Electric Tongue Jack JET-2500

Operation Instructions

1. Park your trailer on a level surface and block all dolly and

trailer wheels. TIP: For night time hookups, flip the light

switch ON to illuminate your work area.

2. Before operating the jack, attach the foot with the 3/8”

safety lock pin provided.

WARNING: DO NOT stack blocks under the jack’s foot to

increase the height. Stacked blocks may become unstable

and fall.

3. Extend the jack by pushing the operating switch UP.

NOTE: Under heavy use, the circuit breaker may open,

causing the motor to switch off. In this case, release the

operating switch and wait 15 seconds for the breaker to

reset. Retract the jack by pushing the operating switch down

NOTE: The jack will slow down and stop as it approaches

the fully retracted position. Release the switch at first sign of

slowing.

4. Before driving, remove the foot or position it in the highest

position and completely retract the jack.

Manual Operation Instructions

1. Disconnect the jack from the power source.

2. Remove the rubber access covers on the top of the jack and

on the side of the motor cover.

3. Insert the manual crank handle into the access hole on the

top of the jack, engaging the drive screw.

4. Rotate the manual crank handle counter-clockwise to extend

the jack, and clockwise to retract it.

Maintenance

To keep your jack in good, functional condition, fully extend the

jack and clean the inner jack tube once a year. After cleaning,

coat the tube with a light grease or silicone spray lubricant.

Replacement Parts

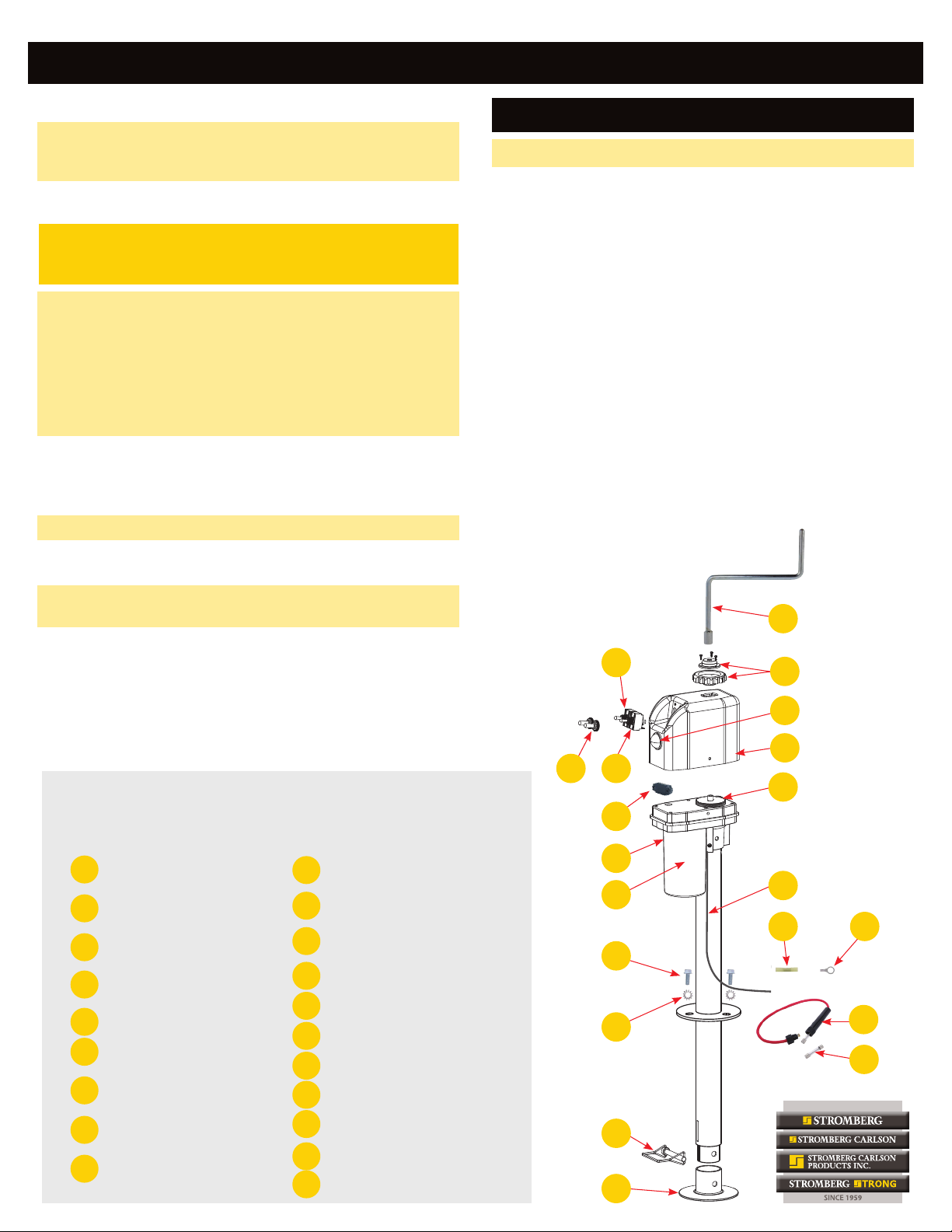

A-H UPPER JACK ASSEMBLY

(Includes all housing, gear motor

box assembly and items A-F)

A1 Extend/retract switch

Item # 2500-03

Light on/off switch

Item # 2500-04

Switch boot (set of 2)

Item # 2500-05

LED light and lens

Item # 2500-06

Circuit breaker

Cap with bubble level

Item # 2500-3755E

Motor

Item #2500-18

Top Housing/Cover

(Item #2500-02)

Motor Housing/Cover

(Item # 2500-20)

A1

A2

B

C

D

E

F

I-S LOWER JACK ASSEMBLY

(Includes outer jack tube, Inner jack

tube, screw shaft and items G-P)

G Removable foot pad

Item # 2500-25

3/8” safety lock pin

Item # 2500-26

Manual crank handle

Item # 2500-24

Star washer (3 pieces)

Power lead

Gear Box

Terminal ring

Wire butt connector

30A spare fuse

Item # 2500-3755K

Fuse holder

3 Bolts

G

H

I

J

K

L

M

N

O

P

Q

R

S

TROUBLESHOOTING

Motor isn’t operating

CAUSE SOLUTION

Open Circuit Breaker Wait 15 seconds for the breaker to close.

Poor Ground Clean area between the jack mounting

plate and coupler, and ensure paint

has been removed by the star washers.

Direct metal-to-metal contact must exist

between mounting components to ensure

good electrical contact.

No or Low Voltage Check battery and electrical connections.

Power supplied must be at least 10V DC.

If the battery is low, plug the trailer cable

into the tow vehicle, and start the tow

vehicle to provide power to the jack.

Blown Fuse Replace fuse with a new 30A fuse.

R

Q

A1

I

A2

J

B

K

C

L

S

D

E

G

N

M

F

H

PO