English

– 5

SAFETY INSTRUCTIONS

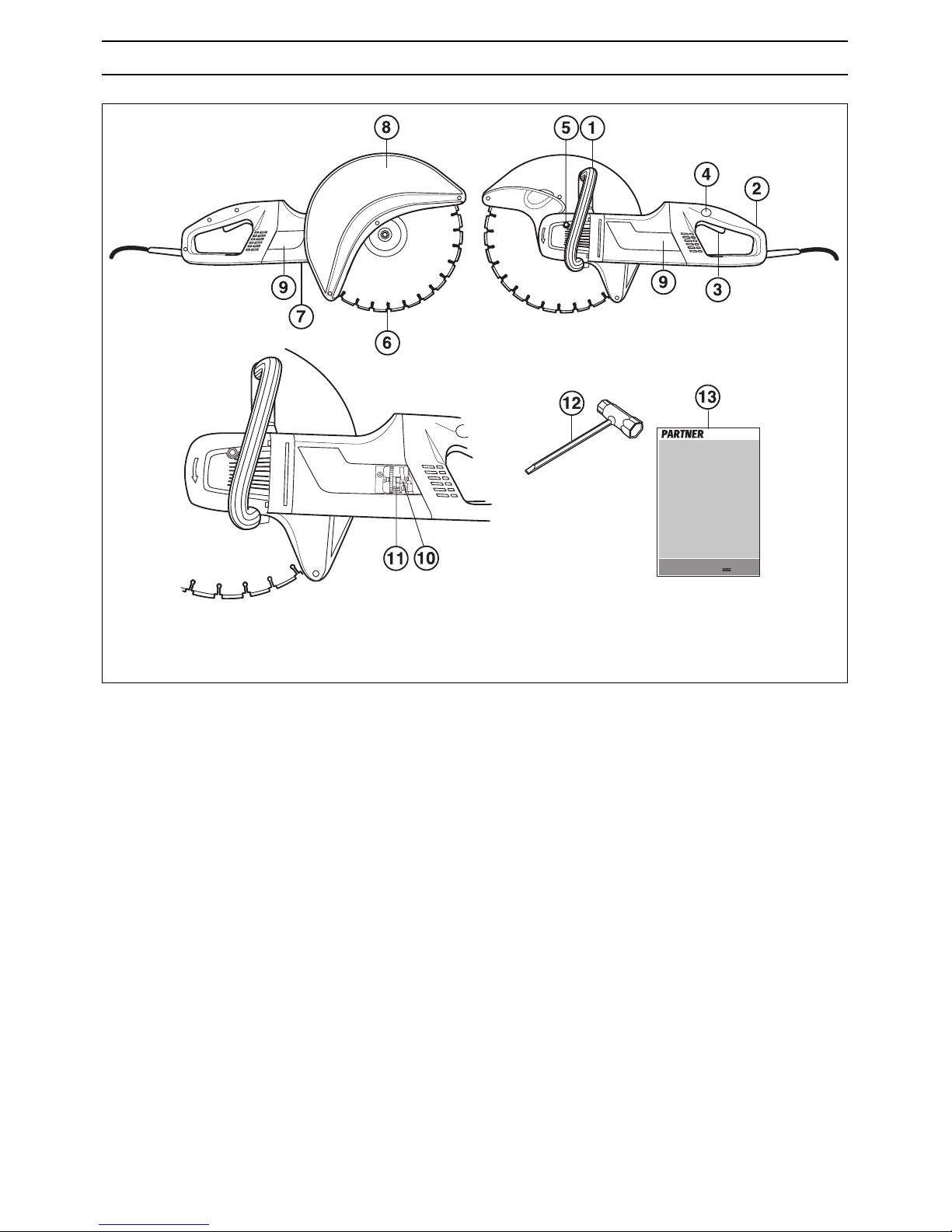

Checking, maintaining and servicing

the machine

′′′′

s safety equipment

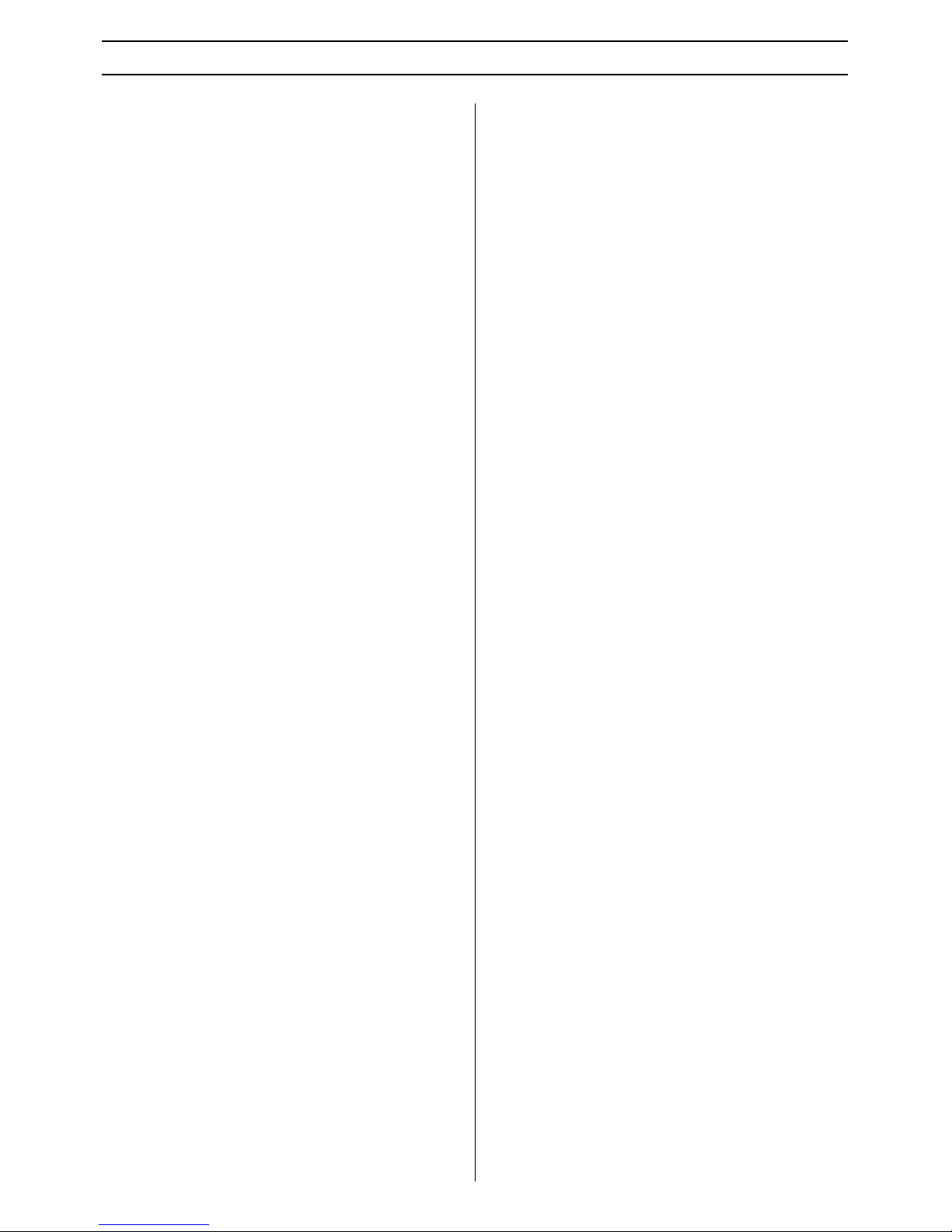

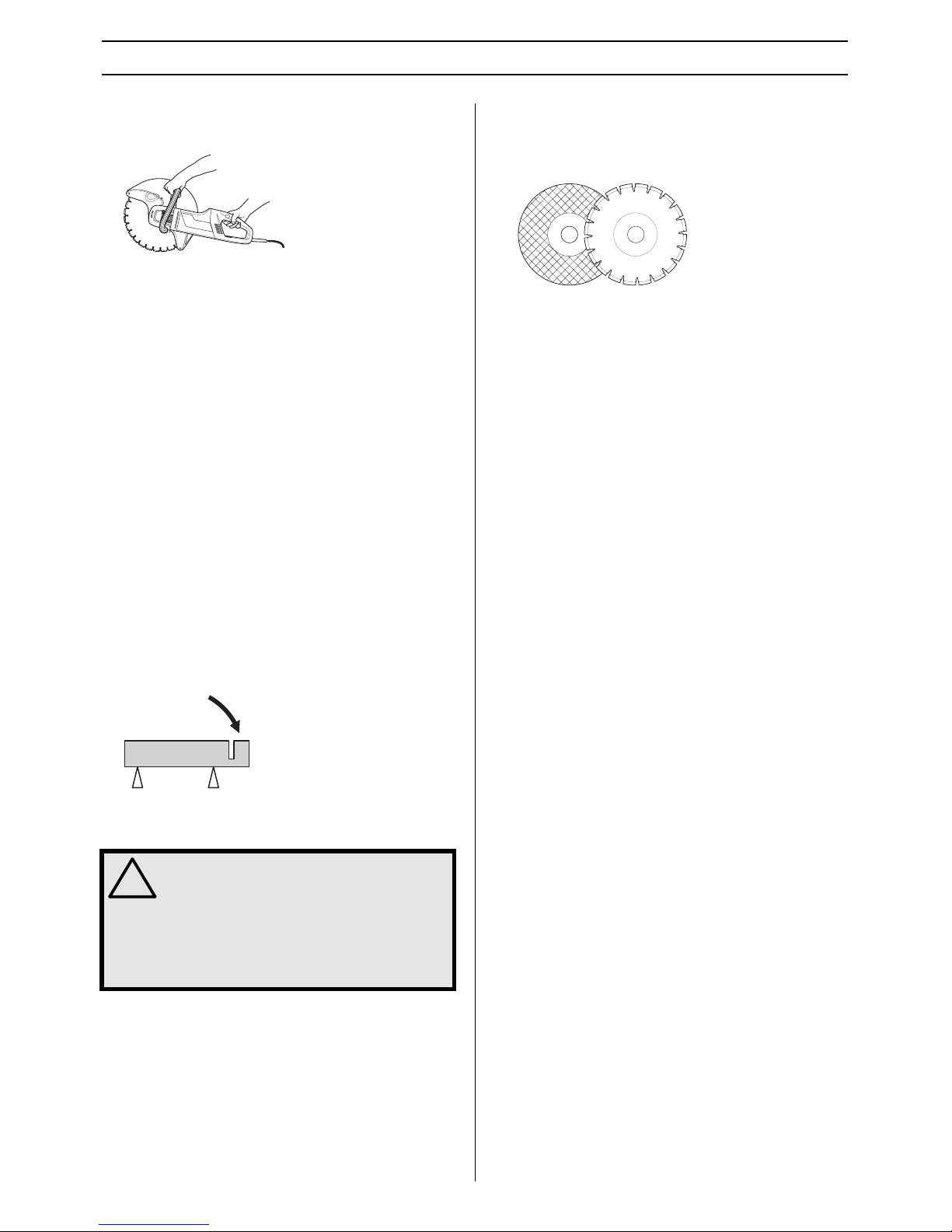

Checking the power switch

Start the machine, release the power switch and check that

the engine and the cutting blade stop.

A defective power switch should be replaced by an authorized

service workshop

Checking the power switch lock

Make sure the power switch is locked when the power switch

lock is in its original position.

Press in the power switch lock and make sure it returns to its

original position when you release it.

Check that the power switch and power switch lock move

freely and that the return springs work properly.

Start the machine, release the power switch and check that

the engine and the cutting blade stop.

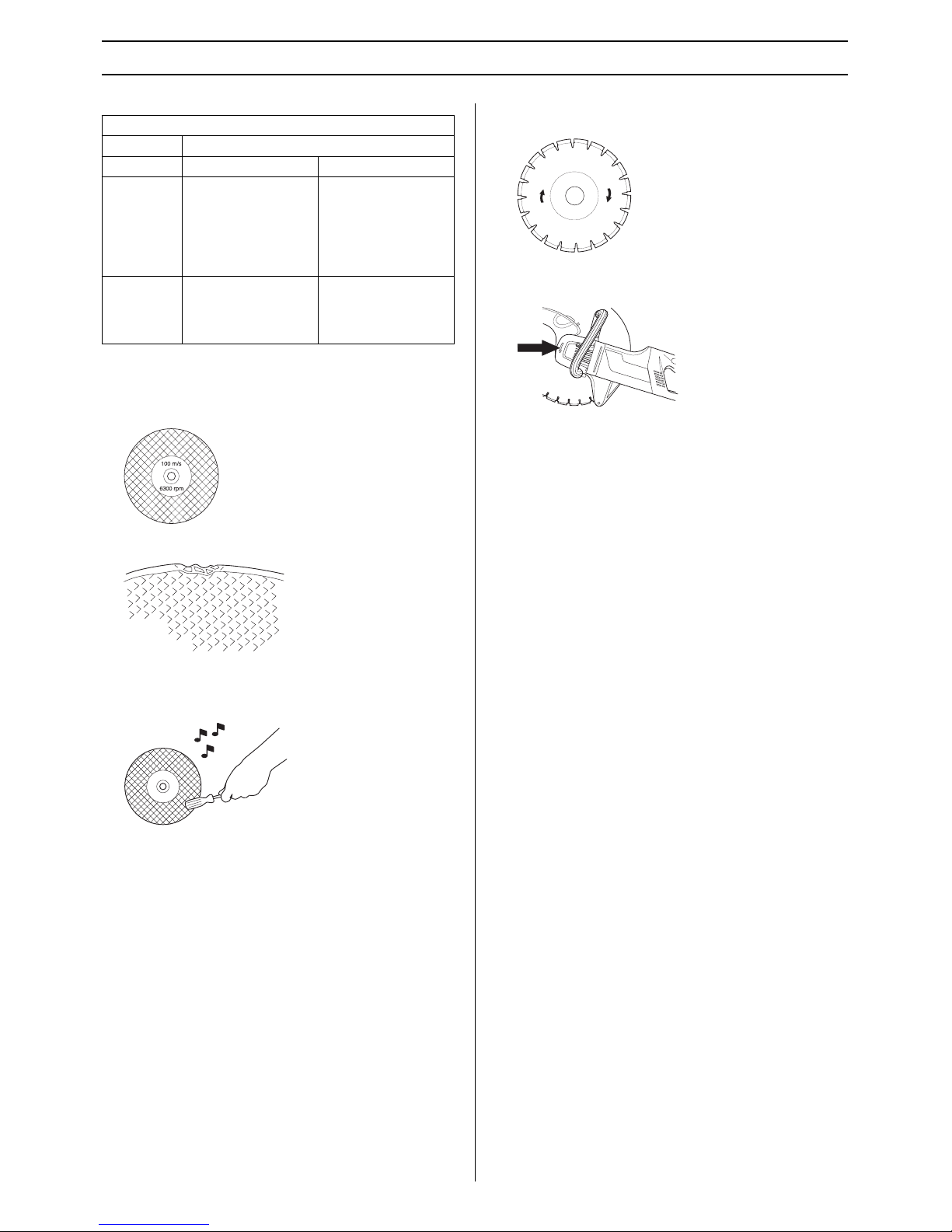

Inspection of the guard for the cutting

blade

Check that the guard is intact and that the material is not

cracked or deformed.

General safety precautions

• A power cutter is designed to cut hard materials such as

concrete/stone and steel/iron. Observe the increased risk

of kickback when cutting soft materials. See instructions

under the heading How to avoid kickback.

• Do not use the power cutter until you have read the entire

contents of this Operator’s Manual.

All servicing, in addition to the points listed in the section

”Control, maintenance and service of the power cutter’s

safety equipment”, should be carried out by trained

service specialists.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

• Never use a machine that has been modified in any way

from its original specification.

• Do not use the machine in wet or humid surroundings,

close to water, in the rain or snow. Dampness can cause

short circuiting.

• Be on your guard for electrical shocks. Avoid having body

contact with lightning-conductors/metal in the ground.

• Never carry the machine by means of the cord and never

pull out the plug by pulling the cord. Keep all cords and

extension cords away from water, oil and sharp edges.

Make sure the cord is not pinched in doors, fences or the

like. Otherwise it can cause the object to become live.

• Check that the cord and extension cord are intact and in

good condition. Never use the machine if the cord is

damaged, hand it in to an authorized service workshop for

repair.

!

WARNING! All servicing and repair work on

the machine requires special training.This is

especially true of the machine′′′′

s safety

equipment. If your machine fails any of the

checks described below you must contact

your service agent.When you buy any of our

products we guarantee the availability of

professional repairs and service. If the

retailer who sells your machine is not a

servicing dealer, ask him for the address of

your nearest service agent.

!

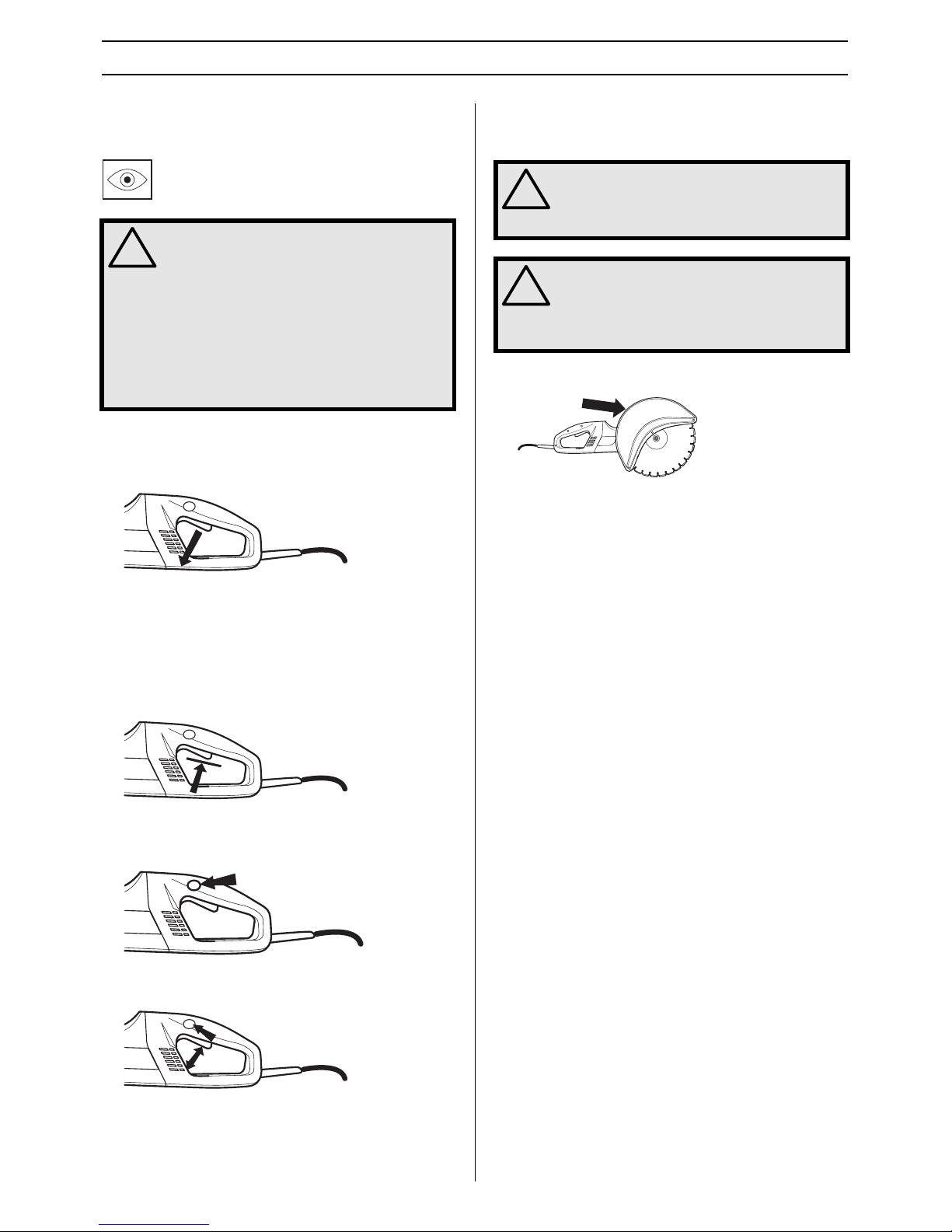

WARNING! Always check that the blade

guard is correctly fitted before starting the

machine. See instructions under the

heading Assembly.

!

WARNING! Check that the cutting blade is

fitted correctly and does not show signs of

damage. A damaged cutting blade can

cause personal injury. See instructions

under the heading Assembly.