Strong International XENON GLADIATOR IV User manual

STRONG INTERNATIONAL

a division of Ballantyne of Omaha, Inc.

4350 McKinley Street

Omaha, Nebraska 68112 USA

Tel 402/453-4444 • Fax 402/453-7238

www.strong-lighting.com

XENON GLADIATOR IV

Follow Spotlight

Type 47070

Rev. September 2006

BULB

WATTAGE CURRENT

RANGE (DC) NOMINAL

CURRENT DO NOT

EXCEED

2000 50-90 A. 75 A. 90 A.

2500 70-100 A. 90 A. 100 A.

3000 60-110 A. 100 A. 110 A.

4000 80-150 A. 125 A. 150 A.

PREFACE

STRONG INTERNATIONAL’S XENON GLADIATOR IV Model 47070 is a direct current

follow spotlight system complete with a lamphouse, xenon power supply, optical system, color boomerang,

and base stand assembly. The spotlight assembly consists of the arc lamp, variable focus lens system, color

boomerang, and base. The separate xenon power supply completes the installation. Only these special power

supplies manufactured by Strong International can be used with the Gladiator IV. For installation and opera-

tion of the power supply, see the instruction manual furnished separately.

THE XENON LAMPHOUSE utilizes a xenon bulb designed for horizontal operation, and a

deep ellipse metal reector, as a light source. The reector operates in a xed position, and is dichroic (“cold”)

coated to reduce heat in the projected light. A lens blower and heat lter, mounted in the spotlight optical

system, further reduce heat at the projection lens and color media.

ONLY XENON BULBS specically designed for horizontal operation should be used in this

follow spot. The Gladiator IV lamphouse is designed to use the LTIX-4500W-HS watt bulb, and replacement

bulbs (4000-4500 watt, not exceeding 4500 watts) must be certied as 100% interchangeable with this bulb.

Lower wattage (2000-3000 watt Type “HS”) bulbs may be installed in the Gladiator IV using an optional anode

support collet supplied by Strong. All required bulb cabling and contact clamps are provided in the xenon

lamphouse, and bulb adapters are not required.

ADJUSTMENT CONTROLfor the xenon bulb is located at the rear of the lamphouse behind

the access cover. The adjustments control the horizontal, vertical and focal movement of the bulb.

INSTRUMENTATION of the lamphouse includes a digital running time meter with DC volt-

age and amperage display. A “wattage” readout on the digital display is an approximate gure and should not

dictate the bulb’s output setting. The running time meter records the elapsed hours of the bulb (resettable),

and the total hours that the spotlight system has been in operation. A rocker switch controls lamp ON/OFF.

THE LAMPHOUSE COOLING BLOWERS are internally wired and operate onAC voltage

derived from the xenon power supply. These blowers are required to maintain a safe operating temperature

at the bulb seals. An additional blower cools the optical system and color boomerang. The blowers operate

continuously until the xenon power supply is de-energized.

THE LAMPHOUSE is supplied with a 13 foot cable containing the DC leads, the AC control

wires, and the ground wire. The cable terminates in a multiple-pin, quick-disconnect plug keyed to mate with

the receptacle on the power supply.

WHEN TRANSPORTING THE SPOTLIGHT, it is necessary to remove the xenon bulb and

place it in its original shipping container to prevent breakage. See the SAFETY PROCEDURES section fol-

lowing, and permit only authorized personnel to handle the xenon bulb.

IF AT ANY TIME you have a suggestion, or desire aid in securing anticipated results, write

directly to STRONG INTERNATIONAL, 4350 McKinley Street, Omaha, Nebraska 68112 USA, or online at

www.strong-lighting.com.

XG4/001

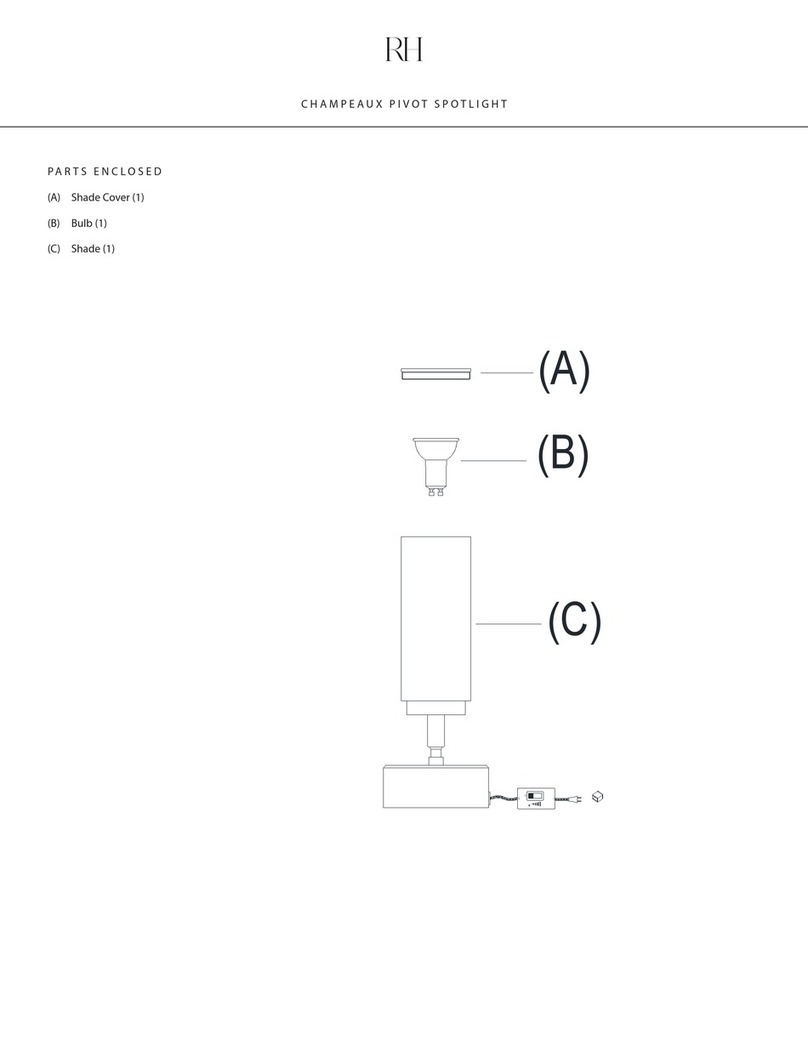

Lamphouse Access Cover

Fade-Out/Douser Control Lever

Masking Shutter (Chopper)

Control Lever

Iris Control Lever

Horizontal Pan

Control Lever

Vertical Tilt

Control Lever

Height Setting Pin

Lifting Strap

Spot Size Control Handle

Color Boomerang

Control Levers*

Spot Focus Knob

Leveling Feet not shown

Lens System

Access Cover

XENON GLADIATOR IV

XG4/002

* Boomerang Type 72-00264; Type

72-00709 not shown: see Figure 5B

INSTALLATIONAND SETTING UP SPOTLIGHT

THE XENON GLADIATOR IV is shipped in sections which must be assembled. Lifting

straps on the yoke assembly permit completely assembling the spotlight on the oor and later hoisting it to an

elevated position.

ASSEMBLE THE FOUR BASE LEGS to the lower square section of the base column using

the 3/8-16 x 2-3/4 inch hex head cap screws and lockwashers provided. Insert a leveling foot and locknut in

each of the four leg brackets and level the base before continuing the installation.

WHEN INSTALLED in a permanent location, the casters and leveling feet must be removed,

and the clearance holes in the base leg brackets used for hardware (user supplied) to bolt the base to the oor

or platform. If it is desired to have the unit portable, when operating, the leveling feet must be adjusted down

until the weight of the spotlight has been shifted from the casters to the leveling feet.

THE INNER TUBE of the support yoke has three holes to permit adjusting the height of the

spotlight. The three holes are on four-inch centers and will allow an optical height of approximately 53 inches,

57 inches, and 61 inches above oor level to the optical center of the lamphouse and lens system. Insert the

height location pin through the hole in the outer tube and one of the holes in the inner tube. The leveling feet

may be adjusted through an additional two-inch range.

THE HORIZONTAL SWING and vertical tilt locking knobs are on the right hand (operating)

side of the yoke assembly. Level the yoke and tighten both of these locking devices securely before attempting

to place the lamphouse and lens system on the support yoke.

PLACE THE LAMPHOUSE and lens system on the yoke assembly, with the spot size con-

trol handle to the right hand (operating) side, the same as the locking controls on the yoke. Line up the four

tapped (5/16-18) mounting holes in the bottom of the base rail mounting bracket with the four mating holes

in the support yoke and secure using the four 5/16-18 wing screws. Note the mounting holes are slotted to

allow ne adjustment for balancing the spotlight.

ATTACH THE LAMPHOUSE CABLE CONNECTOR to the mating receptacle on the power

supply. The lamphouse and power supply connectors are keyed for correct pin alignment; make certain pins

are seated before tightening the locking ring. DO NOT energize the xenon power supply before the xenon

bulb is correctly installed into the lamphouse.

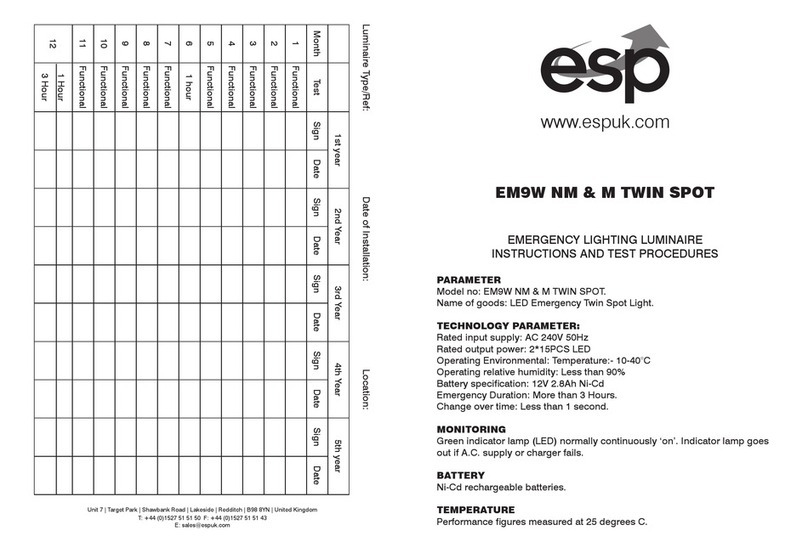

XG4/003

LAMPHOUSE - POWER SUPPLY

Interconnection Diagram

LAMPHOUSE

(Connections Pre-wired) MS CONNECTOR

Pin Wire No,

A DC-

B DC+

C 2

D 3

E 4

F 5

G 6

I 7

J 8

M Grnd

Lamphouse

Cable Assembly

XENON

POWER

SUPPLY

Connector (pre-wired)

DC+

DC-

SYSTEM MUST BE GROUNDED

All wiring must conform to local codes;

shield lamphouse cable in conduit

if required.

Check Slide Switch (below) on Power

Supply for correct positioning.

Slide to LEFT

XG4/004

SAFETY PROCEDURES

READ CAREFULLY BEFORE INSTALLING XENON BULB

THE XENON BULB is highly pressurized. When ignited, the normal operating temperature

of the bulb increases the pressure to a level at which the bulb may explode if not handled in strict accordance

to the manufacturer’s operating instructions.

THE BULB is stable at room temperature, but may still explode if dropped or otherwise mis-

handled. Breakage resulting from transport and handling is not covered by the bulb manufacturer’s warranty,

and it is strongly recommended to dismount the xenon bulb when transporting the spotlight.

REFER bulb replacement and service to QUALIFIED PERSONNEL with adequate protec-

tive clothing (face shield, clean cotton gloves, welder’s jacket). For routine lamphouse service, observe the

following rules:

1. Allow the bulb to cool to room temperature before opening the lamphouse. Put on protective clothing

described above.

2. De-energize the xenon power supply at the AC source before opening the lamphouse compartment.

3. When possible, encase the bulb in its protective cover when cleaning or servicing the lamphouse

interior. The bulb, when outside the lamphouse, must be encased in the cover.

4. Clean the bulb after it has cooled to room temperature. Do not touch the quartz envelope of the bulb;

ngerprints will burn in and create hot spots which may shorten bulb life. If ngermarks are made,

they should be carefully removed with methyl alcohol and cotton prior to bulb operation.

5. Never view an ignited bulb directly. BLINDNESS OR PERMANENT EYE DAMAGE MAY BE

INCURRED.

6. Use only xenon bulbs designated as OZONE FREE. When possible, vent the lamphouse exhaust to

outside atmosphere.

7. Maintain the lamphouse blowers in good operating condition. Keep the blower inlets and grilles clean

for unrestricted air ow.

8. To insure maximum bulb life, operate the lamphouse blowers for at least ten minutes after extinguish-

ing the bulb.

9. If returning a bulb for warranty adjustment, pack it in its original shipping container. Complete and

return all required warranty information.

XG4/005

10. Dispose of expired bulbs that are beyond warranty in the following manner: Wrap the bulb tightly

in several layers of canvas or heavy cloth. Place it on a hard surface and shatter the envelope with a

sharp hammer blow. DO NOT place an unshattered bulb in an ordinary refuse container.

11. DO NOT PERMIT UNAUTHORIZED PERSONNEL TO PERFORM OR ATTEMPT ANY PHASE

OF XENON BULB HANDLING OR SERVICE.

Cathode Pin

Cathode

Anode

Anode Pin

Cathode End Cap

Seal

Seal

Envelope

Anode End Cap

XG4/006

For use in a Gladiator IV lamphouse, it is necessary to remove the

anode lead (if attached) from the anode end cap of the xenon bulb.

Observe all bulb safety procedures and leave the bulb in its protective

cover. Grasp the bulb by the anode (+) end cap. Use small channel

locks or slip-joint pliers and grip the bulb lead tting at the crimp joint

nearest the end cap, and unscrew the lead. If the bulb manufacturer

uses a brazed rather than threaded connection, cut the lead from the

end cap, cutting as close as possible to the end cap.

The standard bulb support collet (72-00285) measures 4-11/16 inches

(120mm) overall and is designed for a 4000 watt “HS” xenon theater

bulb. Whenusinga smaller, lower wattagebulb, alongersupportcollet

(72-00638)measuring6-7/16inches(164mm)mustbeinstalledinplace

ofthestandardcollet,andachromedcathodeadapter(72-01174)must

bemounted to thebulb’scathodepin. Thesecomponentsare included

in the optional Bulb Kit 72-01175, and both should be installed before

performing the Bulb Installation procedure.

PRIOR TO INSTALLING BULB, PLEASE NOTE:

BULB INSTALLATION

OBSERVE ALL SAFETY PROCEDURES when working around the xenon bulb. Open the

lamphouse access cover by releasing the clasps and swinging the cover up to its stop. Loosen the (5) quarter-

turn fasteners and remove the two bulb compartment side covers. Verify that the lamphouse is tted with the

correct support collet appropriate to the desired bulb wattage. The bulb leads and contact clamps are tied down

for shipping. Free the clamps and slide the anode clamp over the brass socket of the rear support collet.

REMOVE THE PLASTIC PROTECTIVE COVER from the xenon bulb only if necessary.

Handle the bulb by the metal end caps only. Dismount the anode lead from the (+) end cap of the bulb if

attached. Grasp the bulb by the metal anode (+) end cap only when unscrewing the lead from the bulb; DO

NOT hold the bulb at the cathode (-) end cap when removing the anode lead.

INSERT THE BULB into the lamphouse, passing the anode (+) end cap through the center

hole of the reector. Take care not to bump or scratch the surface of the reector. Insert the anode (+) pin into

the rear support collet and contact clamp. Rest the cathode (-) end cap in the front bulb support yoke. Seat

the anode (+) pin into the rear support collet as far as possible for correct focus travel. Securely tighten the

socket head clamping screw in the anode contact.

REST THE CATHODE END CAP in the “V” of the bulb yoke. Dress the bulb lead directly in

front of the bulb support yoke to minimize the projected shadow, but do not allow it to touch grounded metal

lamphouse components; the bulb yoke and the support casting are insulated from ground. Slide the cathode

contact clamp over the cathode (-) pin and securely tighten the clamping screw.

REMOVE THE PLASTIC COVER from the bulb. Record the bulb serial number, date, and

lamphouse hours on the Xenon Bulb Record on the inside back cover of this manual. Replace the bulb enclo-

sure covers and secure the quarter-turn fasteners. Use of these covers maximizes bulb cooling for long life.

XG4/007

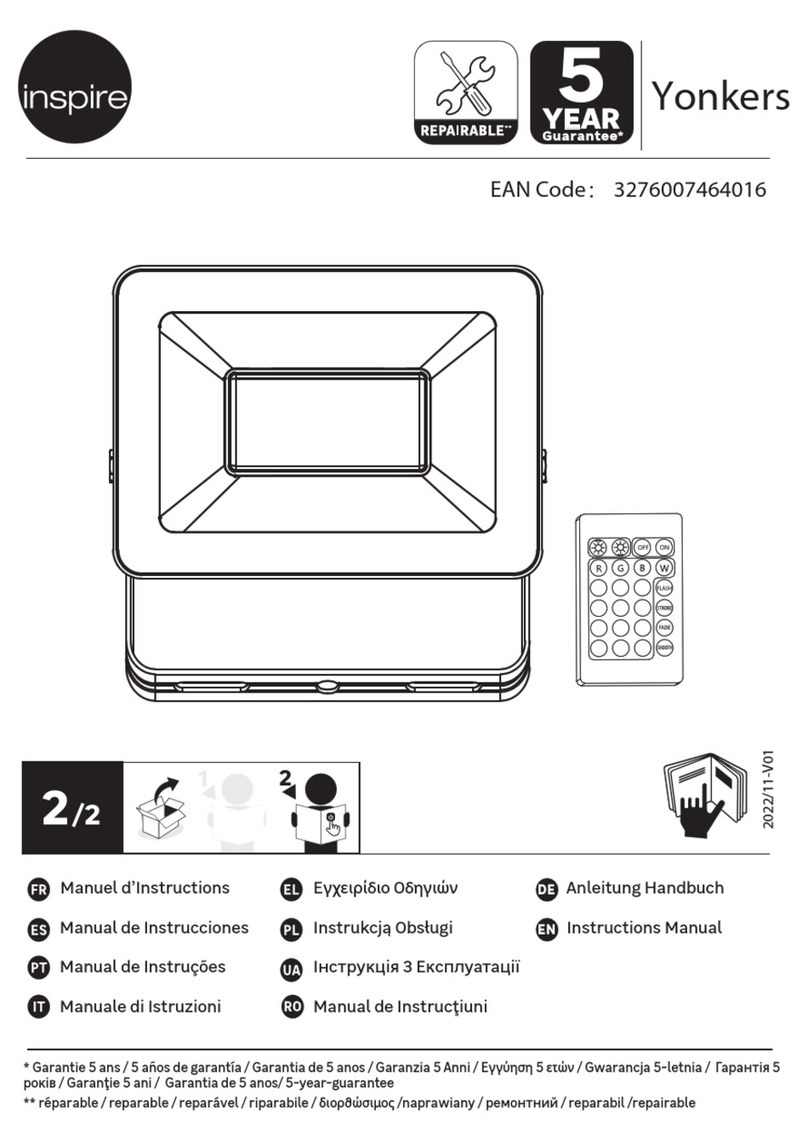

Rear Support Collet

Bulb Socket

Anode Contact Clamp

Anode

Clamping Screw

to Igniter Post

Cathode

Front Bulb Support Yoke

Set Screw

Cathode Contact Clamp

to Negative

Binding Post

Cathode Adapter

(as req’d.)*

* Cathode Adapter & longer Rear Support Collet

are included in the optional Bulb Kit 72-01175

required for 2 kW, 2.5 kW, and 3 kW bulbs.

ESTABLISH A ROUTINE of periodically checking all electrical connections for tightness.

Loose contacts, particularly in the DC circuit, will cause overheating and damage the xenon bulb and other

components. Normal xenon bulb warranties allow no credit for bulb damage caused by overheating.

REFER TO THE BULB MANUFACTURER’S INSTRUCTIONS regarding bulb rotation.

Most bulb manufacturers recommend rotating the bulb 180° at 50% of warranty hours. After rotating the bulb,

operate at maximum allowable current for several hours, and then return to the nominal operating current.

IN THE EVENT of a bulb warranty claim, the bulb must be packaged in its original shipping

container, and returned with all required warranty forms completed. Contact the dealer through whom the

bulb was originally purchased for correct procedures and Return Authorizations.

IT IS A COMMON PRACTICE to replace the bulb at the expiration of its warranty period.

If a xenon bulb explodes in operation, the reector and other lamphouse components are frequently damaged.

The xenon bulb manufacturer will extend no credit for a replacement reector if the defective bulb is beyond

warranty. Explosion-damaged reectors are to be returned to the bulb supplier, NOT Strong International,

unless the bulb was supplied by Strong.

XG4/008

ARC STABILIZATION MAGNET

THE XENON BULB used in the Gladiator IV lamphouse requires an arc stabilization mag-

net. This magnet is located below and behind the reector. The magnet is preset at the factory and should

not require adjustment. Should it become necessary to adjust the magnet, the following procedure must be

followed. Observe all bulb safety procedures when working in the lamphouse compartment.

A NORMAL ARC should appear as shown in Figure “A,” and represents the correct magnet

position. Figure “B” shows the position of the arc when the magnet is too low; Figure “C” shows the position

of the arc when the magnet is too high. Condition “B” or “C” will cause arc icker. If icker is apparent in

the projected spot, raise or lower the magnet on its slots as required to position the arc as illustrated in Figure

“A.”

THE MAGNET must always be installed with the longest portion of the magnet up-

permost (nearest the bulb), and with the NORTH (N) pole pointing toward the operator side access door.

Reversing the magnet will cause bulb icker, and may inhibit bulb ignition. In new equipment, the magnet

is normally in the center of the adjustment range. Changes in the magnet position are required only to correct

an improperly burning arc (Figure “B” or “C”).

ANY REPLACEMENT MAGNET should rst be installed in the center position of the

adjustment range. Raise or lower the magnet as required to center the arc as illustrated in Figure “A.”

OPERATION

OPEN THE BOOMERANG ACCESS COVER and verify that the round glass heat lter and

ring assembly is installed into the bracket mounted to the fadeout and douser support housing. NOTE: The

coated side of the lter, with the XX or other marking, must be facing the reector.

REMOVE THE PLASTIC COVER from the xenon bulb. DO NOT ignite the lamp with the

cover on the bulb. Store the cover for future re-use. Replace and secure the bulb enclosure covers.

CLOSE THE LAMPHOUSE COVER and secure using both latches. Turn on the main line

switch and/or circuit breaker to energize the xenon power supply. The spotlight blowers will start and operate

continuously until the xenon power supply is de-energized.

PLACE THE LAMP SWITCH in the “ON” position and the lamp will ignite. Check the

reading on the lamphouse ammeter. Nominal current for the 4500 watt xenon bulb is 135 amperes. If using

a lower wattage bulb, check the documentation packaged with the bulb for its current ratings. DO NOT, AT

ANYTIME, exceed maximum rated amperage;the “wattage” readout on the digital display is an approximate

gure and should not dictate the output setting. Outputcurrent is adjusted at the xenonpower supply; see power

supply manual for instructions. Operation of a new bulb is normally started at the lower end of its range, and

current is gradually increased as the bulb ages to maintain light output. During the ignition cycle, the display

will also briey indicate the high “no load” (open circuit) DC voltage applied to the xenon bulb for ignition.

REMOVE THE REAR COVER above the instrument panel by releasing the (3) quarter-turn

fasteners. This exposes the bulb positioning controls in the lamphouse back casting. To focus the xenon bulb

and obtain the best light on the stage, the two methods outlined below are the most suitable.

MOVE THE SPOT SIZE CONTROL HANDLE (trombone) on the large lens carriage all the

way forward to project the smallest spot possible; place the iris, masking shutters (choppers) and the fadeout

douser blades in their full open positions. Project a spot to a wall or similar at perpendicular surface opposite

the spotlight position.

XG4/009

THE CENTER SECTION of the bulb

positioning controls is a threaded member that

focuses the bulb in relation to the reector. Turning

this adjustment moves the bulb in only one plane,

into or away from the reector. Turning this section

clockwise moves the arc away from the reector.

Thesmallknurledscrewtotheleftofthissectioncan

be tightened to lock the focusing mechanism after

the following procedures have been completed.

THE LARGE THUMB SCREWS, on

either side of the focusing control, lock the

horizontal and vertical adjustment mechanism

in position.

TURN THE CENTER FOCUSING SECTION of the bulb positioning control counterclock-

wise until a small black spot is projected onto the wall. It may be best to run this adjustment both directions

to permit positive identication of the spot.

LOOSEN THE TWO THUMB SCREWS, one on either side of the center focusing section,

just enough to permit manual movement of the complete assembly. The bulb positioning control will now

move around these two thumb screws, and as this control is shifted, the smooth shadow of the bulb electrode

can be seen extending beyond the projected center hole in the reector. The shadow of the electrode (black

spot) must be centered in the projected hole of the reector (shaded, less dense dark area).

MOVE THE CONTROL SECTION around the two screws until the black spot is as round as

possible to project. It may be necessary to again turn the focus control to project a sharply dened black spot.

AFTER THE BLACK SPOT is as even around the outside as possible to project, and appears

centered in the shaded reector center hole (Spot “A”), tighten the two large thumb screws to lock the position

of the mechanism. Turn the center focus control to obtain the brightest light with the best light distribution (Spot

“B”) and continue to the defocused position (Spot “C”) to verify that the bulb is centered in the reector.

IF THE CENTER BRIGHTSPOT tracks off to the left, right, top, or bottom, it may be neces-

sary to reposition the front bulb support yoke to compensate. Loosen the set screw in the support casting and

reset the yoke as required. The hex nut may be used to lock the height of the yoke. Secure the yoke with the

set screw after the bulb tracks on a straight axis. Return the focus control to the desired Spot “B,” and rotate

the spot focus control knob, located at the extreme front of the lens mechanism, to obtain the sharpest edge

possible on the projected spot.

XG4/010

THE SECOND METHOD of focusing the xenon bulb is to project the spot to the stage, and

working with the above lamphouse controls, adjust these controls to obtain a “hot spot” on the projected spot.

Center this “hot spot” on the projected light by moving the entire control section around the two thumb screws.

Once this “hot spot” is centered in the projected light, lock the control in position with the two thumb screws

and turn the center section to obtain a spot with an even distribution of light. Rotate the lens spot focus control

knob to obtain a sharp edge on the projected spot.

THESE ADJUSTMENTS should not be disturbed until after replacing or rotating the xenon

bulb. At that time, the procedure on obtaining a smooth, round black spot, or “hot spot,” may have to be repeated.

Replace the cover plate over the bulb positioning controls and secure with the (3) quarter-turn fasteners.

BECAUSE OF NORMALBULBAGING, and manufacturing tolerances between individual

xenon bulbs, it may be necessary to operate different lamps at slightly higher or lower current settings to

achieve balanced, uniform light output when two or more spotlights are used in one installation. This entails

a slight current output adjustment at the xenon power supplies. See the power supply manual.

XG4/011

TO EXTINGUISH the arc, place the LAMP switch on the instrument panel to “OFF.” The

lamphouse blowers will continue to operate until the xenon power supply is de-energized. Allow the blowers

to operate for ten minutes before turning off the power supply; a forced-air bulb cooling cycle at shutdown is

required by all bulb manufacturers to comply with their warranty terms.

BEFORE OPENING the lamphouse enclosure for servicing, allow the blowers to operate for

twenty minutes, or until the bulb has cooled to room temperature.

HANDLING THE SPOTLIGHT

GENERALLY THE BEST POSITION for the operator to stand is near the center of the spot-

light on the right side. The angle of tilt, the size of the porthole, and the layout of the spotlight position may

dictate another location.

EACH OPERATOR will, after a few minutes of operation, generally develop his own system

and position for most convenient operation.

THE HORIZONTAL SWING and vertical tilt are individually adjustable to give the desired

degree of friction to suit the operator. The locking clamps are located on the right side of the yoke assembly.

AN EXPERIENCED OPERATOR will usually keep one hand on the spot size control handle.

This allows both directing the spot and changing spot sizes immediately upon cue. Compressing the brake

lever permits free movement of the large lens forward and back, and releasing the lever locks the spot size at

the desired point of travel.

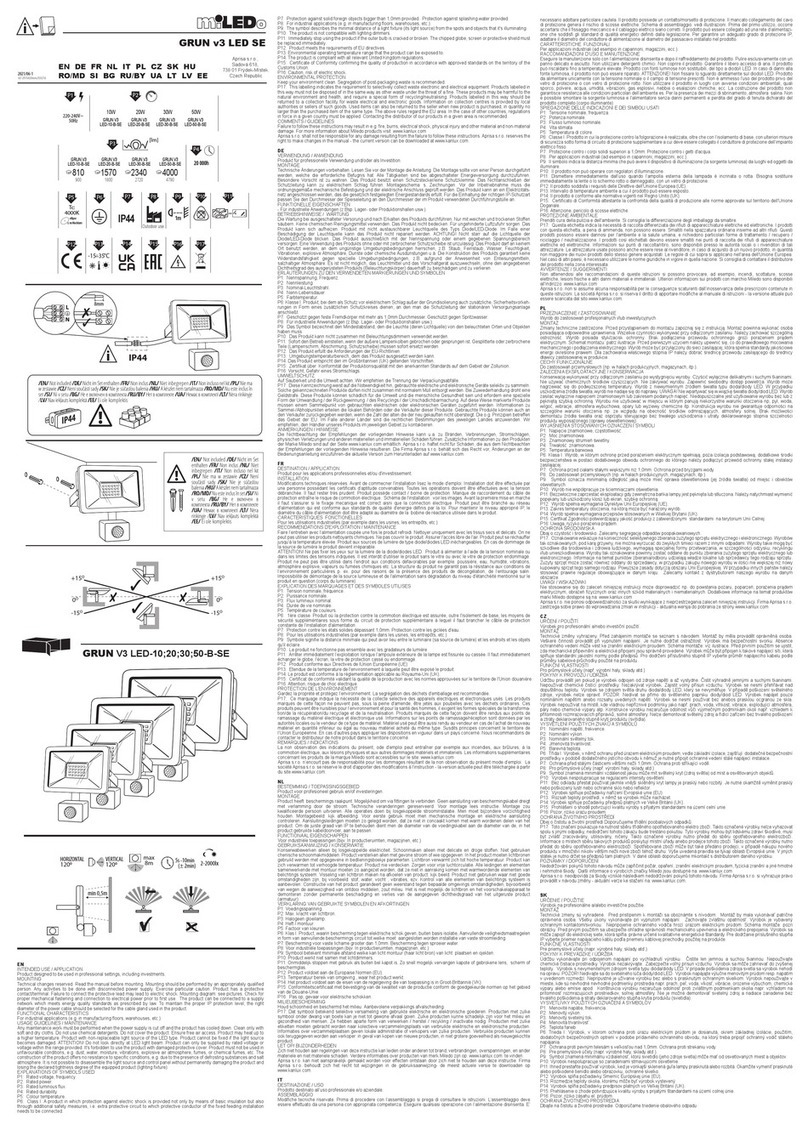

Large Lens

Spot Size Control Handle

Brake Lever

OPERATION OF OPTICAL SYSTEM

THE IRIS CONTROL is the front lever which projects through the top of the optical system

housing. When this lever is to the left (as viewed from the rear of the unit), the largest aperture is provided.

Smaller apertures are obtained as the lever is moved to the left.

THE MAXIMUM FLOOD SPOT is obtained with the iris control lever to the right (near the op-

erating side) for the largest aperture and with the spot size control handle moved as far to the rear as possible.

SMALLER SIZED SPOTS are projected as the spot size control handle is moved forward.

Most of the spot sizes needed will be produced with the iris in its maximum open position.

FOR A “HEAD SPOT,” or any spot smaller than can be obtained with the spot size control

handle in its extreme forward position, shift the iris control lever to the left (away from operating side) for a

smaller aperture. The iris control lever should always be returned to its extreme right position before the spot

size control handle is again moved to obtain larger spots.

THE MASKING SHUTTER (chopper) lever is the middle lever projecting through the top of

the optical system housing. The masking shutter blades are operated by this lever to shape the projected spot

to a rectangle, strip spot, or dousing.

THE DISENGAGED POSITION of the masking shutter lever is to the extreme right (toward

operating side) and varying degrees of masking to complete cutoff are obtained by moving the lever to the left

(away from operating side). If dousing the spot for a prolonged period with the bulb operating, it is highly

recommended to use the Fadeout dousers (below) to prevent heat damage to the masking shutter blades.

THEANGLE of the masking shutter blades can be adjusted to compensate for the horizontal

projection angle. Remove the color arm cover plate and dismount the boomerang. Loosen the (4) screws

holding each of the masking shutter blades enough to allow adjustments. Ignite the bulb and adjust the angle

of the bottom blade by tapping with a screwdriver so its projected edge lies parallel to the footlights. Tighten

the screw. Operate the masking shutter lever to close the blades. Adjust the upper blade to close in line with

the bottom blade and tighten the screw.

THE FADEOUT MECHANISM AND DOUSER CONTROL is the rear lever projecting

through the top of the optical system cover. This lever controls the intensity of light from complete fadeout

when the lever is to the left, to full intensity when the lever is to the right.

THE SPOT SIZE CONTROLHANDLE is located on the right hand side of the optical system

just above the base rail. A variation of spot sizes from full ood to small spot can be obtained by moving the

spot size control handle from one extreme to the other. Beam intensity is increased by this optical system

when reducing from ood to spot, and maximum intensity is reached when the spot size control handle is in

the extreme forward position. Compressing the brake lever forward of the handle permits free movement.

THE SPOT FOCUSING CONTROL KNOB is located on the operating side of the optical

system at the forward end above the base rail. This control is used to adjust the optical system for the length of

throw. When making an adjustment, rotate the spot focusing control knob until the sharpest edge is obtained

on the projected spot.

XG4/012

OPERATION OF COLOR BOOMERANG

THE COLOR BOOMERANG supplied with the Gladiator IV is selected when rst ordering

the spotlight from the factory. The Type 72-00264 boomerang is mounted within the optical system and uses

(6) 50mm dichroic discs as the color media. Type 72-00709 mounts to the front of the lens barrel and uses

conventional high-temperature color gels (i.e. Roscolux®) as color media.

EACH BOOMERANG is equipped with six color arms. A “starter” set of six 50mm dichroic

color discs, or six sheets of commonly-used color gel, is included. Additional colors, including color tem-

perature reduction lters, are available from most theatrical supply dealers.

COLOR FILTERS are controlled by the six color levers of the boomerang. To engage an

individual color lter, lower the desired lter selector lever. A rocker catch located in the color disc housing

holds the lter in the light beam. To release a color, lower the lter release lever or engage another color, thus

releasing the previous color automatically.

TO REPLACE A COLOR FILTER in the 72-00264 boomerang (see Parts List, Figure 5A), it

is recommended to dismount the entire assembly from the optical system and place it on a convenient working

surface. Loosen the (2) quarter-turn fasteners and remove the side cover plate. The entire boomerang assembly

can then be easily removed by loosening the single captive screw securing the boomerang bracket to the base

rail, and lifting the bracket off the (2) locating pins. When re-installing the boomerang, align the holes in the

boomerang base plate onto these pins before again securing the captive screw.

TO ATTACH A COLOR GEL to the color frame of the front-mounted 72-00709 boomerang

(see Parts List, Figure 5B), spray the at surface of the ring (without the channel clip) with an aerosol adhesive.

Center the ring over a precut 13½ by 13½ inch (34 x 34cm) gel, and press the adhesive-coated side onto the

gel. Trim the excess gel material and install the ring into the boomerang. Old gels can be removed from the

color frame by scraping the gel and adhesive from the frame using a single-edge razor blade.

NOTE: WHEN INSTALLING COLOR FILTERS in either boomerang, the less dense colors

(pink, amber) should be placed in the holders toward the rear of the boomerang (close to the arc), and those

of greater density (red, green) should be placed in the holders toward the front of the boomerang (away from

the arc). This measure will prolong the useful life of the lters.

XG4/013

XG4/014

DIGITAL DISPLAY

UPON ENERGIZING the LAMP circuit, the backlighting will illuminate the LCD screen.

The display CHECK TOP COVER will appear if the top cover if not secured. When the lamphouse access

cover is closed and correctly secured, and the blowers are operating, the display will appear as shown:

000V 000A 0000W

1234BLB 12345HR *

FOR PURPOSES OF ILLUSTRATION, the above display indicates a non-operating bulb

with 1,234 hours of use installed into a spotlight with 12,345 hours of operation. The asterisk (*) at the end

of the second line, when ashing, indicates that the display is active and awaiting input. Upon bulb ignition,

the upper line will display the arc voltage (V), the DC current (A), and the operating wattage (W) of the bulb.

The “wattage” readout on the digital display is an approximate gure and should not dictate the DC output

setting. The gures will shift for the rst few moments of bulb operation, but will stabilize after the bulb

reaches normal operating temperature and pressure. A plus sign (+) will replace the asterisk.

CLOSURE OF THE LAMPSWITCH will energize the contactor of the xenon power supply.

The high open circuit (“no load”) DC voltage will be displayed. When the open circuit voltage reaches 140

V.DC, the igniter will generate a RF pulse to bridge the gap between the bulb electrodes. This pulse, coupled

with the high open circuit DC voltage, will ignite the bulb. The voltage reading (V) will then fall to the bulb’s

sustaining level, and the DC amperes (A) and wattage (W) will be displayed continuously until the bulb is

extinguished.

ELAPSED HOURS will begin counting upon bulb ignition. Bulb hours (BLB) are limited to

four digits, and must be re-set when the xenon bulb is replaced. To re-set bulb hours, press the RESET button

accessible through marked hole below the LCD screen. The 5/64” allen wrench supplied with the accessory

kit is the correct diameter to clear the hole.

NOTE: WHEN RECORDING start-up and removal hours on the Xenon Bulb Record, use

the total elapsed hours (HR) gures. The (BLB) gure, re-set upon installation of the bulb, is a convenience

feature ONLY. Basing records of the lamp system on the total hours (HR) gures permits an accurate and

ongoing history of bulb usage.

IF THE XENON BULB fails to ignite, the following diagnostic messages will display on the

lower line of the LCD screen:

CHECK PWR SUPPLY: If no DC current is sensed, and voltage does not exceed 125 V.DC, check the xenon

power supply. Repair or replace as required.

CHECK IGNITER: If the DC open circuit voltage reaches and exceeds 140 V.DC and the igniter fails

to pulse, replace the igniter.

CHECK XENON BULB: Check the DC cables connected to the bulb. If the high voltage is shorting to

ground, and not arcing between the bulb electrodes, locate and correct (insulate)

the short circuit. If the high voltage arc appears between the bulb electrodes, and

the bulb fails to ignite, replace the bulb.

XG4/015

DIAGNOSTIC MESSAGES serve as prompts and suggestions but do not replace traditional

troubleshooting procedures. If the top cover is closed and secured but transmits an error message, check the

subject cover interlock switch with an ohmmeter and replace if defective. Dirt or dust fouling an air vane

switch will cause a “blower” error message. A “power supply” or “igniter” error message might be caused by

a loose or oxidized connection.

XG4/016

MAINTENANCE

THE XENON GLADIATOR IV SPOTLIGHT requires very little maintenance to keep it in

good working order.

THE REFLECTOR should be cleaned periodically with a soft, clean, lint-free cloth to re-

move dust from the reecting surface. If excessively soiled, the reector may be cleaned with Windex®or an

equivalent glass cleaner. DO NOT use abrasive cleaners of any kind. Clean the heat lter glass; replace with

the coated surface toward the lamphouse.

CHECK ALL ELECTRICAL CONNECTIONS for tightness on a regular basis. Loose connec-

tions, particularly in the DC circuit, may cause premature bulb failure and damage lamphouse components.

LUBRICATE the (3) squirrelcage blower motors with two or three drops of non-detergent oil

once every six months.

THE XENON BULB should be checked occasionally for the presence of dust or foreign

materials on the quartz envelope. If necessary, clean the envelope with alcohol, and wipe dry with a clean,

lint-free cloth. Observe all safety procedures when working with the exposed bulb.

THE INSIDE OF THE LAMPHOUSE and the blower squirrelcages should be cleaned peri-

odically, depending on the dust conditions at each installation. Keep the blower inlet and outlet grilles clean

to permit free air ow.

THE LENS SYSTEM should be kept clean to prevent any light reduction in the projected

spot. Tighten the horizontal swing and vertical tilt locking clamps. Remove the operator-side optical system

access panel to clean the back surface of the large lens and access the small projection lens which is held in

place with a large spring-type retainer ring at the front of its lens barrel.

CLEAN THE PROJECTION LENS and large lens with with any cleaner approved for use

on coated projection lenses. Replace the Buhl projection lens with the end with the FL marking ring toward

the iris; the ISCO lens tube has arrows indicating the end nearest the iris. Secure with the retainer ring.

BEFORETRANSPORTING the spotlight, remove the xenon bulb from the lamphouse. Place

the bulb in its plastic cover and original shipping container.

CAUTION: DISCONNECTAC POWER BEFORE SERVICING

LAMPHOUSE WIRING DIAGRAM

Barrier Strip 21-62012

(see Figure 3, Item 44)

XG4/017

XG4/018

WIRING DIAGRAM PARTS LIST

Part No. Description

72-00280 Blower, 230 V.AC, 50/60 Hz. (B1,B2,B3)

72-00255 Capacitor, RF Suppression (C1)

81247000 Shunt (R1), 200 A. 50 mV.

24086000 Rocker Switch, ON/OFF

72-00253 Transformer (X1)

39862000 Igniter Assembly

24275000 Printed Circuit Board Assembly, Voltage Divider (mounts to R1)

25098000 Digital Display Assembly (see Figure 3, Item 45)

23976S00 Printed Circuit Board Assembly, Digital Display Control

25044000 LCD Display Screen

31-30231 Xenon Bulb, LTIX-4500W-HS

72-00251 Interconnect Cable Assembly, Lamphouse/Power Supply (see Figure 8)

72-00252 Terminal Board & Molex Wired Assembly

21-62012 Barrier Strip, (10) Terminal

Table of contents

Other Strong International Spotlight manuals

Strong International

Strong International XENON GLADIATOR III User manual

Strong International

Strong International TrussTrouper 1.2 User manual

Strong International

Strong International FOLLOW SPOTLIGHT 48057 User manual

Strong International

Strong International SUPER TROUPER II User manual

Strong International

Strong International RADIANCE 72-00800 User manual

Strong International

Strong International SUPER TROUPER II User manual

Strong International

Strong International SUPER TROUPER II User manual