Struers Secotom-10 User manual

Manual No.: 15037001

Date of Release .0.2010

Secotom-10

Instruction Manual

Secotom-10

Instruction Manual

Table of Contents Page

User’s Guide....................................................................................1

Reference Guide..........................................................................31

Quick Reference..........................................................................43

Always state Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the Date

and Article No of the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals: Struers Instruction Manuals may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals: Struers Service Manuals may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to changes without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

The contents of this manual is the property of Struers. Reproduction of any part of this manual without the

written permission of Struers is not allowed.

All rights reserved. © Struers 2010.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

Secotom-10

Instruction Manual

Secotom-10

Safety Precaution Sheet

To be read carefully

before use

1. The operator should be fully aware of the use of the machine according

to the Instruction Manual and the instructions of the cut-off wheels.

2. The machine must be placed on a safe and stable support table. All

safety functions and guards of the machine must be in working order.

3. The unit must be installed in compliance with local safety regulations.

4. Use only intact cut-off wheels. The cut-off wheels must be approved for

min. 5,000 rpm.

5. When the manual cutting table is used, the machine is not to be used

with saw-blade type cut-off wheels.

6. Observe the current safety regulations for handling, mixing, filling,

emptying and disposal of the additive for cooling fluid.

7. To achieve maximum safety and lifetime of the machine, use only

original Struers consumables.

8. Struers recommends using cooling fluid when cutting as the materials

being cut may emit harmful dust. Additionally an adequate exhaust

system should be used.

9. The machine emits only moderate noise. However, the cutting process

itself may emit noise, depending on the nature of the workpiece. In

such cases, the use of hearing protection is recommended.

10. Always use Safety Goggles when using the manual cutting table on the

machine.

11. The machine must be disconnected from the mains prior to any service.

Wait until residual potential on the capacitors is discharged.

12. Do not cycle mains power more than once every three minutes.

Damage to the drive will result.

The equipment should only be used for its intended purpose and as detailed in the Instruction Manual.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.).

Secotom-10

Instruction Manual

Disposal

Equipment marked with a WEEE symbol contain electrical and

electronic components and must not be disposed of as general

waste.

Please contact your local authorities for information on the correct

method of disposal in accordance with national legislation.

Secotom-10

Instruction Manual

1

User’s Guide

Table of Contents Page

1. Getting Started

Checking the Contents of the Packing Box........................................2

Removing Secotom-10 from the Pallet...............................................2

Placing Secotom-10...........................................................................2

Cover for Exhaust Hole......................................................................2

Getting Acquainted with Secotom-10.................................................3

Rear of Secotom-10...........................................................................4

Supplying Power ................................................................................5

Single-phase Supply.................................................................5

3-phase Supply.........................................................................5

Connection to the Machine.......................................................5

Mounting the Cut-off Wheel ...............................................................6

Adjusting the Height of the Cut-off Wheel..........................................7

Filling the Cut-off Machine with Cooling Fluid....................................8

Cutting Table......................................................................................9

Positioning the Cutting Table.............................................................9

Attaching Clamping Tools (accessories)..........................................10

Quick-clamping Device...........................................................10

Advanced Clamping Tools......................................................11

Electrical Connections in the Cutting Chamber................................12

Flushing Hose..................................................................................13

2. Basic Operation

Front Panel.......................................................................................14

Front Panel Controls ........................................................................15

Software Settings.............................................................................16

Setting the Language..............................................................17

Reading the Display.........................................................................18

Changing/Editing Values..................................................................19

Numeric Values.......................................................................19

Alphanumeric Values..............................................................20

Setting up the Software....................................................................21

Cutting Setup ...................................................................................22

Setting Wheel Speed..............................................................23

Setting Feed Speed................................................................24

Setting Cut Length..................................................................25

Setting X Position (accessory.................................................26

Chuck Mode (accessory)........................................................28

Starting the Cutting Process ............................................................29

During Cutting.........................................................................29

Stopping the Cutting Process...........................................................30

Secotom-10

Instruction Manual

2

1. Getting Started

In the packing box you should find the following parts:

1 Secotom-10

2 Mains cables

1 Stop pin

1 Socket spanner 17 mm

1 Socket spanner 13 mm

1 Hose for connection to exhaust, 1.5 m x 32 mm dia.

1 Hose clamp, 25-40 mm dia

1 Cover for exhaust hole

1 Instruction Manual Set

Secotom-10 is secured to the wooden pallet with 3 screws. Remove

these screws with a 13 mm socket spanner.

Secotom-10 should be placed on a safe and stable support table with

an adequate working height. The table must be able to carry at least

55 kg. The machine must be placed close to the power supply.

The exhaust pipe at the back of the cutting chamber can be replaced

with the cover for the exhaust hole if Secotom-10 is not to be

connected to an exhaust system.

Checking the Contents of the

Packing Box

Removing Secotom-10

from the Pallet

Placing Secotom-10

Cover for Exhaust Hole

Secotom-10

Instruction Manual

3

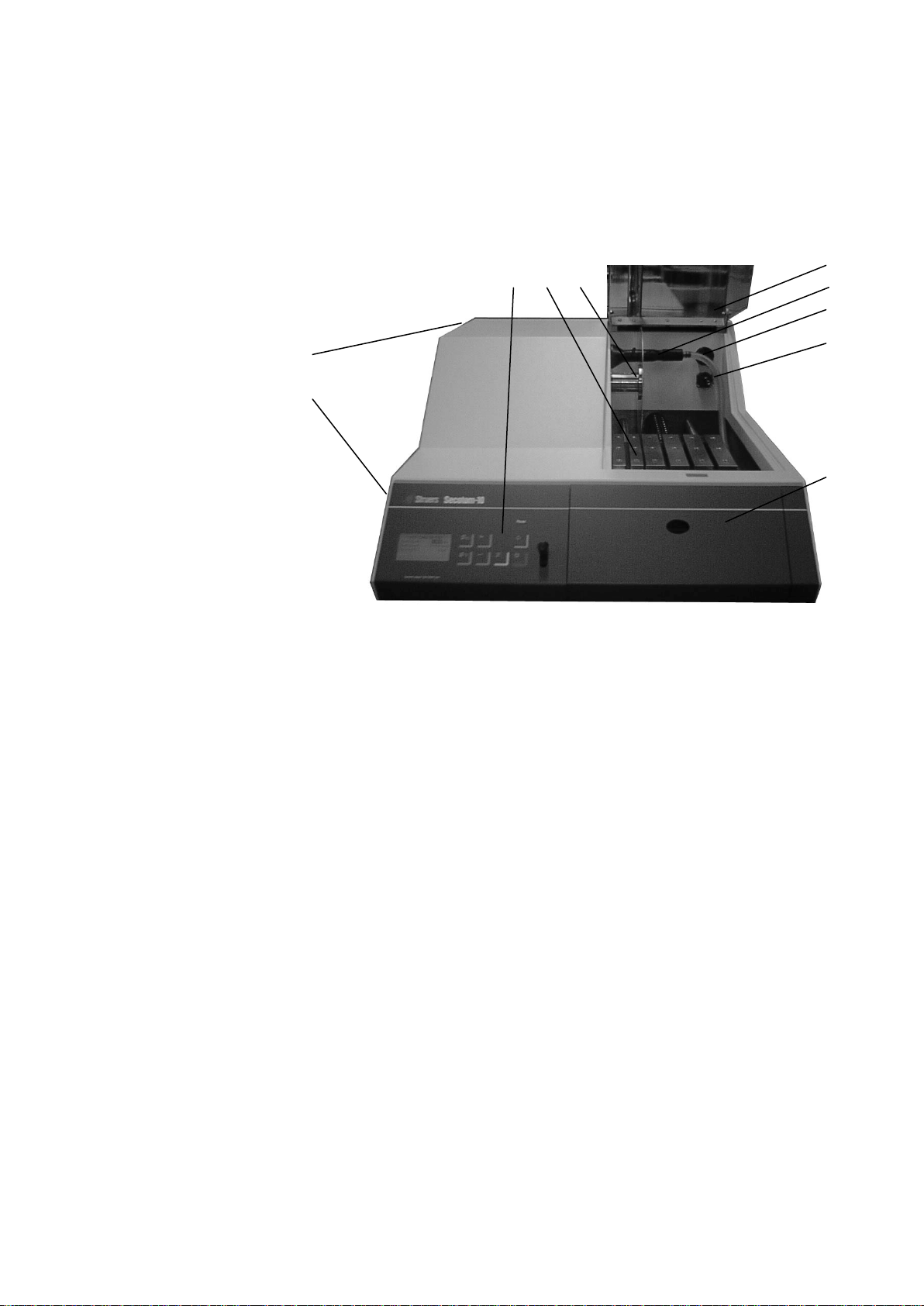

Take a moment to familiarise yourself with the location and names of

the Secotom-10 components.

Control panel (see 2. Basic Operation)

Movable cutting table

Cut-off wheel mounting

Transparent cover

Cooling fluid nozzles

Ventilation hole

Electrical connection socket

Cover (housing cooling fluid bath and cut-off wheel speed guide)

Cut-off wheel height adjustment control

Main switch (at the back of the machine)

Getting Acquainted with

Secotom-10

Secotom-10

Instruction Manual

4

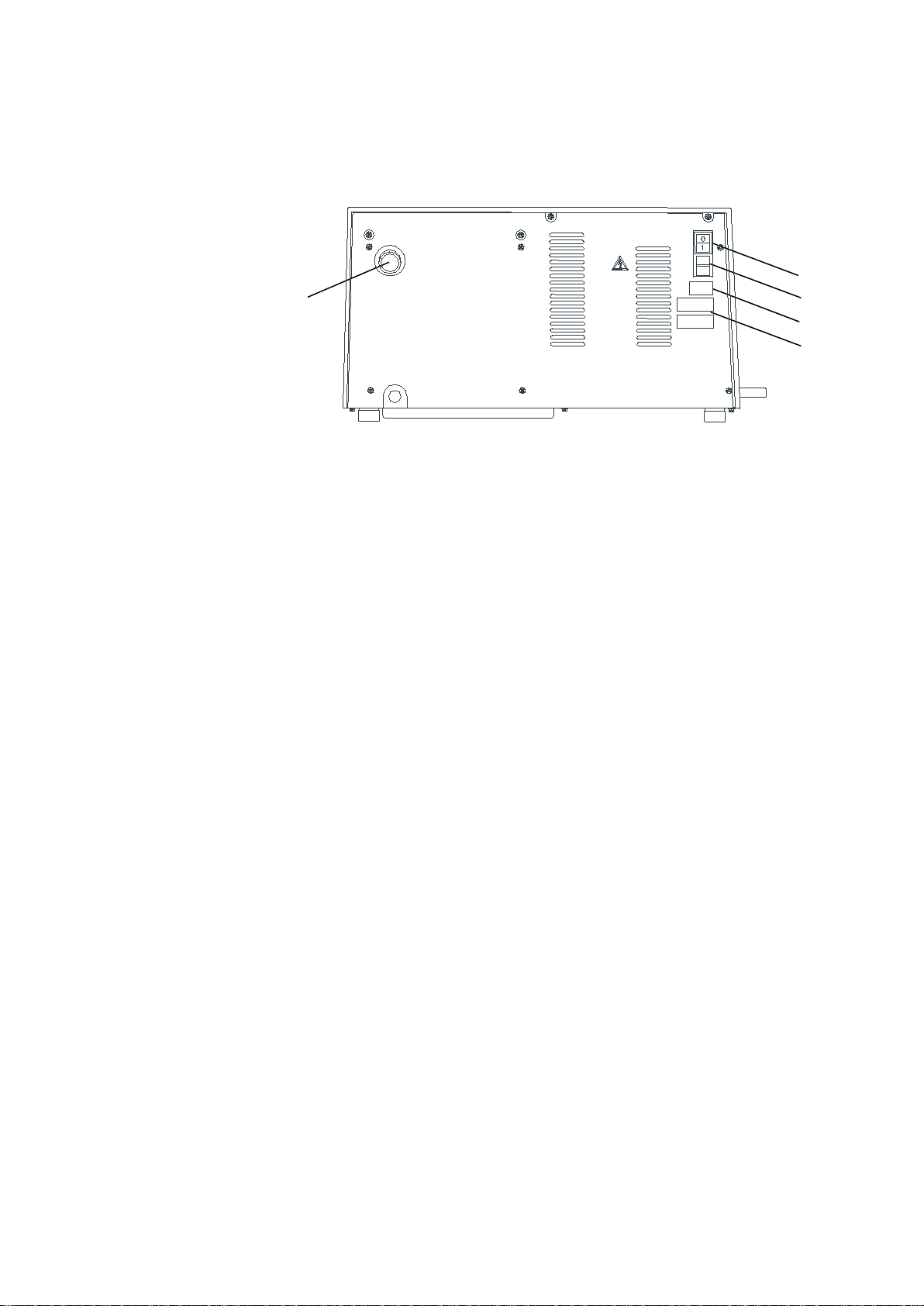

Ventilation Hole

Main switch

Fuses

Mains connection

Type Plate

Rear of Secotom-10

Secotom-10

Instruction Manual

5

Always remember to switch the power off when installing electrical

equipment!

The Secotom-10 is shipped with 2 types of Mains cables:

The 2-pin (European Schuko) plug is for use on single-phase,

200-240 V connections.

If the plug supplied on this cable is not approved in your country,

then the plug must be replaced with an approved plug. The leads

must be connected as follows:

Yellow/green: earth

Brown: line (live)

Blue: neutral

The 3-pin (North American NEMA) plug is for use on 3-phase,

200-240 V power connections.

If the plug supplied on this cable is not approved in your country,

then the plug must be replaced with an approved plug. The leads

must be connected as follows:

Green: earth

Black: line (live)

White: line (live)

Both cables are on the other end equipped with an IEC 320 cable

connector that has to be connected to the Secotom.

Supplying Power

DANGER!

The machine must be earthed

IMPORTANT

Check that the mains voltage corresponds to the voltage stated

on the type plate on the back of the machine.

Single-phase Supply

3-phase Supply

Connection to the Machine

WARNING!

The output voltage from this cable is 200 – 240V and not 110V.

DO NOT use this cable to connect equipment that use a 110V power

supply. Failure to adhere to this may result in material damage.

Secotom-10

Instruction Manual

6

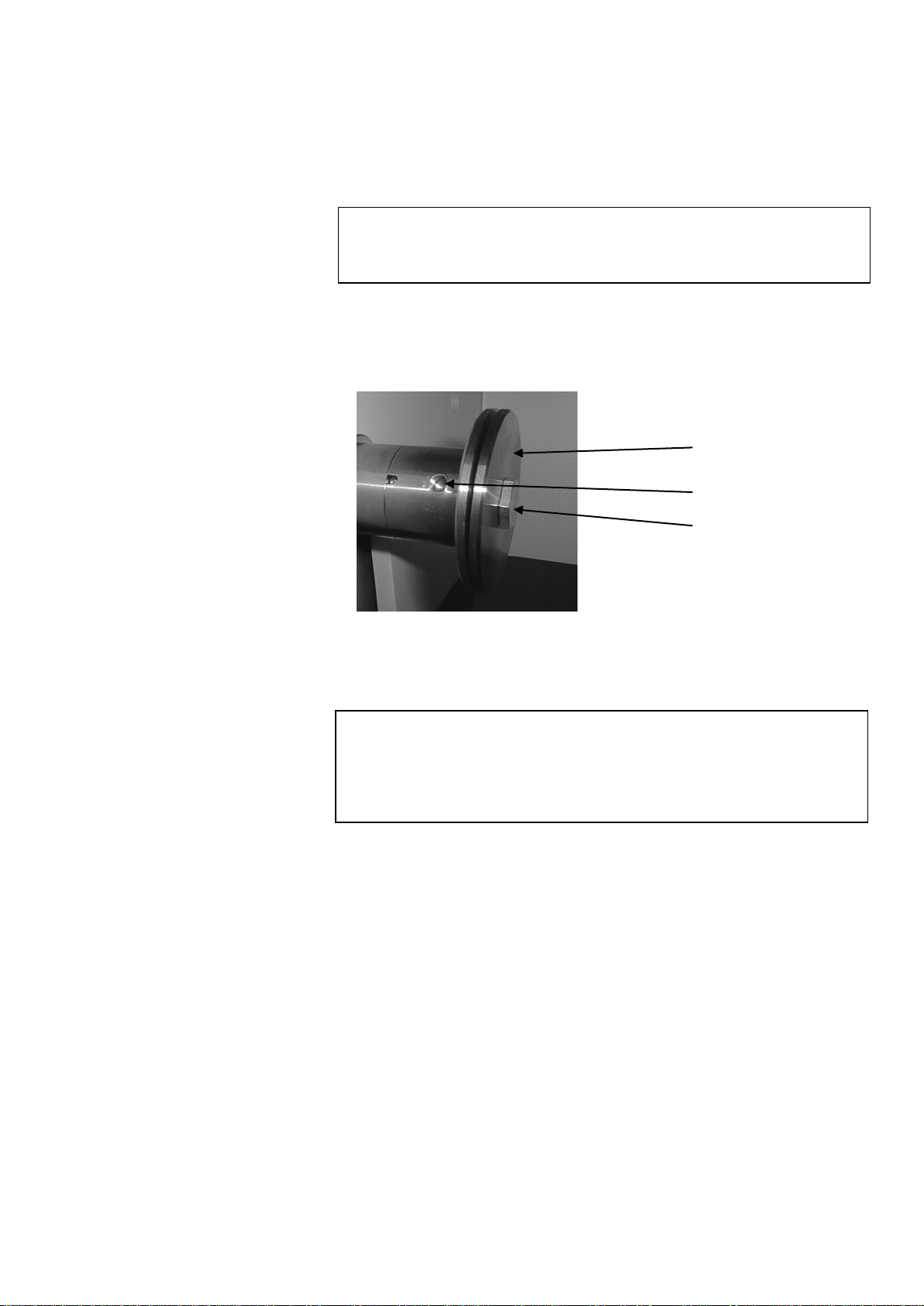

Lift the transparent cover to an angle of 450-600.

Lift the cooling fluid nozzles to gain access to the cut-off wheel

mounting.

Insert the stop pin into the hole of the inner flange.

Use the fork spanner (17 mm) to loosen the flange screw.

Remove the outer flange.

Mounting the Cut-off Wheel

IMPORTANT

For manual cutting: only diamond or CBN cut-off wheels with a metal body

are allowed. Abrasive SiC or Al2O3cut-off wheels or saw blades may not be

used when the manual cutting table accessory is fitted to the Secotom-10.

IMPORTANT

The tolerance between the spindle and inner flange is very small which

means that the two surfaces must be absolutely clean.

Never try to squeeze the cut-off wheel on as this may damage the spindle

or the cut-off wheel. If there are any small burrs, remove them with grinding

paper (grit size 1200).

Outer flange

Flange screw

Hole for stop pin

Secotom-10

Instruction Manual

7

Mount the cut-off wheel (using the 22mm insert if necessary) and

remount the outer flange, with the machined face towards the

inner flange.

Insert the locking pin in the hole in the inner flange.

Gently fasten the flange screw using the fork spanner 17 mm.

Lower the cooling fluid nozzles to their operating positions.

The distance between the cut-off wheel spindle and the cutting table

can be adjusted to suit the individual cut-off wheels or wear caused

during the cutting process.

Use the control on the side of the Secotom-10 (illustrated in

“Getting Acquainted with the Secotom-10”) to raise and lower

cut-off wheel mounting.

IMPORTANT

When mounting cut-off wheels with a 12.7 mm centre hole, make sure that

the 22 mm arbour insert has been removed. Failure to do this will result in

the cut-off wheel being pressed out of shape.

Adjusting the Height of the

Cut-off Wheel

Inner flange

Hole for stop pin

12.7 mm axle

Insert for wheels with

22 mm arbour hole

Secotom-10

Instruction Manual

8

The Secotom-10 has a built-in cooling fluid system. The fluid coming

from the nozzles passes over the cut-off wheel and collects in the

bottom of the cutting chamber; where it then returns to the bath,

which is located under the cutting chamber. Access to this bath, for

cleaning and maintenance purposes, is possible by opening the front

cover of the Secotom-10.

Open and remove the front cover from the Secotom-10.

Lift the inlet tube (as illustrated).

Slide the fluid bath out gently.

Empty any old/used fluid from the bath and ensure that the bath

is clean (free from cutting debris).

Fill the bath with 3.69 litres of water and 110 ml Struers additive

for cooling fluid (Corrozip).

Slide the fluid bath back into position.

Check that the inlet tube is placed correctly so that the pump is

supplied with water.

Filling the Cut-off Machine

with Cooling Fluid

IMPORTANT

Always ensure that there is sufficient water in the tank as the recirculation

pump will be damaged if it is run dry.

Secotom-10

Instruction Manual

9

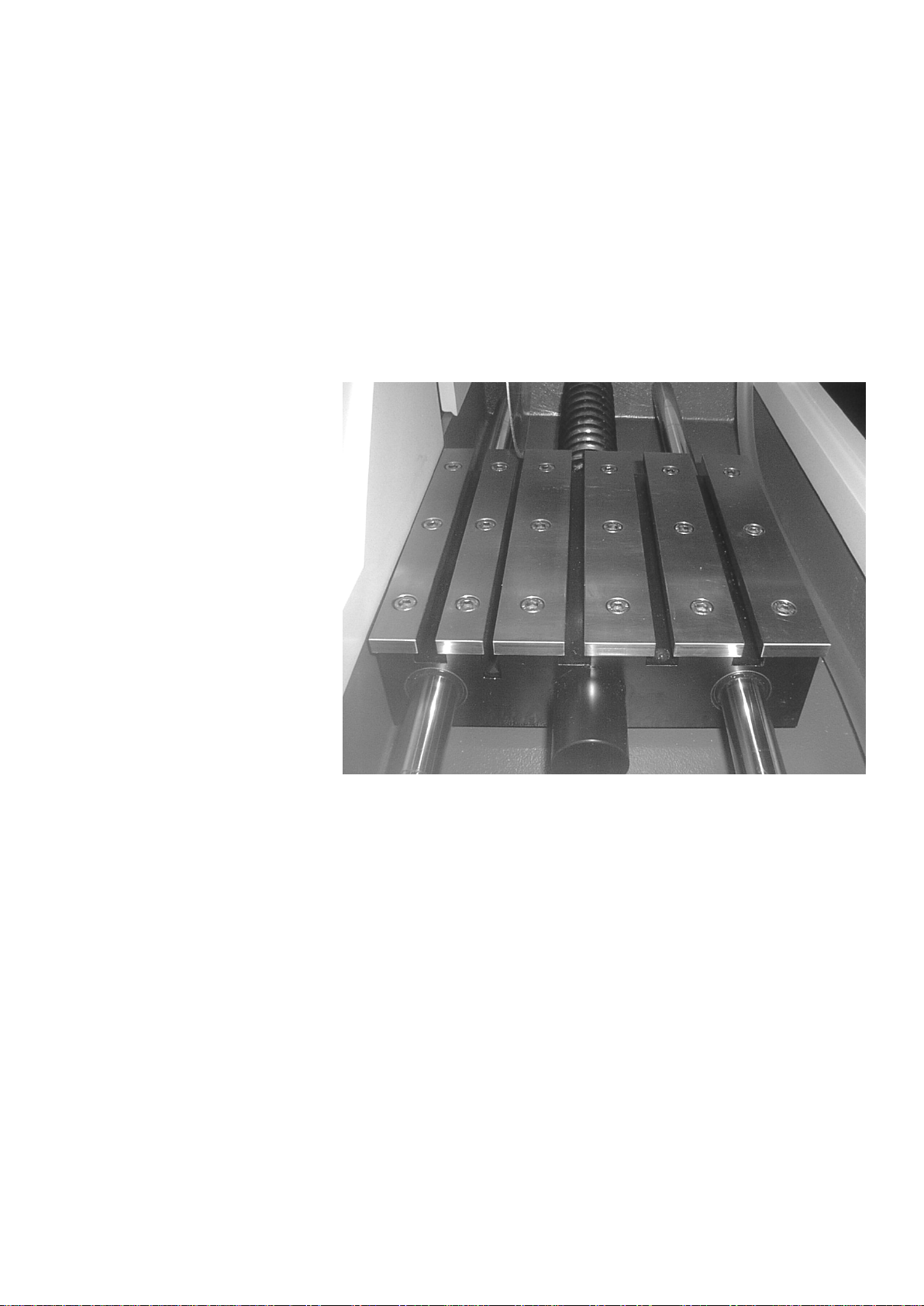

The Secotom-10 is fitted with a moving cutting table. Movement of

the table is controlled using the joystick on the Control Panel and

through the software, which is described in section 2. Basic

Operation. The table has several 8 mm T-slots, which are used to

secure clamping tools. This ensures that workpieces are held

securely during the cutting process. Although these clamping tools

are available as accessories, details about the table and the

clamping tools are described in this and the following sections.

Although during the cutting process the table movement is controlled

through Secotom-10’s software, prior to starting the cutting process,

it is necessary to position the cutting table manually.

Use the joystick on the Control Panel to move the cutting table.

Pull the joystick towards you to move the cutting table away from

the cut-off wheel, or push the joystick away from you to move the

cutting table towards the cut-off wheel.

Cutting Table

Positioning the Cutting Table

Secotom-10

Instruction Manual

10

There are several types of clamping tools available as accessories (a

complete list is provided in the Accessories section). Some of these

are plain, manual quick-clamping tools while others provide more

sophisticated features, and need to be positioned accurately on the

cutting table and require an electrical supply.

Position the back stop and the Quick-clamping device as shown

in the illustration.

Tighten the nuts to secure the Quick-clamping device.

Attaching Clamping Tools

(accessories)

Important!

When fitting clamping tools, always ensure that they cannot come in contact

with the cut-off wheel. Failure to do this may result in the clamping tools

being damaged.

Quick-clamping Device

Secotom-10

Instruction Manual

11

Place the clamping tool on the cutting table so that the securing

bolts align with the T-slot on the right hand side of the cutting

table.

Slide the clamping tool backwards and forwards to insert the

securing bolts in the T-slot.

Press the clamping tool sideways so that the positioning studs

are pressed tight against the table.

Hold the clamping tool in position and tighten the nuts to secure

the clamping tool.

Connect the clamping tool cable as described in Electrical

Connections in the Cutting Chamber on the next page.

A pop-up on the display panel confirms that the unit is now

connected.

The advanced clamping tools are fitted with a dovetail that

accommodates all our standard specimen holders for precision

cutting (a complete list is provided in the Accessories section).

Advanced Clamping Tools

Secotom-10

Instruction Manual

12

Some of the accessories for the Secotom-10, for example the

Manual Cutting Table and the advanced clamping tools require

electrical connections. These are supplied through the electrical

connection socket in the cutting chamber.

Remove the cover on the electrical connection socket in the

cutting chamber.

Using the cable fitted to the clamping tool, connect it to the

electrical connection socket.

Gently tighten the securing ring.

Electrical Connections in the

Cutting Chamber

Important

Always replace the socket’s protective cover when not in use.

Note

The different advanced clamping tools can be exchanged while Secotom-10

is switched on.

Note

The plugs on these clamping tools provide specific pin connections. If for

some reason you have a problem with a connection,

do not attempt to change the connections in the clamping tool plugs or

connection socket.

Securing ring

Plug

Secotom-10

Instruction Manual

13

The Secotom-10 comes complete with a flushing system. This

enables the cutting chamber to be rinsed clean of any debris

discarded during the cutting process. Flushing is operated through

the Control Panel buttons.

Remove the hose from the cooling fluid nozzles.

Holding the hose in the cutting chamber, press FLUSH .

To stop flushing, press FLUSH again or STOP .

Flushing Hose

Warning!

Do not start the flush function until you have removed

the hose from the fluid nozzles and are pointing it

into the cutting chamber.

Important!

Remember to replace the hose when you have finished flushing the cutting

chamber.

Secotom-10

Instruction Manual

14

2. Basic Operation

Power

Spindle speed 300 500 rpm:-

Front Panel

Secotom-10

Instruction Manual

15

This provides information about the individual buttons on the front

panel of the Secotom-10.

Pos. No. Key Function

Pos. No. Key Function

Moves cursor in display upwards

or increases the value when

editing parameter values.

Push button for starting and

stopping the FLUSH operation.

Moves cursor in display

downwards or decreases the

value when editing parameter

values.

Push button for starting the

cutting process.

Esc Leaves the present menu or

aborts functions/changes.

Push button for stopping the

process currently active.

Enables selected parameter

values to be activated for editing.

Saves the edited parameter

values.

Front Panel Controls

Secotom-10

Instruction Manual

16

Switch on the power at the main switch located at the rear of the

machine. The following display will appear briefly:

The display will then change to the last screen shown before the

Secotom-10 was switched off. When switching on Secotom-10 for

the first time, the MAIN MENU will appear. If the heading in the

display is different, press Esc, until the MAIN MENU appears.

The MAIN MENU is the highest level in the menu structure. From this

menu, you can enter the configuration menu and cutting menu.

Software Settings

Table of contents

Languages:

Other Struers Cutter manuals