Page 3 of 22

Table of Contents

Intended Use .......................................................................................................................................... 4

Technical Specifications ...................................................................................................................... 4

Important Safety Information ............................................................................................................... 5

Specific Operation Warnings ............................................................................................................... 6

Grounding .............................................................................................................................................. 7

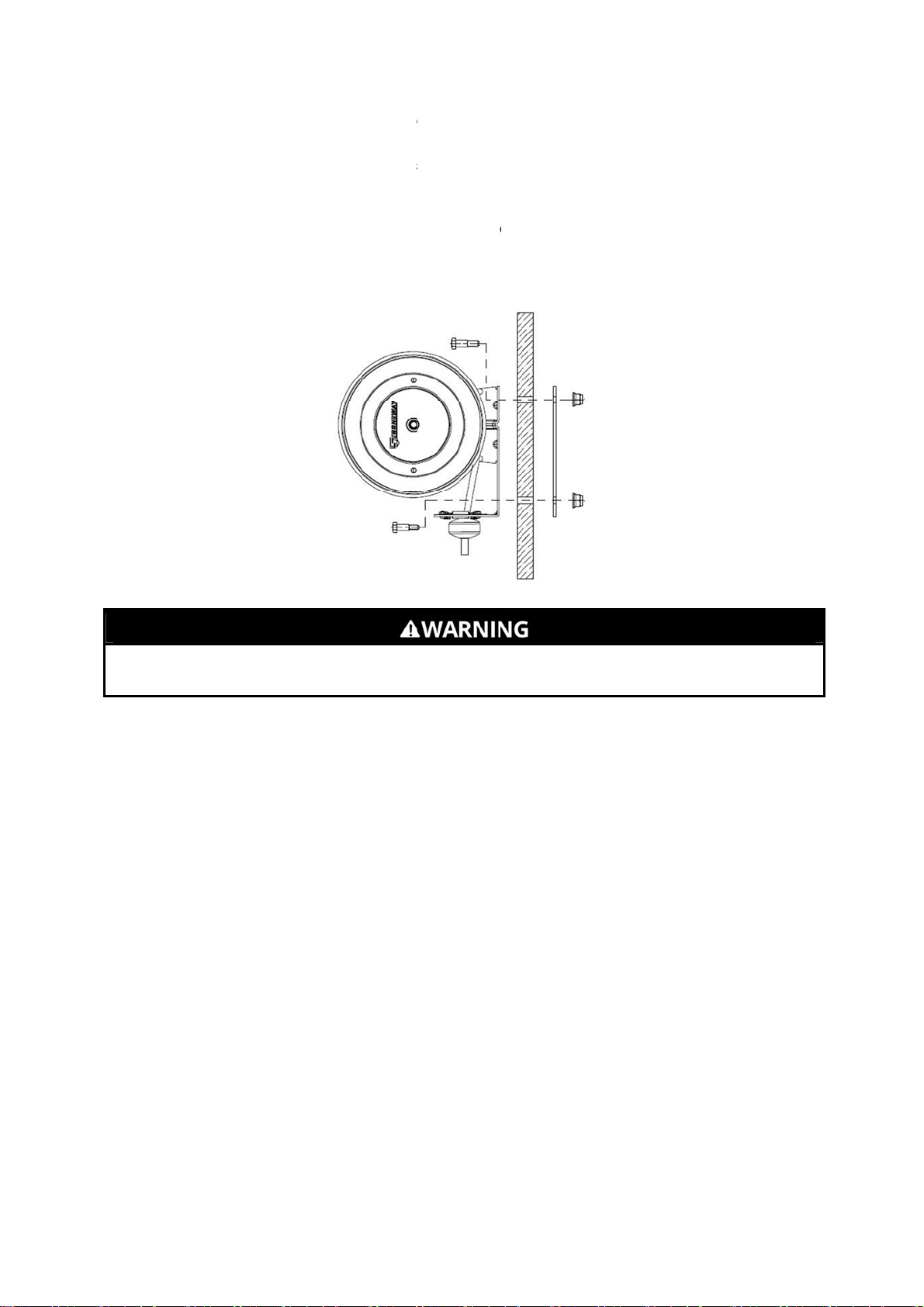

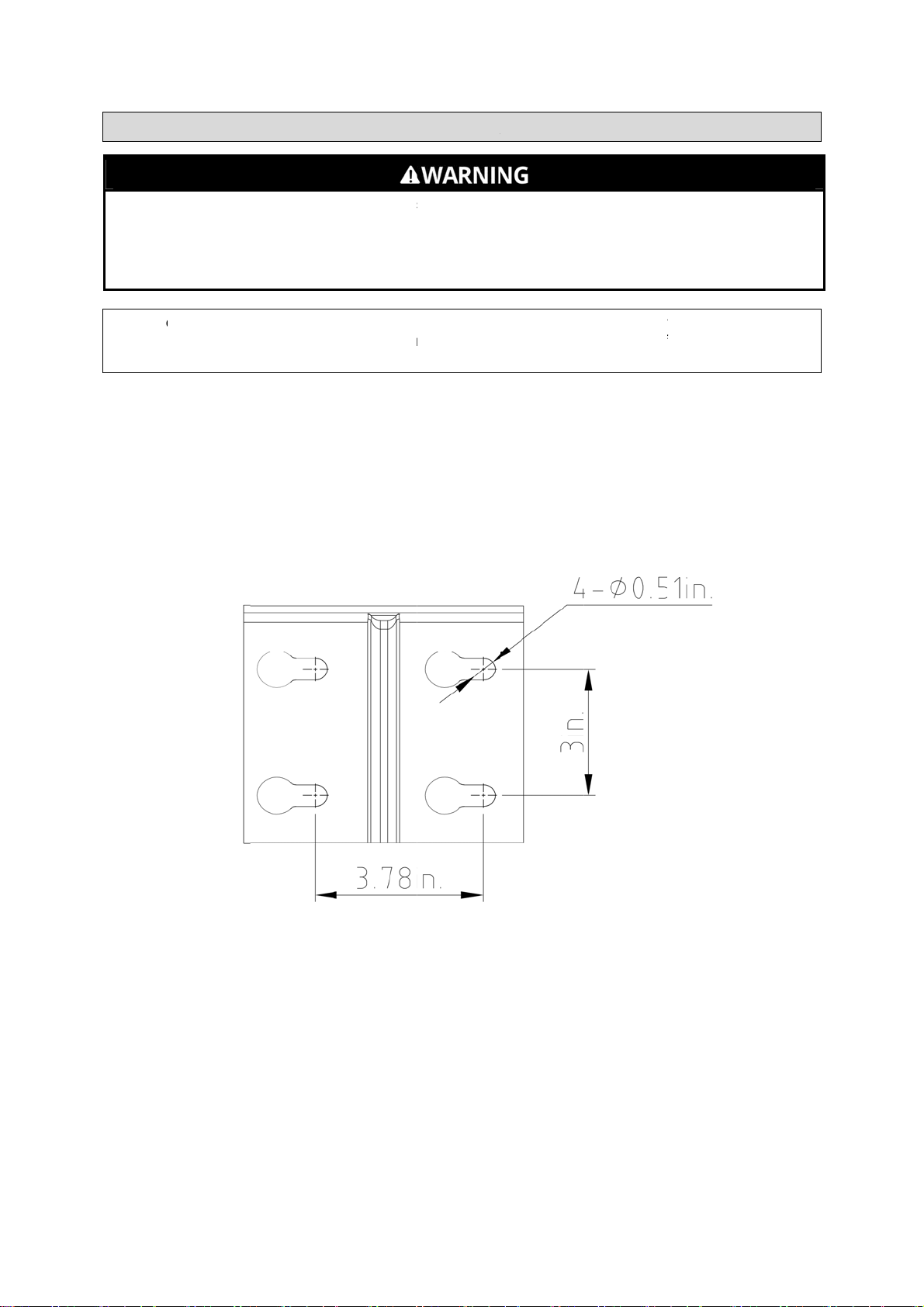

Assembly – 49581 ................................................................................................................................. 8

Assembly – 49582 & 49583................................................................................................................. 10

Before Each Use .................................................................................................................................. 12

Operating Instructions ........................................................................................................................ 13

Spring Tension Adjustment ............................................................................................................ 14

AfterEach Use ...................................................................................................................................... 14

Maintenance ........................................................................................................................................ 15

Parts Diagram – 49581 ........................................................................................................................ 16

Parts List – 49581 ................................................................................................................................ 17

Parts Diagram – 49582 & 49583 ......................................................................................................... 18

Parts List – 49582 & 49583 ................................................................................................................. 19

Troubleshooting .................................................................................................................................. 20

Replacement Parts .............................................................................................................................. 20

Limited Warranty ................................................................................................................................. 21