or air sensor to sense extremely small dimensional changes in the

material. A strain gage is a precision electrical resistance element. When force is applied to these

sensors, the strain gages stretch or compress, causing a change in output signal voltage. This signal

voltage is measured by the VSL Vulcoder and then used to determine weight.

Example: Vulcan Super - Beam Load Cell

Figure 1-E: Vulcan Super - Beam Load Cell

(Covered by one or more of the following patents:

US Patent RE. 35,301, 4,459,863

Canadian Patent 1,245,677)

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

CHAPTER 1 11

1.2 VSL VULCODERS

The VSL Vulcoder is specifically designed to be used with the V600 meter. The functions of the VSL

Vulcoder are to supply power to the load cells or air sensors and receive the analog voltage signal

from the load cells or air sensors. A computer inside the VSL Vulcoder then calculates the weight

based on the calibration values, the “Tare Weight” and the “Cal” number for that particular channel,

which are stored in its memory. When the meter requests weight from a channel, the proper VSL

Vulcoder will respond and send the weight information back to the meter. All VSL Vulcoders connect

to the same single 2-wire cable. Any VSL equipped trailer can be plugged into any truck with a V600

meter and be immediately identified and read properly.

WEIGHT lb/kg

10.5-29 Vdc

V600 METER

LOAD CELL

POWER & 2-WAY COMMUNICATIONS TO OTHER

VSL VULCODERS

VSL VULCODER

AMPLIFIES,

COMPUTES &

STORES DATA

VSL VULCODER

AMPLIFIES,

COMPUTES &

STORES DATA

LOAD CELL LOAD CELL LOAD CELL

Figure 1-F: Vulcan Electronics Diagram

1.3 V600 METER

Application: For vehicle combinations with one to six channels of weight sensing. The V600 Meter

provides a high visibility display and the ability to easily read different trailers.

The V600 Meter uses VSL technology to power and communicate with VSL Vulcoders on a single

2-wire cable. The meter requests weight information from the different Vulcoders. It then displays

individual channel weights and total weight as requested by the operator. The weight can be displayed

in pounds or kilograms. The meter also transfers all setup and calibration information for up to six

independent channels (A, B, C, D, E, and F) into the VSL Vulcoder, where it is stored.

Figure 1-G: V600 Meter

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

12 CHAPTER 1

1.4 EXPLANATION OF METER CHANNELS

The V600 meter can display information on up to six channels: A, B, C, D, E, and F. There is a VSL

Vulcoder for each channel. The number of channels is based on the number of load cells and their

grouping. For example, a trailer could have as many as four load cells per channel. The display code

tells the meter what channels to scan. For more information on how to select the meter display code,

refer to Section 3.2.2 “Configure The Display Code”.

Refuse or Logging Truck Applications:

Typically, a refuse or logging truck application usually requires only one or two meter channels, A, or

A and B. Channel A usually represents the truck or front load cells regardless of the number of load

cells connected to the VSL Vulcoder. Channel B usually represents the trailer or rear load cells. The

total weight for both the front and rear load cells is represented on Channel A+B.

METER

VSL VULCODER VSL VULCODER

LOAD CELL LOAD CELL LOAD CELL

LOAD CELL

LOAD CELLLOAD CELL

CHANNEL A

10.5 - 29 Vdc

10.5 - 29 Vdc

VSL VULCODER VSL VULCODER

LOAD CELL LOAD CELL

METER

CHANNEL A

LOAD CELL LOAD CELL

CHANNEL B

CHANNEL B

Figure 1-H: Vulcan 4 and 6 Cell System Configurations

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

CHAPTER 1 13

1.5 ELECTRONICS INSTALLATION

1. Tape the VSL Vulcoder connectors prior to routing the cabling to avoid contamination. Mount

the VSL Vulcoders on the inside of the truck frame rail or next to a structural member. The

VSL Vulcoder mounting surface must be in an area protected from road and hauling debris.

2. Route the black cable to the load cells. (Do not trim the black cable to length).

3. Important: Check the connectors to make sure they are clean and dry. Do not get moisture,

contact cleaner, or any other substance inside of the connectors.

4. Check the load cell connector coming from the VSL Vulcoder for an O-ring. Attach the black

cable connectors to the bulkhead connectors on the load cells. Make sure they are finger tight

plus an additional 1/8 of a turn more with channel lock pliers. The additional tightening is

necessary to compress the O-ring. This prevents scale errors which can occur from moisture

entering into the load cell connector. Caution: Do not over tighten the connectors as this can

damage them.

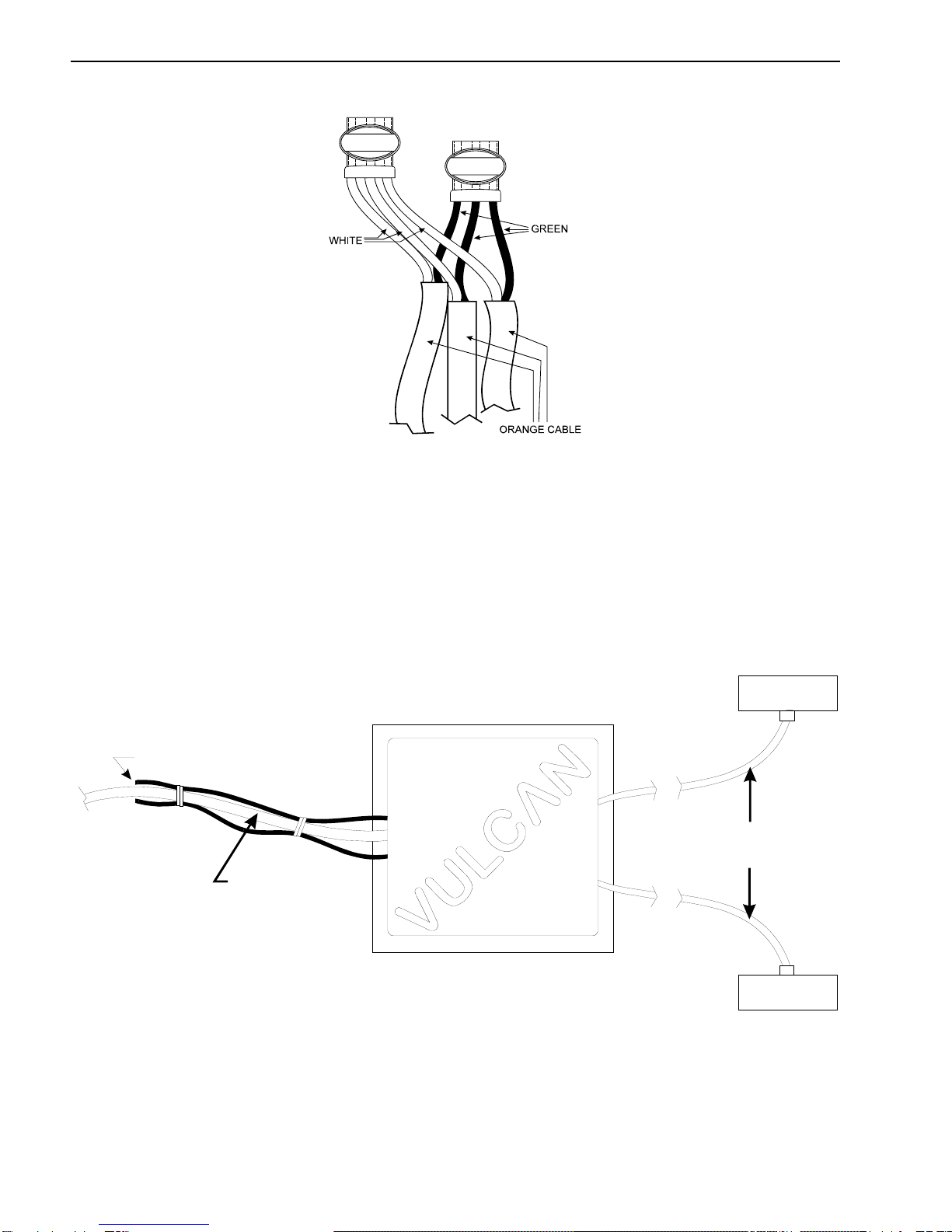

5. Route the single 2-wire orange VSL Vulcoder cable from the meter in the cab to the last VSL

Vulcoder in the system. Be sure to route the cable to the meter and do not trim any excess

wire off at the meter. Trim off the excess cable to approximately 1' - 2' of extra orange cable at

the location of the VSL Vulcoder splice to allow for the splice. Note: On a truck-to-trailer

connection, these wires may be routed using the existing truck-to-trailer wire harness if two

unused ungrounded wires are available. Additionally, you may follow the existing wire

harness and use a separate connector of your choice between the truck and trailer. If using the

separate connector, for the best and most reliable connection, connect each color wire to two

pin connections. For example, connect the green wire to the top two pins of a 4-pin truck-to-

trailer connector, and the white wires to the bottom two pins.

6. Connect the first VSL Vulcoder in the system to the 2-wire cable by splicing each color coded

wire from the communication cable and the VSL Vulcoder cable, (refer to Figure 1-J). When

using the Vulcan supplied 3M connector, do not strip the insulation from each wire. Be sure

to insert wires completely into the connector and check their position by looking through the

translucent connector body. Crimp the connector cap down flush with the top edge of the

connector body, ensuring a good connection. Tape the connection and all of the wires with the

orange insulation stripped off to help seal and prevent wire chaffing that can cause a wire to

short. Wire tie the splice so that the connection is strain relieved.

7. Find a suitable location for each additional VSL Vulcoder needed in the system. Connect

additional VSL Vulcoders in the system to the 2-wire cable by splicing each color coded wire

from the communication cable and the VSL Vulcoder cable (refer to Figure 1-J). When using

the Vulcan supplied 3M connector do not strip the insulation from each wire. Be sure to insert

wires completely into the connector and check their position by looking through the

translucent connector body. Then crimp the connector cap down flush with the top edge of the

connector body ensuring a good connection. Tape the connection and all of the wires with the

orange insulation stripped off to help seal and prevent wire chaffing that can cause a wire to

short. Wire tie the splice so that the connection is strain relieved.

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

14 CHAPTER 1

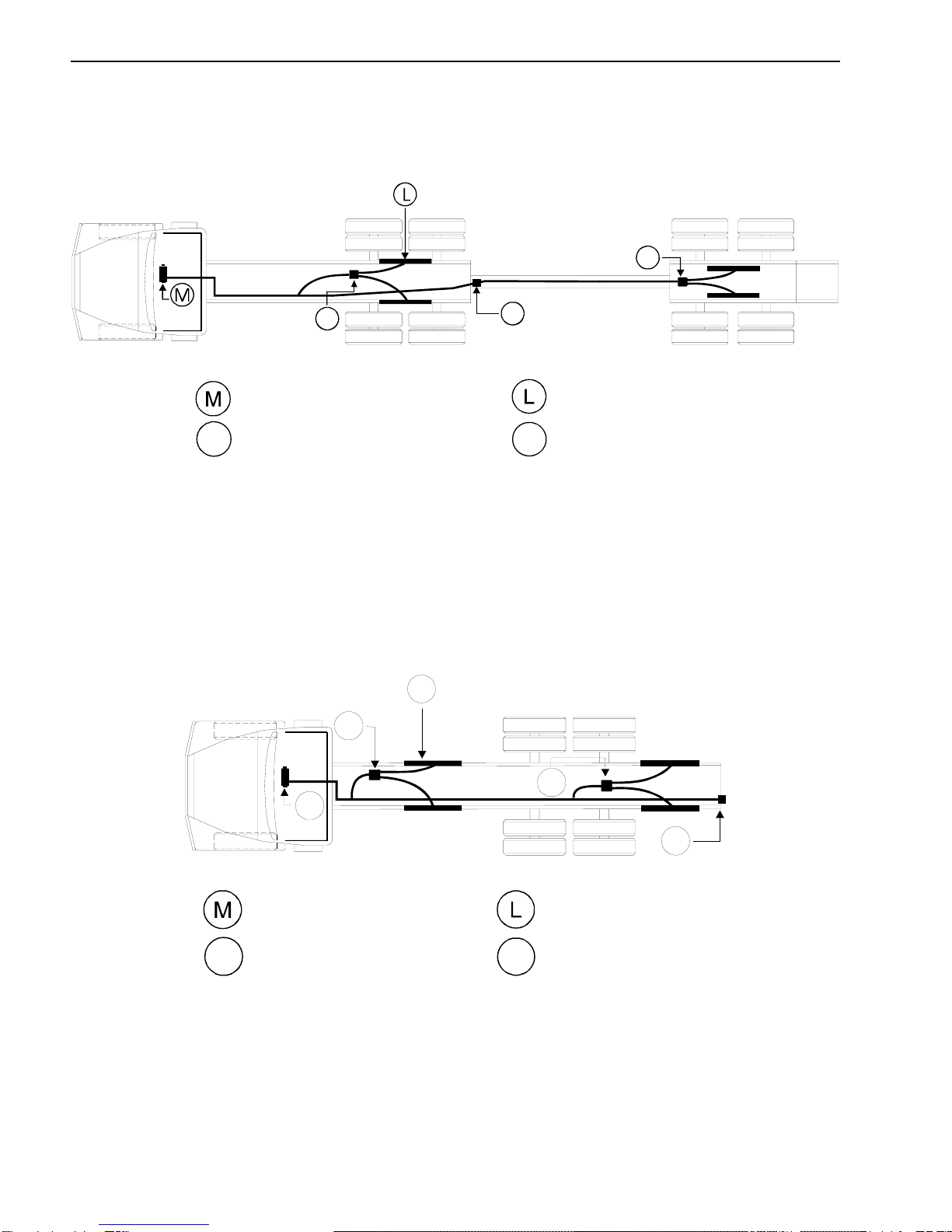

Figure 1-J VSL Vulcoder Communication Connection

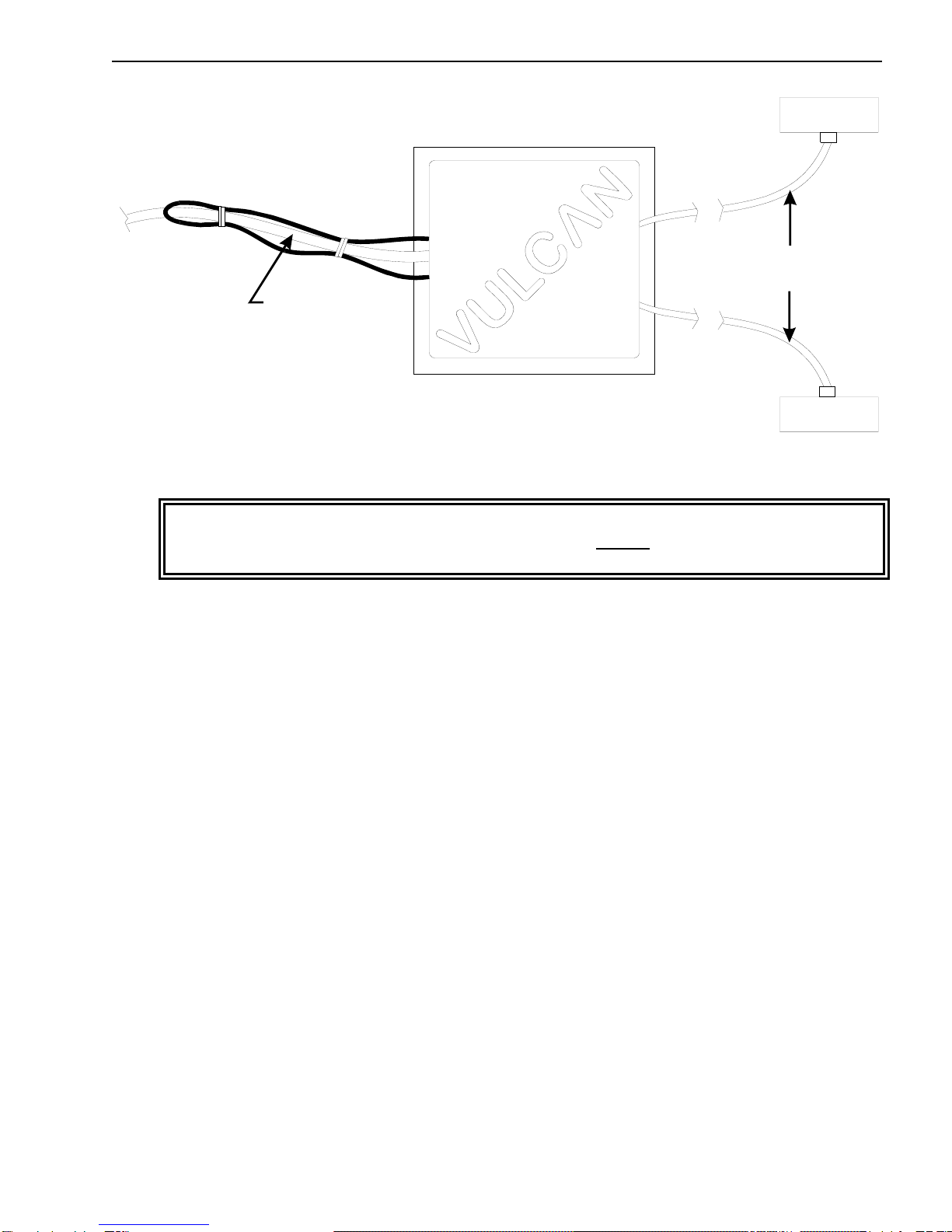

8. Once all of the Vulcoders have been installed, the Vulcoders must have either the wire loop cut

or uncut. Cutting the loop wire will designate the Vulcoder as a Front Vulcoder (refer to

Figure 1-K) and not cutting the Vulcoder designates the Vulcoder as a Rear Vulcoder (refer to

Figure 1-L). Following this procedure will enable the meter to properly assign channels.

For example, on a 2-channel system with the truck having a Front Vulcoder, and the trailer

having a Rear Vulcoder, the meter will sequence the Front Vulcoder as Channel A, and the

Rear Vulcoder as Channel B.

CUT

ORANGE

CABLE

BLACK

CABLE

LOAD CELL

LOAD CELL

Figure 1-K Front VSL Vulcoder Configuration

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

CHAPTER 1 15

ORANGE

CABLE

BLACK

CABLE

LOAD CELL

LOAD CELL

Figure 1-L Rear VSL Vulcoder Configuration

WARNING: If installing the meter in a vehicle with a positive ground electrical system, the

meter chassis, mounting bracket, and mounting fasteners MUST be electrically isolated from

the vehicle chassis.

9. Find a suitable location for the meter and install the mounting bracket. Secure the VSL

Vulcoder cable so it does not obstruct other in cab equipment and strain relieve. Unplug the

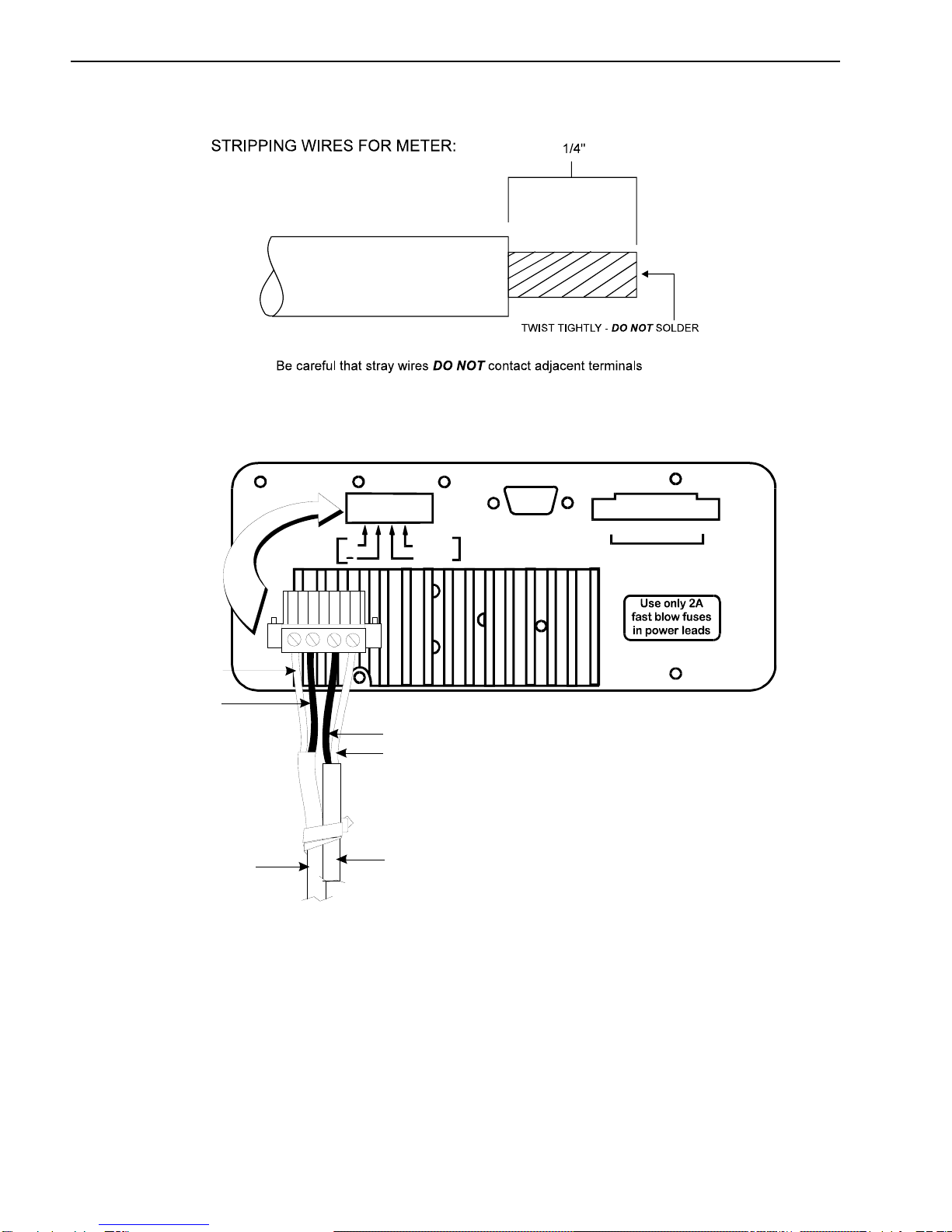

terminal block from the back of the meter, strip the wires, and connect the VSL Vulcoder wires

to the terminal block (refer to Figures 1-M and 1-N). Secure the power cable so it does not

obstruct other in cab equipment, strain relieve the power cable, and cut to length. Strip the

wires, and make all wire connections to the terminal block (refer to Figures 1-M and 1-N).

Note: Cut the shield wire off when stripping wires. Do not plug the terminal block into the

meter at this time.

10. Disassemble the positive fuse holder, (red wire). Apply grease to the positive connector at the

battery post to inhibit corrosion. Connect fused power leads directly to battery posts for best

operation. If not connecting directly to the battery, be sure to use a location that has the proper

voltage available at all times, and never more than 29 Vdc. Note: Vulcan V600 meters are

configured to be used in 12 Vdc system using 2 amp fast blow fuses in both power and

negative leads. To use the V600 meter in a 24 Vdc system, the 2 amp fast blow fuse must be

replaced with a 1 amp fast blow fuse in both power and negative leads. Refer to Section 7.2

“System Specifications.” Do not connect the power cable to a power source activated by the

key switch, power should be supplied at all times.

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

16 CHAPTER 1

Figure 1-M: Stripping Wires for the Meter

Stress-Tek, Inc., Kent, WA, U.S.A

12-24 Vdc White

Green VSL Accessory Port

RS-232 1 2 3 4 5 6 7 8

+

-

VSL VULCODER

COMMUNICATION

CABLE

(COMM LINK)

POWER

CABLE

POWER

POWER

GREEN

WHITE

+

Figure 1-N: V600 Wire Connections to the Meter

11. Review steps 1 to 10 before connecting the terminal block to the back of the meter.

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

CHAPTER 2 17

C H A P T E R 2 . 0

V600 METER OPERATION

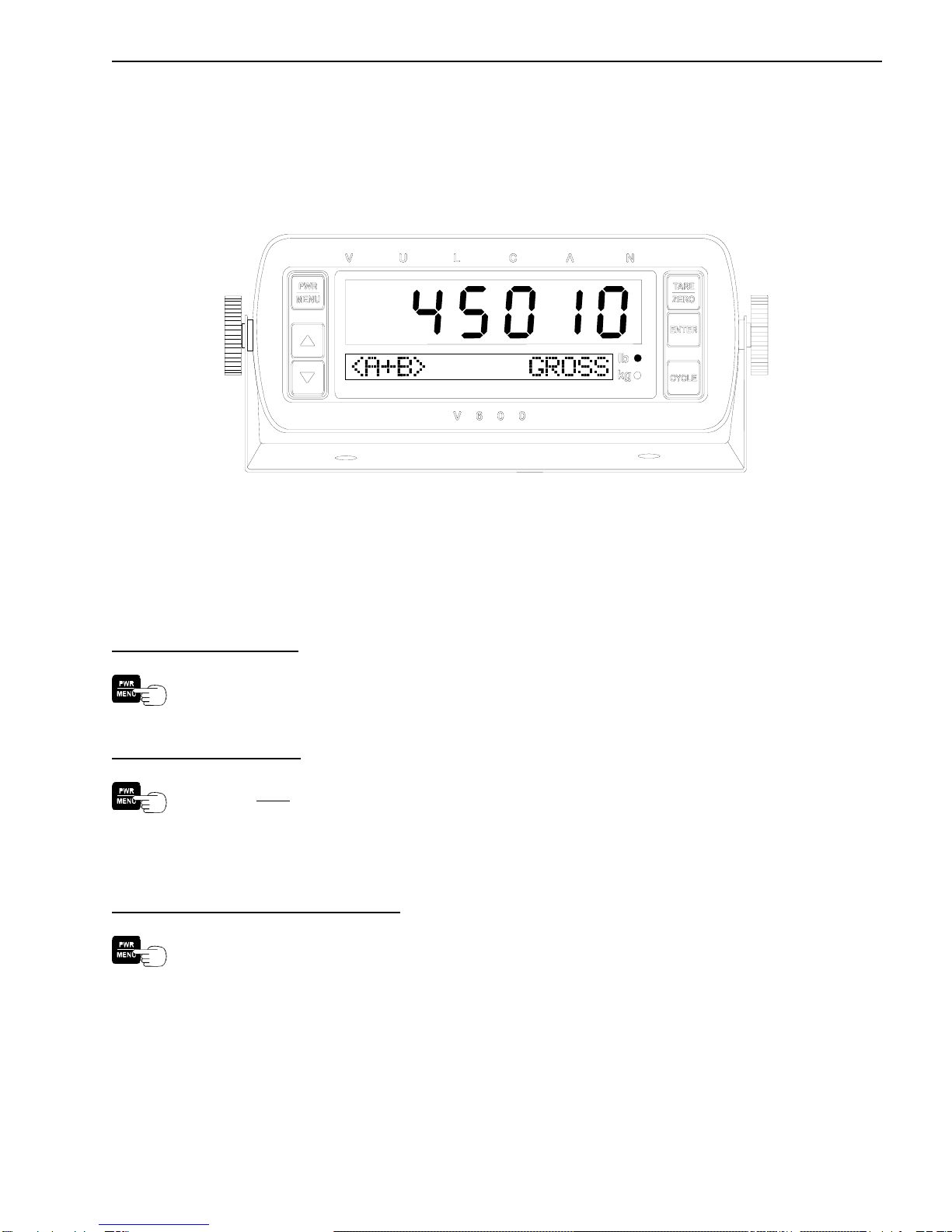

Figure 2-A: V600 Meter

2.1 POWER / MENU BUTTON OPERATION

2.1.1 POWERING THE METER ON / OFF

To Turn the Meter On:

Press the PWR / MENU button for less than 2 seconds.

To Turn the Meter Off:

Press and hold the PWR / MENU button until the meter display goes blank.

2.1.2 ENTERING AND EXITING THE METER PROGRAM MENU

To Enter the Meter Program Menu:

After the meter has completed its start up routine and is running, press the PWR / MENU

button to enter the program menu.

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

18 CHAPTER 2

To Exit the Meter Program Menu:

Press the PWR / MENU button to exit from the program menu at any time to return to the

normal operating mode.

Note: If the PWR / MENU button is held too long the meter will display all 8’s and the meter will

turn off.

2.2 ARROW BUTTONS OPERATION

2.2.1 CHANGING DISPLAY INTENSITY

There are four levels of display intensity to choose from.

To Increase the Display Intensity:

Press the UP ARROW button, while in the normal operating mode.

To Decrease the Display Intensity:

Press the DOWN ARROW button, while in the normal operating mode.

2.2.2 INCREASE / DECREASE METER PROGRAM SETTINGS

The arrow buttons enable the user to customize the system to their particular needs. For example,

adjusting the system Tare Weights use the UP ARROW button to increase the weight.

To Increase A Particular Meter Feature:

Press the UP ARROW button to increase the displayed value.

To Decrease A Particular Meter Feature:

Press the DOWN ARROW button to decrease the displayed value.

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

CHAPTER 2 19

2.3 CYCLE BUTTON OPERATION

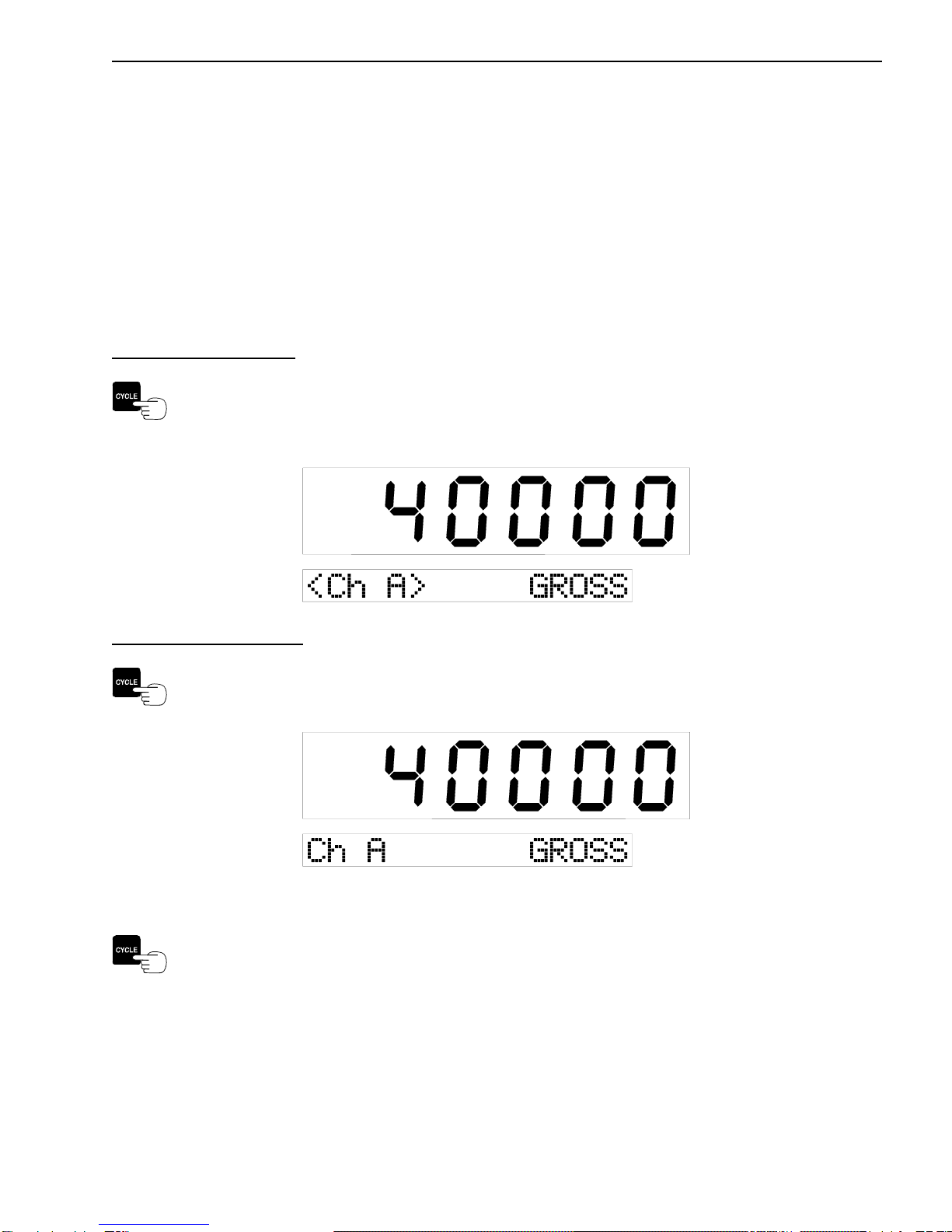

2.3.1 LOCKING THE METER ON A PARTICULAR CHANNEL

The lower yellow display indicates the channel, or group of channels, whose weight is being shown in

the large red upper display. The meter will automatically cycle through the channels and groups of

channels as determined by the display code setting.

If two or more letters are displayed, separated by a plus sign, this represents the sum of the weights on

those channels.

To Lock on a Channel:

When the desired channel or group of channels is being displayed, press the CYCLE button

to stop the automatic advance. The lock brackets “< >” are displayed when the meter is

locked on that particular channel(s).

To Unlock the Channel:

Press the CYCLE button again. The lock brackets “< >” are not displayed and the meter

will continue to cycle through the channels.

2.3.2 SCROLL THROUGH THE METER PROGRAM MENU FUNCTIONS

When in the Program Menu Mode, press the CYCLE button to scroll through the different

Program Menu items.

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

20 CHAPTER 2

2.4 ENTER BUTTON OPERATION

2.4.1 SELECTS / ENTERS PROGRAM MENU ITEMS

Press the ENTER button to select the desired main program menu item when it is shown in

the lower display. For example, press the ENTER button to select the CONFIGURE

SYSTEM Menu after entering the Program Menu.

2.4.2 STORES NEWLY ADJUSTED METER SETTINGS

Press the ENTER button to store the newly adjusted settings. For example, after making

adjustments to the weight mode, press the ENTER button to store the desired setting and

return to the CONF: WT. MODE Menu option.

2.4.3 DISPLAYS TIME AND DATE

To Display The Time And Date:

While the meter is in the normal operating mode, press and hold the ENTER button until the

current time and date is displayed. The meter will continue to display the time until the

ENTER button is pressed and held again. The meter will return to the normal weight

display.

2.4.4 PRINTS A WEIGHT TICKET

To Print A Weight Ticket:

While the meter is in the normal operating mode and the RS232 port is configured for a

printer, press the ENTER button to print a weight ticket.

June 21, 2006 VULCAN ON-BOARD SCALES 1-800-237-0022 Doc. 44-10032-001 Rev. C

©STRESS-TEK, INC. 2006

This manual suits for next models

1

Table of contents