- 6 –

Cont ...

1 IMPORTANT FACTS: READ BEFORE COMMENCING PUMP INSTALLATION

A Water storage capacity.

1.11 The cold water storage capacity must be sufficient to meet the flow rates

required by the pumped equipment and any other water using fittings and

appliances, which may be operated simultaneously.

1.12 Ensure the pump is primed as described in the priming section before

starting, damage to the shaft seal will result otherwise. See Section 4 –

Commissioning.

B Water temperature

The water entering the pump must be controlled as follows:

1.13 The maximum allowable water temperature is 35 oC.

1.14 The minimum allowable water temperature is 4 oC.

C Pipework – General

1.15 Secure pipework: Ensure pipework to and from pump is independently

supported & clipped to prevent forces being transferred to inlet and outlet

branches of pump.

1.16 Flux: Solder joints must be completed and flux residues removed prior to

pump installation (flux damage will void any warranty).

1.17 Pipework design: Care should be taken in the design of pipework runs to

minimize the risk of air locks e.g. use drawn bends rather than 90obends.

1.18 DO NOT introduce solder flux to flexible hoses, pumps or pump parts

manufactured from plastic.

1.19 DO NOT allow contact with oil or cellulose based paints, paint thinners

or strippers, acid based descalents or aggressive cleaning agents.

1.20 DO NOT install a non-return valve, or devices which contain non-return

valves, in the suction (inlet) pipework to the pump. The pump must

be free to vent to the supply tank at all times. Exceptions can be

made in the case of suction lift installations when a footvalve is

required.

1.21 DO NOT connect this pump to the mains water supply.

D Plumbing Installation Regulations

1.22 The plumbing installation must comply with the current water and building

regulations.

1.23 The plumbing installation must be installed by a qualified person.

- 15 –

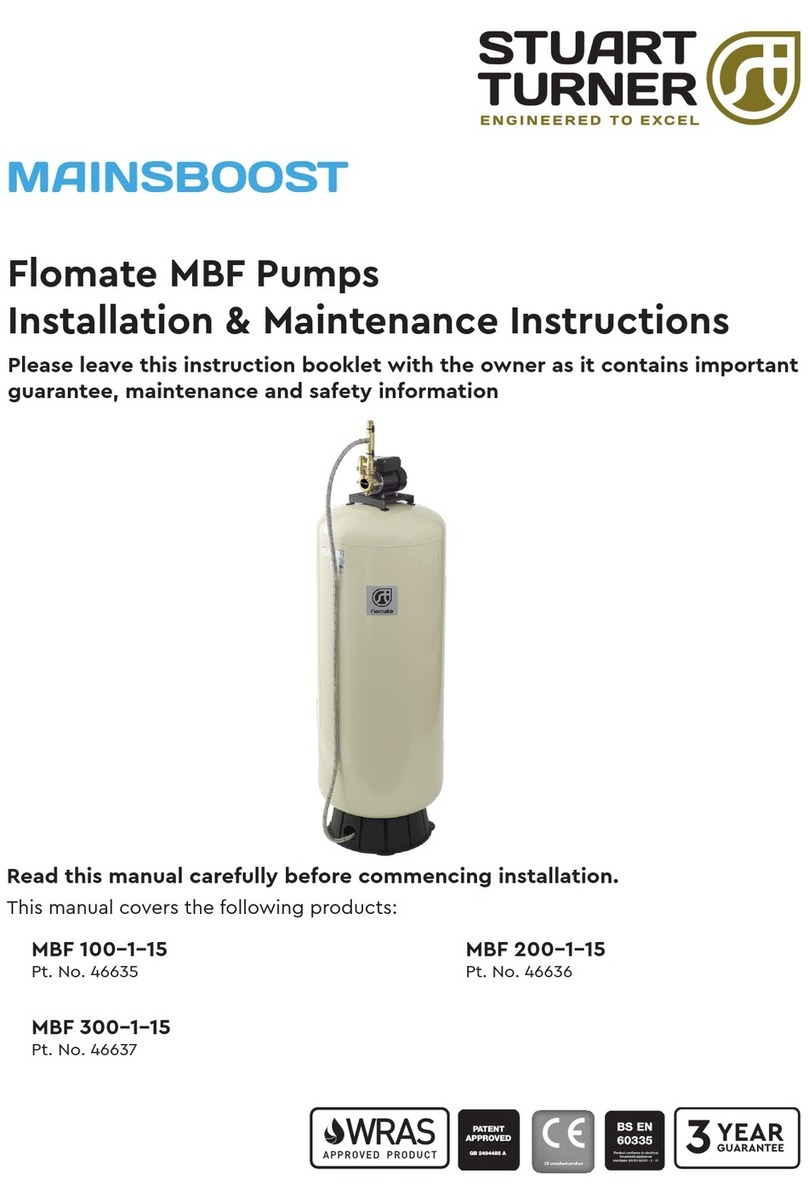

6 TECHNICAL SPECIFICATION

Stuart Turner reserve the right to amend the specification in line with its policy of

continuous development of its products.

*Note: Max working pressure is the maximum pressure that can be applied to the pump internal casing

under any installation conditions.

**Note: With footvalve fitted.

Although these pumps are self priming we recommend a footvalve/strainer is used if a suction lift

is required.

6.11 Noise: The equivalent continuous A-weighted sound pressure level at a

distance of 1 metre from the pump does not exceed 73 dB(A) for Jet 55–45 or

76 dB(A) for Jet 80–45.

Pump Model

Jet 55–45

50 Hz

46587

Jet 80–45

50 Hz

46588

General Guarantee 1 year

Approvals CE

Features Pump type Centrifugal

Self priming

Carry handle

Integral on/off switch

Typical noise 68 dB(A) 72 dB(A)

Materials Pump body Stainless steel

Impeller Plastic

Mechanical seal EPDM / Carbon / Ceramic

Performance Maximum head (closed valve) 4.5 bar / 45 metres 4.5 bar / 45 metres

Performance @ 9 l/min 3.6 bar / 36 metres 4.1 bar / 41 metres

Performance @ 50 l/min 0.7 bar / 7 metres 2.6 bar / 26 metres

Maximum flow 55 l/min 80 l/min

Manimum static inlet pressure 0.1 bar (1 metre)

Maximum static inlet pressure 0.5 bar (5 metres)

Maximum working pressure* 500 kPa (5 bar)

Maximum ambient air temperature 40 oC

Min / Max water temperature Min 4 oC / Max 35 oC

Maximum suction lift** 5 metres

Connections Pump connections G 1 female (inlet), G 1 female (outlet)

Motor Type Induction, auto-reset thermal trip

Duty rating Continuous (S1)

Electrical Power supply (Vac/Ph/Hz) 230 V a.c. / 1 / 50 Hz

Power consumption – P1 640 Watts 925 Watts

Current – full load 2.9 Amps 5.2 Amps

Fuse rating 13 Amps

Power cable length 1.5 metres (pre-wired)

Physical Enclosure protection IPX4

Length 349 mm 374 mm

Width 221 mm 228 mm

Height – excluding hoses 238 mm

Weight – including fittings 6.9 Kg 9.1 Kg