C. THE MAINTENANCE OF THE MACHINE.

C1. Cleaning the string clamp of the tension unit (fig. 20).

* Lift the lever so that the string clamp opens and pull the pin out of the upper jaw (2).

* Pull the upper jaw off the pull rod and clean the surfaces of the string clamp with white spirit.

C2. Cleaning the clamps [fig.20].

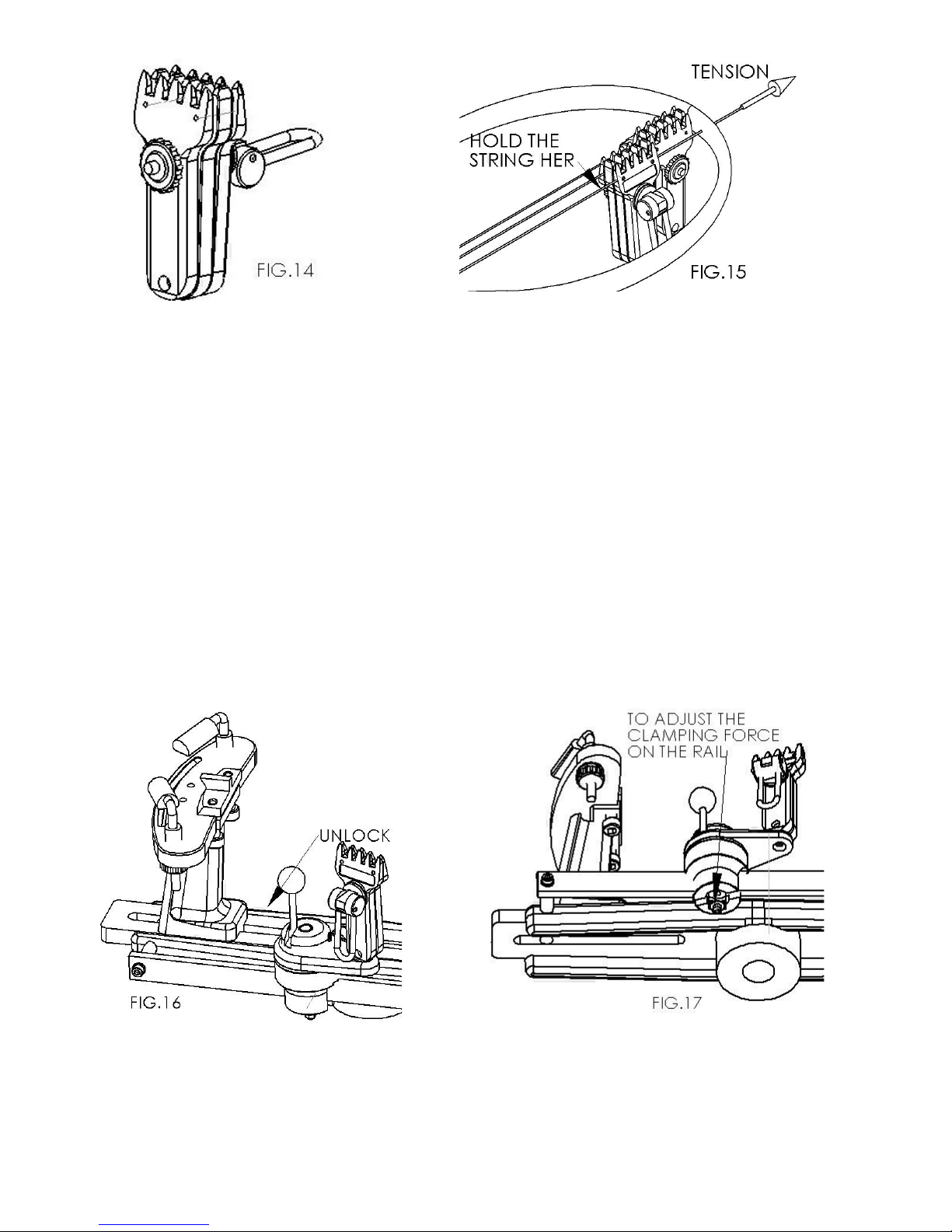

When the string slides through the clamp this can have 2 causes:

1. The adjustment of the clamp is wrong.

2. The silicone coating of the strings has made the clamp greasy, the clamp has to be cleaned:

* Fold a cloth around a thin plate and wet it with a degreasing fluid (white spirit).

* Move the plate and cloth between the jaws of the clamp, close the clamp and move the cloth and plate up and

down between the jaws.

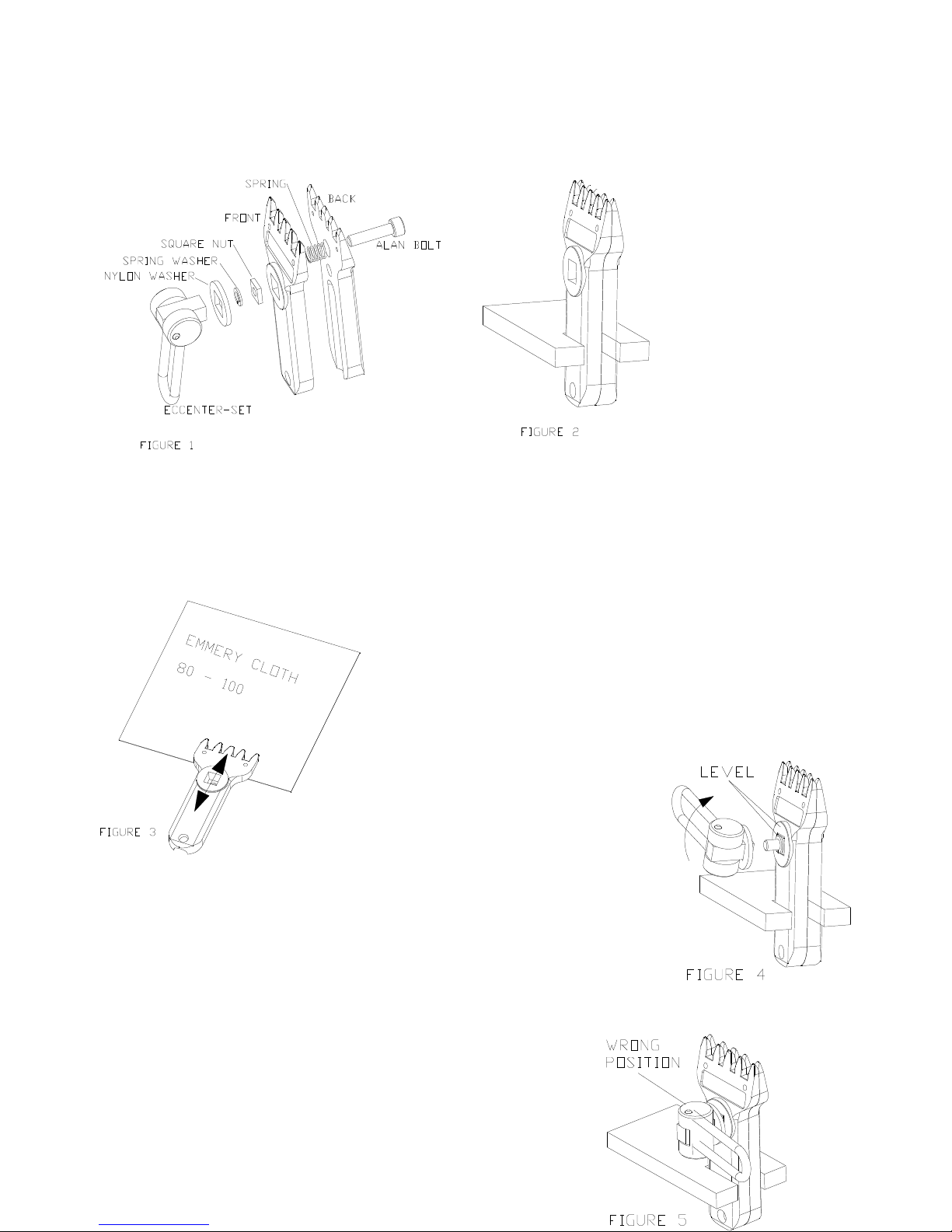

C3. The guide bars of the 'T92' clamp

system.

The clamps can be moved very easy:

* When the longitudinal guide bars are kept

clean. (Don't use any grease!)

* When a little vaseline is put on the cross

guide bars.

* Put some grease every now and then on the

pin that holds the clamp.

C4. The guide bars and clamps of the clamp

system 'T98'.

When the guide bars are greasy the clamps can

slide over the guidebars.

Clean the guidebars regularly with white

spirite.

C5. Calibrating the tension unit.

It is good to check the calibration of the

machine regularly, with the calibrator that is supplied with the machine .

* Adjust the tension at 44,4 lbs.

* Check if the tension system is adjusted at the higher range.

* Switch the lower locking handle to the down position.

* Tension the string of the calibrator as shown in fig.. 21..

* Figure 21 shows the mark when the tension is too high, o.k. or too low.

* When the tension is too high or too low it can be adjusted with the adjusting screw down in the floor stand of

the machine.