Strong International RADIANCE 72-00800 User manual

RADIANCE

Follow Spotlight

Type 72-00800

PRELIMINARY

STRONG INTERNATIONAL

a division of Ballantyne of Omaha, Inc.

4350 McKinley Street

Omaha, Nebraska 68112 USA

Tel 402/453-4444 • Fax 402/453-7238

www.strongint.com

RAD/001

PREFACE

THE STRONG RADIANCE SPOTLIGHT is an AC follow spot complete with

lamphouse, igniter, power supply, optical system, and color boomerang. It is available in either 1200 or

2500 watt models, and is designed for use with one of two single-ended metal halide bulbs. Bulbs are

not supplied with the unit, but are available from theatrical supply distributors.

AN ELLIPICALREFLECTOR and condenser lenses are designed to operate in a fixed

position with the bulb mounted vertically in the lamphouse. The bulb socket is adjustable in relation to

the optics to permit positioning the arc on the optical center line of the reflector and lenses. The igniter

is contained within the lamphouse enclosure.

THE SEPARATE POWER SUPPLY comes equipped with a three-wire AC line cord

and connects to a 230 volt (±10 volt), single phase 60 Hz.AC line. The 1200 watt Radiance is available

in a 115 volt model. A230 volt, 50 Hz. power supply is shipped with export models of either wattage.

The power supply is protected by a double-pole circuit breaker, and operation of the power supply is

controlled by the ON/OFF switch on the lamphouse.

THE IGNITER in the lamphouse requires a 237 V.AC open circuit pulse, provided by a

step-uptransformer in the power supply, to ignite the bulb.After ignition, the powersupply automatically

drops the voltage to the value required to maintain the arc.

ADJUSTMENT CONTROLS for positioning the metal halide bulb are located below

the bulb socket at the rear of the lamphouse. This control mechanism permits concise positioning of the

bulb in relation to the reflector and also allows the bulb to be centered both vertically and horizontally

on the optical center of the reflector.

THEPOWERSUPPLYis connected to the lamphouse by a cable assembly approximately

13 feet long, terminating in a quick-disconnect plug for easy attachment to the power supply. This

cable assembly contains all the control wires for the operation of the lamphouse and power supply.

ANINTERNALLYWIREDBLOWERisusedinthefollowspot lamphouse and operates

from the AC control circuit. This blower is used to cool both the lamphouse and optical system.

METAL HALIDE BULB (not provided with unit)

1200 Watt (G22 Base) 2500 Watt (G38 Base)

Philips MSR 1200/2 Philips MSR 2500 HR

or equivalent

RAD/002

Horizontal

Masking

Shutter

Iris Vertical

Masking

Shutter

Fade-Out

Spot Size Control Handle

Color

Boomerang

Color Release

Lever

Color Frame

Color

Selector

Arm

Tripod Floor Stand

(optional)

Spigot & Cantilever Arm

Tilt Friction

Adjustment

Intake Blower,

ON/OFF Switch

(Rear Cover)

Cover, Bulb

Positioning

Screws

RAD/003

SETTING UP SPOTLIGHT

THE RADIANCE FOLLOW SPOT is shipped in sections which must be assembled.

The cantilever arm and spigot (truss pin) mount to the round tension plate on the off-operator side of

the spotlight head using (2) truss head screws. Keyhole slots in the cantilever arm align to the screws.

THE SPIGOT is a standard 28mm (1-1/8 inch) diameter for truss mounting. The spigot

will also seat into the top of the optional tripod base stand. Height of the unit may be determined by the

user, but when adjusting the tripod base, make certain the unit remains stable. Setting the tripod base

to an extreme operating height contributes to making the spotlight assembly topheavy and unsteady.

THERADIANCE COLOR BOOMERANG makesprovision for “stowing” colorframes

for shipment. When stowed, the color frames are protected from breakage or other damage caused by

transporting the spotlight. To enable operation of the color boomerang, raise the spring-loaded lockpin

and push the retainer bar into its recess. This allows the color frames to drop into a “deployed” position

for normal operation. To again stow the color frames for transport, raise all six color frames to their

engaged position, raise the lockpin, and extend the retainer bar from its recess.

CONNECTTHE CABLEASSEMBLYfrom the lamphouse to the mating receptacle on

the side of the power supply and tighten firmly. The connector and receptacle are keyed to prevent

misalignment of the pins; check for correct pin alignment before tightening the locking ring. Do not

connect the power supply to the AC line until completing the installation of the metal halide bulb.

“Stowed” “Deployed”

Lockpin

Retainer Bar

RAD/004

BULB INSTALLATION AND OPERATION

REMOVE THE REAR TOP COVER PLATE by releasing the four chromed captive

quarter-turn screws and lifting the plate from the top of the lamphouse enclosure. This will expose the

ceramic base of the two-pin bulb socket located on the base of the lamphouse between the reflector and

the condenser lenses.

THE BULB SOCKET accommodates either the 1200 (G22) or the 2500 watt (G38)

single-ended metal halide bulb. Carefully check the data plates on the spotlight head and on the power

supply to verify correct wattage before installing either bulb.

DO NOT TOUCH the quartz portion of the metal halide bulb with bare fingers! Any

fingermarks accidentally placed on the bulb envelope must be removed with alcohol before lighting

the bulb; skin oils will rapidly burn into the envelope material and shorten bulb life. Wear clean cloth

gloves or grasp the envelope using a clean cloth towel when handling the bulb.

INSERT THE METAL HALIDE BULB into the lamphouse and seat the two pins into

the bulb socket. Press firmly downward to insure correct fit and good electrical contact.

REPLACE THE TOP COVER PLATE over the lamphouse opening. Tighten all four

quarter-turn fasteners. Make certain the ON/OFF switch on the rear cover is in its OFF position.

CHECK THE POWER SUPPLYDATAPLATE for the required input voltage. Plug the

AC cord from the power supply into an appropriate AC outlet. Turn the circuit breaker on the side of

the power supply case to the “ON” position. The blowers in the power supply and in the spotlight

lamphouse will operate. Press the “ON” switch on the lamphouse and the bulb will ignite.

ALLOW THE BULB to heat up for three to five minutes to reach full brightness, then

proceed with the instructions for alignment of the bulb with the reflector. Leave the bulb on throughout

the alignment procedure; a metal halide bulb will not readily restart when hot.

USING A PHILLIPS SCREWDRIVER, rotate the three adjusting screws below the

lamphouse base pan to center and focus the bulb inside the reflector. Screw heads are accessible through

three clearance holes in the cover plate. The ideal light field is as flat as possible at highest intensity.

BOTHTHE RELFLECTORand the condenser lens assembly are positioned at the factory

for optimum light collection. Do not loosen the set screws retaining these components to the slide

rods, or otherwise reposition these elements.

RAD/005

BULB INSTALLATION AND OPERATION(continued)

WHEN TRANSPORTING THE SPOTLIGHT, or if the bulb may be subjected to a hard

shock when moving to another location, remove the metal halide bulb from the lamphouse by reversing

the installation procedures. If the control section of the bulb adjustment is not changed, the bulb should

be able to be replaced without any necessity to repeat the aligning procedures.

THE METAL HALIDE BULB ignites best when cold. After extinguishing the bulb,

allow at least thirty minutes cooling before attempting re-ignition.

EXPECTED BULB LIFE ranges from 500 to 800 hours (depending upon wattage), but

because of manufacturing tolerances, some bulbs may lose color quality before this period. Refer to

the bulb manufacturer’s specifications and information packaged with the bulb.

BULB LIFE can be maximized by avoiding repeated ignitions.Allow the lamp to burn

throughout the spotlight’s use cycle, dousing out with the masking shutter blades or fade-out mechanism

as required.

CAUTION

ULTRAVIOLET RADIATION is emitted when the bulb is ignited. Wear

protective clothing and goggles or glasses when adjusting the shutter

bladesorperforming any service with theopticalsystemhousingremoved.

RAD/006

OPERATION OF OPTICAL SYSTEM

THE SPOT SIZE CONTROL is located on the right side of the optical system protruding

from a slot in the spotlight housing. A variation of spot sizes from full flood to a small spot can be

obtained by moving the spot size control from one extreme to the other. Beam intensity is increased by

this optical system when reducing from flood to spot, and maximum intensity is reached when the spot

size control is in the extreme forward position. Depressing a thumb lever adjacent to the control

permits free movement forward and back, and releasing the thumb lever locks the control in position.

ROTATING THE CONTROLKNOB operates the spot focus control. When making an

adjustment, rotate the spot size control until the sharpest edge is obtained on the projected spot. Moving

the large lens to its center of travel and then adjusting for a sharp edge should give satisfactory results

for the full movement of the lens system.

THREE BEAM SHAPING CONTROL LEVERS are located immediately in front of

the lamphouse compartment and project through the top of the optical system housing. The iris control

is the center lever. When this lever is to the left (viewing the spotlamp from the rear), the largest

aperture is provided. Smaller apertures are obtained as the lever is moved to the right.

THE MAXIMUM FLOOD SPOT is obtained with the iris control lever to the left (away

from operating side) for the large aperture and with the spot size control moved as far as possible

toward the rear. Smaller sized spots are projected as the spot size control is moved forward. Most of

the spot sizes needed will be produced with the iris in its maximum open position.

FORA“HEAD SPOT,” or any spot size smaller than can be obtained with the spot size

control in its extreme forward position, shift the iris control lever to the right (toward operating side)

for a smaller aperture. The iris control lever should always be returned to its extreme left position

before the spot size control is again moved to obtain larger spots.

THE HORIZONTAL MASKING SHUTTER LEVER is the rearmost lever projecting

through the top of the optical system housing. The horizontal masking shutter blades are operated by

this lever to shape the projected spot to a rectangle, strip spot, or for dousing.

THE VERTICALMASKING SHUTTER LEVER is the lever in front of the iris control.

The vertical masking shutter blades are operated by this lever to narrow the projected spot from full

width to complete douse.

THE DISENGAGED POSITION of both masking shutter levers is to the extreme left

(away from operating side). Varying degrees of masking, from open to complete cutoff, are obtained

by moving the levers to the right (toward operating side).

RAD/007

OPERATION OF OPTICAL SYSTEM (continued)

THEANGLE OF THE MASKING SHUTTER BLADES can be adjusted to compensate

for the horizontal projection angle. If the spotlight is installed at an extreme house-right or house-left

position, the projected edges of the masking blades may not align horizontally with the apron, or

vertically with the proscenium. Alternately tightening and loosening the 6-32 socket head adjusting

screws (see Figure 3, Items __ and __) using a long, ball-ended 3/32" allen key will shift the position of

these blades.

THE FADE-OUT MECHANISM AND DOUSER CONTROL is the single lever

projecting through the top of the optical system housing near the center of the unit. This lever controls

the amount of light from full intensity when the lever is to the left, to complete fadeout and douse when

the lever is to the extreme right.

RAD/008

HANDLING THE SPOTLIGHT

GENERALLYTHE BEST POSITION for the operator to stand is near the center of the

spotlight, on the right hand side, although the angle of tilt and the size of porthole may alter the position

for the most convenient operation.

EACH OPERATOR will, after a few minutes of operation, generally develop his or her

own system and preferred position for operating the follow spot.

THE VERTICALTILT TENSION KNOB is located on the side of the housing adjacent

to the fade-out lever. Counterclockwise rotation of the knob frees the tilt tension, and clockwise rotation

applies tension. The individual operator can set his or her desired degree of tension.

OPERATION OF COLOR BOOMERANG

SEETHE “SETTING UPSPOTLIGHT” SECTION in the preceding pagesofthismanual

for details of the “Stowed” and “Deployed” configurations of the Radiance boomerang. It is

recommended to “stow” the color frames whenever transporting the spotlight.

THE COLOR BOOMERANG is equipped with six color filter gels containing the

following colors in order from rear to front: (1)Amber, (2) Flesh Pink, (3) Daylight Blue, (4) Light Sky

Blue, (5) Primary Blue, (6) Light Red. Keep the darkest or most dense colors (red, dark blue) to the

front of the boomerang, farthest from the bulb.

THE SIX COLOR ARMS are mounted to the side of the boomerang. To insert a color

disc in the light beam, move the proper color arm downward until the latch engages. To release a color

disc, raise the color release lever, or engage another color, thereby canceling the previous color.

TO REMOVE A COLOR DISC ASSEMBLY, release the arm and lift the color holder

ring from the arm bracket. To attach a color gel to a color frame, spray the flat surface of the ring

(without the channel clip) with an aerosol adhesive. Center the ring over a precut 12 by 12 inch (30 x

30cm) gel, and press the adhesive-coated side onto the gel. Trim the excess gel material and install the

color frame into the boomerang. Only the six above-noted colors are supplied with the boomerang;

additional colors, and color temperature reduction filters, are available from theatrical supply dealers.

RAD/009

MAINTENANCE

TO CLEAN THE CONDENSER LENSES, dismount the lamphouse top cover and

remove the bulb. Using a good grade of alcohol and piece of lens tissue (facial tissue can be used as a

substitute), gently wipe both sides of each lens until the surfaces are clean. Clean the envelope of the

bulb before replacing in the same manner.

THE REFLECTOR should be cleaned periodically with a clean, soft lint-free cloth to

remove any dust from the reflecting surface. USE NO ABRASIVES.

AREMOVABLE OPTICAL SYSTEM COVER, secured with quarter-turn fasteners, is

located immediately in front of the fade-out control lever. The center lens, and the back surface of the

large lens, can be cleaned easily through this opening.

TO CLEANTHE FRONT SURFACE of the large lens, slide the lens carriage to the full

forward position. The front surface is now readily accessible through the front of the housing.

THE INSIDE of the lamphouse and lens mechanism and the blowers should be cleaned

periodically, depending on the dust conditions at each installation. The blower blades and inlet grilles

need cleaning to remove the dust buildup that accumulates over a period of time.

THE FOLLOW SPOT does not require any lubrication.

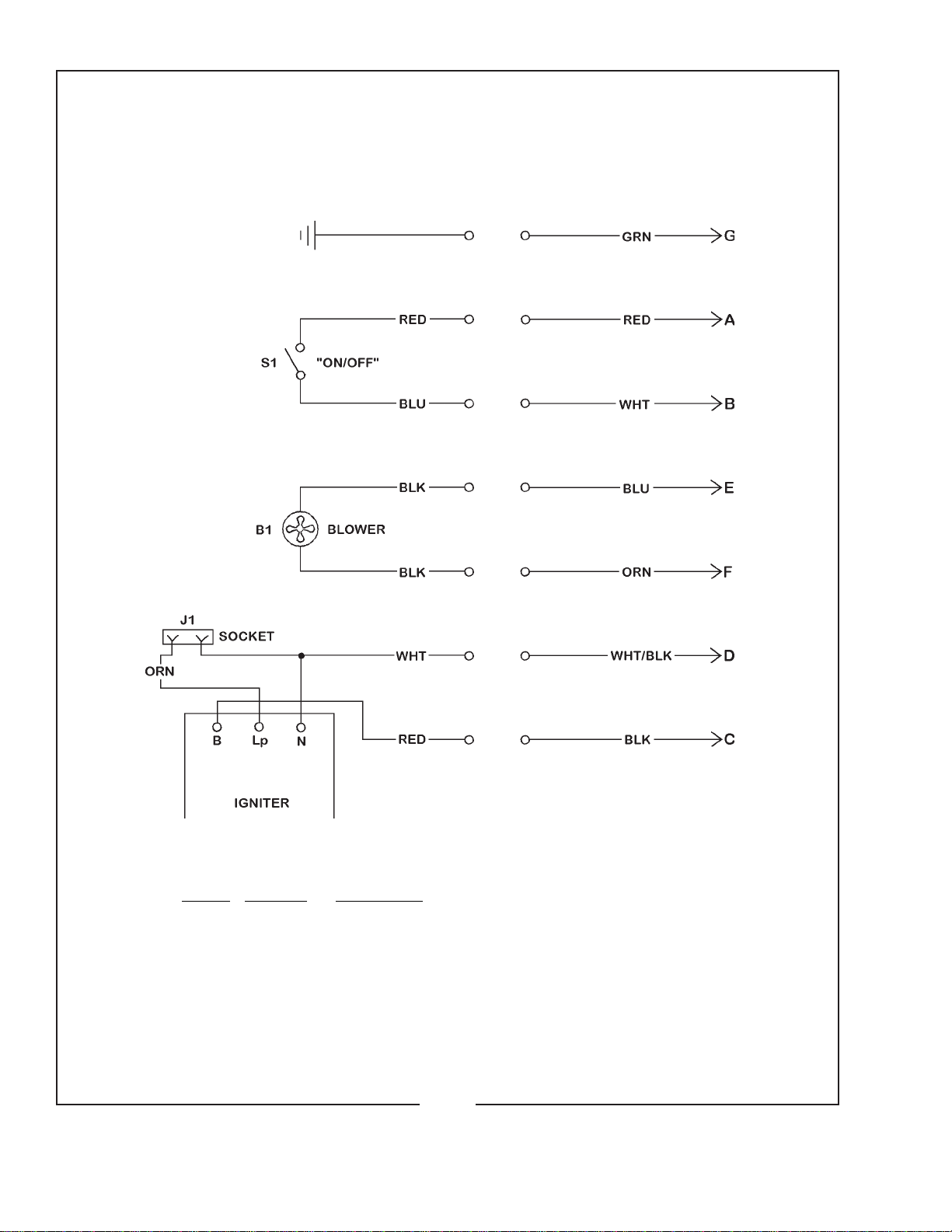

Ref.

Desig. Part No. Description

B1 71627000 Lamphouse Blower, 230 V.AC, 50/60 Hz.

J1 G22 Socket (1200 W.)

J1 71-40001 G38 Socket (2500 W.)

S1 71-61110 Rocker Switch, ON/OFF

- 71-64001 Igniter

- 71-71001 Lamphouse/Power Supply Interconnect Cable Assembly

includes (7) Pin Quick-Disconnect Plug

LAMPHOUSE SCHEMATIC DIAGRAM

575/012

575/027

RADIANCE POWER SUPPLY

2500 Watt: 72-00939

PARTS LIST

Power Supply

Item Part No. Description

1 72-00932 Cabinet Corner Extrusion (4 req’d.)

2 72-00934 Bottom Plate, Cabinet

3 72-00933 Cabinet Side Panel (2 req’d.)

4 72-00937 End Panel, Blower Mount

5 72-00938 End Cover, Louvered

6 72-00799 End Cover Bracket (8 req’d.)

7 72-00935 Top Cover Plate

8 72-00936 Transformer Mounting Bracket

9 72-00882 Extrusion Dress Plug (8 req’d.)

10 4100371 Screw, 10-32 x 3/8" Pan Head (42 req’d.)

11 4080624 Screw, 8-32 x 5/8" Pan Head (3 req’d.)

12 4060310 Screw, 6-32 x 5/16" Pan Head (7 req’d.)

13 4250508 Screw, 1/4-20 x 1/2" Pan Head (4 req’d.)

14 4258001 Hexnut, 1/4-20 Self-Locking

15 71-71002 Receptacle, (7) Pin

16 4080622 Screw, 8-32 x 5/8" Flat Head (4 req’d.)

17 4068007 Hexnut, 6-32 Self-Locking

18 71-14110 Contactor

19 71-61120 Switching Circuit Breaker, 30 A. 2 Pole

20 71627000 Blower, 230 V.AC, 50/60 Hz.

21 21-21016 Fuse, 1 A. 250 V.

22 71-64002 Transformer, 2500 Watt

22 Transformer, 1200 Watt

23 31-10001 Capacitor Clamp, 2-1/2" Diameter

24 31-08133 Capacitor, 60 µf, 370 V.AC

25 31-28039 Carry Handle

26 4100629 Screw, 10-32 x 5/8" Button Head (4 req’d.)

27 81-98254 Traction Foot, Rubber (4 req’d.)

28 4108002 Hexnut, 10-32 NyLock (4 req’d.)

29 4107101 Flatwasher, #10 SAE (4 req’d.)

30 4313000 Cap Screw, 5/16-18 x 3" Hex Head (4 req’d.)

31 4317100 Flatwasher, 5/16" (4 req’d.)

32 4318001 Nexnut, 5/16-18 (4 req’d.)

33 71307000 Blower Grille

34 31-98163 Cord Grip, Strain Relief

35 91-21001 Fuseholder

Table of contents

Other Strong International Spotlight manuals

Strong International

Strong International SUPER TROUPER II User manual

Strong International

Strong International TrussTrouper 1.2 User manual

Strong International

Strong International XENON GLADIATOR III User manual

Strong International

Strong International SUPER TROUPER II User manual

Strong International

Strong International SUPER TROUPER II User manual

Strong International

Strong International XENON GLADIATOR IV User manual

Strong International

Strong International FOLLOW SPOTLIGHT 48057 User manual