Struers AbraPol-10 User manual

Manual No.: 15097001

Date of Release 15.06.2005

AbraPol-10

Instruction Manual

AbraPol-10

Instruction Manual

Table of Contents Page

User’s Guide ..............................................................1

Reference Guide.......................................................31

Quick Reference Guide............................................63

A

lways state Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the Date

and Article No of the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals: Struers Instruction Manual may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals: Struers Service Manual may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to changes without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

The contents of this manual is the property of Struers. Reproduction of any part of this manual without the

written permission of Struers is not allowed.

A

ll rights reserved. © Struers 2005.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

AbraPol-10

Instruction Manual

AbraPol-10

Safety Precaution Sheet

To be read carefully

before use

1. The operator should be fully aware of the use of the machine according

to the instruction manual.

2. The machine must be installed in compliance with local safety

regulations.

3. The machine must be placed on a safe and stable support. The

machine must be leveled by means of the adjustable legs.

4. The machine must be placed in an adequate working position.

5. Make sure that the actual voltage corresponds to the voltage stated on

the side of the machine. The machine must be earthed.

6. Make sure that the water connections are without leaks. The main

water supply should be turned off if you leave the machine unattended.

7. The machine must be disconnected from the mains prior to any service.

8. Make sure that the specimens in the specimen holder are securely

fixed when operating.

9. Alcohol based consumables: follow the current safety rules for

handling, mixing, filling, emptying and disposal of the

alcohol-based liquids.

Struers recommend the use of an external exhaust system.

10. Observe the current safety regulations for handling, mixing, filling,

emptying and disposal of the additive for cooling fluid.

11. To achieve maximum safety and lifetime of the machine, use only

original Struers consumables.

AbraPol-10

Instruction Manual

12. Ensure that the splash ring is in place when operating.

13. Keep clear of the preparation disc when operating.

14. If you observe malfunctions or hear unusual noises - stop the machine

and call technical service.

15. Make sure that the screws for the specimen holder have the right

length and do not protrude.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.).

AbraPol-10

Instruction Manual

1

User’s Guide

Table of Contents Page

1. Getting Started

Checking the Contents of the Packing Box ..................................... 3

Recirculation Cooling Unit TRECI (accessory)........................ 3

Additional Dosing Unit ABTDO (accessory) ............................ 3

Placing AbraPol-10 ........................................................................... 3

Getting Acquainted with AbraPol-10 ..............................................4

Front of AbraPol-10................................................................... 4

Supplying Power ............................................................................... 5

Direction of Rotation ................................................................. 5

Supplying Compressed Air............................................................... 6

Connection to an External Exhaust System ................................... 6

Mounting a Recirculation Cooling Unit (accessory)........................ 7

Placing Bottles in the Dosing Unit .................................................. 8

Mounting an Additional Dosing Unit (accessory) ........................... 8

Mounting the Outlet Kit (accessory).............................................. 10

Mounting the Water Supply Kit (accessory) ................................. 12

Mounting the Disc Cooling Kit (accessory).................................... 13

Mounting the Stock Removal Sensor (accessory).......................... 14

Mounting the Water Level Sensor (accessory)..............................15

2. Operation

Front Panel ..................................................................................... 16

Front Panel Controls ...................................................................... 17

Software Settings............................................................................ 18

Setting the Language .............................................................. 19

Setup Bottle Configuration ..................................................... 20

Reading the Display ....................................................................... 22

Sleep Mode............................................................................... 22

Changing/Editing Values ............................................................... 23

Numeric Values ....................................................................... 23

Alphanumeric Values .............................................................. 24

Programming a Preparation Step.................................................. 25

Mounting a Preparation Disc (300 or 350 mm)............................. 25

Inserting the Specimen Holder ...................................................... 25

Adjusting the Specimen Holder Position....................................... 25

Starting the Preparation Process (Struers Method)..................... 25

Stopping the Preparation Process.................................................. 26

AbraPol-10

Instruction Manual

2

Manual Functions........................................................................... 26

When Grinding with Water ....................................................26

When Grinding/Polishing with Lubricant.............................. 26

3. Maintenance

Weekly............................................................................................. 27

Coolant ..................................................................................... 27

General Cleaning............................................................................ 27

Cooling Tank............................................................................ 27

Painted Surfaces...................................................................... 27

Cleaning of Tubes.................................................................... 28

AbraPol-10

Instruction Manual

3

1. Getting Started

In the packing box you should find the following parts:

1 AbraPol-10 complete

1 Splash ring

1 Drain angle, 900

1 Pipe angle connection ø50

1 Pipe angle connection ø32

1 Hose for compressed air

3 Hose clamps

1 Allen key 4 mm

2Bottles,½ l

2 Bottle lids

1Bottle,1 l

1 Set of Instruction Manuals

1 TRECI complete

1 Drain angle, 450

1 Funnel

2Disposable plastic inserts

Three additional pumps for dosing of OP-Suspension, lubricants

and suspensions.

AbraPol-10 should be placed on a plane and horizontal floor. The

machine must be placed close to the power supply, compressed

air, water mains and water outlet facilities.

Checking the Contents of the

Packing Box

Recirculation Cooling Unit

TRECI (accessory)

A

dditional Dosing Unit ABTDO

(accessory)

Placing AbraPol-10

AbraPol-10

Instruction Manual

4

Take a moment to familiarise yourself with the location and

names of the AbraPol-10 components.

Specimen holder motor Turn/push button

DisplayHandle for adjusting

specimen holder position Front panel keys

Quick coupling Nozzle block

Double start buttons Emergency stop

Bottle unit

Getting Acquainted with

AbraPol-10

Front of AbraPol-10

AbraPol-10

Instruction Manual

5

Remove the 4 Allen screws, on the right hand side of the

machine, securing the electrical panel, and let the electrical

panel rest on the two tabs.

Lead the cable through the relief angle and connect the 3

phases and earth according to local regulations.

In case of an external Recirculation Cooling Unit, connect the

electrical cable from the pump, according to the diagram

inside the panel.

The preparation disc should rotate counter-clockwise.

If the direction of rotation is clockwise, switch off AbraPol-10 and

unplug the machine.

Change two of the phases.

Repeat the rotation check.

Supplying Power

IMPORTANT

Check that the mains voltage corresponds to the voltage stated on the type

plate on the side of the machine.

Direction of Rotation

A

llen screws

AbraPol-10

Instruction Manual

6

Connect the compressed air supply with the inlet on the rear,

left side of the machine by means of the air hose and the hose

connection delivered with the machine.

Fasten the air hose with a hose clamp.

The pressure supply should be 6-10 bar and should be supplied

either from a central compressor, portable compressor with

compressed air reservoir or compressed-air bottle. A capacity of 20

l/min at atmospheric pressure is sufficient.

Please refer to the section on Technical Data for recommended air

quality.

An exhaust system can be connected when using alcohol based

suspensions or lubricants.

Slot the 50 mm pipe angle connection into the hole on the left

hand side of the splash guard and connect to the exhaust system.

Recommended capacity for exhaust system: 180m3/h at 0mm

water gauge.

Supplying Compressed Air

Connection to an External

Exhaust System

AbraPol-10

Instruction Manual

7

Place the unit where you find it convenient, either inside the

machine or outside, on the left.

Connect the inlet hose from the dosing arm to the pump of the

Recirculation Cooling Unit and tighten the clamp.

(If the cooling unit is placed outside the machine, pass the

hose under the cabinet).

Lead the electrical cable into the electrical panel and connect

to the terminal points.

(If the cooling unit is placed outside, lead through the angle

on the panel).

Slot the 900 drain angle into the pipe in the top of the

reservoir lid. (Note: The 450elbow pipe delivered with the

Recirculation Cooling Unit is not used with this machine).

Cut the drain hose to an appropriate length, and twist it into

the hole located on top of the unit.

(If the cooling unit is placed outside, lead the drain hose

through the hole on the rear left of the machine).

Check that there is a steady fall on the whole course of the

outlet hose.

Check that when the power is turned on, the pump rotates in

the direction indicated by an arrow on the top of the pump. If

not, change two of the phases on the pump motor cable.

Replace the panel/ back plate.

Place a disposable plastic insert in the tank and fold it over

the rim.

Fill the tank with 29.1 l water and 900 ml Struers Additive

for Cooling Fluid.

The water level should be 8-10 cm below the upper rim of the

tank.

Fit the tank lid and sieve.

Replace the front cover.

Mounting a Recirculation

Cooling Unit (accessory)

Warning

Disconnect the machine from the mains power supply before connecting or

disconnecting the recirculation pump.

Note!

The Recirculation Cooling Unit cannot be positioned outside the machine

when an outlet kit (ABTDR) is also used.

IMPORTANT

Too high a level of coolant in the tank might damage the pump. To avoid

this, place the disposable insert so that the pre-punched hole is in front of

the overflow aperture in the tank.

Always maintain the correct concentration of Struers Additive in the cooling

water (percentage stated on the Additive container).

Remember to top up with Struers Additive each time you refill with water.

Inlet hose 90

0

drain angle

AbraPol-10

Instruction Manual

8

Place the filled bottles in the dosing unit and connect the

tubing.

Enter the bottle details in the Bottle Configuration menu to

make them available for preparation methods. See “Setup

Bottle Configuration”.

The tubes can easily go through the bottle unit to reach larger

containers placed on the floor e.g. Lubricants.

Disconnect main power.

Open the doors to the bottle unit.

Remove the rectangular cover plate with the 4 mm Allen

key supplied.

Remove the cover plate located on the left side of the machine

with the supplied 4 mm Allen key supplied, and loosen the

plug.

Lead the reinforced water hose from the hole on the left,

through the hole in the reinforcement beam on the inside of

the bottle unit, and through the rectangular hole in the dosing

unit.

Connect the hose to the additional dosing unit, and tighten

the clamp.

Place the ½" - ¾" fitting in the hole ( ¾" on outside) and

tighten the ½" nut.

Connect the reinforced hose to the ½" thread.

Placing Bottles in the

Dosing Unit

Nb!

OP-X can not be placed on the floor.

Mounting an Additional Dosing

Unit (accessory)

ABTDO

plug

AbraPol-10

Instruction Manual

9

Connect the plug on the additional dosing unit to the plug

located in the bottom of the dosing unit.

Replace the two cover plates.

Connect the white water hose to the ¾" thread.

Mount the straight end of the pressure hose onto the water

inlet tube on the back of AbraPol-10:

− Insert the filter gasket in the coupling nut with the flat

side against the pressure hose.

− Tighten the coupling nut completely.

Mount the other end of the pressure hose on the water mains

tap for cold water:

− Mount the reduction ring with gasket on the water mains

tap, if necessary.

− Introduce the gasket and tighten the coupling nut

completely.

Connect the silicone tubes to the inlets/outlets of the dosing

pumps.

Check that the reinforced hose does not interfere with the

belts.

Reconnect main power and allocate the bottles.

NB

Remember the earth connections.

NB

OP-X suspension can only be used in bottle 4.

AbraPol-10

Instruction Manual

10

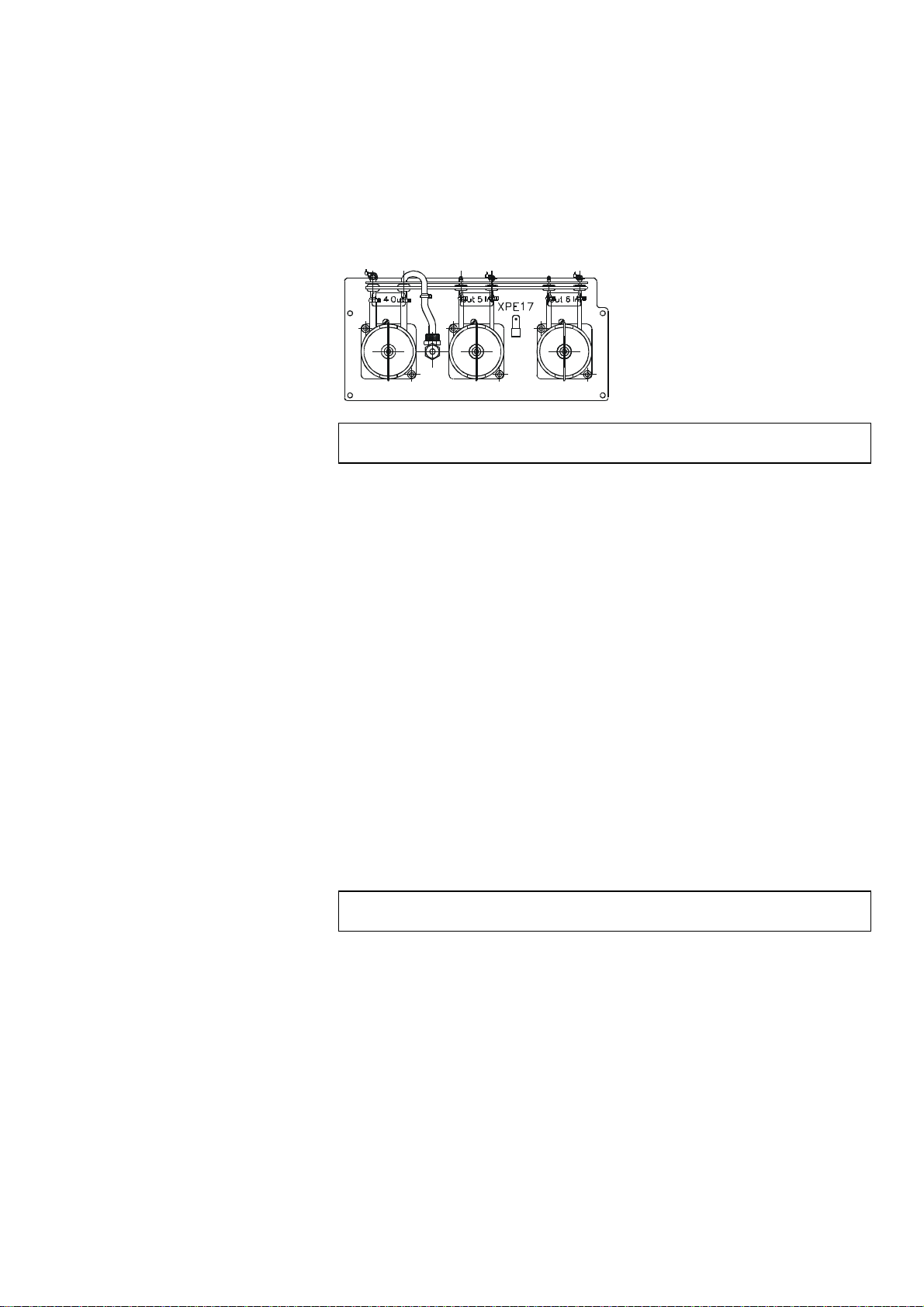

Disconnect main power.

Remove the lower front cover plate.

Remove the Recirculation Cooling Unit, if there is one.

Take the entire unit, and place it in position by letting the two

Allen bolts slide into the slots located in the left rear side.

Tighten the Allen bolts.

A

B

C

Strip the steel spring from approx. 3 cm of the drain hose and

cut. Bend the cut end of the steel spring inwards towards the

centre of the hose. Mount the drain hose onto pipe Aand

clamp the stripped section using a hose clamp.

Take another piece of drain hose and check that it is long

enough to reach the Recirculation Cooling Unit. Mount onto

pipe B. (Strip some steel spring from the hose and secure the

hose as described earlier).

Connect to the Recirculation Cooling Unit.

Connect a piece of drain hose from the outlet at the rear (C)

and lead to the drain.

Reposition the Recirculation Cooling Unit.

Make sure that the hoses do not interfere with the belts.

Mounting the Outlet Kit

(accessory)

ABTDR

Lead outlet hose

to the drain

Connect to

Recirculation Cooling Unit

Connect to

drain hose

Stripped

hose Pipe

AbraPol-10

Instruction Manual

11

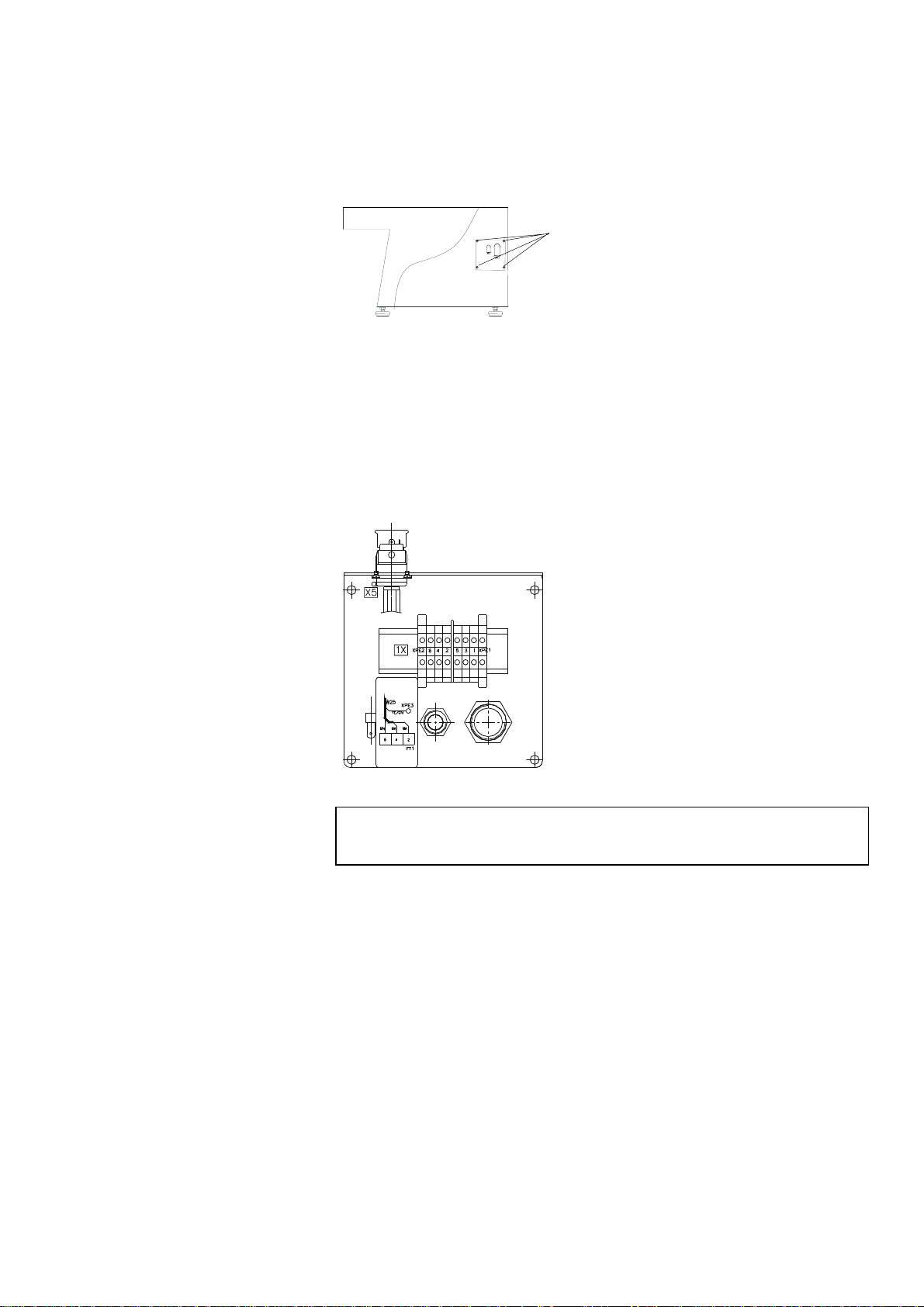

Locate the electrical cable for the air solenoid valve (located

on the inner left side of the machine) and remove the cap

covering the stripped wires.

Open the cover of the DIN terminal by removing the screw

and connect the wires to the terminals.

Replace the cover for the DIN terminal.

Find the air supply hose and cut off the plug (stopper). Fix the

cut end into the air supply inlet.

Replace the front cover and reconnect main power.

Note:

It is not important to which terminal the wires are connected,

each wire can be connected to either terminal.

Air supply inlet

Air supply hose

DIN terminal

Screw

AbraPol-10

Instruction Manual

12

Disconnect main power.

Remove the lower front cover plate.

Remove the cover plate located on the left side of the machine

with the supplied Allen key, and break loose the plug.

Mount the water solenoid valve with the supplied Allen bolts

and key according to the type plate.

Connect the two blades (cable W23) to the solenoid.

Connect the reinforced hose from the doser arm to the hose

nipple, and tighten the clamp.

Be careful that the hose does not interfere with the belts.

Remount the cover plate.

Connect the white hose to the solenoid valve.

Mount the straight end of the pressure hose onto the water

inlet tube on the back of AbraPol-10:

− Insert the filter gasket in the coupling nut with the flat

side against the pressure hose.

− Tighten the coupling nut completely.

Mount the other end of the pressure hose on the water mains

tap for cold water:

− Mount the reduction ring with gasket on the water mains

tap, if necessary.

− Introduce the gasket and tighten the coupling nut

completely.

Replace the front cover and reconnect the main power.

Mounting the Water Supply Kit

(accessory)

ABWAT

Blades

Hose nipple

Cable

W23

AbraPol-10

Instruction Manual

13

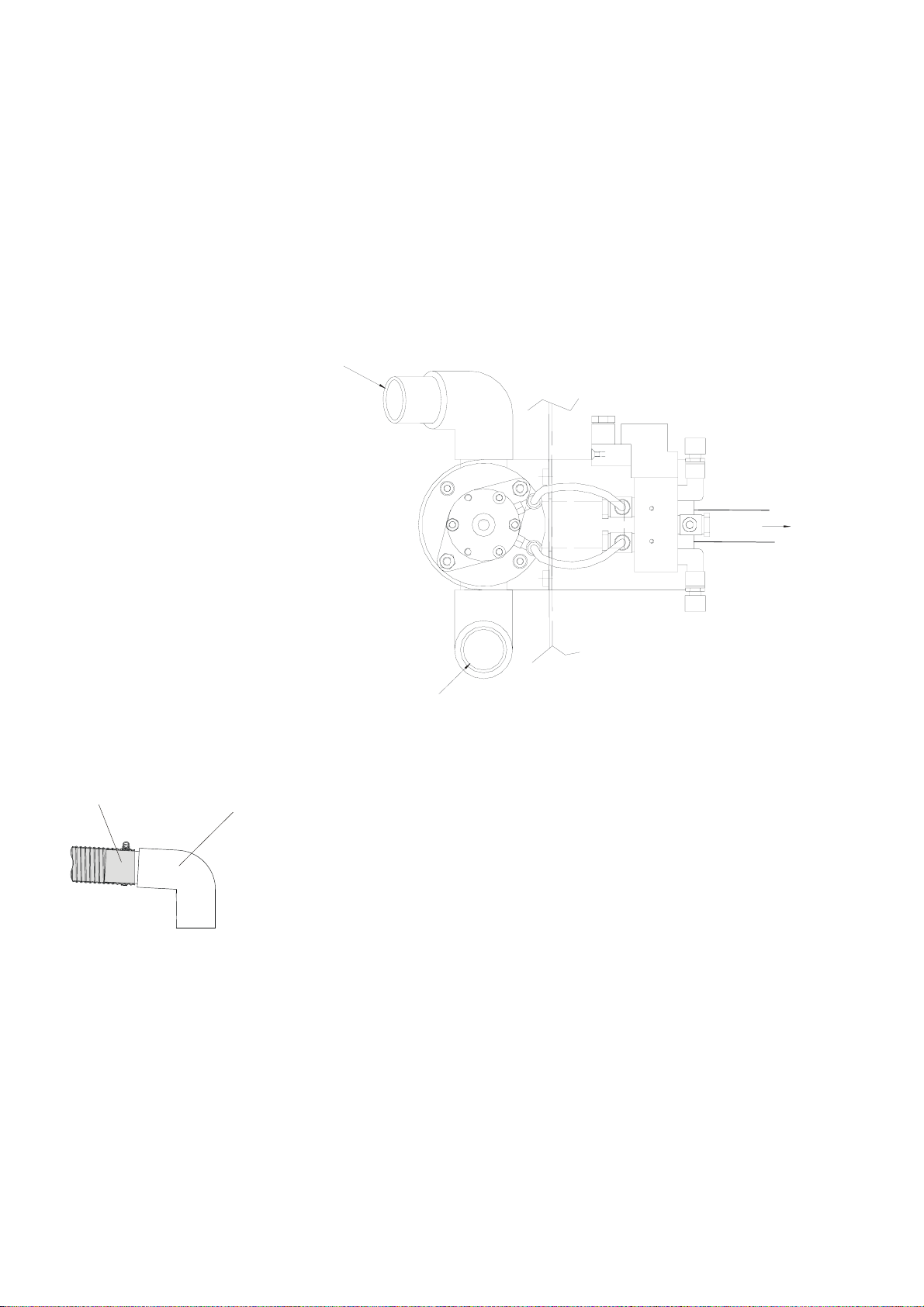

Disconnect main power.

Remove the lower front cover plate.

Remove the cover plate located on the left side of the machine

with the supplied Allen key, and break loose the plug.

Mount the water solenoid valve and the throttle valve with

the Allen bolts supplied.

Connect the two blades (cable W24) to the solenoid.

Cooling is factory installed; simply connect the grey hose (ø4)

from the nozzle to the single banjo located on the throttle

valve.

Remount the cover plate.

Connect the white hose to the solenoid valve.

Mount the straight end of the pressure hose onto the water

inlet tube on the back of AbraPol-10:

− Insert the filter gasket in the coupling nut with the flat

side against the pressure hose.

− Tighten the coupling nut completely.

Mount the other end of the pressure hose on the water mains

tap for cold water:

− Mount the reduction ring with gasket on the water mains

tap, if necessary.

− Introduce the gasket and tighten the coupling nut

completely.

Replace the front cover and reconnect main power

Should the rate of disc cooling require adjustment:

Loosen the contra nut and turn the regulator screw to the

required rate.

Re-tighten the contra nut.

Mounting the Disc Cooling Kit

(accessory)

Adjusting Disc Cooling

Water solenoid valve

Throttle valve

Blades

Grey hose

Cable

W24

Regulator

screw

AbraPol-10

Instruction Manual

14

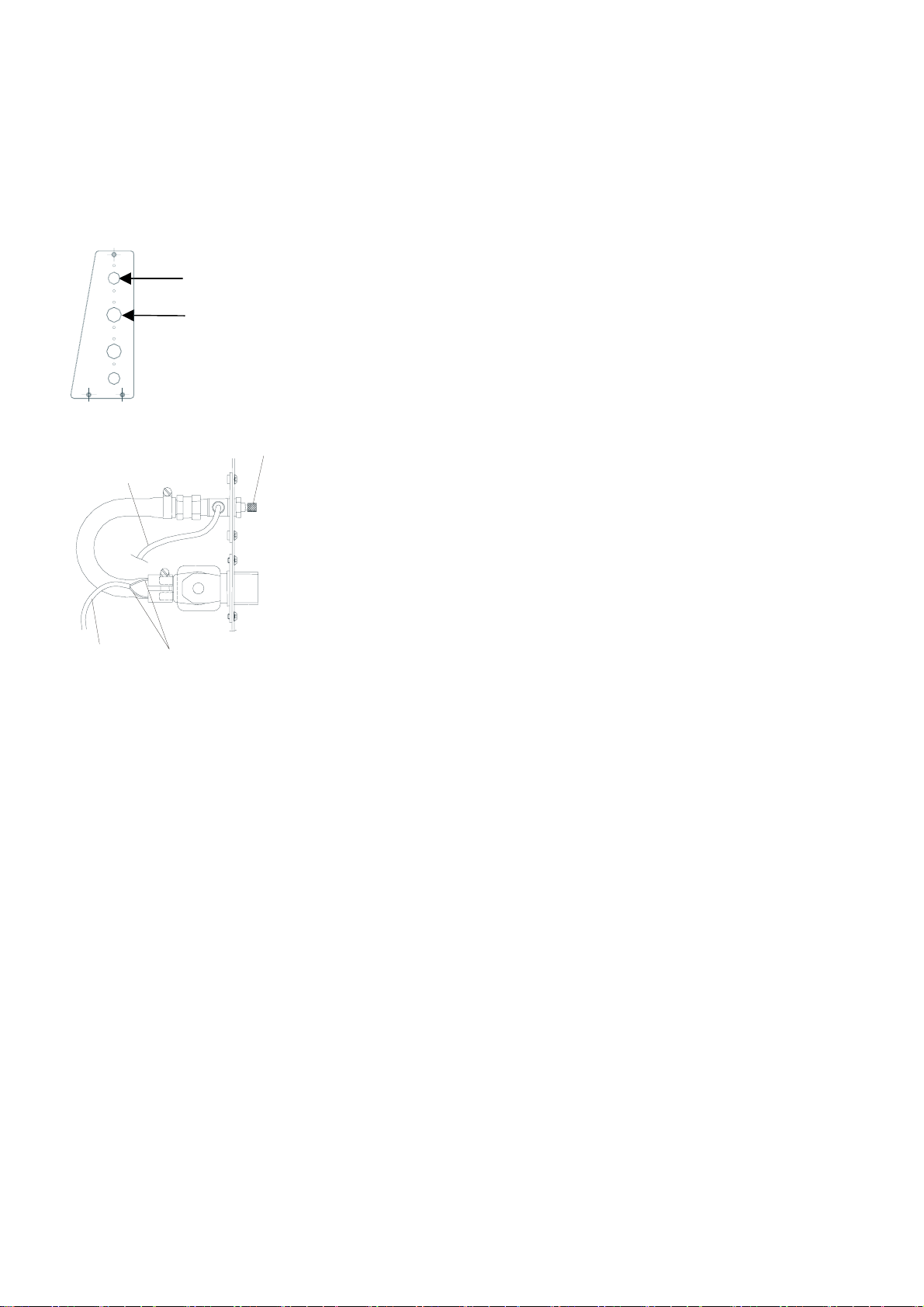

Disconnect main power.

Remove the lower front cover.

Connect the plug on the removal sensor with the plug located

in the recess to the left of the control panel.

Take the removal sensor and gently slide it up in the hole

located in the bottom of the cast iron beam.

Let the bracket slide over the factory installed support

bracket.

From the left, slide the two screws through the brackets, and

tighten with a 10mm spanner.

Reconnect main power and follow the instructions on the

screen, using the tools supplied and the calibrating sticks.

Mounting the Stock Removal

Sensor (accessory)

ABMEU

Plug

Stock Removal Sensor

Slide up into

beam

Support bracket

Screws

Table of contents

Languages:

Other Struers Cutter manuals